Rice Bran Oil Fractionation Techniques for Specialty Applications — Methods and Equipment Guide

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rice Bran Oil Fractionation Background and Objectives

Rice bran oil, a byproduct of rice milling, has emerged as a valuable resource in the food, cosmetic, and pharmaceutical industries due to its unique nutritional and functional properties. The evolution of fractionation techniques for rice bran oil represents a significant technological advancement that has transformed how we utilize this once-undervalued resource. Historically, rice bran was primarily considered an agricultural waste product until research in the mid-20th century revealed its rich oil content and potential applications.

The technological trajectory of rice bran oil fractionation has progressed from basic mechanical extraction methods to sophisticated separation techniques that can isolate specific components with precision. Early extraction relied on solvent-based processes, which have gradually been supplemented or replaced by more environmentally friendly and efficient methods such as supercritical fluid extraction, molecular distillation, and enzymatic processes.

Recent advancements in fractionation technology have been driven by increasing demand for specialty lipids and bioactive compounds found in rice bran oil, including γ-oryzanol, tocotrienols, phytosterols, and specific fatty acid fractions. These components have demonstrated significant potential in nutraceutical applications, cosmetic formulations, and pharmaceutical developments, creating new market opportunities and research directions.

The global emphasis on sustainable production and clean-label products has further accelerated innovation in rice bran oil fractionation. Modern techniques aim to maximize yield while minimizing environmental impact, energy consumption, and chemical usage. This shift reflects broader industry trends toward green chemistry principles and circular economy models in bioprocessing.

The primary objectives of current rice bran oil fractionation research and development include enhancing separation efficiency, improving scalability of processes, reducing production costs, and developing novel applications for isolated fractions. Particular attention is being paid to the development of continuous processing systems that can maintain consistent quality while accommodating industrial-scale production requirements.

Another key goal is the standardization of fractionation protocols to ensure reproducible quality across different production batches and facilities. This standardization is essential for meeting regulatory requirements and consumer expectations, particularly as rice bran oil derivatives increasingly enter regulated markets such as pharmaceuticals and medical foods.

The integration of digital technologies, including process automation, real-time monitoring systems, and machine learning algorithms for process optimization, represents the frontier of rice bran oil fractionation technology. These innovations promise to further refine separation precision while reducing operational variability and resource consumption.

The technological trajectory of rice bran oil fractionation has progressed from basic mechanical extraction methods to sophisticated separation techniques that can isolate specific components with precision. Early extraction relied on solvent-based processes, which have gradually been supplemented or replaced by more environmentally friendly and efficient methods such as supercritical fluid extraction, molecular distillation, and enzymatic processes.

Recent advancements in fractionation technology have been driven by increasing demand for specialty lipids and bioactive compounds found in rice bran oil, including γ-oryzanol, tocotrienols, phytosterols, and specific fatty acid fractions. These components have demonstrated significant potential in nutraceutical applications, cosmetic formulations, and pharmaceutical developments, creating new market opportunities and research directions.

The global emphasis on sustainable production and clean-label products has further accelerated innovation in rice bran oil fractionation. Modern techniques aim to maximize yield while minimizing environmental impact, energy consumption, and chemical usage. This shift reflects broader industry trends toward green chemistry principles and circular economy models in bioprocessing.

The primary objectives of current rice bran oil fractionation research and development include enhancing separation efficiency, improving scalability of processes, reducing production costs, and developing novel applications for isolated fractions. Particular attention is being paid to the development of continuous processing systems that can maintain consistent quality while accommodating industrial-scale production requirements.

Another key goal is the standardization of fractionation protocols to ensure reproducible quality across different production batches and facilities. This standardization is essential for meeting regulatory requirements and consumer expectations, particularly as rice bran oil derivatives increasingly enter regulated markets such as pharmaceuticals and medical foods.

The integration of digital technologies, including process automation, real-time monitoring systems, and machine learning algorithms for process optimization, represents the frontier of rice bran oil fractionation technology. These innovations promise to further refine separation precision while reducing operational variability and resource consumption.

Market Analysis for Specialty Rice Bran Oil Products

The global specialty rice bran oil market has been experiencing significant growth, driven by increasing consumer awareness of its health benefits and unique properties. The market size was valued at approximately $320 million in 2022 and is projected to reach $480 million by 2028, representing a compound annual growth rate (CAGR) of 7.2%. This growth trajectory is particularly pronounced in regions with established rice production infrastructure, including Asia-Pacific, North America, and parts of Europe.

Consumer demand for specialty rice bran oil products is primarily fueled by their nutritional profile, including high levels of antioxidants, vitamin E, gamma-oryzanol, and phytosterols. The cosmetic and personal care segment represents the fastest-growing application area, with a market share increase from 18% to 23% over the past three years. This surge is attributed to rice bran oil's moisturizing properties, anti-aging benefits, and compatibility with sensitive skin formulations.

The food industry remains the largest consumer of specialty rice bran oil products, accounting for approximately 65% of total market volume. Within this sector, premium cooking oils and functional food ingredients are experiencing the strongest demand growth. The pharmaceutical sector, though smaller at 12% market share, shows promising growth potential due to increasing research into rice bran oil's cholesterol-lowering and anti-inflammatory properties.

Regional market analysis reveals that Asia-Pacific dominates with 58% of global consumption, followed by North America (22%) and Europe (15%). However, the most rapid growth is occurring in North American and European markets, where premium and organic variants command price premiums of 30-45% over conventional rice bran oil. This trend reflects broader consumer shifts toward clean-label, sustainably sourced specialty oils.

Market segmentation by fractionation technique shows that supercritical fluid extraction products command the highest price points, followed by winterization and solvent fractionation methods. Products derived from enzymatic modification techniques are gaining market share due to their "natural processing" appeal to health-conscious consumers.

Key market challenges include supply chain volatility, as rice bran oil production is dependent on rice milling operations, and increasing competition from other specialty oils such as avocado and pumpkin seed oils. Additionally, consumer education remains a barrier to wider adoption, as awareness of rice bran oil's benefits outside of traditional markets is still developing.

Future market opportunities lie in the development of highly specialized fractions targeting specific health concerns, such as cardiovascular health, skin care, and anti-inflammatory applications. The organic and non-GMO certified segments are projected to grow at twice the rate of conventional products, indicating strong potential for premium positioning in these categories.

Consumer demand for specialty rice bran oil products is primarily fueled by their nutritional profile, including high levels of antioxidants, vitamin E, gamma-oryzanol, and phytosterols. The cosmetic and personal care segment represents the fastest-growing application area, with a market share increase from 18% to 23% over the past three years. This surge is attributed to rice bran oil's moisturizing properties, anti-aging benefits, and compatibility with sensitive skin formulations.

The food industry remains the largest consumer of specialty rice bran oil products, accounting for approximately 65% of total market volume. Within this sector, premium cooking oils and functional food ingredients are experiencing the strongest demand growth. The pharmaceutical sector, though smaller at 12% market share, shows promising growth potential due to increasing research into rice bran oil's cholesterol-lowering and anti-inflammatory properties.

Regional market analysis reveals that Asia-Pacific dominates with 58% of global consumption, followed by North America (22%) and Europe (15%). However, the most rapid growth is occurring in North American and European markets, where premium and organic variants command price premiums of 30-45% over conventional rice bran oil. This trend reflects broader consumer shifts toward clean-label, sustainably sourced specialty oils.

Market segmentation by fractionation technique shows that supercritical fluid extraction products command the highest price points, followed by winterization and solvent fractionation methods. Products derived from enzymatic modification techniques are gaining market share due to their "natural processing" appeal to health-conscious consumers.

Key market challenges include supply chain volatility, as rice bran oil production is dependent on rice milling operations, and increasing competition from other specialty oils such as avocado and pumpkin seed oils. Additionally, consumer education remains a barrier to wider adoption, as awareness of rice bran oil's benefits outside of traditional markets is still developing.

Future market opportunities lie in the development of highly specialized fractions targeting specific health concerns, such as cardiovascular health, skin care, and anti-inflammatory applications. The organic and non-GMO certified segments are projected to grow at twice the rate of conventional products, indicating strong potential for premium positioning in these categories.

Current Fractionation Technologies and Challenges

Rice bran oil fractionation currently employs several established technologies, each with distinct advantages and limitations. Dry fractionation remains the most widely implemented method due to its cost-effectiveness and environmental friendliness. This process involves controlled cooling of rice bran oil to crystallize higher-melting fractions, followed by filtration to separate the solid stearin from liquid olein. While operationally straightforward, achieving precise crystal formation and consistent separation efficiency presents ongoing challenges, particularly when targeting specialty applications requiring specific fatty acid profiles.

Solvent fractionation offers superior separation efficiency through the use of organic solvents like hexane or acetone. This technique enables more precise isolation of high-value components such as γ-oryzanol and tocotrienols, which are increasingly sought after in nutraceutical applications. However, the technology faces significant regulatory hurdles due to environmental concerns and potential solvent residues in final products, limiting its widespread adoption despite technical advantages.

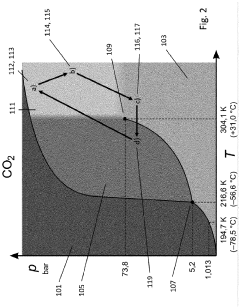

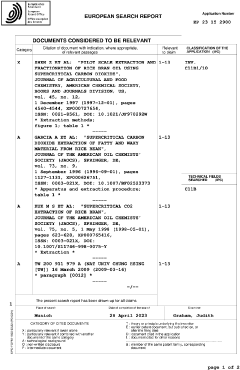

Supercritical fluid extraction (SFE), particularly using CO2, represents an emerging alternative that addresses many environmental concerns. This technology operates at moderate temperatures, preserving heat-sensitive bioactive compounds while achieving excellent fractionation precision. The major impediments to broader implementation include high equipment costs, significant energy requirements, and complex pressure management systems, making it economically viable primarily for high-value specialty products.

Membrane technology has recently gained attention for rice bran oil fractionation, employing ultrafiltration and nanofiltration to separate components based on molecular size. This approach offers energy efficiency advantages and eliminates solvent usage, but faces challenges with membrane fouling and limited throughput capacity when processing viscous rice bran oil.

Enzymatic fractionation represents the cutting edge of selective modification, using lipases to target specific fatty acid positions. While offering unprecedented precision in creating structured lipids with enhanced nutritional profiles, the technology struggles with high enzyme costs, complex reaction control requirements, and scalability limitations.

Equipment challenges persist across all fractionation methods, particularly in designing systems that can handle the unique properties of rice bran oil, including its high wax content and tendency toward oxidation. Manufacturers continue to struggle with developing economical cooling systems for dry fractionation that ensure uniform crystallization while minimizing energy consumption. Similarly, filtration equipment must balance throughput capacity with separation efficiency, especially when processing high-viscosity fractions.

Solvent fractionation offers superior separation efficiency through the use of organic solvents like hexane or acetone. This technique enables more precise isolation of high-value components such as γ-oryzanol and tocotrienols, which are increasingly sought after in nutraceutical applications. However, the technology faces significant regulatory hurdles due to environmental concerns and potential solvent residues in final products, limiting its widespread adoption despite technical advantages.

Supercritical fluid extraction (SFE), particularly using CO2, represents an emerging alternative that addresses many environmental concerns. This technology operates at moderate temperatures, preserving heat-sensitive bioactive compounds while achieving excellent fractionation precision. The major impediments to broader implementation include high equipment costs, significant energy requirements, and complex pressure management systems, making it economically viable primarily for high-value specialty products.

Membrane technology has recently gained attention for rice bran oil fractionation, employing ultrafiltration and nanofiltration to separate components based on molecular size. This approach offers energy efficiency advantages and eliminates solvent usage, but faces challenges with membrane fouling and limited throughput capacity when processing viscous rice bran oil.

Enzymatic fractionation represents the cutting edge of selective modification, using lipases to target specific fatty acid positions. While offering unprecedented precision in creating structured lipids with enhanced nutritional profiles, the technology struggles with high enzyme costs, complex reaction control requirements, and scalability limitations.

Equipment challenges persist across all fractionation methods, particularly in designing systems that can handle the unique properties of rice bran oil, including its high wax content and tendency toward oxidation. Manufacturers continue to struggle with developing economical cooling systems for dry fractionation that ensure uniform crystallization while minimizing energy consumption. Similarly, filtration equipment must balance throughput capacity with separation efficiency, especially when processing high-viscosity fractions.

Established Fractionation Methods and Equipment

01 Solvent-based fractionation techniques

Solvent-based methods are widely used for rice bran oil fractionation, employing various solvents to separate different components based on their solubility. These techniques typically involve extraction with organic solvents like hexane, followed by winterization or crystallization processes to separate fractions with different melting points. This approach allows for efficient separation of high-value components such as oryzanol, tocopherols, and specific fatty acid fractions from rice bran oil.- Solvent-based fractionation techniques: Solvent-based methods are widely used for rice bran oil fractionation, involving the use of organic solvents like hexane, ethanol, or acetone to separate different components based on their solubility. These techniques allow for selective extraction of valuable compounds such as oryzanol, tocopherols, and phytosterols from rice bran oil. The process typically involves mixing the oil with the solvent, followed by separation and recovery of the fractions through evaporation or distillation steps.

- Crystallization and winterization processes: Crystallization-based fractionation involves cooling rice bran oil under controlled conditions to separate components based on their melting points. Winterization is a specific type of crystallization process where the oil is cooled to low temperatures to precipitate high-melting point compounds like waxes and saturated triglycerides. These techniques are particularly useful for improving the cold stability and clarity of rice bran oil while concentrating valuable bioactive compounds in specific fractions.

- Supercritical fluid extraction and fractionation: Supercritical fluid extraction, particularly using carbon dioxide (CO2), offers an environmentally friendly approach to rice bran oil fractionation. This technique utilizes the unique properties of supercritical fluids to selectively extract and separate components based on their molecular weight and polarity. By adjusting parameters such as pressure, temperature, and co-solvents, different fractions with specific functional properties can be obtained. This method is particularly valuable for producing high-purity fractions without solvent residues.

- Membrane-based separation technologies: Membrane filtration technologies, including ultrafiltration, nanofiltration, and reverse osmosis, are emerging techniques for rice bran oil fractionation. These methods separate components based on molecular size and charge using semi-permeable membranes. The process operates at lower temperatures than conventional methods, helping preserve heat-sensitive bioactive compounds. Membrane technologies can be used to concentrate specific components like phospholipids, proteins, and antioxidants from rice bran oil.

- Enzymatic and biotechnological fractionation methods: Enzymatic fractionation utilizes specific enzymes to selectively modify or separate components in rice bran oil. These biological catalysts can hydrolyze, esterify, or transesterify lipid components under mild conditions, allowing for precise control over the fractionation process. Biotechnological approaches may also involve microbial fermentation to transform rice bran oil components. These methods are particularly valuable for producing structured lipids, concentrating bioactive compounds, and improving the nutritional profile of rice bran oil fractions.

02 Temperature-controlled fractionation methods

Temperature-controlled fractionation involves manipulating crystallization conditions to separate rice bran oil components based on their melting points. This includes winterization processes where the oil is cooled under controlled conditions to crystallize higher-melting fractions, followed by filtration to separate solid and liquid fractions. These methods can be optimized to produce specialty fractions with specific functional properties for food, cosmetic, or pharmaceutical applications.Expand Specific Solutions03 Supercritical fluid extraction and fractionation

Supercritical fluid extraction, particularly using carbon dioxide, offers an environmentally friendly approach to rice bran oil fractionation. This technique utilizes the unique properties of supercritical fluids to selectively extract and separate components based on their molecular weight and polarity. By adjusting pressure and temperature parameters, different fractions with specific bioactive compounds can be isolated without using organic solvents, resulting in high-purity fractions with preserved bioactivity.Expand Specific Solutions04 Membrane and chromatographic separation techniques

Advanced separation technologies including membrane filtration and various chromatographic methods are employed for high-precision fractionation of rice bran oil. These techniques separate components based on molecular size, charge, or affinity. Ultrafiltration, nanofiltration, and specialized chromatography columns allow for the isolation of specific high-value components like oryzanol, phytosterols, and specialized lipid fractions with minimal thermal degradation, preserving their functional properties.Expand Specific Solutions05 Enzymatic and biotechnological fractionation approaches

Enzymatic methods utilize specific lipases and other enzymes to selectively modify and fractionate rice bran oil components. These biotechnological approaches allow for targeted hydrolysis, esterification, or transesterification reactions that can alter the composition and properties of the oil. The enzymatic processes operate under mild conditions, preserving heat-sensitive components while enabling the production of structured lipids and other specialized fractions with enhanced nutritional or functional properties.Expand Specific Solutions

Leading Companies in Rice Bran Oil Fractionation

Rice bran oil fractionation technology is currently in a growth phase, with the global specialty oils market expanding at approximately 6-8% annually. The competitive landscape is characterized by a mix of established petrochemical giants like China Petroleum & Chemical Corp. and PetroChina, alongside specialized food oil companies such as J-Oil Mills, Oryza Oil & Fat Chemical, and Fuji Oil. Technical maturity varies significantly, with companies like Unilever and Kaneka Corp. demonstrating advanced fractionation capabilities through patented processes, while emerging players like Heliae Development are introducing innovative biotechnology approaches. Regional specialization is evident, with Asian companies (particularly Japanese firms) leading in rice bran oil processing technology, reflecting the geographic concentration of rice production and traditional expertise in this field.

China Petroleum & Chemical Corp.

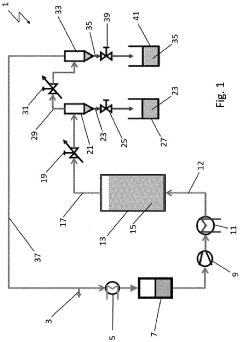

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an industrial-scale rice bran oil fractionation technology that leverages their expertise in petroleum fractionation. Their approach utilizes a modified molecular distillation system operating under high vacuum conditions (0.001-0.01 mbar) combined with short-path distillation to minimize thermal degradation of sensitive compounds. The process employs a series of fractionation columns with precisely controlled temperature gradients (ranging from 180-250°C) to separate components based on boiling point differences. For specialty applications, Sinopec has integrated supercritical fluid extraction technology using CO2 as a solvent at pressures of 200-350 bar and temperatures of 40-60°C. This allows for selective extraction of high-value components like γ-oryzanol, tocotrienols, and specific fatty acid fractions without thermal degradation. Their equipment includes custom-designed wiped-film evaporators with surface areas exceeding 20m² and residence times of less than 30 seconds to minimize heat exposure while maximizing separation efficiency. The system incorporates automated process control with real-time monitoring of critical parameters to ensure consistent quality of specialty fractions.

Strengths: Large-scale production capacity suitable for industrial applications; high efficiency separation with minimal thermal degradation; integrated process control systems ensuring consistent quality. Weaknesses: High energy consumption; substantial capital investment required; complex operation requiring specialized technical expertise; primarily focused on industrial-scale rather than small-batch specialty production.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed a comprehensive rice bran oil fractionation technology platform that combines multiple approaches for specialty applications. Their system integrates solvent fractionation using food-grade solvents (acetone, hexane) at varying ratios and temperatures (-10°C to 25°C) to selectively separate lipid fractions based on solubility differences. For high-purity specialty ingredients, CSIR employs a counter-current chromatographic technique with specially designed stationary phases that can separate compounds based on subtle structural differences. Their equipment includes pilot-scale supercritical fluid fractionation units operating at pressures of 100-400 bar and temperatures of 35-60°C, with the capability to use CO2 modified with ethanol (5-15%) to adjust selectivity for specific bioactive compounds. CSIR has also developed a proprietary enzymatic fractionation process using region-specific lipases that can modify the position of fatty acids on the glycerol backbone, creating structured lipids with enhanced functional properties. This integrated approach allows for the production of highly specialized fractions with concentrations of γ-oryzanol exceeding 15%, phytosterols at 8-10%, and custom fatty acid profiles tailored for pharmaceutical, cosmetic, and functional food applications.

Strengths: Highly versatile fractionation platform capable of producing numerous specialty fractions; research-driven approach with continuous technology improvements; ability to create highly purified bioactive compounds. Weaknesses: Some techniques remain at pilot scale rather than full commercial implementation; complex multi-step processes may have higher production costs; requires sophisticated analytical capabilities to monitor product quality.

Key Patents and Innovations in Fractionation Technology

Method for the separate extraction of rice bran oil an rice bran waxes

PatentPendingEP4209570A1

Innovation

- A method using supercritical CO2 to selectively separate rice bran oil and wax by adjusting pressure and temperature ranges, allowing for the precipitation of oil and wax as distinct products without toxic residues, utilizing a multi-step process involving extraction, separation, and recovery of CO2.

System and method for rice bran oil refinement

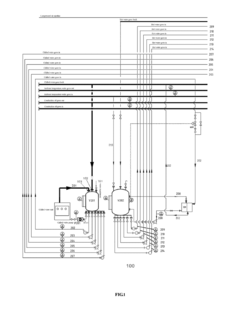

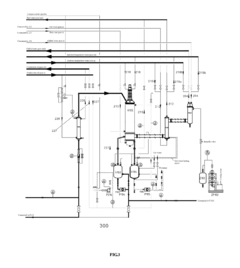

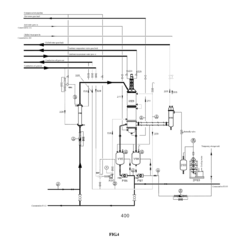

PatentActiveUS10233405B2

Innovation

- An oil refining system incorporating a water circulation system with chilled and hot water units, a deacidification and deodorization system with preheating, evaporation, and condensing units, and a decoloration system with reheating and distillation units, utilizing a fully automated process to separate oil components by adjusting pressure and temperature, eliminating the need for additives and minimizing human intervention.

Sustainability Aspects of Rice Bran Oil Production

The sustainability of rice bran oil production represents a critical dimension in the evaluation of fractionation techniques for specialty applications. Rice bran oil extraction and processing traditionally involve significant resource consumption, including energy, water, and chemical solvents, which can lead to substantial environmental impacts if not managed properly.

Energy efficiency in rice bran oil fractionation has seen remarkable improvements in recent years. Modern fractionation equipment incorporates heat recovery systems, reducing overall energy consumption by up to 30% compared to conventional methods. Supercritical fluid extraction using CO2, while initially more energy-intensive, offers long-term sustainability benefits through solvent elimination and reduced waste generation.

Water usage remains a significant concern in rice bran oil processing. Traditional wet extraction methods can consume 4-6 liters of water per kilogram of oil produced. Advanced dry fractionation techniques have emerged as environmentally preferable alternatives, reducing water consumption by approximately 70% while maintaining comparable oil quality and yield characteristics.

Chemical solvent reduction represents another key sustainability advancement. Hexane, traditionally used in extraction processes, poses environmental and health risks. Enzyme-assisted extraction methods have demonstrated potential to reduce or eliminate solvent requirements while enhancing the recovery of bioactive compounds. These enzymatic approaches typically operate at lower temperatures, further reducing energy demands.

Waste valorization has transformed the sustainability profile of rice bran oil production. The defatted rice bran remaining after oil extraction contains valuable proteins, antioxidants, and dietary fiber that can be repurposed for human consumption or animal feed. Some processors have implemented closed-loop systems where extraction byproducts generate biogas, providing up to 40% of the facility's energy requirements.

Carbon footprint assessments of modern rice bran oil fractionation facilities indicate that implementing best practices in sustainability can reduce greenhouse gas emissions by 25-35% compared to conventional operations. Life cycle analyses further demonstrate that rice bran oil, particularly when produced using sustainable fractionation techniques, offers environmental advantages over many competing vegetable oils.

Regulatory frameworks increasingly incentivize sustainable production methods through certification programs and environmental standards. Companies adopting advanced fractionation technologies with enhanced sustainability profiles often gain competitive advantages in premium markets where environmental considerations influence purchasing decisions.

Energy efficiency in rice bran oil fractionation has seen remarkable improvements in recent years. Modern fractionation equipment incorporates heat recovery systems, reducing overall energy consumption by up to 30% compared to conventional methods. Supercritical fluid extraction using CO2, while initially more energy-intensive, offers long-term sustainability benefits through solvent elimination and reduced waste generation.

Water usage remains a significant concern in rice bran oil processing. Traditional wet extraction methods can consume 4-6 liters of water per kilogram of oil produced. Advanced dry fractionation techniques have emerged as environmentally preferable alternatives, reducing water consumption by approximately 70% while maintaining comparable oil quality and yield characteristics.

Chemical solvent reduction represents another key sustainability advancement. Hexane, traditionally used in extraction processes, poses environmental and health risks. Enzyme-assisted extraction methods have demonstrated potential to reduce or eliminate solvent requirements while enhancing the recovery of bioactive compounds. These enzymatic approaches typically operate at lower temperatures, further reducing energy demands.

Waste valorization has transformed the sustainability profile of rice bran oil production. The defatted rice bran remaining after oil extraction contains valuable proteins, antioxidants, and dietary fiber that can be repurposed for human consumption or animal feed. Some processors have implemented closed-loop systems where extraction byproducts generate biogas, providing up to 40% of the facility's energy requirements.

Carbon footprint assessments of modern rice bran oil fractionation facilities indicate that implementing best practices in sustainability can reduce greenhouse gas emissions by 25-35% compared to conventional operations. Life cycle analyses further demonstrate that rice bran oil, particularly when produced using sustainable fractionation techniques, offers environmental advantages over many competing vegetable oils.

Regulatory frameworks increasingly incentivize sustainable production methods through certification programs and environmental standards. Companies adopting advanced fractionation technologies with enhanced sustainability profiles often gain competitive advantages in premium markets where environmental considerations influence purchasing decisions.

Quality Standards and Regulatory Compliance

Rice bran oil fractionation for specialty applications must adhere to stringent quality standards and regulatory frameworks that vary across global markets. The Codex Alimentarius Commission has established international standards for rice bran oil, specifying acceptable levels of free fatty acids, moisture content, insoluble impurities, and other quality parameters. These standards serve as benchmarks for producers seeking to develop specialized fractions for high-value applications.

In the United States, the FDA regulates rice bran oil under its edible oil regulations, with specific attention to labeling requirements when marketing fractionated products with enhanced functional properties. The European Food Safety Authority (EFSA) has implemented more stringent requirements, particularly regarding contaminant levels and traceability throughout the fractionation process. Japan's regulatory framework places emphasis on the purity of specialty fractions, especially those marketed for cosmetic or pharmaceutical applications.

Quality control during fractionation processes requires systematic monitoring of critical parameters. Acid value, peroxide value, iodine value, and saponification value serve as primary indicators of oil quality and stability. For specialty applications, additional parameters such as oryzanol content, tocopherol profiles, and fatty acid composition must be regularly assessed using chromatographic techniques. AOCS (American Oil Chemists' Society) methods are widely recognized as industry standards for these analyses.

Certification systems play a crucial role in market access for specialty rice bran oil fractions. GRAS (Generally Recognized As Safe) status in the US market, Novel Food approval in the EU, and FOSHU (Foods for Specified Health Uses) certification in Japan represent significant regulatory hurdles that manufacturers must navigate. These certifications often require extensive documentation of fractionation processes, quality control protocols, and safety assessments.

Environmental compliance has become increasingly important in fractionation operations. Regulations governing solvent usage, waste disposal, and emissions must be carefully considered when designing fractionation facilities. The shift toward greener fractionation technologies is partly driven by stricter environmental regulations in major markets, particularly regarding hexane usage limitations and wastewater management requirements.

Traceability systems have evolved from optional best practices to regulatory requirements in many jurisdictions. Documentation must track rice bran sourcing, processing conditions, fractionation parameters, and post-processing handling. This comprehensive approach ensures that quality issues can be rapidly identified and addressed, while also supporting claims regarding the specialized properties of fractionated products.

In the United States, the FDA regulates rice bran oil under its edible oil regulations, with specific attention to labeling requirements when marketing fractionated products with enhanced functional properties. The European Food Safety Authority (EFSA) has implemented more stringent requirements, particularly regarding contaminant levels and traceability throughout the fractionation process. Japan's regulatory framework places emphasis on the purity of specialty fractions, especially those marketed for cosmetic or pharmaceutical applications.

Quality control during fractionation processes requires systematic monitoring of critical parameters. Acid value, peroxide value, iodine value, and saponification value serve as primary indicators of oil quality and stability. For specialty applications, additional parameters such as oryzanol content, tocopherol profiles, and fatty acid composition must be regularly assessed using chromatographic techniques. AOCS (American Oil Chemists' Society) methods are widely recognized as industry standards for these analyses.

Certification systems play a crucial role in market access for specialty rice bran oil fractions. GRAS (Generally Recognized As Safe) status in the US market, Novel Food approval in the EU, and FOSHU (Foods for Specified Health Uses) certification in Japan represent significant regulatory hurdles that manufacturers must navigate. These certifications often require extensive documentation of fractionation processes, quality control protocols, and safety assessments.

Environmental compliance has become increasingly important in fractionation operations. Regulations governing solvent usage, waste disposal, and emissions must be carefully considered when designing fractionation facilities. The shift toward greener fractionation technologies is partly driven by stricter environmental regulations in major markets, particularly regarding hexane usage limitations and wastewater management requirements.

Traceability systems have evolved from optional best practices to regulatory requirements in many jurisdictions. Documentation must track rice bran sourcing, processing conditions, fractionation parameters, and post-processing handling. This comprehensive approach ensures that quality issues can be rapidly identified and addressed, while also supporting claims regarding the specialized properties of fractionated products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!