HPLC-MS Column Choices: Particle Size, Pore Volume And Backpressure

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HPLC-MS Column Technology Evolution and Objectives

High-performance liquid chromatography coupled with mass spectrometry (HPLC-MS) has evolved significantly since its inception in the 1970s. The technology has transformed from simple analytical separations to sophisticated high-resolution systems capable of detecting compounds at picogram levels. Column technology, as the heart of HPLC systems, has undergone remarkable advancements, particularly in three critical parameters: particle size, pore volume, and the resulting backpressure dynamics.

The evolution of particle size represents one of the most significant technological progressions in HPLC column development. Early columns utilized particles of 10μm diameter, which gradually decreased to 5μm in the 1980s, 3μm in the 1990s, and sub-2μm particles in the 2000s. This reduction in particle size has dramatically improved separation efficiency and resolution, following the van Deemter equation which demonstrates that smaller particles provide better chromatographic performance.

Concurrently, pore volume technology has evolved to address the growing demands of biomolecule analysis. Initial columns featured limited pore volumes unsuitable for large molecule separation. Modern columns now offer precisely engineered pore structures ranging from small pores (80-120Å) for small molecules to wide-pore materials (300-1000Å) designed specifically for proteins, peptides, and other macromolecules.

The relationship between these parameters and system backpressure represents a fundamental challenge in HPLC-MS development. As particle size decreases, backpressure increases according to Darcy's Law, necessitating the development of Ultra-High Performance Liquid Chromatography (UHPLC) systems capable of operating at pressures exceeding 15,000 psi, compared to traditional HPLC systems limited to approximately 6,000 psi.

The primary objective in this technological domain is achieving optimal balance between separation efficiency, analysis speed, and system durability. Current research focuses on developing columns that maximize performance while minimizing the operational constraints imposed by extreme backpressure. This includes exploration of core-shell particles, monolithic columns, and novel stationary phase chemistries.

Future technological goals include the development of columns capable of maintaining high efficiency at lower backpressures, materials with enhanced thermal and pH stability, and specialized columns for emerging applications such as multi-dimensional chromatography and high-throughput screening. Additionally, there is significant interest in "green chromatography" approaches that reduce solvent consumption and environmental impact while maintaining analytical performance.

The convergence of these technological advancements aims to address the growing demands for faster analysis, higher sensitivity, improved reproducibility, and expanded application range in fields spanning from pharmaceutical development to environmental monitoring, clinical diagnostics, and emerging "-omics" sciences.

The evolution of particle size represents one of the most significant technological progressions in HPLC column development. Early columns utilized particles of 10μm diameter, which gradually decreased to 5μm in the 1980s, 3μm in the 1990s, and sub-2μm particles in the 2000s. This reduction in particle size has dramatically improved separation efficiency and resolution, following the van Deemter equation which demonstrates that smaller particles provide better chromatographic performance.

Concurrently, pore volume technology has evolved to address the growing demands of biomolecule analysis. Initial columns featured limited pore volumes unsuitable for large molecule separation. Modern columns now offer precisely engineered pore structures ranging from small pores (80-120Å) for small molecules to wide-pore materials (300-1000Å) designed specifically for proteins, peptides, and other macromolecules.

The relationship between these parameters and system backpressure represents a fundamental challenge in HPLC-MS development. As particle size decreases, backpressure increases according to Darcy's Law, necessitating the development of Ultra-High Performance Liquid Chromatography (UHPLC) systems capable of operating at pressures exceeding 15,000 psi, compared to traditional HPLC systems limited to approximately 6,000 psi.

The primary objective in this technological domain is achieving optimal balance between separation efficiency, analysis speed, and system durability. Current research focuses on developing columns that maximize performance while minimizing the operational constraints imposed by extreme backpressure. This includes exploration of core-shell particles, monolithic columns, and novel stationary phase chemistries.

Future technological goals include the development of columns capable of maintaining high efficiency at lower backpressures, materials with enhanced thermal and pH stability, and specialized columns for emerging applications such as multi-dimensional chromatography and high-throughput screening. Additionally, there is significant interest in "green chromatography" approaches that reduce solvent consumption and environmental impact while maintaining analytical performance.

The convergence of these technological advancements aims to address the growing demands for faster analysis, higher sensitivity, improved reproducibility, and expanded application range in fields spanning from pharmaceutical development to environmental monitoring, clinical diagnostics, and emerging "-omics" sciences.

Market Demand Analysis for Advanced Chromatography Columns

The global market for advanced chromatography columns has experienced significant growth in recent years, driven by increasing applications in pharmaceutical research, clinical diagnostics, and environmental testing. The HPLC-MS column market specifically is projected to reach $1.5 billion by 2026, with a compound annual growth rate of 5.7% from 2021 to 2026, according to recent industry reports.

Pharmaceutical and biotechnology sectors represent the largest market segment, accounting for approximately 60% of the total demand. This dominance stems from stringent regulatory requirements for drug development and quality control processes, where high-resolution separation techniques are essential. The growing pipeline of biopharmaceuticals and increasing R&D investments further amplify this demand.

Academic and research institutions constitute the second-largest market segment, driven by fundamental research in proteomics, metabolomics, and other life science disciplines. These institutions often seek columns with superior resolution capabilities and specialized selectivity profiles, particularly for complex biological sample analysis.

Regional analysis reveals North America as the leading market for advanced chromatography columns, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is witnessing the fastest growth rate due to expanding pharmaceutical manufacturing capabilities, increasing research activities, and rising healthcare expenditures in countries like China and India.

A notable market trend is the growing demand for sub-2μm particle size columns that enable ultra-high-performance liquid chromatography (UHPLC). These columns offer superior resolution, faster analysis times, and improved sensitivity, albeit with higher backpressure requirements. Market data indicates that UHPLC columns now represent over 35% of new column purchases in pharmaceutical laboratories.

Columns with optimized pore volume characteristics are gaining traction, particularly for the analysis of large biomolecules such as proteins and antibodies. Wide-pore columns (300-400Å) have seen a 25% increase in demand over the past three years, reflecting the pharmaceutical industry's shift toward biotherapeutics development.

Customer surveys indicate that laboratories are increasingly willing to invest in advanced column technologies that offer improved efficiency and resolution, even at premium prices. This trend is particularly evident in regulated industries where analytical precision directly impacts product quality and regulatory compliance.

The market is also witnessing growing demand for application-specific columns designed for particular compound classes or analytical challenges, moving away from general-purpose columns toward more specialized separation solutions that optimize the balance between particle size, pore volume, and operating pressure for specific analytical needs.

Pharmaceutical and biotechnology sectors represent the largest market segment, accounting for approximately 60% of the total demand. This dominance stems from stringent regulatory requirements for drug development and quality control processes, where high-resolution separation techniques are essential. The growing pipeline of biopharmaceuticals and increasing R&D investments further amplify this demand.

Academic and research institutions constitute the second-largest market segment, driven by fundamental research in proteomics, metabolomics, and other life science disciplines. These institutions often seek columns with superior resolution capabilities and specialized selectivity profiles, particularly for complex biological sample analysis.

Regional analysis reveals North America as the leading market for advanced chromatography columns, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is witnessing the fastest growth rate due to expanding pharmaceutical manufacturing capabilities, increasing research activities, and rising healthcare expenditures in countries like China and India.

A notable market trend is the growing demand for sub-2μm particle size columns that enable ultra-high-performance liquid chromatography (UHPLC). These columns offer superior resolution, faster analysis times, and improved sensitivity, albeit with higher backpressure requirements. Market data indicates that UHPLC columns now represent over 35% of new column purchases in pharmaceutical laboratories.

Columns with optimized pore volume characteristics are gaining traction, particularly for the analysis of large biomolecules such as proteins and antibodies. Wide-pore columns (300-400Å) have seen a 25% increase in demand over the past three years, reflecting the pharmaceutical industry's shift toward biotherapeutics development.

Customer surveys indicate that laboratories are increasingly willing to invest in advanced column technologies that offer improved efficiency and resolution, even at premium prices. This trend is particularly evident in regulated industries where analytical precision directly impacts product quality and regulatory compliance.

The market is also witnessing growing demand for application-specific columns designed for particular compound classes or analytical challenges, moving away from general-purpose columns toward more specialized separation solutions that optimize the balance between particle size, pore volume, and operating pressure for specific analytical needs.

Current Challenges in Column Particle Size and Backpressure

The HPLC-MS column technology faces significant challenges related to particle size and backpressure management. As column particle sizes have decreased from traditional 5μm to sub-2μm particles in modern UHPLC systems, backpressure has emerged as a critical limiting factor. These ultra-small particles generate exponentially higher backpressure according to the Kozeny-Carman equation, where pressure is inversely proportional to the square of particle diameter. This relationship creates a fundamental trade-off between chromatographic efficiency and operational constraints.

Current UHPLC systems typically operate at pressure limits of 15,000-22,000 psi (1,000-1,500 bar), which restricts the practical lower limit of particle size. While sub-1μm particles would theoretically offer superior separation efficiency, the resulting backpressure exceeds the mechanical tolerances of most commercial systems. This limitation has driven manufacturers to explore alternative particle morphologies rather than continuing to reduce particle size.

Column heating presents another challenge, as elevated temperatures reduce mobile phase viscosity and thus backpressure, but simultaneously accelerate column degradation and may cause thermal instability of analytes. The practical upper temperature limit for most applications remains around 80°C, beyond which stationary phase bleed becomes problematic for MS detection.

Pore volume optimization creates additional complexity, as smaller particles require carefully engineered pore structures to maintain adequate surface area for analyte interaction. The industry trend toward core-shell (superficially porous) particles represents an attempt to address backpressure limitations while maintaining separation efficiency, but these particles introduce manufacturing challenges related to consistent shell thickness and uniform pore distribution.

For MS coupling specifically, the backpressure challenge extends to the interface between HPLC and mass spectrometer. High backpressure systems require specialized interface designs to prevent pressure-induced peak broadening during the transition from high-pressure liquid chromatography to the vacuum environment of the mass analyzer.

Column longevity under high-pressure conditions remains problematic, with mechanical stress causing faster deterioration of sub-2μm packed columns. This accelerated degradation increases operational costs and introduces reproducibility challenges in long-term studies. Additionally, frit clogging occurs more frequently with smaller particles, as the necessarily smaller frit pore sizes are more susceptible to blockage by sample particulates.

The balance between throughput, resolution, and system durability continues to drive research into novel particle technologies and column designs. Current development efforts focus on monolithic columns, pillar array columns, and hybrid particle morphologies that might overcome the fundamental limitations imposed by the particle size-backpressure relationship.

Current UHPLC systems typically operate at pressure limits of 15,000-22,000 psi (1,000-1,500 bar), which restricts the practical lower limit of particle size. While sub-1μm particles would theoretically offer superior separation efficiency, the resulting backpressure exceeds the mechanical tolerances of most commercial systems. This limitation has driven manufacturers to explore alternative particle morphologies rather than continuing to reduce particle size.

Column heating presents another challenge, as elevated temperatures reduce mobile phase viscosity and thus backpressure, but simultaneously accelerate column degradation and may cause thermal instability of analytes. The practical upper temperature limit for most applications remains around 80°C, beyond which stationary phase bleed becomes problematic for MS detection.

Pore volume optimization creates additional complexity, as smaller particles require carefully engineered pore structures to maintain adequate surface area for analyte interaction. The industry trend toward core-shell (superficially porous) particles represents an attempt to address backpressure limitations while maintaining separation efficiency, but these particles introduce manufacturing challenges related to consistent shell thickness and uniform pore distribution.

For MS coupling specifically, the backpressure challenge extends to the interface between HPLC and mass spectrometer. High backpressure systems require specialized interface designs to prevent pressure-induced peak broadening during the transition from high-pressure liquid chromatography to the vacuum environment of the mass analyzer.

Column longevity under high-pressure conditions remains problematic, with mechanical stress causing faster deterioration of sub-2μm packed columns. This accelerated degradation increases operational costs and introduces reproducibility challenges in long-term studies. Additionally, frit clogging occurs more frequently with smaller particles, as the necessarily smaller frit pore sizes are more susceptible to blockage by sample particulates.

The balance between throughput, resolution, and system durability continues to drive research into novel particle technologies and column designs. Current development efforts focus on monolithic columns, pillar array columns, and hybrid particle morphologies that might overcome the fundamental limitations imposed by the particle size-backpressure relationship.

Comparative Analysis of Current Column Technologies

01 Particle size optimization for HPLC-MS columns

The particle size of HPLC-MS columns significantly impacts separation efficiency and backpressure. Smaller particles (sub-2μm) provide higher resolution and efficiency but generate higher backpressure, requiring specialized equipment. Medium-sized particles (2-3μm) offer a balance between performance and pressure requirements. Larger particles (5μm and above) generate lower backpressure but with reduced separation efficiency. Optimizing particle size selection is crucial for achieving desired chromatographic performance while managing system pressure constraints.- Particle size optimization for HPLC-MS columns: The particle size of HPLC-MS columns significantly impacts separation efficiency and backpressure. Smaller particle sizes (sub-2μm) provide higher resolution and efficiency but generate higher backpressure, requiring specialized equipment. Medium-sized particles (2-3μm) offer a balance between performance and pressure requirements. Larger particles (5-10μm) generate lower backpressure but with reduced separation efficiency. Optimizing particle size selection is crucial for achieving desired chromatographic performance while managing system pressure constraints.

- Pore volume and surface area effects on column performance: Pore volume and surface area characteristics of HPLC-MS column materials directly influence analyte retention, selectivity, and loading capacity. Materials with larger pore volumes allow better access to internal surface area for larger molecules, improving separation of biomolecules and polymers. Controlled pore architecture enhances mass transfer kinetics and reduces band broadening. The relationship between pore volume, surface area, and particle morphology must be optimized for specific analytical applications to achieve desired chromatographic performance.

- Backpressure management techniques in HPLC-MS systems: Managing backpressure is critical in HPLC-MS systems to ensure instrument longevity and reliable performance. Techniques include using monolithic columns with enhanced permeability, core-shell particles that generate lower backpressure than fully porous particles of equivalent size, and column temperature control to reduce mobile phase viscosity. System modifications such as optimized flow path designs, reduced connection tubing lengths, and gradient optimization help minimize pressure while maintaining separation efficiency. Advanced pressure-tolerant column hardware enables operation at higher pressures without compromising performance.

- Novel column materials and manufacturing processes: Innovative column materials and manufacturing processes have been developed to enhance HPLC-MS performance. These include hybrid organic-inorganic particles with improved mechanical stability, functionalized silica materials with specialized selectivity, and polymer-based stationary phases resistant to extreme pH conditions. Advanced manufacturing techniques produce particles with more uniform size distribution and controlled porosity, resulting in improved column-to-column reproducibility. These materials enable specialized applications such as chiral separations, hydrophilic interaction chromatography, and high-temperature liquid chromatography.

- Column geometry and dimension optimization: Column geometry and dimensions significantly impact HPLC-MS separation performance and system backpressure. Shorter columns reduce analysis time and backpressure but may compromise resolution. Narrower internal diameters enhance sensitivity for mass spectrometry detection while requiring lower flow rates. Column aspect ratio (length-to-diameter) optimization balances efficiency against pressure constraints. Specialized geometries such as tapered columns and multi-dimensional column arrangements provide enhanced separation power for complex samples while managing system pressure limitations.

02 Pore volume characteristics and their impact on separation

Pore volume in HPLC-MS columns affects analyte retention, selectivity, and loading capacity. Columns with larger pore volumes provide better access for larger molecules and improved mass transfer kinetics. The relationship between pore volume, surface area, and retention factor is critical for method development. Optimized pore structures enable better separation of complex mixtures while maintaining column efficiency. Different pore architectures can be tailored for specific analytical applications, with mesoporous materials offering advantages for biomolecule analysis.Expand Specific Solutions03 Backpressure management techniques in HPLC-MS systems

Managing backpressure is essential for HPLC-MS system performance and longevity. Techniques include using monolithic columns with enhanced permeability, core-shell particles that reduce diffusion paths while maintaining lower pressure, and temperature control to decrease mobile phase viscosity. Column dimensions can be optimized by reducing length or increasing diameter to lower pressure while maintaining separation quality. Advanced pump technologies and gradient profiles help manage pressure fluctuations during analysis, ensuring consistent chromatographic performance.Expand Specific Solutions04 Novel column materials and manufacturing processes

Innovative materials and manufacturing processes are advancing HPLC-MS column technology. Hybrid organic-inorganic materials combine the mechanical strength of silica with the chemical stability of polymers. Surface modification techniques create specialized stationary phases with enhanced selectivity and reduced secondary interactions. Advanced bonding chemistries improve column lifetime and reproducibility. Manufacturing innovations include improved particle synthesis methods that yield more uniform particles with controlled porosity and surface characteristics, resulting in columns with superior performance and consistency.Expand Specific Solutions05 Column performance optimization for specific applications

Optimizing HPLC-MS columns for specific applications involves tailoring particle size, pore volume, and surface chemistry. For small molecule analysis, columns with smaller particles and moderate pore volumes provide excellent efficiency. Biomolecule separations benefit from larger pore volumes that accommodate macromolecules. High-throughput screening applications utilize shorter columns with optimized flow characteristics. Environmental and food safety analyses require columns with enhanced chemical stability and selectivity. Method development strategies include systematic evaluation of column parameters to achieve optimal resolution, sensitivity, and analysis time.Expand Specific Solutions

Leading Manufacturers and Research Institutions in HPLC-MS

The HPLC-MS column market is currently in a growth phase, driven by increasing demand for high-resolution analytical techniques in pharmaceutical research and clinical diagnostics. The global market size is estimated to exceed $1.5 billion, with projected annual growth of 5-7%. Key technological advancements focus on optimizing the trade-off between particle size, pore volume, and backpressure to enhance separation efficiency while maintaining column durability. Leading players include Waters Technology, Agilent Technologies, and Phenomenex, who are developing sub-2μm particle columns with optimized pore structures. Thermo Fisher Scientific (via Thermo Electron) and Merck are advancing hybrid silica technologies to withstand higher pressures, while pharmaceutical companies like Roche, Novartis, and Janssen are driving application-specific column development for complex biological samples.

Waters Technology Corp.

Technical Solution: Waters Technology has developed innovative HPLC-MS column technologies focusing on particle engineering and pore architecture optimization. Their ACQUITY UPLC columns utilize sub-2μm particles that provide superior resolution while managing backpressure through advanced particle design. The company's BEH (Ethylene Bridged Hybrid) technology combines silica and organic materials to create mechanically strong particles that withstand high pressures (up to 15,000 psi) while maintaining column longevity. Waters has also pioneered Charged Surface Hybrid (CSH) particles with controlled pore volumes (typically 130-150 Å) that enhance peak shape for basic compounds while reducing ion suppression effects in MS detection. Their columns feature optimized particle size distribution to maximize bed homogeneity, resulting in reduced eddy diffusion and improved chromatographic efficiency. Waters' CORTECS columns with solid-core particle technology offer a balance between fully porous and non-porous particles, providing enhanced mass transfer characteristics while generating lower backpressure compared to fully porous particles of equivalent diameter.

Strengths: Industry-leading particle engineering expertise; comprehensive column portfolio addressing various separation challenges; proprietary hybrid particle technologies that withstand extreme pressures. Weaknesses: Premium pricing compared to competitors; some specialized columns require dedicated instrumentation capable of handling ultra-high pressures.

Phenomenex, Inc.

Technical Solution: Phenomenex has developed innovative HPLC-MS column technologies focusing on particle morphology and pore architecture optimization. Their Kinetex core-shell technology features superficially porous particles with precisely controlled shell thickness (0.35-0.5μm) and core-to-particle diameter ratios that optimize the balance between surface area and mass transfer efficiency. This design delivers up to 90% greater efficiency than traditional fully porous particles while generating approximately 50% less backpressure at equivalent particle diameters. Phenomenex offers multiple particle sizes (1.3, 1.7, 2.6, and 5μm) across their core-shell portfolio, allowing users to select the optimal balance between efficiency, pressure, and run time for their specific instrumentation capabilities. Their Luna columns utilize fully porous particles with highly uniform spherical morphology and narrow particle size distribution, minimizing eddy diffusion effects while maximizing bed stability under high-pressure conditions. Phenomenex has engineered various pore volume options (80-300Å) across their product lines, with specialized offerings like Aeris PEPTIDE (100Å) and Aeris WIDEPORE (300Å) targeting specific molecular weight ranges. Their proprietary Axia column packing technology creates highly stable beds with reduced channeling effects, maintaining column performance over extended usage cycles even under high-pressure conditions.

Strengths: Excellent price-to-performance ratio; innovative core-shell particle designs across multiple particle diameters; strong application support and method development resources. Weaknesses: Smaller overall product portfolio compared to some larger competitors; some specialized stationary phases may have limited availability across all particle formats.

Breakthrough Innovations in Particle Engineering

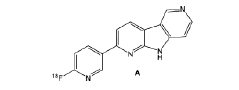

Novel method of preparing an imaging compound

PatentWO2019145294A1

Innovation

- A novel method involving reacting a compound of formula II with an 18F fluorinating agent, followed by optional cleavage of an amine protecting group and high-performance liquid chromatography (HPLC) using a mobile phase of ethanol and water, which simplifies the process, eliminates the need for solid phase extraction, and enhances yield and automation.

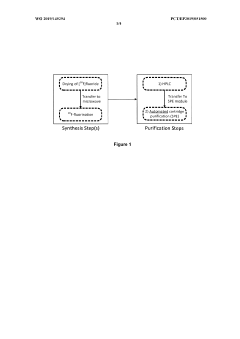

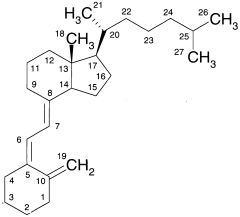

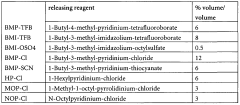

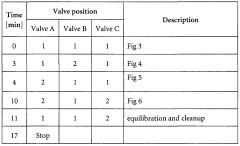

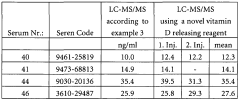

Improved measurement of vitamin d

PatentWO2007140962A2

Innovation

- A method using a vitamin D releasing reagent that allows for the direct online chromatographic separation of vitamin D metabolites from vitamin D-binding protein without protein precipitation, eliminating the need for extraction and manual handling steps.

Regulatory Standards for Analytical Column Performance

Regulatory standards for analytical column performance in HPLC-MS systems have evolved significantly over the past decades, reflecting the increasing demands for precision, reproducibility, and reliability in analytical chemistry. These standards are primarily established by international organizations such as the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), the United States Pharmacopeia (USP), and the European Pharmacopoeia (EP).

The ICH has developed comprehensive guidelines, particularly ICH Q2(R1), which addresses validation of analytical procedures including specificity, linearity, range, accuracy, and precision. For HPLC-MS column performance specifically, these guidelines establish minimum requirements for column efficiency, typically measured by theoretical plate count, which directly correlates with particle size and pore volume characteristics.

USP standards provide more detailed specifications, including Chapter <621> on chromatography, which outlines requirements for system suitability tests. These tests evaluate critical parameters such as resolution, tailing factor, and column efficiency. The standards specify that HPLC columns must demonstrate reproducible performance with relative standard deviations (RSDs) typically below 2% for retention times and peak areas across multiple injections.

European Pharmacopoeia standards complement these with specific requirements for backpressure stability, stipulating that columns must maintain consistent pressure profiles throughout their validated lifespan. EP standards typically require that backpressure variations remain within ±15% of initial values under specified conditions to ensure reliable quantitative analysis.

The Japanese Pharmacopoeia (JP) has established similar but sometimes more stringent requirements, particularly regarding metal contamination levels in columns used for biological sample analysis. These standards specify maximum allowable concentrations for various metal ions that might interfere with mass spectrometric detection.

Regulatory bodies also address column-to-column and batch-to-batch reproducibility. Current standards mandate that manufacturers provide certificates of analysis demonstrating consistent performance across production batches, with particular emphasis on particle size distribution uniformity (typically requiring >90% of particles within ±10% of the nominal size).

Recent updates to these standards have begun incorporating requirements specific to sub-2μm particle columns and core-shell technology, acknowledging their widespread adoption. These updates include modified backpressure tolerance ranges and efficiency requirements that account for the unique performance characteristics of these modern column technologies.

The ICH has developed comprehensive guidelines, particularly ICH Q2(R1), which addresses validation of analytical procedures including specificity, linearity, range, accuracy, and precision. For HPLC-MS column performance specifically, these guidelines establish minimum requirements for column efficiency, typically measured by theoretical plate count, which directly correlates with particle size and pore volume characteristics.

USP standards provide more detailed specifications, including Chapter <621> on chromatography, which outlines requirements for system suitability tests. These tests evaluate critical parameters such as resolution, tailing factor, and column efficiency. The standards specify that HPLC columns must demonstrate reproducible performance with relative standard deviations (RSDs) typically below 2% for retention times and peak areas across multiple injections.

European Pharmacopoeia standards complement these with specific requirements for backpressure stability, stipulating that columns must maintain consistent pressure profiles throughout their validated lifespan. EP standards typically require that backpressure variations remain within ±15% of initial values under specified conditions to ensure reliable quantitative analysis.

The Japanese Pharmacopoeia (JP) has established similar but sometimes more stringent requirements, particularly regarding metal contamination levels in columns used for biological sample analysis. These standards specify maximum allowable concentrations for various metal ions that might interfere with mass spectrometric detection.

Regulatory bodies also address column-to-column and batch-to-batch reproducibility. Current standards mandate that manufacturers provide certificates of analysis demonstrating consistent performance across production batches, with particular emphasis on particle size distribution uniformity (typically requiring >90% of particles within ±10% of the nominal size).

Recent updates to these standards have begun incorporating requirements specific to sub-2μm particle columns and core-shell technology, acknowledging their widespread adoption. These updates include modified backpressure tolerance ranges and efficiency requirements that account for the unique performance characteristics of these modern column technologies.

Environmental Impact of Modern Column Manufacturing

The manufacturing processes of modern HPLC-MS columns have significant environmental implications that warrant careful consideration. Traditional column production methods involve extensive use of organic solvents, particularly in the bonding and end-capping phases of silica modification. These processes typically generate substantial chemical waste, with estimates suggesting that for every kilogram of finished column material, up to 100 liters of various solvents may be consumed and subsequently require disposal.

Recent advancements in green chemistry approaches have begun to address these concerns through the development of more environmentally sustainable manufacturing techniques. Several leading column manufacturers have implemented solvent recycling systems that can recover and purify up to 80% of the organic solvents used in production. Additionally, water-based bonding chemistries are emerging as promising alternatives to traditional organic solvent-dependent methods, potentially reducing hazardous waste by 40-60%.

The environmental footprint of particle size reduction processes also presents challenges. The mechanical milling required to produce sub-2μm particles for UHPLC columns demands significant energy input, with energy consumption increasing exponentially as target particle size decreases. Manufacturers are exploring alternative approaches such as bottom-up particle synthesis methods that can produce uniform particles with less energy expenditure and fewer waste byproducts.

Column packaging materials contribute substantially to the industry's environmental impact. Traditional columns utilize significant amounts of stainless steel and specialized polymers, materials with high embodied energy. The trend toward smaller column dimensions has partially mitigated this issue, with modern microcolumns using up to 75% less material than their conventional counterparts. Several manufacturers have also introduced recycling programs for spent columns, recovering precious metals and reducing landfill contributions.

Water consumption represents another environmental concern in column manufacturing. The production and quality testing of high-purity silica substrates requires substantial volumes of ultrapure water. Industry estimates suggest that manufacturing a single batch of column packing material may consume between 2,000-5,000 liters of purified water. Advanced water recycling systems and process optimizations have enabled leading manufacturers to reduce water usage by approximately 30% over the past decade.

Carbon footprint assessments of column manufacturing facilities indicate that energy-intensive processes such as high-temperature silica activation and clean room operations contribute significantly to greenhouse gas emissions. Several major manufacturers have committed to carbon neutrality goals, implementing renewable energy sources and more efficient equipment to reduce their climate impact.

Recent advancements in green chemistry approaches have begun to address these concerns through the development of more environmentally sustainable manufacturing techniques. Several leading column manufacturers have implemented solvent recycling systems that can recover and purify up to 80% of the organic solvents used in production. Additionally, water-based bonding chemistries are emerging as promising alternatives to traditional organic solvent-dependent methods, potentially reducing hazardous waste by 40-60%.

The environmental footprint of particle size reduction processes also presents challenges. The mechanical milling required to produce sub-2μm particles for UHPLC columns demands significant energy input, with energy consumption increasing exponentially as target particle size decreases. Manufacturers are exploring alternative approaches such as bottom-up particle synthesis methods that can produce uniform particles with less energy expenditure and fewer waste byproducts.

Column packaging materials contribute substantially to the industry's environmental impact. Traditional columns utilize significant amounts of stainless steel and specialized polymers, materials with high embodied energy. The trend toward smaller column dimensions has partially mitigated this issue, with modern microcolumns using up to 75% less material than their conventional counterparts. Several manufacturers have also introduced recycling programs for spent columns, recovering precious metals and reducing landfill contributions.

Water consumption represents another environmental concern in column manufacturing. The production and quality testing of high-purity silica substrates requires substantial volumes of ultrapure water. Industry estimates suggest that manufacturing a single batch of column packing material may consume between 2,000-5,000 liters of purified water. Advanced water recycling systems and process optimizations have enabled leading manufacturers to reduce water usage by approximately 30% over the past decade.

Carbon footprint assessments of column manufacturing facilities indicate that energy-intensive processes such as high-temperature silica activation and clean room operations contribute significantly to greenhouse gas emissions. Several major manufacturers have committed to carbon neutrality goals, implementing renewable energy sources and more efficient equipment to reduce their climate impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!