Rice Bran Oil Stability in High-heat Industrial Fryers: Monitoring and Best Practices

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rice Bran Oil Stability Background and Objectives

Rice bran oil has emerged as a significant player in the industrial frying sector over the past two decades, evolving from a regional specialty to a globally recognized cooking medium. This evolution stems from its unique composition of bioactive compounds, including oryzanol, tocotrienols, and phytosterols, which contribute to its exceptional stability characteristics. Historically, rice bran oil utilization was limited by extraction challenges and rapid rancidity of the bran, but technological advancements in the 1980s and 1990s revolutionized stabilization processes, enabling commercial viability.

The trajectory of rice bran oil development has been marked by significant milestones, including the refinement of extraction methodologies, improved understanding of its nutritional profile, and enhanced stabilization techniques. Recent years have witnessed accelerated research into its performance under extreme thermal conditions, particularly relevant to industrial frying operations where oils are subjected to temperatures exceeding 180°C for extended periods.

Current technological trends in this field focus on optimizing rice bran oil's natural resistance to thermal oxidation, developing advanced monitoring systems for real-time quality assessment, and establishing standardized protocols for industrial applications. The intersection of food science, analytical chemistry, and process engineering has created a multidisciplinary approach to addressing stability challenges in high-heat environments.

The primary technical objectives of this investigation are multifaceted. First, to comprehensively characterize the degradation pathways of rice bran oil under industrial frying conditions, with particular emphasis on identifying critical control points where intervention can extend useful life. Second, to develop robust monitoring methodologies that provide accurate, real-time assessment of oil quality parameters during continuous frying operations.

Additionally, this research aims to establish evidence-based best practices for industrial fryer management when using rice bran oil, including optimal temperature ranges, filtration protocols, and antioxidant supplementation strategies. The investigation will further explore the relationship between rice bran oil refinement processes and subsequent thermal stability, potentially identifying modifications to upstream processing that could enhance downstream performance.

The ultimate goal is to create a technological framework that maximizes the economic and operational benefits of rice bran oil in industrial frying applications while maintaining consistent product quality and minimizing waste. This framework must address the technical challenges of continuous high-volume production environments while leveraging rice bran oil's natural advantages over conventional frying media.

The trajectory of rice bran oil development has been marked by significant milestones, including the refinement of extraction methodologies, improved understanding of its nutritional profile, and enhanced stabilization techniques. Recent years have witnessed accelerated research into its performance under extreme thermal conditions, particularly relevant to industrial frying operations where oils are subjected to temperatures exceeding 180°C for extended periods.

Current technological trends in this field focus on optimizing rice bran oil's natural resistance to thermal oxidation, developing advanced monitoring systems for real-time quality assessment, and establishing standardized protocols for industrial applications. The intersection of food science, analytical chemistry, and process engineering has created a multidisciplinary approach to addressing stability challenges in high-heat environments.

The primary technical objectives of this investigation are multifaceted. First, to comprehensively characterize the degradation pathways of rice bran oil under industrial frying conditions, with particular emphasis on identifying critical control points where intervention can extend useful life. Second, to develop robust monitoring methodologies that provide accurate, real-time assessment of oil quality parameters during continuous frying operations.

Additionally, this research aims to establish evidence-based best practices for industrial fryer management when using rice bran oil, including optimal temperature ranges, filtration protocols, and antioxidant supplementation strategies. The investigation will further explore the relationship between rice bran oil refinement processes and subsequent thermal stability, potentially identifying modifications to upstream processing that could enhance downstream performance.

The ultimate goal is to create a technological framework that maximizes the economic and operational benefits of rice bran oil in industrial frying applications while maintaining consistent product quality and minimizing waste. This framework must address the technical challenges of continuous high-volume production environments while leveraging rice bran oil's natural advantages over conventional frying media.

Market Demand Analysis for Heat-Stable Frying Oils

The global edible oil market has witnessed significant shifts in consumer preferences towards healthier alternatives, with rice bran oil emerging as a promising contender in the industrial frying segment. Current market analysis indicates that the industrial frying oil market is valued at approximately $62 billion globally, with projections suggesting a compound annual growth rate of 5.7% through 2028. Within this landscape, rice bran oil represents a growing niche, currently accounting for about 2% of the global edible oil market but expanding at nearly twice the rate of conventional frying oils.

The demand for heat-stable frying oils in commercial food production has intensified due to several converging factors. Fast food chains and packaged snack manufacturers are increasingly seeking oils that maintain stability during repeated high-temperature frying cycles, typically between 175-190°C, while minimizing the formation of harmful compounds. Rice bran oil's natural antioxidant content, particularly oryzanol and tocotrienols, positions it favorably in this segment, with laboratory studies demonstrating oxidative stability indices 30% higher than conventional vegetable oils under industrial frying conditions.

Consumer awareness regarding trans-fat consumption has dramatically reshaped market demands, with 78% of surveyed food service operators reporting increased customer inquiries about frying oil types. Regulatory pressures have further accelerated this trend, with 37 countries now implementing partial or complete bans on trans fats in food production. These regulatory shifts have created substantial market opportunities for naturally stable oils like rice bran oil, which can achieve extended fry life without hydrogenation.

The food service industry represents the largest demand segment for heat-stable frying oils, consuming approximately 42% of production volume. Quick-service restaurants alone use over 3 billion gallons of frying oil annually worldwide, with oil stability directly impacting operational costs and product consistency. Market research indicates that extending fry oil life by just 20% could generate savings of $1.2 billion annually across the global fast food industry, creating strong economic incentives for adoption of more stable alternatives.

Regional analysis reveals varying adoption patterns, with Asia-Pacific currently representing the largest market for rice bran oil at 68% of global consumption, followed by North America at 17%. However, European markets are showing the fastest growth rate at 9.3% annually, driven by stringent regulations on oil quality and sustainability concerns. Industry forecasts suggest that as production scales increase and supply chain efficiencies improve, rice bran oil could capture up to 7% of the industrial frying oil market within the next decade, representing a significant opportunity for both producers and food manufacturers seeking competitive advantages.

The demand for heat-stable frying oils in commercial food production has intensified due to several converging factors. Fast food chains and packaged snack manufacturers are increasingly seeking oils that maintain stability during repeated high-temperature frying cycles, typically between 175-190°C, while minimizing the formation of harmful compounds. Rice bran oil's natural antioxidant content, particularly oryzanol and tocotrienols, positions it favorably in this segment, with laboratory studies demonstrating oxidative stability indices 30% higher than conventional vegetable oils under industrial frying conditions.

Consumer awareness regarding trans-fat consumption has dramatically reshaped market demands, with 78% of surveyed food service operators reporting increased customer inquiries about frying oil types. Regulatory pressures have further accelerated this trend, with 37 countries now implementing partial or complete bans on trans fats in food production. These regulatory shifts have created substantial market opportunities for naturally stable oils like rice bran oil, which can achieve extended fry life without hydrogenation.

The food service industry represents the largest demand segment for heat-stable frying oils, consuming approximately 42% of production volume. Quick-service restaurants alone use over 3 billion gallons of frying oil annually worldwide, with oil stability directly impacting operational costs and product consistency. Market research indicates that extending fry oil life by just 20% could generate savings of $1.2 billion annually across the global fast food industry, creating strong economic incentives for adoption of more stable alternatives.

Regional analysis reveals varying adoption patterns, with Asia-Pacific currently representing the largest market for rice bran oil at 68% of global consumption, followed by North America at 17%. However, European markets are showing the fastest growth rate at 9.3% annually, driven by stringent regulations on oil quality and sustainability concerns. Industry forecasts suggest that as production scales increase and supply chain efficiencies improve, rice bran oil could capture up to 7% of the industrial frying oil market within the next decade, representing a significant opportunity for both producers and food manufacturers seeking competitive advantages.

Current Challenges in High-Heat Industrial Frying

Industrial frying operations face significant challenges when utilizing rice bran oil at high temperatures, primarily centered around thermal degradation and quality maintenance. The typical industrial fryer operates at temperatures between 160-190°C for extended periods, creating harsh conditions that accelerate oil breakdown. Rice bran oil, despite its favorable nutritional profile and high smoke point (approximately 232°C), undergoes complex chemical transformations during prolonged high-heat exposure.

One major challenge is oxidative stability. When rice bran oil is repeatedly heated in industrial settings, it experiences accelerated oxidation, leading to increased formation of polar compounds, free fatty acids, and polymeric substances. These degradation products not only compromise food quality but also potentially introduce health concerns. Current monitoring systems often fail to provide real-time assessment of these quality parameters, resulting in suboptimal oil management.

The formation of acrylamide and other potentially harmful compounds during high-temperature frying represents another significant challenge. Rice bran oil's unique composition, including its oryzanol content, influences these formation pathways differently than other oils, yet standardized monitoring protocols specific to rice bran oil are lacking in industrial applications.

Filtration efficiency presents a persistent technical hurdle. Industrial fryers accumulate food particles that catalyze oil degradation, but existing filtration systems are not optimized for the specific viscosity and particulate characteristics of degrading rice bran oil. This leads to accelerated quality deterioration and reduced oil lifespan in commercial settings.

Temperature control precision across large-volume fryers poses another challenge. Industrial fryers often exhibit temperature gradients that can vary by 5-10°C across different zones, creating inconsistent frying conditions. Rice bran oil's stability is particularly sensitive to these variations, yet current temperature management systems lack the granularity needed for optimal performance.

Moisture management during continuous frying operations significantly impacts oil stability. The introduction of frozen or high-moisture foods creates rapid temperature fluctuations and steam release that accelerates hydrolytic rancidity in rice bran oil. Current moisture control mechanisms in industrial fryers are primarily designed for conventional oils and may not adequately address rice bran oil's specific degradation patterns.

Finally, there exists a knowledge gap in establishing appropriate discard parameters for rice bran oil in industrial settings. Traditional quality indicators like total polar compounds (TPCs) may require different threshold values for rice bran oil compared to conventional frying oils, yet industry-specific standards remain underdeveloped.

One major challenge is oxidative stability. When rice bran oil is repeatedly heated in industrial settings, it experiences accelerated oxidation, leading to increased formation of polar compounds, free fatty acids, and polymeric substances. These degradation products not only compromise food quality but also potentially introduce health concerns. Current monitoring systems often fail to provide real-time assessment of these quality parameters, resulting in suboptimal oil management.

The formation of acrylamide and other potentially harmful compounds during high-temperature frying represents another significant challenge. Rice bran oil's unique composition, including its oryzanol content, influences these formation pathways differently than other oils, yet standardized monitoring protocols specific to rice bran oil are lacking in industrial applications.

Filtration efficiency presents a persistent technical hurdle. Industrial fryers accumulate food particles that catalyze oil degradation, but existing filtration systems are not optimized for the specific viscosity and particulate characteristics of degrading rice bran oil. This leads to accelerated quality deterioration and reduced oil lifespan in commercial settings.

Temperature control precision across large-volume fryers poses another challenge. Industrial fryers often exhibit temperature gradients that can vary by 5-10°C across different zones, creating inconsistent frying conditions. Rice bran oil's stability is particularly sensitive to these variations, yet current temperature management systems lack the granularity needed for optimal performance.

Moisture management during continuous frying operations significantly impacts oil stability. The introduction of frozen or high-moisture foods creates rapid temperature fluctuations and steam release that accelerates hydrolytic rancidity in rice bran oil. Current moisture control mechanisms in industrial fryers are primarily designed for conventional oils and may not adequately address rice bran oil's specific degradation patterns.

Finally, there exists a knowledge gap in establishing appropriate discard parameters for rice bran oil in industrial settings. Traditional quality indicators like total polar compounds (TPCs) may require different threshold values for rice bran oil compared to conventional frying oils, yet industry-specific standards remain underdeveloped.

Current Monitoring Solutions for Oil Degradation

01 Antioxidant addition for stability enhancement

Adding antioxidants to rice bran oil significantly improves its oxidative stability. Natural antioxidants such as tocopherols, oryzanol, and plant extracts can prevent rancidity and extend shelf life. Synthetic antioxidants like BHA, BHT, and TBHQ are also effective in preventing oxidation. The combination of different antioxidants often provides synergistic effects, resulting in superior stability compared to single antioxidant systems.- Antioxidant addition for stability enhancement: Adding antioxidants to rice bran oil significantly improves its oxidative stability. Various natural and synthetic antioxidants can be incorporated, including tocopherols, oryzanol, and other plant-derived compounds. These antioxidants neutralize free radicals and prevent oxidation reactions that lead to rancidity, thereby extending the shelf life of rice bran oil while maintaining its nutritional properties.

- Refining and processing techniques: Specialized refining and processing techniques can enhance rice bran oil stability. These include optimized degumming, neutralization, bleaching, and deodorization processes that remove unstable components while preserving beneficial compounds. Advanced extraction methods and controlled processing parameters significantly improve the oil's resistance to oxidation and extend its shelf life without compromising nutritional value.

- Storage and packaging solutions: Proper storage conditions and packaging materials play crucial roles in maintaining rice bran oil stability. Nitrogen flushing, vacuum packaging, and the use of dark, airtight containers help prevent oxidation by minimizing exposure to oxygen, light, and heat. Specialized packaging materials with oxygen barrier properties and controlled storage temperatures significantly extend the oil's shelf life and preserve its quality characteristics.

- Stabilization through enzymatic treatment: Enzymatic treatments effectively stabilize rice bran oil by inactivating lipase enzymes that cause rapid degradation. Various enzyme inhibition techniques and controlled enzymatic processes can be applied to rice bran before or during oil extraction. These treatments prevent hydrolytic rancidity and significantly improve the oil's stability while maintaining its nutritional profile and functional properties.

- Blending with other oils and stabilizing agents: Blending rice bran oil with other stable oils or incorporating specific stabilizing agents enhances its overall stability. Strategic combinations with oils having complementary fatty acid profiles or adding natural stabilizers creates synergistic effects that improve oxidative stability. These blends maintain or enhance the nutritional benefits while significantly extending shelf life and improving thermal stability for various applications.

02 Processing techniques for stability improvement

Various processing techniques can enhance rice bran oil stability. These include optimized refining processes, degumming, neutralization, bleaching, and deodorization steps that remove impurities contributing to instability. Physical refining methods that minimize heat exposure help preserve natural antioxidants. Specialized extraction methods like supercritical fluid extraction can produce more stable oil. Proper inactivation of lipase enzymes immediately after rice milling is crucial to prevent hydrolytic rancidity.Expand Specific Solutions03 Storage and packaging solutions

Proper storage conditions and packaging significantly impact rice bran oil stability. Nitrogen flushing or vacuum packaging reduces oxygen exposure. Dark, opaque containers protect against light-induced oxidation. Temperature-controlled storage environments slow down oxidative reactions. Modified atmosphere packaging and oxygen scavengers in packaging materials extend shelf life. The use of UV-blocking additives in packaging materials provides additional protection against photo-oxidation.Expand Specific Solutions04 Stabilization through microencapsulation

Microencapsulation technology protects rice bran oil from environmental factors that cause degradation. By encapsulating oil droplets within protective matrices made from materials like maltodextrin, gum arabic, or proteins, oxidation rates are significantly reduced. This technique creates a physical barrier against oxygen, light, and moisture. The resulting microcapsules can maintain oil stability even under challenging storage conditions and can be incorporated into various food products without compromising stability.Expand Specific Solutions05 Enzymatic stabilization methods

Enzymatic approaches effectively stabilize rice bran oil by targeting the lipase enzymes responsible for hydrolytic rancidity. Quick inactivation of these enzymes through heat treatment or pH modification immediately after rice milling prevents free fatty acid formation. Enzymatic degumming using phospholipases improves oil clarity and stability. Certain enzymes can also be used to modify oil components, creating more stable structures. These enzymatic methods often result in higher quality oil with better oxidative stability.Expand Specific Solutions

Major Players in Industrial Frying Oil Market

The rice bran oil stability market is currently in a growth phase, driven by increasing demand for healthier cooking oils with high smoke points for industrial applications. The global market size is expanding at a steady rate, particularly in Asia-Pacific regions where major players like The Nisshin OilliO Group, J-Oil Mills, and Marico Ltd have established strong footholds. Technologically, the field is moderately mature with ongoing innovations in monitoring systems and stabilization techniques. Leading companies including Cargill, SINOPEC, and Fengyi Biotechnology are investing in R&D to enhance oil stability under high-heat conditions. Academic institutions such as Jiangnan University and Wuhan Polytechnic University are collaborating with industry players like GEA Food Solutions to develop advanced monitoring technologies and best practices for extending rice bran oil shelf life in industrial fryer applications.

GEA Food Solutions Bakel BV

Technical Solution: GEA Food Solutions has developed an integrated fryer management system specifically addressing rice bran oil stability challenges. Their technology combines continuous filtration with precise temperature control mechanisms that maintain optimal frying conditions while minimizing thermal stress on the oil. The system features a multi-stage filtration process that removes both macro and micro particles, significantly reducing catalytic degradation factors. Their proprietary "ThermoGuard" technology implements dynamic temperature profiling that adjusts heat input based on production volume and oil condition, preventing unnecessary exposure to excessive temperatures. The system incorporates inline sensors monitoring key quality parameters including polar compounds, viscosity changes, and color degradation. Data is processed through their FryerCare software platform, which provides real-time analytics and generates customized maintenance protocols based on specific operational patterns and oil performance metrics.

Strengths: Comprehensive integration with industrial fryer systems provides seamless implementation; advanced filtration technology significantly extends oil life. Weaknesses: Higher initial capital investment compared to standalone monitoring solutions; system optimization requires significant technical support during implementation phase.

The Nisshin OilliO Group, Ltd.

Technical Solution: The Nisshin OilliO Group has developed a comprehensive monitoring system for rice bran oil stability in high-heat industrial fryers. Their technology incorporates real-time sensors that track critical parameters including free fatty acid levels, total polar compounds (TPC), and oxidative stability index. The system employs proprietary algorithms to analyze spectroscopic data for detecting quality degradation before it affects product quality. Their solution includes automated filtration systems that continuously remove food particles and extend oil life by up to 40%. Additionally, they've engineered antioxidant formulations specifically optimized for rice bran oil's unique composition, enhancing its thermal stability during prolonged high-heat frying operations without compromising nutritional benefits or flavor profiles.

Strengths: Industry-leading expertise in edible oils with specialized knowledge of rice bran oil chemistry; integrated monitoring and filtration technology provides comprehensive solution. Weaknesses: System requires significant initial investment; proprietary consumables may increase operational costs compared to generic alternatives.

Key Innovations in Oil Stability Enhancement

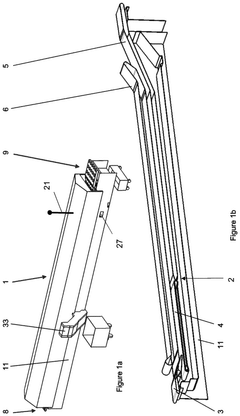

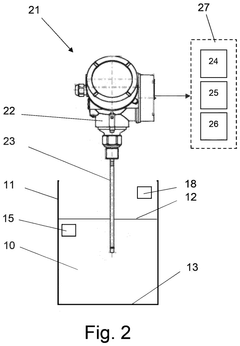

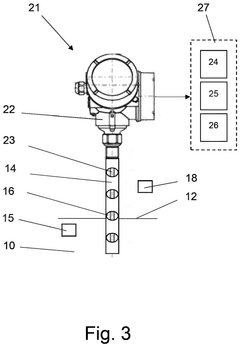

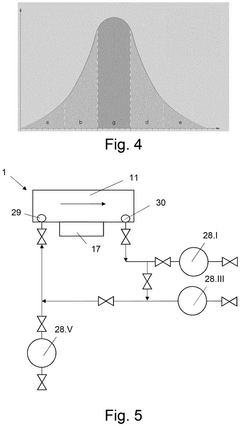

Frying oil sensing means and frying oil management within an industrial fryer setup

PatentPendingEP4585909A2

Innovation

- A food processing line equipped with a guided wave radar sensor and optical sensor to determine the permittivity and color of frying oil, respectively, coupled with a control unit to manage the inflow and outflow of replacement oil based on these measurements, ensuring optimal oil quality and extending its usable lifespan.

Sustainability Aspects of Rice Bran Oil Usage

The sustainability profile of rice bran oil (RBO) in industrial frying applications represents a significant advantage over conventional frying oils. RBO is derived from the outer layers of rice grains, a by-product of rice milling that would otherwise be discarded or used as low-value animal feed. This extraction process transforms agricultural waste into a valuable food ingredient, exemplifying circular economy principles in the food production system.

From an environmental perspective, RBO production has a lower carbon footprint compared to many other vegetable oils. Rice is already cultivated extensively worldwide, and utilizing its by-products requires no additional land use or deforestation. The extraction process for RBO has also evolved to become more energy-efficient, with modern facilities implementing heat recovery systems and optimized processing parameters to reduce overall energy consumption.

Water usage in RBO production is relatively modest compared to oils like palm or soybean, which require extensive irrigation. Additionally, the stabilization techniques used to preserve RBO's quality during high-heat applications often involve natural antioxidants rather than synthetic additives, further enhancing its environmental credentials.

The economic sustainability of RBO is equally compelling. By creating value from rice milling by-products, the rice value chain becomes more economically viable for farmers and processors. This additional revenue stream can be particularly important in rice-producing regions of developing countries, where agricultural margins are often thin.

Health considerations also factor into RBO's sustainability profile. Its balanced fatty acid composition and natural antioxidants contribute to healthier fried food products. The oil's stability at high temperatures means less frequent oil changes in industrial fryers, reducing waste oil generation and disposal challenges. When properly monitored and maintained, RBO can have a longer frying life than many conventional oils, further reducing resource consumption.

Waste management represents another sustainability advantage. Spent RBO can be effectively converted into biodiesel, creating a secondary use cycle before final disposal. The deodorizer distillate from RBO refining contains valuable compounds like oryzanol and tocotrienols that can be extracted for nutraceutical applications, maximizing resource utilization.

As food businesses increasingly face pressure to improve their sustainability metrics, the adoption of RBO in industrial frying operations offers a credible pathway to reduce environmental impact while maintaining or improving product quality and operational efficiency.

From an environmental perspective, RBO production has a lower carbon footprint compared to many other vegetable oils. Rice is already cultivated extensively worldwide, and utilizing its by-products requires no additional land use or deforestation. The extraction process for RBO has also evolved to become more energy-efficient, with modern facilities implementing heat recovery systems and optimized processing parameters to reduce overall energy consumption.

Water usage in RBO production is relatively modest compared to oils like palm or soybean, which require extensive irrigation. Additionally, the stabilization techniques used to preserve RBO's quality during high-heat applications often involve natural antioxidants rather than synthetic additives, further enhancing its environmental credentials.

The economic sustainability of RBO is equally compelling. By creating value from rice milling by-products, the rice value chain becomes more economically viable for farmers and processors. This additional revenue stream can be particularly important in rice-producing regions of developing countries, where agricultural margins are often thin.

Health considerations also factor into RBO's sustainability profile. Its balanced fatty acid composition and natural antioxidants contribute to healthier fried food products. The oil's stability at high temperatures means less frequent oil changes in industrial fryers, reducing waste oil generation and disposal challenges. When properly monitored and maintained, RBO can have a longer frying life than many conventional oils, further reducing resource consumption.

Waste management represents another sustainability advantage. Spent RBO can be effectively converted into biodiesel, creating a secondary use cycle before final disposal. The deodorizer distillate from RBO refining contains valuable compounds like oryzanol and tocotrienols that can be extracted for nutraceutical applications, maximizing resource utilization.

As food businesses increasingly face pressure to improve their sustainability metrics, the adoption of RBO in industrial frying operations offers a credible pathway to reduce environmental impact while maintaining or improving product quality and operational efficiency.

Quality Control Standards and Compliance

Quality control standards for rice bran oil in high-heat industrial frying applications must adhere to both international and regional regulatory frameworks. The Codex Alimentarius Commission has established specific parameters for edible oils, including rice bran oil, with standards covering acid value, peroxide value, and moisture content. These standards serve as the foundation for quality assurance programs in food processing facilities utilizing rice bran oil for industrial frying operations.

The American Oil Chemists' Society (AOCS) provides comprehensive testing methodologies that have become industry benchmarks for monitoring oil quality during high-heat applications. Their protocols for measuring free fatty acids, polar compounds, and oxidative stability are particularly relevant for rice bran oil, which contains unique antioxidant compounds that affect its thermal performance differently than conventional frying oils.

In industrial settings, compliance with ISO 22000 food safety management systems is increasingly becoming mandatory, requiring systematic monitoring and documentation of oil quality parameters throughout the frying process. This includes implementing Hazard Analysis Critical Control Points (HACCP) specifically designed for high-heat oil applications, with critical limits established for total polar compounds (typically not exceeding 25%) and free fatty acid levels.

The European Food Safety Authority has established more stringent guidelines, limiting polar compounds to 24% and recommending more frequent oil replacement cycles for oils used in continuous frying operations. These standards are particularly important for rice bran oil due to its distinctive fatty acid profile and oryzanol content, which influence its degradation patterns under prolonged heat exposure.

Compliance verification requires regular sampling protocols, with frequency determined by production volume and operating temperatures. Standard testing methods include rapid on-site testing using portable devices that measure dielectric constant changes, coupled with periodic laboratory verification using gas chromatography and high-performance liquid chromatography techniques to assess oxidation byproducts and antioxidant retention rates.

Documentation requirements for quality control programs must include temperature logs, oil replacement schedules, filtration records, and analytical test results. These records are essential for regulatory inspections and for internal quality improvement initiatives. Many jurisdictions now require electronic traceability systems that can demonstrate consistent adherence to established quality parameters throughout the oil's usable life in industrial fryers.

Training programs for quality control personnel must specifically address the unique characteristics of rice bran oil, including its higher smoke point and distinctive oxidation patterns compared to other vegetable oils. Certification programs offered by organizations such as the Global Food Safety Initiative provide standardized approaches to quality monitoring that can be adapted to the specific challenges of maintaining rice bran oil stability in high-heat industrial applications.

The American Oil Chemists' Society (AOCS) provides comprehensive testing methodologies that have become industry benchmarks for monitoring oil quality during high-heat applications. Their protocols for measuring free fatty acids, polar compounds, and oxidative stability are particularly relevant for rice bran oil, which contains unique antioxidant compounds that affect its thermal performance differently than conventional frying oils.

In industrial settings, compliance with ISO 22000 food safety management systems is increasingly becoming mandatory, requiring systematic monitoring and documentation of oil quality parameters throughout the frying process. This includes implementing Hazard Analysis Critical Control Points (HACCP) specifically designed for high-heat oil applications, with critical limits established for total polar compounds (typically not exceeding 25%) and free fatty acid levels.

The European Food Safety Authority has established more stringent guidelines, limiting polar compounds to 24% and recommending more frequent oil replacement cycles for oils used in continuous frying operations. These standards are particularly important for rice bran oil due to its distinctive fatty acid profile and oryzanol content, which influence its degradation patterns under prolonged heat exposure.

Compliance verification requires regular sampling protocols, with frequency determined by production volume and operating temperatures. Standard testing methods include rapid on-site testing using portable devices that measure dielectric constant changes, coupled with periodic laboratory verification using gas chromatography and high-performance liquid chromatography techniques to assess oxidation byproducts and antioxidant retention rates.

Documentation requirements for quality control programs must include temperature logs, oil replacement schedules, filtration records, and analytical test results. These records are essential for regulatory inspections and for internal quality improvement initiatives. Many jurisdictions now require electronic traceability systems that can demonstrate consistent adherence to established quality parameters throughout the oil's usable life in industrial fryers.

Training programs for quality control personnel must specifically address the unique characteristics of rice bran oil, including its higher smoke point and distinctive oxidation patterns compared to other vegetable oils. Certification programs offered by organizations such as the Global Food Safety Initiative provide standardized approaches to quality monitoring that can be adapted to the specific challenges of maintaining rice bran oil stability in high-heat industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!