How to Test Free Fatty Acid Levels in Rice Bran Oil — Titration SOP and Reporting Format

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rice Bran Oil FFA Testing Background and Objectives

Free Fatty Acid (FFA) testing in rice bran oil represents a critical quality control parameter that has evolved significantly over the past century. Rice bran oil, extracted from the outer layer of rice grains, has gained prominence in global markets due to its nutritional profile and cooking properties. The measurement of FFA levels serves as a primary indicator of oil quality, refinement efficiency, and storage stability, making accurate testing methodologies essential for industry stakeholders.

Historically, FFA testing began with rudimentary chemical analyses in the early 20th century, progressing through various analytical improvements to today's standardized titration methods. The evolution of these testing protocols has been driven by increasing quality demands from consumers, stricter regulatory requirements, and the expansion of rice bran oil into premium market segments where precise quality metrics are paramount.

The technical landscape for FFA testing has been shaped by international standards organizations including AOCS (American Oil Chemists' Society), ISO (International Organization for Standardization), and Codex Alimentarius, which have established benchmark methodologies that balance analytical precision with practical implementation in industrial settings.

Current industry standards typically specify maximum acceptable FFA levels ranging from 0.1% to 0.5% for refined rice bran oil, with variations depending on grade and intended use. These thresholds necessitate testing methods with sufficient sensitivity and reproducibility to ensure compliance and product consistency.

The primary objective of FFA testing in rice bran oil is to quantify the percentage of free fatty acids present, typically expressed as oleic acid equivalents. This measurement directly correlates with oil quality, processing efficiency, and potential shelf life. Secondary objectives include process optimization during refining, quality assurance during storage and distribution, and compliance verification for regulatory and certification purposes.

Emerging trends in FFA testing include the development of rapid analysis techniques, automation of traditional titration methods, and integration with digital quality management systems. These innovations aim to reduce testing time, minimize human error, and provide real-time quality data throughout the production chain.

The technical goals for advancing FFA testing methodologies focus on improving precision while reducing analysis time, minimizing reagent consumption, simplifying procedures for non-specialist operators, and developing cost-effective solutions suitable for implementation across various scales of production, from artisanal processors to industrial refineries.

Historically, FFA testing began with rudimentary chemical analyses in the early 20th century, progressing through various analytical improvements to today's standardized titration methods. The evolution of these testing protocols has been driven by increasing quality demands from consumers, stricter regulatory requirements, and the expansion of rice bran oil into premium market segments where precise quality metrics are paramount.

The technical landscape for FFA testing has been shaped by international standards organizations including AOCS (American Oil Chemists' Society), ISO (International Organization for Standardization), and Codex Alimentarius, which have established benchmark methodologies that balance analytical precision with practical implementation in industrial settings.

Current industry standards typically specify maximum acceptable FFA levels ranging from 0.1% to 0.5% for refined rice bran oil, with variations depending on grade and intended use. These thresholds necessitate testing methods with sufficient sensitivity and reproducibility to ensure compliance and product consistency.

The primary objective of FFA testing in rice bran oil is to quantify the percentage of free fatty acids present, typically expressed as oleic acid equivalents. This measurement directly correlates with oil quality, processing efficiency, and potential shelf life. Secondary objectives include process optimization during refining, quality assurance during storage and distribution, and compliance verification for regulatory and certification purposes.

Emerging trends in FFA testing include the development of rapid analysis techniques, automation of traditional titration methods, and integration with digital quality management systems. These innovations aim to reduce testing time, minimize human error, and provide real-time quality data throughout the production chain.

The technical goals for advancing FFA testing methodologies focus on improving precision while reducing analysis time, minimizing reagent consumption, simplifying procedures for non-specialist operators, and developing cost-effective solutions suitable for implementation across various scales of production, from artisanal processors to industrial refineries.

Market Demand for Quality Control in Edible Oils

The global edible oil market has witnessed significant growth in recent years, with increasing consumer awareness regarding health benefits driving demand for premium quality oils like rice bran oil. Market research indicates that the global rice bran oil market was valued at approximately $4.1 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2030. This growth trajectory underscores the critical importance of quality control measures, particularly free fatty acid (FFA) testing, in maintaining product standards.

Consumer preferences have shifted dramatically toward healthier cooking oil options, with rice bran oil gaining popularity due to its balanced fatty acid profile and high smoke point. Market surveys reveal that over 65% of consumers now consider nutritional value and purity as primary factors when purchasing edible oils, representing a significant increase from just 38% a decade ago. This trend has intensified the need for rigorous quality control protocols across the supply chain.

Regulatory frameworks worldwide have simultaneously become more stringent regarding edible oil quality parameters. The Codex Alimentarius Commission has established maximum FFA limits for various edible oils, with rice bran oil typically required to maintain FFA levels below 0.3% for refined products. Similarly, the FDA and European Food Safety Authority have implemented comprehensive guidelines for oil quality assessment, with FFA testing being a mandatory component of compliance verification.

The industrial sector has responded to these market demands by investing heavily in quality control infrastructure. Major edible oil producers have reported allocating between 8-12% of their operational budgets toward quality testing equipment and protocols, with FFA testing representing a significant portion of these investments. This trend is particularly pronounced in emerging markets like India and China, where rice bran oil production has expanded rapidly.

Food service and hospitality industries have also emerged as key drivers of quality control demand, with restaurants and hotel chains implementing strict supplier verification processes that include FFA certification. Market analysis shows that 78% of commercial food service operations now require documented quality control reports from oil suppliers, compared to just 45% in 2015.

The retail sector has similarly embraced quality parameters as a marketing differentiator, with premium oil brands prominently featuring quality certifications on packaging. Consumer willingness to pay price premiums of 15-25% for oils with verified quality parameters has created strong economic incentives for producers to invest in comprehensive testing protocols, including standardized FFA testing methodologies.

Consumer preferences have shifted dramatically toward healthier cooking oil options, with rice bran oil gaining popularity due to its balanced fatty acid profile and high smoke point. Market surveys reveal that over 65% of consumers now consider nutritional value and purity as primary factors when purchasing edible oils, representing a significant increase from just 38% a decade ago. This trend has intensified the need for rigorous quality control protocols across the supply chain.

Regulatory frameworks worldwide have simultaneously become more stringent regarding edible oil quality parameters. The Codex Alimentarius Commission has established maximum FFA limits for various edible oils, with rice bran oil typically required to maintain FFA levels below 0.3% for refined products. Similarly, the FDA and European Food Safety Authority have implemented comprehensive guidelines for oil quality assessment, with FFA testing being a mandatory component of compliance verification.

The industrial sector has responded to these market demands by investing heavily in quality control infrastructure. Major edible oil producers have reported allocating between 8-12% of their operational budgets toward quality testing equipment and protocols, with FFA testing representing a significant portion of these investments. This trend is particularly pronounced in emerging markets like India and China, where rice bran oil production has expanded rapidly.

Food service and hospitality industries have also emerged as key drivers of quality control demand, with restaurants and hotel chains implementing strict supplier verification processes that include FFA certification. Market analysis shows that 78% of commercial food service operations now require documented quality control reports from oil suppliers, compared to just 45% in 2015.

The retail sector has similarly embraced quality parameters as a marketing differentiator, with premium oil brands prominently featuring quality certifications on packaging. Consumer willingness to pay price premiums of 15-25% for oils with verified quality parameters has created strong economic incentives for producers to invest in comprehensive testing protocols, including standardized FFA testing methodologies.

Current FFA Testing Methods and Challenges

The assessment of Free Fatty Acid (FFA) levels in rice bran oil represents a critical quality control parameter in the edible oil industry. Currently, several methodologies exist for FFA determination, with titration-based approaches remaining the gold standard despite technological advancements in analytical chemistry. The traditional AOCS Official Method Ca 5a-40 employs alkaline titration with phenolphthalein as an indicator, providing reliable results but requiring significant operator expertise.

Automated titrators have emerged as an improvement over manual methods, offering enhanced precision and reduced human error. These systems utilize potentiometric endpoints rather than visual indicators, allowing for more objective determination of the titration endpoint. However, their high cost presents a barrier to adoption for smaller producers and quality control laboratories.

Near-infrared spectroscopy (NIRS) represents a non-destructive alternative gaining traction in the industry. This method correlates spectral data with FFA content through chemometric models, enabling rapid analysis without chemical reagents. Despite these advantages, NIRS requires extensive calibration against reference methods and may struggle with accuracy at very low FFA concentrations typical in refined rice bran oil.

Gas chromatography (GC) offers superior specificity by separating and quantifying individual fatty acids rather than total acidity. This provides valuable compositional information beyond simple FFA percentage but demands sophisticated equipment and technical expertise. The sample preparation for GC analysis is also more complex, involving derivatization steps that extend analysis time.

A significant challenge across all methodologies is the lack of standardization specific to rice bran oil. Most protocols were developed for other vegetable oils and may not account for the unique composition of rice bran oil, particularly its high content of oryzanol and waxes that can interfere with analytical results.

Temperature sensitivity represents another critical challenge, as FFA determination accuracy varies significantly with ambient conditions. Without strict temperature control during testing, results may fluctuate by up to 0.5% FFA, potentially leading to erroneous quality classifications and commercial disputes.

Sample handling introduces additional variability, with exposure to air accelerating hydrolysis and increasing FFA content artificially. This necessitates strict protocols for sample storage and preparation that are not consistently implemented across laboratories.

The reporting format for FFA results also lacks uniformity, with some facilities expressing results as percentage oleic acid while others use acid value or alternative fatty acid bases. This inconsistency complicates inter-laboratory comparisons and creates confusion in international trade of rice bran oil.

Automated titrators have emerged as an improvement over manual methods, offering enhanced precision and reduced human error. These systems utilize potentiometric endpoints rather than visual indicators, allowing for more objective determination of the titration endpoint. However, their high cost presents a barrier to adoption for smaller producers and quality control laboratories.

Near-infrared spectroscopy (NIRS) represents a non-destructive alternative gaining traction in the industry. This method correlates spectral data with FFA content through chemometric models, enabling rapid analysis without chemical reagents. Despite these advantages, NIRS requires extensive calibration against reference methods and may struggle with accuracy at very low FFA concentrations typical in refined rice bran oil.

Gas chromatography (GC) offers superior specificity by separating and quantifying individual fatty acids rather than total acidity. This provides valuable compositional information beyond simple FFA percentage but demands sophisticated equipment and technical expertise. The sample preparation for GC analysis is also more complex, involving derivatization steps that extend analysis time.

A significant challenge across all methodologies is the lack of standardization specific to rice bran oil. Most protocols were developed for other vegetable oils and may not account for the unique composition of rice bran oil, particularly its high content of oryzanol and waxes that can interfere with analytical results.

Temperature sensitivity represents another critical challenge, as FFA determination accuracy varies significantly with ambient conditions. Without strict temperature control during testing, results may fluctuate by up to 0.5% FFA, potentially leading to erroneous quality classifications and commercial disputes.

Sample handling introduces additional variability, with exposure to air accelerating hydrolysis and increasing FFA content artificially. This necessitates strict protocols for sample storage and preparation that are not consistently implemented across laboratories.

The reporting format for FFA results also lacks uniformity, with some facilities expressing results as percentage oleic acid while others use acid value or alternative fatty acid bases. This inconsistency complicates inter-laboratory comparisons and creates confusion in international trade of rice bran oil.

Standard Operating Procedures for FFA Titration

01 Titration methods for measuring free fatty acid levels in rice bran oil

Titration is a common method for determining free fatty acid (FFA) levels in rice bran oil. This typically involves dissolving the oil sample in a solvent mixture, adding a pH indicator, and titrating with a standardized alkaline solution until a color change indicates the endpoint. The amount of alkaline solution used correlates directly with the FFA content, which can be expressed as acid value or percentage of oleic acid. This method provides accurate quantification of FFA levels, which is crucial for quality assessment of rice bran oil.- Titration methods for free fatty acid determination: Titration is a common method for determining free fatty acid levels in rice bran oil. This typically involves dissolving the oil sample in a solvent mixture, adding a pH indicator, and titrating with a standardized alkaline solution until a color change occurs. The amount of alkaline solution used is proportional to the free fatty acid content, which can be calculated and expressed as a percentage or acid value. This method provides accurate quantification of free fatty acids for quality control purposes.

- Spectroscopic analysis techniques: Spectroscopic methods offer rapid and non-destructive analysis of free fatty acid levels in rice bran oil. These include near-infrared spectroscopy (NIR), Fourier transform infrared spectroscopy (FTIR), and UV-visible spectroscopy. These techniques measure the absorption or emission of electromagnetic radiation by the oil sample, which correlates with free fatty acid content. Spectroscopic methods often require calibration with reference samples analyzed by traditional methods but provide faster results with minimal sample preparation.

- Chromatographic methods for fatty acid analysis: Chromatographic techniques such as gas chromatography (GC) and high-performance liquid chromatography (HPLC) are used for detailed analysis of free fatty acids in rice bran oil. These methods separate individual fatty acids based on their physical and chemical properties, allowing for identification and quantification of specific fatty acid components. Sample preparation typically involves extraction and derivatization steps to make the fatty acids more suitable for chromatographic analysis. These methods provide comprehensive fatty acid profiles beyond just total free fatty acid content.

- Automated and rapid testing equipment: Specialized equipment and devices have been developed for rapid and automated testing of free fatty acid levels in rice bran oil. These include dedicated analyzers that combine sample preparation, reaction, and measurement steps into integrated systems. Some devices use electrochemical sensors or enzymatic reactions to detect free fatty acids. These automated systems are designed for routine quality control in production environments, offering advantages in terms of speed, ease of use, and consistency of results compared to manual methods.

- Novel and improved testing methodologies: Innovative approaches have been developed to improve the accuracy, efficiency, and sustainability of free fatty acid testing in rice bran oil. These include modified extraction procedures, alternative solvents that are more environmentally friendly, and new reagents that provide better selectivity or sensitivity. Some methods combine multiple analytical techniques or incorporate mathematical models to enhance result interpretation. These innovations aim to address limitations of traditional methods while maintaining or improving analytical performance.

02 Chromatographic techniques for FFA analysis in rice bran oil

Chromatographic methods such as gas chromatography (GC) and high-performance liquid chromatography (HPLC) are used for detailed analysis of free fatty acid profiles in rice bran oil. These techniques can separate and quantify individual fatty acids, providing comprehensive information about the oil's composition. Sample preparation typically involves derivatization of fatty acids to increase volatility for GC analysis. These methods offer higher specificity and sensitivity compared to traditional titration methods, allowing for detection of minor fatty acid components and contaminants.Expand Specific Solutions03 Automated and rapid testing equipment for FFA determination

Specialized automated equipment has been developed for rapid and efficient testing of free fatty acid levels in rice bran oil. These systems often incorporate sensors, spectroscopic methods, or electrochemical detection to provide quick results with minimal sample preparation. Some devices feature continuous monitoring capabilities for production environments, while others are designed for batch testing in laboratory settings. These automated systems reduce human error, increase throughput, and provide consistent results compared to manual testing methods.Expand Specific Solutions04 Near-infrared spectroscopy and other spectroscopic methods

Near-infrared (NIR) spectroscopy and other spectroscopic techniques offer non-destructive and rapid methods for measuring free fatty acid content in rice bran oil. These methods analyze the absorption or reflection of specific wavelengths of light by the oil sample, correlating spectral data with FFA content through calibration models. Fourier transform infrared spectroscopy (FTIR) and Raman spectroscopy are also employed for similar purposes. These techniques require minimal sample preparation and can provide results in seconds to minutes, making them suitable for online monitoring in production environments.Expand Specific Solutions05 Sample preparation and extraction methods for FFA analysis

Proper sample preparation is crucial for accurate determination of free fatty acid levels in rice bran oil. Various extraction and preparation techniques have been developed to isolate fatty acids from the oil matrix before analysis. These include solvent extraction methods, solid-phase extraction, and derivatization procedures. The choice of extraction solvent, temperature conditions, and extraction time significantly impact the recovery of fatty acids. Standardized protocols ensure reproducibility and comparability of results across different laboratories and testing facilities.Expand Specific Solutions

Leading Organizations in Oil Quality Testing Standards

The rice bran oil free fatty acid testing market is in a growth phase, driven by increasing demand for quality control in edible oils and expanding applications in food and cosmetic industries. The market size is projected to grow steadily as health-conscious consumers seek higher quality oils. Technologically, titration methods remain the standard approach, though innovation is occurring in automation and precision. Companies like 3M Innovative Properties, Kao Corp., and BASF are leading technological advancements, while specialized players such as Riceland Foods, Tsuno Food Industrial, and ZeaKal focus on rice bran oil applications. Research institutions including Michigan State University, Council of Scientific & Industrial Research, and Oil Crops Research Institute are contributing to method refinement and standardization, indicating a collaborative ecosystem developing around this niche but important quality parameter.

Oil Crops Research Institute

Technical Solution: The Oil Crops Research Institute has developed a standardized titration protocol for FFA determination in rice bran oil that emphasizes research-grade precision while maintaining practical applicability for industrial settings. Their methodology incorporates a modified cold titration technique that minimizes the risk of saponification during analysis, which can artificially lower FFA readings in conventional hot titration methods. The institute's approach includes careful calibration procedures using certified reference materials specifically matched to rice bran oil fatty acid profiles. Their SOP details specific sample preparation steps including centrifugation parameters (3000 rpm for 5 minutes) to remove any suspended solids that might interfere with endpoint detection. The institute has also developed correction factors for various rice varieties and processing conditions, accounting for how different cultivars and extraction methods affect the fatty acid composition. Their reporting format includes uncertainty calculations and traceability documentation that meets ISO 17025 requirements for analytical testing laboratories.

Strengths: Exceptional analytical precision suitable for research applications; well-documented traceability to international standards; adaptable to different rice varieties. Weaknesses: More complex methodology than needed for routine quality control; higher implementation costs due to reference material requirements and specialized training.

Tsuno Food Industrial Co. Ltd.

Technical Solution: Tsuno Food Industrial has pioneered an enhanced titration methodology specifically optimized for rice bran oil FFA analysis that addresses the unique challenges posed by the complex composition of rice bran oil. Their technical approach incorporates a two-phase titration process that first neutralizes stronger acids followed by a more sensitive titration for weaker fatty acids, providing more accurate total FFA measurements. The company utilizes a proprietary solvent mixture that improves the dissolution of all fatty acid components while minimizing interference from pigments and phospholipids common in rice bran oil. Their SOP includes precise guidelines for sample handling that account for the rapid oxidative changes in freshly milled rice bran, including immediate analysis or controlled storage conditions. Tsuno's reporting system incorporates digital data management with automated calculation of acid value and conversion to oleic acid equivalents, with results expressed as both percentage and mg KOH/g values for comprehensive quality assessment.

Strengths: Highly specialized for rice bran oil's unique composition; excellent accuracy even with varying degrees of oil refinement; comprehensive reporting that supports regulatory compliance. Weaknesses: Proprietary solvent systems may be more expensive than standard methods; requires specialized training specific to their methodology.

Technical Analysis of Titration Chemistry for FFA Detection

Determination of the content of free fatty acids in oils or fats and methods thereof.

PatentPendingTH157634A

Innovation

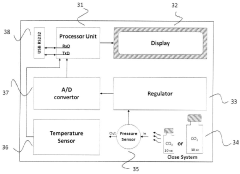

- Using carbonyldiimidazole (CDI) reaction with free fatty acids in oils to generate gas pressure in a closed system, which is then measured to determine free fatty acid content.

- Measurement based on pressure changes in a closed system rather than color changes, making the method applicable to oils of any color, including dark-colored rice bran oil.

- Closed sampling unit design that maintains system integrity during measurement, improving accuracy by preventing external contamination or gas leakage.

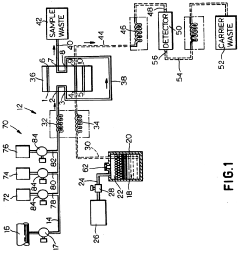

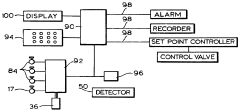

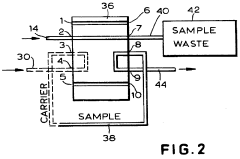

Method and system for determining free fatty acid content

PatentInactiveUS5196169A

Innovation

- A colorimetric system with a flow-through detector, pressurized carrier solution, and automated sample injection valve, which reacts with free fatty acids to produce a measurable color change, allowing for continuous and accurate analysis of free fatty acid content in edible oils, even under wide temperature ranges.

Regulatory Compliance for Edible Oil Quality Standards

Regulatory compliance for edible oil quality standards is a critical framework governing the production, testing, and distribution of rice bran oil globally. The determination of Free Fatty Acid (FFA) levels through titration represents a fundamental quality control measure that manufacturers must adhere to across various jurisdictions.

The Codex Alimentarius Commission, established by FAO and WHO, provides international standards for rice bran oil quality, specifying maximum FFA content typically between 0.3% and 0.5% for refined oils. These standards serve as the foundation for many national regulatory frameworks, though specific requirements may vary by region.

In the United States, the FDA regulates edible oils under 21 CFR Part 101, with specific provisions for labeling and quality standards. While not explicitly regulating FFA levels in rice bran oil, the FDA requires manufacturers to ensure product safety and quality. The American Oil Chemists' Society (AOCS) Official Method Ca 5a-40 is widely recognized for FFA determination in oils and fats.

The European Union enforces stricter regulations through Commission Regulation (EEC) No 2568/91, which outlines specific analytical methods for determining the characteristics of olive oil and olive-residue oil, with principles applicable to rice bran oil quality assessment. The European Committee for Standardization (CEN) has established EN ISO 660 as the standard method for determining acid value and acidity in animal and vegetable fats and oils.

In major rice bran oil producing countries like India, the Food Safety and Standards Authority of India (FSSAI) mandates specific quality parameters, including maximum FFA levels of 0.5% for refined rice bran oil under the Food Safety and Standards (Food Products Standards and Food Additives) Regulations, 2011.

Japan's Ministry of Health, Labour and Welfare enforces the Japanese Agricultural Standard (JAS) for edible vegetable oils, which includes specifications for rice bran oil quality parameters, including FFA content limits.

Compliance documentation requirements typically include detailed records of titration procedures, calibration certificates for equipment, traceability of reagents, staff training records, and comprehensive test reports. These reports must follow standardized formats that include sample identification, test conditions, results expressed as percentage of oleic acid, uncertainty measurements, and references to the specific analytical methods employed.

For international trade, exporters must ensure their testing methodologies align with both domestic regulations and those of destination markets, often requiring certification from accredited laboratories that follow ISO/IEC 17025 standards for testing competence.

The Codex Alimentarius Commission, established by FAO and WHO, provides international standards for rice bran oil quality, specifying maximum FFA content typically between 0.3% and 0.5% for refined oils. These standards serve as the foundation for many national regulatory frameworks, though specific requirements may vary by region.

In the United States, the FDA regulates edible oils under 21 CFR Part 101, with specific provisions for labeling and quality standards. While not explicitly regulating FFA levels in rice bran oil, the FDA requires manufacturers to ensure product safety and quality. The American Oil Chemists' Society (AOCS) Official Method Ca 5a-40 is widely recognized for FFA determination in oils and fats.

The European Union enforces stricter regulations through Commission Regulation (EEC) No 2568/91, which outlines specific analytical methods for determining the characteristics of olive oil and olive-residue oil, with principles applicable to rice bran oil quality assessment. The European Committee for Standardization (CEN) has established EN ISO 660 as the standard method for determining acid value and acidity in animal and vegetable fats and oils.

In major rice bran oil producing countries like India, the Food Safety and Standards Authority of India (FSSAI) mandates specific quality parameters, including maximum FFA levels of 0.5% for refined rice bran oil under the Food Safety and Standards (Food Products Standards and Food Additives) Regulations, 2011.

Japan's Ministry of Health, Labour and Welfare enforces the Japanese Agricultural Standard (JAS) for edible vegetable oils, which includes specifications for rice bran oil quality parameters, including FFA content limits.

Compliance documentation requirements typically include detailed records of titration procedures, calibration certificates for equipment, traceability of reagents, staff training records, and comprehensive test reports. These reports must follow standardized formats that include sample identification, test conditions, results expressed as percentage of oleic acid, uncertainty measurements, and references to the specific analytical methods employed.

For international trade, exporters must ensure their testing methodologies align with both domestic regulations and those of destination markets, often requiring certification from accredited laboratories that follow ISO/IEC 17025 standards for testing competence.

Data Management Systems for Oil Quality Reporting

Effective data management systems are crucial for maintaining quality control in rice bran oil production, particularly for tracking free fatty acid (FFA) levels. Current industry solutions integrate laboratory information management systems (LIMS) with specialized modules for oil quality parameters. These systems typically feature automated data capture from titration equipment, eliminating manual entry errors and ensuring data integrity throughout the testing process.

Cloud-based platforms have emerged as the preferred solution for oil quality reporting, offering real-time access to test results across multiple production facilities. Leading systems such as LabWare LIMS, SAP Quality Management, and specialized solutions like OilQC Pro provide comprehensive data management capabilities specifically designed for edible oil manufacturers. These platforms incorporate statistical process control tools that automatically flag FFA values exceeding predetermined thresholds.

The reporting architecture generally follows a three-tier model: data acquisition from titration equipment, centralized storage with validation protocols, and customizable reporting interfaces. Modern systems implement blockchain technology to create immutable records of quality tests, particularly valuable for regulatory compliance and supply chain transparency in premium rice bran oil production.

Data visualization capabilities have become increasingly sophisticated, with dashboard interfaces displaying FFA trend analysis across production batches. These visual tools enable quality managers to identify patterns that might indicate equipment calibration issues or raw material quality variations. Machine learning algorithms are now being integrated to predict potential quality deviations before they occur, based on historical titration data patterns.

Integration with enterprise resource planning (ERP) systems represents another significant advancement, allowing FFA test results to directly influence inventory management decisions. This integration creates a closed-loop system where oils exceeding acceptable FFA levels can be automatically flagged for reprocessing or alternative use channels.

Security protocols in these systems have evolved to meet industry-specific requirements, with role-based access controls ensuring that only qualified laboratory personnel can approve final FFA results. Audit trail functionality records all data modifications, supporting both internal quality assurance processes and external regulatory inspections. The most advanced systems now incorporate digital signatures compliant with FDA 21 CFR Part 11 requirements, enabling fully paperless quality documentation workflows.

Cloud-based platforms have emerged as the preferred solution for oil quality reporting, offering real-time access to test results across multiple production facilities. Leading systems such as LabWare LIMS, SAP Quality Management, and specialized solutions like OilQC Pro provide comprehensive data management capabilities specifically designed for edible oil manufacturers. These platforms incorporate statistical process control tools that automatically flag FFA values exceeding predetermined thresholds.

The reporting architecture generally follows a three-tier model: data acquisition from titration equipment, centralized storage with validation protocols, and customizable reporting interfaces. Modern systems implement blockchain technology to create immutable records of quality tests, particularly valuable for regulatory compliance and supply chain transparency in premium rice bran oil production.

Data visualization capabilities have become increasingly sophisticated, with dashboard interfaces displaying FFA trend analysis across production batches. These visual tools enable quality managers to identify patterns that might indicate equipment calibration issues or raw material quality variations. Machine learning algorithms are now being integrated to predict potential quality deviations before they occur, based on historical titration data patterns.

Integration with enterprise resource planning (ERP) systems represents another significant advancement, allowing FFA test results to directly influence inventory management decisions. This integration creates a closed-loop system where oils exceeding acceptable FFA levels can be automatically flagged for reprocessing or alternative use channels.

Security protocols in these systems have evolved to meet industry-specific requirements, with role-based access controls ensuring that only qualified laboratory personnel can approve final FFA results. Audit trail functionality records all data modifications, supporting both internal quality assurance processes and external regulatory inspections. The most advanced systems now incorporate digital signatures compliant with FDA 21 CFR Part 11 requirements, enabling fully paperless quality documentation workflows.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!