How to Refine Rice Bran Oil for Food Use: Degumming, Neutralization and Bleaching Steps

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rice Bran Oil Refining Background and Objectives

Rice bran oil, extracted from the outer layer of rice grains, has emerged as a valuable edible oil with significant nutritional and functional properties. The historical development of rice bran oil refining can be traced back to the early 20th century, with major advancements occurring in the 1980s and 1990s when efficient extraction and refining technologies were developed. Initially considered a by-product of rice milling, rice bran oil has gradually gained recognition for its unique composition of bioactive compounds including oryzanol, tocotrienols, and phytosterols.

The evolution of refining technologies has been driven by the need to overcome the inherent challenges in rice bran oil processing. Rice bran rapidly deteriorates after milling due to lipase enzyme activity, which increases free fatty acid content and complicates the refining process. This technical challenge has spurred innovations in stabilization methods and refining techniques over the decades, leading to the current three-step refining approach: degumming, neutralization, and bleaching.

Global production of rice bran oil has shown a steady increase, with major producing countries including India, Japan, China, and Thailand. The market has expanded from regional consumption to international trade, reflecting growing consumer awareness of its health benefits. The technical trajectory indicates a shift from conventional chemical refining methods toward more environmentally friendly and nutrient-preserving approaches, including physical refining and enzymatic processes.

The primary technical objective in rice bran oil refining is to remove undesirable components while preserving its beneficial bioactive compounds. Specifically, the degumming process aims to remove phospholipids and mucilaginous substances; neutralization targets the reduction of free fatty acids; and bleaching focuses on eliminating pigments, residual soaps, and trace metals. These processes must be optimized to maintain the stability and nutritional value of the final product.

Current research trends are focused on developing refining methods that minimize the loss of bioactive compounds, reduce environmental impact, and improve process efficiency. Emerging technologies include membrane filtration for degumming, enzymatic degumming and neutralization, and alternative adsorbents for bleaching. The industry is also exploring integrated refining systems that combine multiple steps to reduce processing time and energy consumption.

The anticipated technical goals for future development include the establishment of standardized refining protocols specific to rice bran oil, development of continuous processing systems with real-time quality monitoring, and creation of specialized refining approaches for different rice varieties and their corresponding bran oils. These advancements aim to position rice bran oil as a premium edible oil with preserved functional properties and extended shelf life.

The evolution of refining technologies has been driven by the need to overcome the inherent challenges in rice bran oil processing. Rice bran rapidly deteriorates after milling due to lipase enzyme activity, which increases free fatty acid content and complicates the refining process. This technical challenge has spurred innovations in stabilization methods and refining techniques over the decades, leading to the current three-step refining approach: degumming, neutralization, and bleaching.

Global production of rice bran oil has shown a steady increase, with major producing countries including India, Japan, China, and Thailand. The market has expanded from regional consumption to international trade, reflecting growing consumer awareness of its health benefits. The technical trajectory indicates a shift from conventional chemical refining methods toward more environmentally friendly and nutrient-preserving approaches, including physical refining and enzymatic processes.

The primary technical objective in rice bran oil refining is to remove undesirable components while preserving its beneficial bioactive compounds. Specifically, the degumming process aims to remove phospholipids and mucilaginous substances; neutralization targets the reduction of free fatty acids; and bleaching focuses on eliminating pigments, residual soaps, and trace metals. These processes must be optimized to maintain the stability and nutritional value of the final product.

Current research trends are focused on developing refining methods that minimize the loss of bioactive compounds, reduce environmental impact, and improve process efficiency. Emerging technologies include membrane filtration for degumming, enzymatic degumming and neutralization, and alternative adsorbents for bleaching. The industry is also exploring integrated refining systems that combine multiple steps to reduce processing time and energy consumption.

The anticipated technical goals for future development include the establishment of standardized refining protocols specific to rice bran oil, development of continuous processing systems with real-time quality monitoring, and creation of specialized refining approaches for different rice varieties and their corresponding bran oils. These advancements aim to position rice bran oil as a premium edible oil with preserved functional properties and extended shelf life.

Market Analysis for Refined Rice Bran Oil Products

The global market for refined rice bran oil has been experiencing steady growth, driven by increasing consumer awareness of its health benefits and versatile applications in the food industry. Currently valued at approximately 4.5 billion USD, the market is projected to grow at a compound annual growth rate of 5.8% over the next five years, reaching an estimated 6 billion USD by 2028.

Asia-Pacific dominates the refined rice bran oil market, accounting for over 65% of global consumption, with India and Japan being the largest consumers. This regional dominance is attributed to the abundance of rice production and traditional use of rice bran oil in Asian cuisines. North America and Europe are emerging as significant markets, showing growth rates of 7.2% and 6.5% respectively, primarily driven by increasing health consciousness among consumers.

The food service industry represents the largest end-user segment for refined rice bran oil, constituting about 45% of total consumption. Retail consumers account for approximately 30%, while food manufacturing companies make up the remaining 25%. The premium segment of refined rice bran oil has shown particularly strong growth, with consumers willing to pay higher prices for high-quality, well-refined products with superior nutritional profiles.

Market research indicates that consumers are increasingly seeking rice bran oil specifically for its balanced fatty acid composition, high smoke point, and presence of bioactive compounds like oryzanol. Products marketed with clear labeling about refining processes, particularly those emphasizing minimal processing and retention of natural nutrients, command premium prices, typically 15-20% higher than standard vegetable oils.

Competition in the refined rice bran oil market is intensifying, with approximately 200 significant producers globally. Large-scale producers with advanced refining capabilities hold about 40% market share, while medium and small-scale producers constitute the remainder. The market is witnessing consolidation, with larger companies acquiring smaller producers to expand their production capacity and geographic reach.

Distribution channels for refined rice bran oil are evolving, with supermarkets and hypermarkets accounting for 55% of sales, online retail growing rapidly at 25% annually, and specialty stores maintaining a stable 20% market share. Direct-to-consumer models through e-commerce platforms are gaining traction, particularly for premium refined rice bran oil products.

Consumer preferences are shifting toward refined rice bran oil products that maintain nutritional integrity while ensuring safety and stability. Products that can demonstrate effective degumming, neutralization, and bleaching processes without compromising the oil's natural beneficial compounds are positioned to capture greater market share in the growing health-conscious consumer segment.

Asia-Pacific dominates the refined rice bran oil market, accounting for over 65% of global consumption, with India and Japan being the largest consumers. This regional dominance is attributed to the abundance of rice production and traditional use of rice bran oil in Asian cuisines. North America and Europe are emerging as significant markets, showing growth rates of 7.2% and 6.5% respectively, primarily driven by increasing health consciousness among consumers.

The food service industry represents the largest end-user segment for refined rice bran oil, constituting about 45% of total consumption. Retail consumers account for approximately 30%, while food manufacturing companies make up the remaining 25%. The premium segment of refined rice bran oil has shown particularly strong growth, with consumers willing to pay higher prices for high-quality, well-refined products with superior nutritional profiles.

Market research indicates that consumers are increasingly seeking rice bran oil specifically for its balanced fatty acid composition, high smoke point, and presence of bioactive compounds like oryzanol. Products marketed with clear labeling about refining processes, particularly those emphasizing minimal processing and retention of natural nutrients, command premium prices, typically 15-20% higher than standard vegetable oils.

Competition in the refined rice bran oil market is intensifying, with approximately 200 significant producers globally. Large-scale producers with advanced refining capabilities hold about 40% market share, while medium and small-scale producers constitute the remainder. The market is witnessing consolidation, with larger companies acquiring smaller producers to expand their production capacity and geographic reach.

Distribution channels for refined rice bran oil are evolving, with supermarkets and hypermarkets accounting for 55% of sales, online retail growing rapidly at 25% annually, and specialty stores maintaining a stable 20% market share. Direct-to-consumer models through e-commerce platforms are gaining traction, particularly for premium refined rice bran oil products.

Consumer preferences are shifting toward refined rice bran oil products that maintain nutritional integrity while ensuring safety and stability. Products that can demonstrate effective degumming, neutralization, and bleaching processes without compromising the oil's natural beneficial compounds are positioned to capture greater market share in the growing health-conscious consumer segment.

Current Refining Technologies and Challenges

Rice bran oil refining for food use currently employs several established technologies, each with specific advantages and limitations. The conventional chemical refining process remains the industry standard, involving sequential degumming, neutralization, and bleaching steps. Water degumming, the simplest approach, removes hydratable phospholipids by adding 1-3% water at 60-70°C, but leaves behind non-hydratable phospholipids. Acid degumming addresses this limitation by incorporating phosphoric or citric acid (0.1-0.3%) to convert non-hydratable phospholipids to hydratable forms, achieving phospholipid reduction to 5-10 ppm.

For neutralization, alkali refining with sodium hydroxide (caustic soda) solution effectively removes free fatty acids (FFAs), reducing them to below 0.05%. However, this process suffers from significant oil loss (2-3%) and generates substantial soapstock waste requiring treatment. Physical refining alternatives using steam distillation operate at high temperatures (220-260°C), offering better oil yield but requiring oils with low phospholipid content and potentially affecting heat-sensitive components.

Bleaching technologies primarily utilize activated earth (bentonite) or activated carbon to adsorb pigments and residual impurities. Modern systems employ vacuum bleaching at 90-110°C with 0.5-2% bleaching earth, but face challenges in optimizing adsorbent usage while maintaining effective color removal. Regenerable synthetic adsorbents have emerged as alternatives but remain costly for widespread implementation.

The industry faces several critical challenges in rice bran oil refining. Oxidative stability represents a major concern as rice bran oil contains high levels of unsaturated fatty acids prone to oxidation during processing. The presence of oryzanol, while beneficial for health, complicates refining as conventional methods can significantly reduce this valuable component by 30-50%.

Environmental considerations pose increasing challenges, particularly regarding chemical usage, water consumption (typically 1-1.5 tons per ton of oil), and waste management. The soapstock from neutralization contains 40-50% water and requires additional processing before disposal. Energy efficiency remains suboptimal, with conventional refining consuming 25-40 kWh of electricity and 300-600 kg of steam per ton of oil processed.

Scale-appropriate technology development presents another challenge, as small to medium processors struggle to implement capital-intensive refining systems while maintaining product quality. Additionally, regulatory compliance across different markets requires adaptable refining approaches to meet varying standards for contaminants, residues, and quality parameters.

For neutralization, alkali refining with sodium hydroxide (caustic soda) solution effectively removes free fatty acids (FFAs), reducing them to below 0.05%. However, this process suffers from significant oil loss (2-3%) and generates substantial soapstock waste requiring treatment. Physical refining alternatives using steam distillation operate at high temperatures (220-260°C), offering better oil yield but requiring oils with low phospholipid content and potentially affecting heat-sensitive components.

Bleaching technologies primarily utilize activated earth (bentonite) or activated carbon to adsorb pigments and residual impurities. Modern systems employ vacuum bleaching at 90-110°C with 0.5-2% bleaching earth, but face challenges in optimizing adsorbent usage while maintaining effective color removal. Regenerable synthetic adsorbents have emerged as alternatives but remain costly for widespread implementation.

The industry faces several critical challenges in rice bran oil refining. Oxidative stability represents a major concern as rice bran oil contains high levels of unsaturated fatty acids prone to oxidation during processing. The presence of oryzanol, while beneficial for health, complicates refining as conventional methods can significantly reduce this valuable component by 30-50%.

Environmental considerations pose increasing challenges, particularly regarding chemical usage, water consumption (typically 1-1.5 tons per ton of oil), and waste management. The soapstock from neutralization contains 40-50% water and requires additional processing before disposal. Energy efficiency remains suboptimal, with conventional refining consuming 25-40 kWh of electricity and 300-600 kg of steam per ton of oil processed.

Scale-appropriate technology development presents another challenge, as small to medium processors struggle to implement capital-intensive refining systems while maintaining product quality. Additionally, regulatory compliance across different markets requires adaptable refining approaches to meet varying standards for contaminants, residues, and quality parameters.

Technical Analysis of Degumming, Neutralization and Bleaching Processes

01 Refining processes for improving rice bran oil quality

Various refining processes can be employed to enhance the quality of rice bran oil. These processes typically involve multiple stages such as degumming, neutralization, bleaching, and deodorization to remove impurities and undesirable components. Advanced refining techniques help in reducing free fatty acids, phospholipids, and other contaminants while preserving the beneficial components of the oil, resulting in improved clarity, stability, and sensory characteristics.- Refining processes for improving rice bran oil quality: Various refining processes can be employed to improve the quality of rice bran oil. These processes include degumming, neutralization, bleaching, and deodorization steps that remove impurities and undesirable components from the crude oil. Advanced refining techniques help to reduce free fatty acids, phospholipids, and other contaminants, resulting in higher quality rice bran oil with improved stability, clarity, and sensory characteristics.

- Equipment and apparatus for rice bran oil refining: Specialized equipment and apparatus play a crucial role in the efficient refining of rice bran oil. These include filtration systems, centrifugal separators, deodorizers, and integrated refining units designed specifically for rice bran oil processing. The equipment is engineered to optimize the removal of impurities while preserving the beneficial components of the oil, thereby enhancing the overall quality of the final product.

- Quality assessment and control methods for rice bran oil: Various analytical methods and quality control procedures are employed to assess and maintain the quality of refined rice bran oil. These include spectroscopic techniques, chromatography, and physical property measurements to evaluate parameters such as acid value, peroxide value, color, clarity, and oxidative stability. Implementing strict quality control protocols throughout the refining process ensures consistent production of high-quality rice bran oil that meets industry standards.

- Preservation of bioactive compounds during rice bran oil refining: Specialized refining techniques have been developed to preserve the valuable bioactive compounds in rice bran oil, such as oryzanol, tocopherols, tocotrienols, and phytosterols. These methods include mild processing conditions, molecular distillation, and selective extraction processes that minimize the degradation of these beneficial components. Preserving these bioactive compounds enhances the nutritional value and health benefits of the refined rice bran oil.

- Innovative approaches for enhancing rice bran oil quality: Novel and innovative approaches are being developed to enhance the quality of rice bran oil. These include enzymatic processing, membrane filtration technologies, supercritical fluid extraction, and the integration of green chemistry principles into refining processes. These innovative methods aim to improve oil yield, reduce environmental impact, and enhance the overall quality characteristics of rice bran oil while maintaining energy efficiency in the refining process.

02 Equipment and apparatus for rice bran oil refining

Specialized equipment and apparatus play a crucial role in the efficient refining of rice bran oil. These include innovative filtration systems, centrifugal separators, deodorizers, and integrated refining units designed specifically for rice bran oil processing. The equipment is engineered to optimize the removal of impurities while minimizing oil loss and energy consumption, thereby enhancing the overall quality of the refined oil.Expand Specific Solutions03 Quality assessment and control methods

Various analytical methods and quality control procedures are employed to assess and maintain the quality of refined rice bran oil. These include spectroscopic techniques, chromatography, and physical property measurements to evaluate parameters such as acid value, peroxide value, color, clarity, and oxidative stability. Implementing stringent quality control protocols throughout the refining process ensures consistent production of high-quality rice bran oil that meets industry standards and consumer expectations.Expand Specific Solutions04 Preservation of bioactive compounds during refining

Maintaining the nutritional value of rice bran oil during refining is essential for producing high-quality oil. Specialized techniques focus on preserving bioactive compounds such as oryzanol, tocopherols, tocotrienols, and phytosterols while removing undesirable components. These methods often involve modified refining conditions, such as lower temperatures, reduced exposure to chemicals, and alternative processing approaches that minimize the degradation of beneficial compounds.Expand Specific Solutions05 Innovative and eco-friendly refining technologies

Emerging technologies are being developed to improve rice bran oil refining processes with a focus on sustainability and environmental impact. These include enzymatic refining, membrane filtration, supercritical fluid extraction, and other green technologies that reduce chemical usage and waste generation. Such innovative approaches not only enhance the quality of the final product but also contribute to more sustainable and environmentally friendly production methods for rice bran oil.Expand Specific Solutions

Major Industry Players in Rice Bran Oil Production

The rice bran oil refining industry is currently in a growth phase, driven by increasing consumer demand for healthier cooking oils. The global market size is estimated to reach approximately $1.2 billion by 2025, with Asia-Pacific dominating production. Technologically, the refining process has reached moderate maturity, with ongoing innovations focused on improving efficiency and product quality. Leading companies like Cargill, DSM IP Assets BV, and Riceland Foods have established advanced degumming and neutralization techniques, while regional players such as Oryza Oil & Fat Chemical and Jianghuai Cereals & Oils are developing specialized bleaching processes. Academic institutions including Jiangnan University and Universiti Putra Malaysia are contributing significant research to improve refining methods, particularly in reducing chemical usage and preserving nutritional components during processing.

Cargill, Inc.

Technical Solution: Cargill has developed an advanced multi-stage rice bran oil refining process that begins with a water degumming step using citric acid at 70-80°C to remove phospholipids. This is followed by their proprietary "soft neutralization" technique that uses lower concentrations of alkali (0.5-1.0% NaOH solution) at controlled temperatures (65-75°C) to minimize neutral oil losses. For bleaching, Cargill employs activated clay (1-3% by weight) combined with activated carbon (0.1-0.3%) in a vacuum environment at 100-110°C, which effectively removes pigments, residual soaps, and trace metals while preserving bioactive compounds like oryzanol. Their process incorporates continuous monitoring systems that adjust parameters in real-time based on oil quality measurements, resulting in refined rice bran oil with less than 0.1% free fatty acids and improved oxidative stability[1][3]. Cargill's method also includes a specialized winterization step that removes waxes at precisely controlled cooling rates (0.5-1°C/hour) to maintain clarity at refrigeration temperatures.

Strengths: Cargill's process achieves higher oryzanol retention (up to 80% of original content) compared to conventional methods, providing superior nutritional value. Their continuous processing system reduces processing time by approximately 30% while minimizing oxidation. Weaknesses: The multi-stage process requires significant capital investment and specialized equipment. The soft neutralization approach, while preserving bioactive compounds, may sometimes result in slightly higher residual free fatty acids requiring additional processing steps.

PRAJ Industries Ltd.

Technical Solution: PRAJ Industries has developed an innovative rice bran oil refining technology called "EnzyRef" that incorporates enzymatic degumming as a key differentiator. Their process begins with crude rice bran oil pretreatment at 65-70°C, followed by the application of proprietary phospholipase enzymes (dosage: 30-50 ppm) that specifically target and hydrolyze non-hydratable phospholipids. This enzymatic treatment operates at mild pH conditions (4.5-5.5) for 2-4 hours, achieving phosphorus reduction to below 5 ppm. The neutralization phase employs a calculated amount of sodium hydroxide solution based on free fatty acid content, with the addition of citric acid (0.05-0.1%) to sequester metal ions. PRAJ's bleaching process utilizes a specialized blend of activated earth (1-2%) and activated carbon (0.2-0.5%) under vacuum conditions (50-100 mbar) at 100-105°C for 30-45 minutes. The company has also integrated heat recovery systems that reduce energy consumption by approximately 25% compared to conventional methods[2]. Their process maintains oryzanol content at 1.5-1.8% in the final refined oil, significantly higher than traditional chemical refining approaches.

Strengths: The enzymatic degumming process results in significantly lower oil losses (reduced by up to 40% compared to conventional methods) and higher yields. The technology requires less water and chemicals, making it more environmentally sustainable with reduced effluent generation. Weaknesses: The enzymatic process requires precise control of temperature, pH, and reaction time, necessitating more sophisticated monitoring systems. The initial investment cost is higher than conventional refining systems, though this is offset by improved yields and quality over time.

Key Patents and Innovations in Rice Bran Oil Refining

Rice bran-like composition and food

PatentActiveEP2172116A1

Innovation

- A rice bran-like composition is created by mixing defatted rice bran obtained through pressing and refined rice bran oil in a specific weight ratio of 85:15 to 60:40, which enhances bioactivity and reduces visceral fat, neutral fat, and blood cholesterol levels, while improving taste and smell.

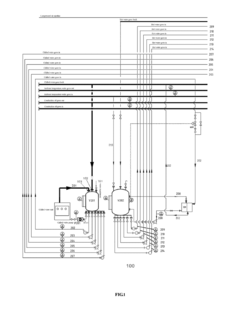

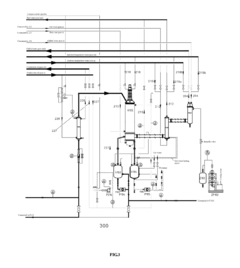

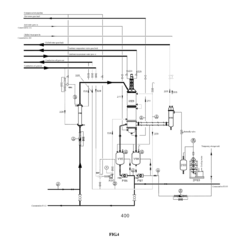

System and method for rice bran oil refinement

PatentActiveUS10233405B2

Innovation

- An oil refining system incorporating a water circulation system with chilled and hot water units, a deacidification and deodorization system with preheating, evaporation, and condensing units, and a decoloration system with reheating and distillation units, utilizing a fully automated process to separate oil components by adjusting pressure and temperature, eliminating the need for additives and minimizing human intervention.

Quality Standards and Regulatory Requirements for Edible Rice Bran Oil

Rice bran oil intended for food consumption must adhere to stringent quality standards and regulatory requirements established by various international and national food safety authorities. The Codex Alimentarius Commission has established specific standards for edible rice bran oil, including maximum limits for acid value (≤0.6 mg KOH/g), peroxide value (≤10 meq O2/kg), and moisture content (≤0.1%). These parameters directly reflect the effectiveness of the refining process, particularly the degumming, neutralization, and bleaching steps.

In the United States, the FDA regulates rice bran oil under the general provisions for edible oils, requiring compliance with Good Manufacturing Practices (GMPs) and proper labeling. The European Food Safety Authority (EFSA) has established similar requirements, with additional specifications regarding contaminant levels, particularly for heavy metals and polycyclic aromatic hydrocarbons (PAHs).

Asian countries, as major producers and consumers of rice bran oil, have developed comprehensive regulatory frameworks. Japan's specifications under the Japan Agricultural Standards (JAS) are particularly stringent, with detailed requirements for color, clarity, and oxidative stability. India's Food Safety and Standards Authority (FSSAI) has established specific standards for rice bran oil, including requirements for refractive index, saponification value, and unsaponifiable matter.

The refining process must be carefully controlled to ensure compliance with these regulatory requirements. Degumming efficiency directly impacts phospholipid content, which must typically be below 50 ppm for food-grade oil. The neutralization step must reduce free fatty acid content to below 0.1% while minimizing neutral oil loss. Bleaching must effectively remove pigments, trace metals, and oxidation products without introducing new contaminants.

Quality control testing throughout the refining process is mandatory, with specific attention to critical control points that could affect food safety. Modern analytical techniques such as gas chromatography, high-performance liquid chromatography, and spectrophotometric methods are commonly employed to verify compliance with regulatory standards.

Traceability requirements have become increasingly important in recent years, with many jurisdictions requiring documentation of the entire production chain from raw material sourcing to final product distribution. This includes validation of refining parameters and verification that all processing aids and chemicals used meet food-grade specifications.

Sustainability certifications are becoming increasingly relevant in regulatory frameworks, with some markets requiring documentation of environmental impact and sustainable sourcing practices. This trend is expected to continue, potentially adding new dimensions to quality standards for edible rice bran oil in the coming years.

In the United States, the FDA regulates rice bran oil under the general provisions for edible oils, requiring compliance with Good Manufacturing Practices (GMPs) and proper labeling. The European Food Safety Authority (EFSA) has established similar requirements, with additional specifications regarding contaminant levels, particularly for heavy metals and polycyclic aromatic hydrocarbons (PAHs).

Asian countries, as major producers and consumers of rice bran oil, have developed comprehensive regulatory frameworks. Japan's specifications under the Japan Agricultural Standards (JAS) are particularly stringent, with detailed requirements for color, clarity, and oxidative stability. India's Food Safety and Standards Authority (FSSAI) has established specific standards for rice bran oil, including requirements for refractive index, saponification value, and unsaponifiable matter.

The refining process must be carefully controlled to ensure compliance with these regulatory requirements. Degumming efficiency directly impacts phospholipid content, which must typically be below 50 ppm for food-grade oil. The neutralization step must reduce free fatty acid content to below 0.1% while minimizing neutral oil loss. Bleaching must effectively remove pigments, trace metals, and oxidation products without introducing new contaminants.

Quality control testing throughout the refining process is mandatory, with specific attention to critical control points that could affect food safety. Modern analytical techniques such as gas chromatography, high-performance liquid chromatography, and spectrophotometric methods are commonly employed to verify compliance with regulatory standards.

Traceability requirements have become increasingly important in recent years, with many jurisdictions requiring documentation of the entire production chain from raw material sourcing to final product distribution. This includes validation of refining parameters and verification that all processing aids and chemicals used meet food-grade specifications.

Sustainability certifications are becoming increasingly relevant in regulatory frameworks, with some markets requiring documentation of environmental impact and sustainable sourcing practices. This trend is expected to continue, potentially adding new dimensions to quality standards for edible rice bran oil in the coming years.

Sustainability Aspects of Rice Bran Oil Production

The sustainability of rice bran oil production represents a critical dimension in modern food processing systems. Rice bran oil extraction and refining processes offer significant environmental advantages compared to other vegetable oils, primarily due to the utilization of a by-product that would otherwise be discarded. The valorization of rice bran transforms what was once considered waste into a valuable resource, exemplifying circular economy principles.

Energy consumption during the refining process presents both challenges and opportunities for sustainability improvement. Traditional degumming, neutralization, and bleaching steps require substantial thermal and electrical energy inputs. However, innovations such as enzymatic degumming can reduce energy requirements by operating at lower temperatures compared to conventional chemical methods. These enzymatic approaches not only decrease energy consumption but also minimize chemical usage, resulting in a smaller environmental footprint.

Water usage represents another critical sustainability factor in rice bran oil refining. The neutralization process particularly demands significant water volumes for washing alkali residues. Advanced water recycling systems and optimized washing techniques can substantially reduce freshwater requirements, addressing water scarcity concerns in production regions.

Chemical inputs during refining pose environmental considerations that warrant attention. The neutralization step typically employs sodium hydroxide, while bleaching requires activated clay materials. Transitioning to biodegradable alternatives and implementing precise dosing systems can minimize chemical consumption while maintaining oil quality standards. Additionally, enzymatic approaches in degumming reduce phosphoric acid requirements, further enhancing the sustainability profile.

Waste management constitutes a fundamental sustainability challenge in rice bran oil production. The refining process generates spent bleaching earth, soapstock from neutralization, and gums from degumming. These by-products contain valuable components that can be recovered through advanced separation technologies. Spent bleaching earth can be repurposed for biogas production, while soapstock can be processed into fatty acids for industrial applications.

Carbon footprint reduction opportunities exist throughout the rice bran oil refining chain. Process integration techniques that recover and reuse heat from various refining stages can significantly decrease greenhouse gas emissions. Furthermore, transitioning to renewable energy sources for powering refining operations represents a viable pathway toward carbon neutrality in production facilities.

The economic sustainability of rice bran oil production depends on balancing processing costs with market value. Implementing energy-efficient technologies and waste valorization systems may require initial capital investment but typically deliver long-term operational savings while enhancing environmental performance. This alignment of economic and environmental objectives strengthens the overall sustainability proposition of refined rice bran oil as a food ingredient.

Energy consumption during the refining process presents both challenges and opportunities for sustainability improvement. Traditional degumming, neutralization, and bleaching steps require substantial thermal and electrical energy inputs. However, innovations such as enzymatic degumming can reduce energy requirements by operating at lower temperatures compared to conventional chemical methods. These enzymatic approaches not only decrease energy consumption but also minimize chemical usage, resulting in a smaller environmental footprint.

Water usage represents another critical sustainability factor in rice bran oil refining. The neutralization process particularly demands significant water volumes for washing alkali residues. Advanced water recycling systems and optimized washing techniques can substantially reduce freshwater requirements, addressing water scarcity concerns in production regions.

Chemical inputs during refining pose environmental considerations that warrant attention. The neutralization step typically employs sodium hydroxide, while bleaching requires activated clay materials. Transitioning to biodegradable alternatives and implementing precise dosing systems can minimize chemical consumption while maintaining oil quality standards. Additionally, enzymatic approaches in degumming reduce phosphoric acid requirements, further enhancing the sustainability profile.

Waste management constitutes a fundamental sustainability challenge in rice bran oil production. The refining process generates spent bleaching earth, soapstock from neutralization, and gums from degumming. These by-products contain valuable components that can be recovered through advanced separation technologies. Spent bleaching earth can be repurposed for biogas production, while soapstock can be processed into fatty acids for industrial applications.

Carbon footprint reduction opportunities exist throughout the rice bran oil refining chain. Process integration techniques that recover and reuse heat from various refining stages can significantly decrease greenhouse gas emissions. Furthermore, transitioning to renewable energy sources for powering refining operations represents a viable pathway toward carbon neutrality in production facilities.

The economic sustainability of rice bran oil production depends on balancing processing costs with market value. Implementing energy-efficient technologies and waste valorization systems may require initial capital investment but typically deliver long-term operational savings while enhancing environmental performance. This alignment of economic and environmental objectives strengthens the overall sustainability proposition of refined rice bran oil as a food ingredient.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!