Rice Bran Oil Quality Grading: Parameters, Methods and Specification Template

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rice Bran Oil Background and Quality Objectives

Rice bran oil, a byproduct of rice milling, has emerged as a premium edible oil with significant nutritional and health benefits over the past few decades. Historically, rice bran was primarily used as animal feed or discarded as waste until technological advancements in the 1980s enabled efficient extraction and stabilization of the oil. The evolution of rice bran oil technology has been marked by significant improvements in extraction methods, from traditional solvent extraction to modern supercritical fluid extraction, resulting in higher yields and better quality oil.

The global market for rice bran oil has witnessed steady growth, particularly in Asian countries like Japan, India, and Thailand, where rice is a staple food. This growth trajectory is expected to continue as consumers increasingly seek healthier cooking oil alternatives. Rice bran oil's unique composition, including oryzanol, tocotrienols, and phytosterols, positions it as a functional food with potential applications beyond culinary uses.

The primary objective of rice bran oil quality grading is to establish standardized parameters that ensure consistency, safety, and nutritional value across different production batches and geographical origins. These standards aim to protect consumers, facilitate fair trade practices, and promote industry growth through quality assurance. Quality objectives also include minimizing free fatty acid content, which is critical for shelf stability, and preserving bioactive compounds that contribute to the oil's health benefits.

Current technological trends in rice bran oil production focus on improving extraction efficiency while preserving nutritional components, developing rapid and non-destructive quality assessment methods, and implementing sustainable processing practices. Innovations in stabilization techniques address the challenge of rapid oil degradation due to lipase enzyme activity in freshly milled rice bran.

The establishment of comprehensive quality grading systems serves multiple stakeholders: producers benefit from clear production targets and potential price premiums for higher grades; processors gain operational efficiency through standardized inputs; and consumers receive consistent product quality with transparent information about nutritional and health attributes. These systems must balance technical precision with practical applicability across diverse production environments.

Looking forward, the rice bran oil industry faces opportunities to harmonize international quality standards, incorporate emerging analytical technologies for more precise quality assessment, and develop specialized grades for different applications, from culinary to cosmetic and pharmaceutical uses.

The global market for rice bran oil has witnessed steady growth, particularly in Asian countries like Japan, India, and Thailand, where rice is a staple food. This growth trajectory is expected to continue as consumers increasingly seek healthier cooking oil alternatives. Rice bran oil's unique composition, including oryzanol, tocotrienols, and phytosterols, positions it as a functional food with potential applications beyond culinary uses.

The primary objective of rice bran oil quality grading is to establish standardized parameters that ensure consistency, safety, and nutritional value across different production batches and geographical origins. These standards aim to protect consumers, facilitate fair trade practices, and promote industry growth through quality assurance. Quality objectives also include minimizing free fatty acid content, which is critical for shelf stability, and preserving bioactive compounds that contribute to the oil's health benefits.

Current technological trends in rice bran oil production focus on improving extraction efficiency while preserving nutritional components, developing rapid and non-destructive quality assessment methods, and implementing sustainable processing practices. Innovations in stabilization techniques address the challenge of rapid oil degradation due to lipase enzyme activity in freshly milled rice bran.

The establishment of comprehensive quality grading systems serves multiple stakeholders: producers benefit from clear production targets and potential price premiums for higher grades; processors gain operational efficiency through standardized inputs; and consumers receive consistent product quality with transparent information about nutritional and health attributes. These systems must balance technical precision with practical applicability across diverse production environments.

Looking forward, the rice bran oil industry faces opportunities to harmonize international quality standards, incorporate emerging analytical technologies for more precise quality assessment, and develop specialized grades for different applications, from culinary to cosmetic and pharmaceutical uses.

Market Analysis of Premium Rice Bran Oil Demand

The global premium rice bran oil market has witnessed significant growth in recent years, driven by increasing consumer awareness about health benefits and nutritional value. Market research indicates that the premium segment of rice bran oil is expanding at a compound annual growth rate of approximately 5.8%, outpacing the standard rice bran oil market which grows at about 4.2% annually.

Consumer demand for premium rice bran oil is primarily concentrated in Asia-Pacific regions, particularly Japan, India, and Thailand, where rice is a staple food and consumers have traditional familiarity with rice-derived products. However, North America and Europe are emerging as rapidly growing markets due to increasing health consciousness and the rising popularity of specialty cooking oils.

The premium rice bran oil segment is characterized by specific consumer preferences that directly influence quality grading parameters. Market surveys reveal that consumers prioritize oil clarity, mild nutty flavor profile, high smoke point, and extended shelf stability as key purchasing factors. Additionally, the presence of natural antioxidants, particularly oryzanol content, has become a significant marketing advantage in premium positioning.

Health-conscious consumers represent the largest market segment for premium rice bran oil, with particular interest in its cholesterol-lowering properties and balanced fatty acid profile. This segment is willing to pay a premium of 30-40% above standard rice bran oil prices for products with verified quality parameters and health benefits.

The foodservice industry constitutes another substantial market segment, with high-end restaurants and culinary establishments increasingly adopting premium rice bran oil for its superior heat stability and neutral flavor profile that enhances rather than masks food flavors. Market analysis shows that this segment values consistency in quality parameters across batches.

Retail packaging and branding significantly influence consumer perception of premium quality. Clear certification of quality parameters on packaging, transparent sourcing information, and educational content about grading standards correlate strongly with consumer willingness to pay premium prices. Products featuring detailed quality specifications typically command 15-25% higher retail prices.

Market forecasts suggest that demand for premium rice bran oil with standardized quality grading will continue to grow, particularly in developed markets where consumers increasingly seek specialized cooking oils with specific nutritional profiles. The development of internationally recognized grading standards would likely accelerate market growth by building consumer confidence and facilitating global trade of premium rice bran oil products.

Consumer demand for premium rice bran oil is primarily concentrated in Asia-Pacific regions, particularly Japan, India, and Thailand, where rice is a staple food and consumers have traditional familiarity with rice-derived products. However, North America and Europe are emerging as rapidly growing markets due to increasing health consciousness and the rising popularity of specialty cooking oils.

The premium rice bran oil segment is characterized by specific consumer preferences that directly influence quality grading parameters. Market surveys reveal that consumers prioritize oil clarity, mild nutty flavor profile, high smoke point, and extended shelf stability as key purchasing factors. Additionally, the presence of natural antioxidants, particularly oryzanol content, has become a significant marketing advantage in premium positioning.

Health-conscious consumers represent the largest market segment for premium rice bran oil, with particular interest in its cholesterol-lowering properties and balanced fatty acid profile. This segment is willing to pay a premium of 30-40% above standard rice bran oil prices for products with verified quality parameters and health benefits.

The foodservice industry constitutes another substantial market segment, with high-end restaurants and culinary establishments increasingly adopting premium rice bran oil for its superior heat stability and neutral flavor profile that enhances rather than masks food flavors. Market analysis shows that this segment values consistency in quality parameters across batches.

Retail packaging and branding significantly influence consumer perception of premium quality. Clear certification of quality parameters on packaging, transparent sourcing information, and educational content about grading standards correlate strongly with consumer willingness to pay premium prices. Products featuring detailed quality specifications typically command 15-25% higher retail prices.

Market forecasts suggest that demand for premium rice bran oil with standardized quality grading will continue to grow, particularly in developed markets where consumers increasingly seek specialized cooking oils with specific nutritional profiles. The development of internationally recognized grading standards would likely accelerate market growth by building consumer confidence and facilitating global trade of premium rice bran oil products.

Current Grading Challenges and Technical Limitations

Despite significant advancements in rice bran oil (RBO) quality assessment, the industry continues to face substantial challenges in establishing standardized grading systems. Current grading practices suffer from inconsistency across different regions and manufacturers, creating market confusion and hindering international trade. The absence of universally accepted quality parameters specifically tailored for RBO represents a fundamental limitation, as many producers still rely on general edible oil standards that fail to address the unique characteristics of rice bran oil.

Technical limitations in analytical methodologies present another significant obstacle. Traditional quality assessment techniques often lack the sensitivity required to detect subtle quality variations in RBO, particularly regarding its distinctive bioactive compounds like oryzanol, tocotrienols, and phytosterols. The equipment necessary for comprehensive analysis remains expensive and requires specialized expertise, making routine quality assessment prohibitively costly for smaller producers and developing markets.

The inherent variability of rice bran as a raw material compounds these challenges. Factors such as rice variety, cultivation conditions, harvesting time, and post-harvest handling significantly influence oil quality, yet current grading systems rarely account for these variables. This results in inconsistent quality benchmarks that fail to reflect the true value and potential applications of different RBO grades.

Storage stability assessment represents another technical limitation. Rice bran oil's unique composition makes it susceptible to specific degradation pathways that conventional stability tests may not adequately capture. The industry lacks standardized accelerated aging protocols specifically designed for RBO, making shelf-life predictions unreliable and complicating quality grading decisions.

Adulteration detection presents a persistent challenge, as sophisticated adulterants can bypass conventional testing methods. Current techniques struggle to identify the deliberate addition of lower-quality oils or synthetic compounds designed to mimic RBO's characteristic profile, undermining quality grading efforts and consumer trust.

The digital transformation gap further exacerbates these issues. While other industries have embraced advanced technologies like spectroscopic methods, machine learning algorithms, and blockchain traceability, the RBO sector has been slow to adopt these innovations. The lack of accessible, rapid, and non-destructive testing methods suitable for production environments limits the implementation of real-time quality monitoring systems essential for consistent grading.

Regulatory fragmentation across different countries creates additional complications, with varying quality standards and testing requirements creating trade barriers and market inefficiencies. This regulatory inconsistency hampers the development of globally recognized grading systems that could otherwise facilitate international commerce and quality assurance.

Technical limitations in analytical methodologies present another significant obstacle. Traditional quality assessment techniques often lack the sensitivity required to detect subtle quality variations in RBO, particularly regarding its distinctive bioactive compounds like oryzanol, tocotrienols, and phytosterols. The equipment necessary for comprehensive analysis remains expensive and requires specialized expertise, making routine quality assessment prohibitively costly for smaller producers and developing markets.

The inherent variability of rice bran as a raw material compounds these challenges. Factors such as rice variety, cultivation conditions, harvesting time, and post-harvest handling significantly influence oil quality, yet current grading systems rarely account for these variables. This results in inconsistent quality benchmarks that fail to reflect the true value and potential applications of different RBO grades.

Storage stability assessment represents another technical limitation. Rice bran oil's unique composition makes it susceptible to specific degradation pathways that conventional stability tests may not adequately capture. The industry lacks standardized accelerated aging protocols specifically designed for RBO, making shelf-life predictions unreliable and complicating quality grading decisions.

Adulteration detection presents a persistent challenge, as sophisticated adulterants can bypass conventional testing methods. Current techniques struggle to identify the deliberate addition of lower-quality oils or synthetic compounds designed to mimic RBO's characteristic profile, undermining quality grading efforts and consumer trust.

The digital transformation gap further exacerbates these issues. While other industries have embraced advanced technologies like spectroscopic methods, machine learning algorithms, and blockchain traceability, the RBO sector has been slow to adopt these innovations. The lack of accessible, rapid, and non-destructive testing methods suitable for production environments limits the implementation of real-time quality monitoring systems essential for consistent grading.

Regulatory fragmentation across different countries creates additional complications, with varying quality standards and testing requirements creating trade barriers and market inefficiencies. This regulatory inconsistency hampers the development of globally recognized grading systems that could otherwise facilitate international commerce and quality assurance.

Standard Grading Parameters and Testing Protocols

01 Chemical composition analysis for quality grading

Rice bran oil quality can be graded based on its chemical composition, including fatty acid profile, oryzanol content, and antioxidant levels. Advanced analytical techniques such as chromatography and spectroscopy are used to determine these parameters. The presence of specific bioactive compounds like tocopherols, tocotrienols, and phytosterols contributes to higher quality grades. These chemical markers help establish standardized quality criteria for different grades of rice bran oil.- Chemical composition analysis for quality grading: Rice bran oil quality can be graded based on its chemical composition, including fatty acid profile, antioxidant content, and bioactive compounds. Advanced analytical techniques are used to measure key components such as oryzanol, tocopherols, and tocotrienols that contribute to oil quality and stability. These measurements help establish quality standards and differentiate between premium and standard grades of rice bran oil.

- Physical property assessment methods: Quality grading of rice bran oil involves evaluation of physical properties such as color, clarity, viscosity, and refractive index. Specialized equipment and standardized testing protocols are used to measure these parameters consistently. Physical property assessment provides objective criteria for quality classification and helps identify oils suitable for different applications, from cosmetic to culinary uses.

- Refining processes impact on quality grades: The refining process significantly impacts the final quality grade of rice bran oil. Different refining techniques, including physical refining, chemical refining, and enzymatic processes, affect the retention of beneficial compounds while removing undesirable components. Advanced refining methods can preserve more bioactive compounds, resulting in higher quality grades that maintain nutritional value while achieving desired clarity and stability.

- Sensory evaluation and organoleptic grading: Sensory evaluation plays a crucial role in rice bran oil quality grading, assessing attributes such as taste, aroma, and mouthfeel. Trained panels use standardized protocols to evaluate these subjective qualities and assign scores. This organoleptic assessment complements instrumental analysis and helps determine suitability for premium culinary applications where flavor profile is particularly important.

- Stability testing and shelf-life determination: Quality grading of rice bran oil includes stability testing to determine resistance to oxidation and rancidity development during storage. Accelerated aging tests, peroxide value measurements, and free fatty acid content analysis help predict shelf life and establish quality classifications. Oils with superior oxidative stability receive higher quality grades and command premium prices in markets where extended shelf life is valued.

02 Physical property assessment methods

Quality grading of rice bran oil involves evaluation of physical properties such as color, clarity, viscosity, specific gravity, and refractive index. Specialized equipment and standardized testing protocols are used to measure these parameters. The color of the oil, ranging from light yellow to dark amber, serves as a key indicator of quality. Sensory evaluation techniques are also employed to assess characteristics like odor and taste, which contribute to the overall quality grade determination.Expand Specific Solutions03 Refining processes for quality improvement

Various refining processes are employed to improve rice bran oil quality and achieve higher grades. These include degumming, neutralization, bleaching, and deodorization steps that remove impurities and undesirable components. Modified refining techniques help preserve beneficial compounds while eliminating contaminants. The degree of refining directly impacts the final quality grade, with optimized processes yielding premium-grade oils that maintain nutritional value while meeting purity standards.Expand Specific Solutions04 Storage stability and shelf-life evaluation

The quality grading of rice bran oil includes assessment of its storage stability and shelf-life characteristics. Factors such as oxidative stability, resistance to rancidity, and maintenance of nutritional properties during storage are evaluated. Accelerated aging tests and monitoring of peroxide values help predict shelf-life. Packaging materials and storage conditions significantly influence stability. Higher quality grades demonstrate superior resistance to oxidation and longer shelf-life under standardized storage conditions.Expand Specific Solutions05 Automated and digital quality assessment systems

Modern rice bran oil quality grading incorporates automated and digital assessment systems that provide objective and consistent evaluation. These systems utilize computer vision, machine learning algorithms, and electronic sensors to analyze multiple quality parameters simultaneously. Near-infrared spectroscopy and image analysis techniques enable rapid, non-destructive testing. Digital platforms integrate quality data and generate comprehensive quality profiles, facilitating standardized grading across different production batches and geographical regions.Expand Specific Solutions

Key Industry Players and Certification Bodies

The rice bran oil quality grading market is currently in a growth phase, with increasing demand driven by health-conscious consumers and industrial applications. The global market size is expanding at a CAGR of approximately 5-6%, valued at over $1.2 billion. Technologically, the field is moderately mature but evolving, with companies like Fengyi Biotechnology, Oryza Oil & Fat Chemical, and Riceland Foods leading innovation in extraction and quality assessment methods. Academic institutions including Huazhong Agricultural University and National Chung Hsing University are advancing research in standardization parameters. PetroChina and Phillips 66 are leveraging their refining expertise to improve processing techniques, while specialized players like China National Rice Research Institute focus on developing region-specific quality metrics and certification standards to meet growing international trade requirements.

China National Rice Research Institute

Technical Solution: The China National Rice Research Institute has established a comprehensive rice bran oil quality grading system based on both compositional analysis and functional properties. Their approach integrates traditional quality parameters (acid value, peroxide value, color) with advanced analytical techniques to quantify bioactive compounds. The institute has developed specialized methodologies for oryzanol profiling using HPLC with UV detection, enabling detailed characterization of individual oryzanol components rather than just total content. Their system also incorporates thermal analysis techniques including differential scanning calorimetry (DSC) to evaluate crystallization behavior and oxidative stability. CNRRI has established correlations between rice cultivar characteristics and resulting oil quality, creating a database that links genetic factors to oil quality parameters. Their grading system includes specialized parameters for evaluating the suitability of different oil grades for various applications including cooking, cosmetics, and pharmaceutical uses.

Strengths: Strong integration of agricultural science with oil quality assessment; comprehensive database linking rice varieties to oil characteristics; specialized application-specific quality parameters. Weaknesses: Complex analytical requirements may limit widespread adoption; system optimized primarily for Chinese rice varieties which may require adaptation for other regions.

Council of Scientific & Industrial Research

Technical Solution: CSIR has pioneered a multi-parameter rice bran oil quality assessment framework that combines traditional analytical methods with advanced instrumentation. Their approach establishes a comprehensive grading system based on physicochemical properties (acid value, peroxide value, saponification value), nutritional components (oryzanol content, tocopherols, tocotrienols), and sensory characteristics. The methodology employs gas chromatography-mass spectrometry (GC-MS) for fatty acid profiling and liquid chromatography with diode array detection for bioactive compound quantification. CSIR has developed standardized protocols for sample preparation and analysis, ensuring reproducibility across different laboratories. Their system incorporates statistical models that correlate multiple quality parameters to establish definitive quality grades, with particular emphasis on detecting adulteration and ensuring authenticity of rice bran oil samples.

Strengths: Comprehensive analytical approach covering physical, chemical and nutritional parameters; established protocols suitable for regulatory adoption; strong focus on authenticity verification. Weaknesses: Complex methodology requiring sophisticated laboratory infrastructure; time-intensive analysis process that may limit throughput in commercial settings.

Critical Quality Indicators and Analytical Techniques

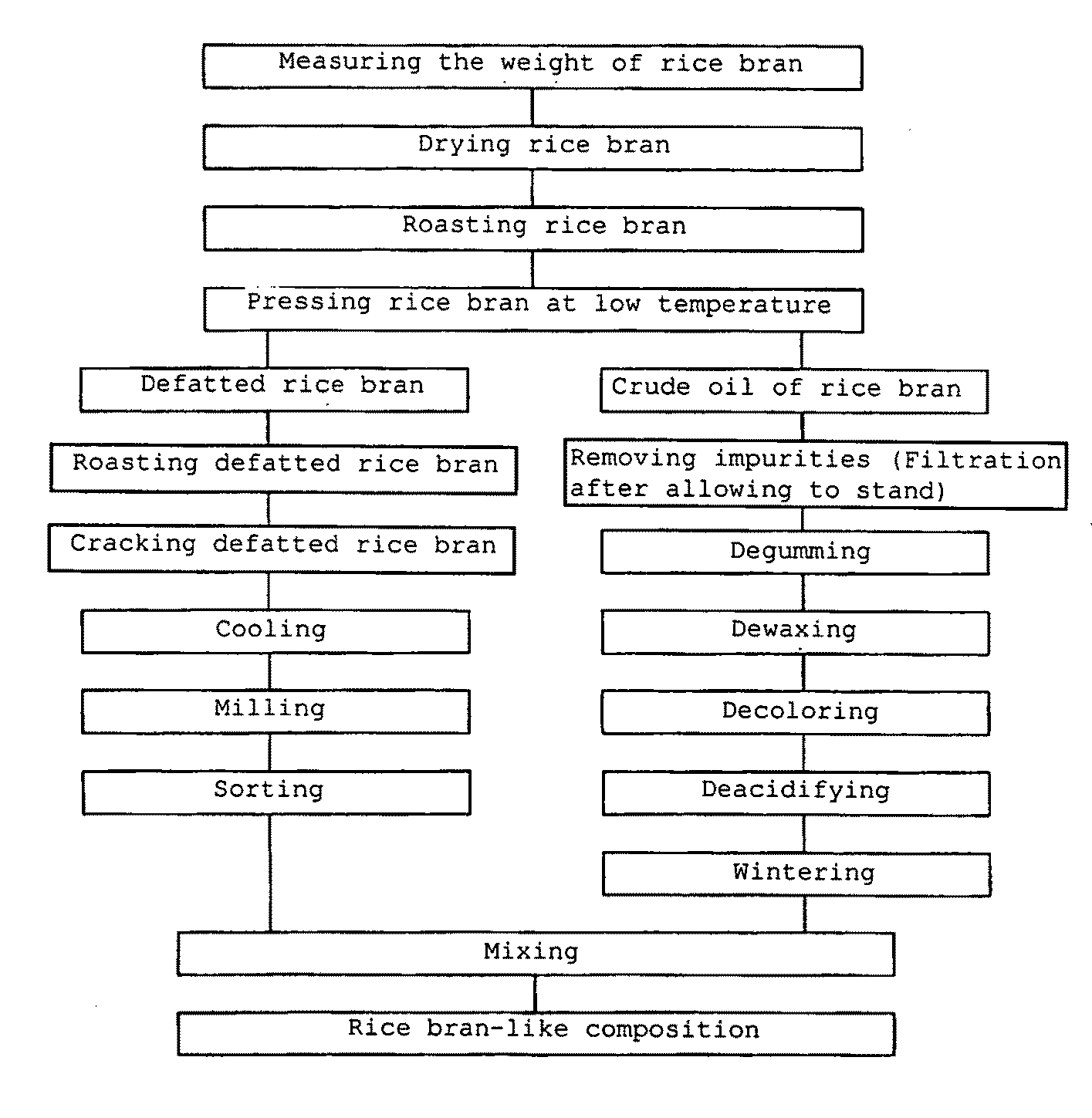

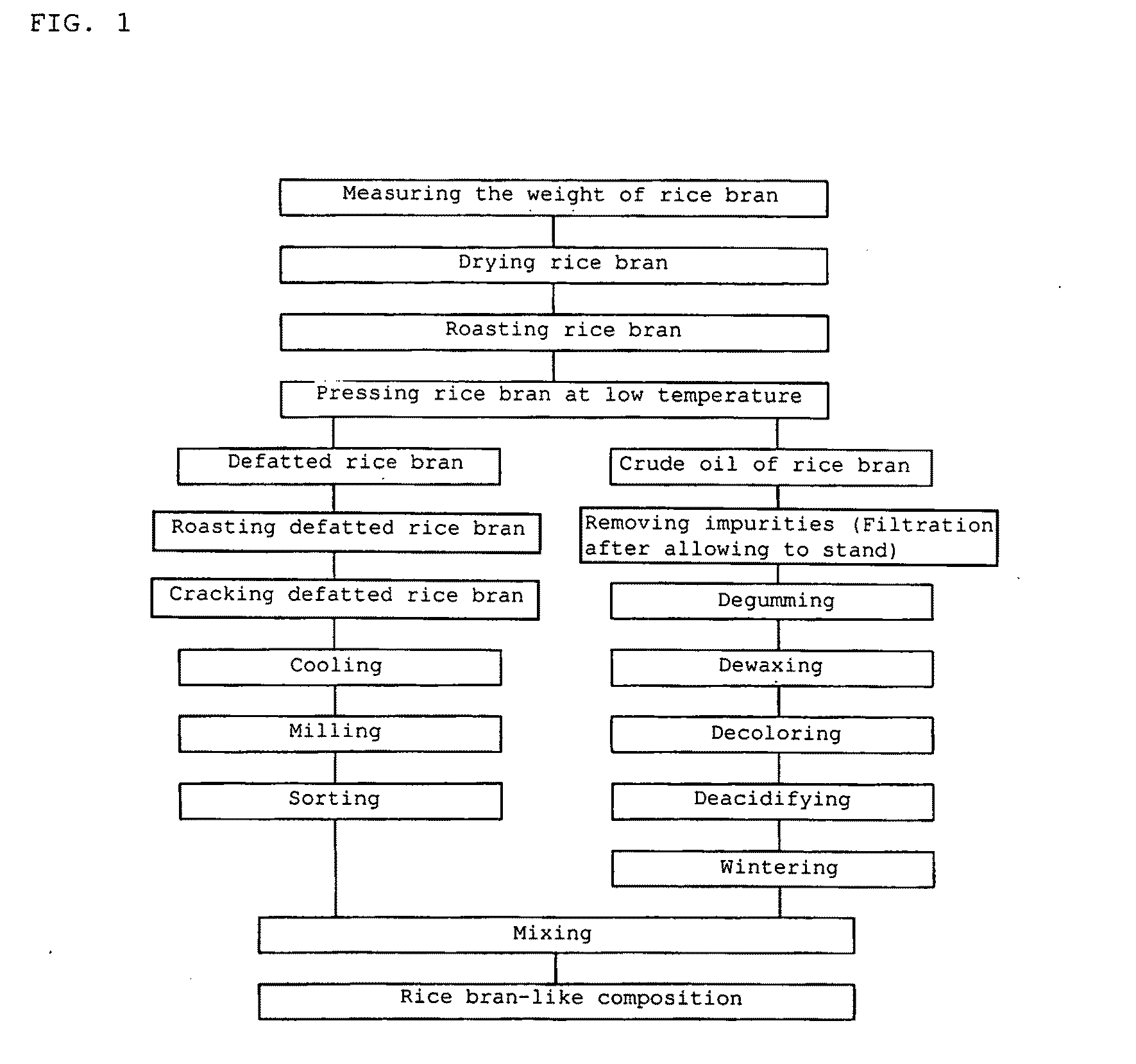

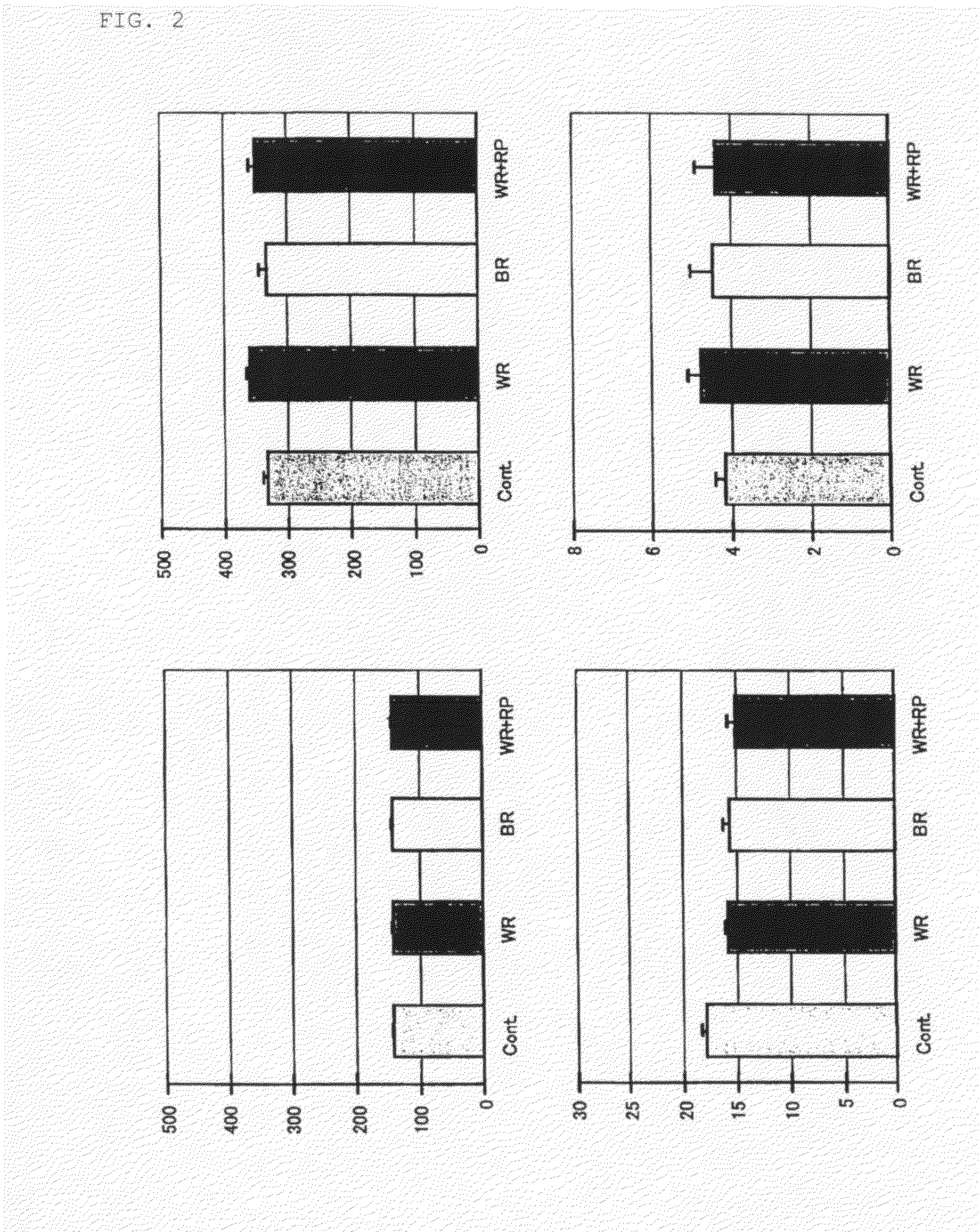

Rice bran-like composition and food

PatentInactiveUS20100196583A1

Innovation

- A rice bran-like composition is created by mixing defatted rice bran obtained through pressing with refined rice bran oil in a specific weight ratio of 85:15 to 60:40, which enhances bioactivity and improves taste and smell, while also reducing visceral fat, blood cholesterol, and neutral fat accumulation.

Method for realization of combined production of high quality rice bran oil and ferulic acid from rice bran

PatentInactiveCN104711112A

Innovation

- A new preparation method is adopted, including the steps of leaching, filtration, dewaxing, evaporation, degumming, deacidification, decolorization and deodorization, and using n-hexane or isohexane as the solvent, the oil in the rice bran is leached and evaporated multiple times. And steam stripping, combined with the use of phosphoric acid and alkali, gradually removes impurities, forming a mixed solution for saponification separation and acidification filtration, and finally obtains high-quality rice bran oil and ferulic acid.

International Standards and Regulatory Compliance

Rice bran oil quality grading is subject to various international standards and regulatory frameworks that ensure product safety, quality, and consistency across global markets. The Codex Alimentarius Commission, established by FAO and WHO, provides the most comprehensive international standards for rice bran oil through its Standard for Named Vegetable Oils (CODEX STAN 210-1999). This standard defines specific parameters for rice bran oil including composition, quality factors, contaminant limits, and labeling requirements.

The International Organization for Standardization (ISO) has developed several standards applicable to rice bran oil quality assessment, including ISO 660 for acid value determination, ISO 3960 for peroxide value, and ISO 3961 for iodine value. These standards provide globally recognized testing methodologies that facilitate international trade and ensure consistency in quality evaluation.

In the United States, rice bran oil must comply with FDA regulations for edible oils, including 21 CFR Part 101 for labeling requirements and 21 CFR Part 170 for food additives. The USDA's Agricultural Marketing Service also provides voluntary quality grading standards that can be applied to rice bran oil.

The European Union regulates rice bran oil under Regulation (EU) No 1169/2011 concerning food information to consumers and Commission Regulation (EC) No 1881/2006 setting maximum levels for certain contaminants in foodstuffs. These regulations establish strict parameters for heavy metals, pesticide residues, and other potential contaminants.

In major rice bran oil producing countries like India, Japan, and Thailand, national standards provide additional specifications. India's Food Safety and Standards Authority (FSSAI) has established specific standards for rice bran oil under the Food Safety and Standards Regulations, 2011. Japan's Agricultural Standards (JAS) and Thailand's Thai Industrial Standards Institute (TISI) have similar regulatory frameworks.

Compliance with these international and regional standards requires rigorous testing protocols. Key testing methods include gas chromatography for fatty acid composition, high-performance liquid chromatography for oryzanol content, and spectrophotometric methods for color evaluation. These methods must be performed according to internationally recognized protocols to ensure results are accepted across different regulatory jurisdictions.

For exporters and importers, navigating these complex regulatory requirements necessitates comprehensive documentation, including certificates of analysis that demonstrate compliance with both exporting and importing country regulations. This documentation typically includes test results for all required quality parameters according to the applicable standards.

The International Organization for Standardization (ISO) has developed several standards applicable to rice bran oil quality assessment, including ISO 660 for acid value determination, ISO 3960 for peroxide value, and ISO 3961 for iodine value. These standards provide globally recognized testing methodologies that facilitate international trade and ensure consistency in quality evaluation.

In the United States, rice bran oil must comply with FDA regulations for edible oils, including 21 CFR Part 101 for labeling requirements and 21 CFR Part 170 for food additives. The USDA's Agricultural Marketing Service also provides voluntary quality grading standards that can be applied to rice bran oil.

The European Union regulates rice bran oil under Regulation (EU) No 1169/2011 concerning food information to consumers and Commission Regulation (EC) No 1881/2006 setting maximum levels for certain contaminants in foodstuffs. These regulations establish strict parameters for heavy metals, pesticide residues, and other potential contaminants.

In major rice bran oil producing countries like India, Japan, and Thailand, national standards provide additional specifications. India's Food Safety and Standards Authority (FSSAI) has established specific standards for rice bran oil under the Food Safety and Standards Regulations, 2011. Japan's Agricultural Standards (JAS) and Thailand's Thai Industrial Standards Institute (TISI) have similar regulatory frameworks.

Compliance with these international and regional standards requires rigorous testing protocols. Key testing methods include gas chromatography for fatty acid composition, high-performance liquid chromatography for oryzanol content, and spectrophotometric methods for color evaluation. These methods must be performed according to internationally recognized protocols to ensure results are accepted across different regulatory jurisdictions.

For exporters and importers, navigating these complex regulatory requirements necessitates comprehensive documentation, including certificates of analysis that demonstrate compliance with both exporting and importing country regulations. This documentation typically includes test results for all required quality parameters according to the applicable standards.

Sustainability Aspects in Rice Bran Oil Production

The sustainability of rice bran oil production has become increasingly important as global demand for healthier cooking oils rises. Rice bran oil extraction processes traditionally consume significant energy and resources, prompting the industry to develop more environmentally friendly approaches. Modern sustainable practices focus on reducing water usage through closed-loop systems that recycle processing water, minimizing the environmental footprint of production facilities.

Energy efficiency improvements represent another critical sustainability aspect, with manufacturers implementing heat recovery systems and renewable energy sources to power extraction processes. These innovations have reduced carbon emissions by up to 30% in advanced facilities compared to conventional methods. Additionally, waste valorization has emerged as a cornerstone of sustainable rice bran oil production, with spent rice bran being repurposed as animal feed, organic fertilizer, or biomass fuel.

The circular economy concept is gaining traction in rice bran oil production, where byproducts like rice bran wax and rice bran protein are extracted and commercialized as valuable commodities. This integrated biorefinery approach maximizes resource utilization while creating additional revenue streams. Furthermore, organic and chemical-free extraction methods are being developed to replace hexane-based processes, reducing environmental hazards and improving worker safety.

Quality grading systems for rice bran oil increasingly incorporate sustainability metrics alongside traditional quality parameters. Producers now track carbon footprint, water usage, and waste generation per unit of oil produced. These sustainability indicators are becoming important differentiators in the marketplace, with consumers showing preference for products with lower environmental impact.

Certification programs like the Roundtable on Sustainable Palm Oil (RSPO) are being adapted for rice bran oil, establishing industry standards for environmentally responsible production. These frameworks encourage producers to implement best practices throughout the supply chain, from rice cultivation to oil extraction and packaging. Life cycle assessment (LCA) studies indicate that sustainable rice bran oil production can reduce environmental impact by 40-60% compared to conventional methods.

Looking forward, emerging technologies such as enzyme-assisted extraction and supercritical CO2 extraction promise to further enhance sustainability while maintaining or improving oil quality. These innovations align with global sustainability goals while meeting the increasing consumer demand for environmentally responsible food products.

Energy efficiency improvements represent another critical sustainability aspect, with manufacturers implementing heat recovery systems and renewable energy sources to power extraction processes. These innovations have reduced carbon emissions by up to 30% in advanced facilities compared to conventional methods. Additionally, waste valorization has emerged as a cornerstone of sustainable rice bran oil production, with spent rice bran being repurposed as animal feed, organic fertilizer, or biomass fuel.

The circular economy concept is gaining traction in rice bran oil production, where byproducts like rice bran wax and rice bran protein are extracted and commercialized as valuable commodities. This integrated biorefinery approach maximizes resource utilization while creating additional revenue streams. Furthermore, organic and chemical-free extraction methods are being developed to replace hexane-based processes, reducing environmental hazards and improving worker safety.

Quality grading systems for rice bran oil increasingly incorporate sustainability metrics alongside traditional quality parameters. Producers now track carbon footprint, water usage, and waste generation per unit of oil produced. These sustainability indicators are becoming important differentiators in the marketplace, with consumers showing preference for products with lower environmental impact.

Certification programs like the Roundtable on Sustainable Palm Oil (RSPO) are being adapted for rice bran oil, establishing industry standards for environmentally responsible production. These frameworks encourage producers to implement best practices throughout the supply chain, from rice cultivation to oil extraction and packaging. Life cycle assessment (LCA) studies indicate that sustainable rice bran oil production can reduce environmental impact by 40-60% compared to conventional methods.

Looking forward, emerging technologies such as enzyme-assisted extraction and supercritical CO2 extraction promise to further enhance sustainability while maintaining or improving oil quality. These innovations align with global sustainability goals while meeting the increasing consumer demand for environmentally responsible food products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!