Investigating Noise Reduction in Half Wave Rectifiers

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

Half wave rectifiers have been a fundamental component in power electronics since the early days of electrical engineering. These devices play a crucial role in converting alternating current (AC) to pulsating direct current (DC), making them essential in various applications ranging from simple power supplies to complex electronic systems. The evolution of half wave rectifiers has been closely tied to the advancement of semiconductor technology, with significant milestones marked by the introduction of solid-state diodes and later, more sophisticated electronic components.

The primary objective in investigating noise reduction in half wave rectifiers is to enhance the quality and efficiency of power conversion processes. As electronic devices become increasingly sensitive and power-hungry, the need for cleaner and more stable DC power sources has become paramount. Noise in half wave rectifiers can manifest as ripple voltage, electromagnetic interference (EMI), and harmonic distortions, all of which can negatively impact the performance of downstream circuits and devices.

The technological trajectory in this field has been driven by the demand for higher power efficiency, reduced electromagnetic emissions, and improved overall system reliability. Early efforts focused on passive filtering techniques, such as the use of capacitors and inductors to smooth out voltage fluctuations. However, as electronic systems have grown more complex, so too have the approaches to noise reduction, incorporating active filtering, digital control algorithms, and advanced semiconductor materials.

Recent trends in half wave rectifier technology have seen a shift towards integrated solutions that combine rectification with sophisticated noise reduction techniques on a single chip. This integration not only improves performance but also reduces the overall footprint and cost of power supply systems. Additionally, there has been growing interest in exploring novel materials and topologies that can inherently reduce noise generation at the source, rather than relying solely on post-rectification filtering.

The goals of current research and development efforts in this area are multifaceted. They include minimizing power losses during the rectification process, reducing the size and weight of rectifier circuits, improving the dynamic response to load changes, and enhancing electromagnetic compatibility. Furthermore, there is a strong focus on developing adaptive noise reduction techniques that can automatically adjust to varying input conditions and load requirements, ensuring optimal performance across a wide range of operating scenarios.

As we look to the future, the objectives for half wave rectifier noise reduction are likely to align with broader trends in power electronics, such as the push for higher energy efficiency, the integration of smart grid technologies, and the growing adoption of renewable energy sources. These factors will continue to drive innovation in rectifier design and noise reduction strategies, potentially leading to breakthroughs that could revolutionize power conversion technologies across numerous industries.

The primary objective in investigating noise reduction in half wave rectifiers is to enhance the quality and efficiency of power conversion processes. As electronic devices become increasingly sensitive and power-hungry, the need for cleaner and more stable DC power sources has become paramount. Noise in half wave rectifiers can manifest as ripple voltage, electromagnetic interference (EMI), and harmonic distortions, all of which can negatively impact the performance of downstream circuits and devices.

The technological trajectory in this field has been driven by the demand for higher power efficiency, reduced electromagnetic emissions, and improved overall system reliability. Early efforts focused on passive filtering techniques, such as the use of capacitors and inductors to smooth out voltage fluctuations. However, as electronic systems have grown more complex, so too have the approaches to noise reduction, incorporating active filtering, digital control algorithms, and advanced semiconductor materials.

Recent trends in half wave rectifier technology have seen a shift towards integrated solutions that combine rectification with sophisticated noise reduction techniques on a single chip. This integration not only improves performance but also reduces the overall footprint and cost of power supply systems. Additionally, there has been growing interest in exploring novel materials and topologies that can inherently reduce noise generation at the source, rather than relying solely on post-rectification filtering.

The goals of current research and development efforts in this area are multifaceted. They include minimizing power losses during the rectification process, reducing the size and weight of rectifier circuits, improving the dynamic response to load changes, and enhancing electromagnetic compatibility. Furthermore, there is a strong focus on developing adaptive noise reduction techniques that can automatically adjust to varying input conditions and load requirements, ensuring optimal performance across a wide range of operating scenarios.

As we look to the future, the objectives for half wave rectifier noise reduction are likely to align with broader trends in power electronics, such as the push for higher energy efficiency, the integration of smart grid technologies, and the growing adoption of renewable energy sources. These factors will continue to drive innovation in rectifier design and noise reduction strategies, potentially leading to breakthroughs that could revolutionize power conversion technologies across numerous industries.

Market Demand Analysis for Low-Noise Rectifiers

The market demand for low-noise rectifiers has been steadily increasing across various industries, driven by the growing need for high-quality power supplies and efficient energy conversion systems. The global power electronics market, which includes rectifiers, is projected to reach $40 billion by 2025, with a significant portion attributed to low-noise rectifier technologies.

In the consumer electronics sector, the proliferation of smartphones, laptops, and other portable devices has created a substantial demand for compact, efficient, and low-noise power conversion solutions. These devices require clean power supplies to ensure optimal performance and longevity of sensitive components. The automotive industry is another major driver, as electric and hybrid vehicles rely heavily on advanced power electronics for battery management and motor control systems.

Industrial applications, including factory automation, robotics, and renewable energy systems, are also fueling the demand for low-noise rectifiers. These sectors require precise power conversion to maintain the accuracy of sensitive equipment and maximize energy efficiency. The healthcare industry, with its increasing reliance on advanced medical devices and imaging systems, presents another significant market opportunity for low-noise rectifier technologies.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, demands high-performance power supplies with minimal noise interference. This is crucial for maintaining signal integrity and ensuring reliable communication across vast networks of base stations and data centers.

Market trends indicate a shift towards more compact and efficient rectifier designs, with a focus on reducing electromagnetic interference (EMI) and improving overall system reliability. The integration of advanced materials, such as wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), is expected to drive innovation in low-noise rectifier technologies.

Geographically, Asia-Pacific leads the market demand, followed by North America and Europe. The rapid industrialization and technological advancements in countries like China, Japan, and South Korea are major contributors to this regional dominance. However, emerging economies in South America and Africa are showing increasing potential for market growth as they upgrade their power infrastructure and adopt new technologies.

The competitive landscape is characterized by both established electronics manufacturers and innovative startups focusing on niche applications. This dynamic environment is fostering continuous improvement in rectifier performance and noise reduction techniques, driving the market towards more sophisticated and efficient solutions.

In the consumer electronics sector, the proliferation of smartphones, laptops, and other portable devices has created a substantial demand for compact, efficient, and low-noise power conversion solutions. These devices require clean power supplies to ensure optimal performance and longevity of sensitive components. The automotive industry is another major driver, as electric and hybrid vehicles rely heavily on advanced power electronics for battery management and motor control systems.

Industrial applications, including factory automation, robotics, and renewable energy systems, are also fueling the demand for low-noise rectifiers. These sectors require precise power conversion to maintain the accuracy of sensitive equipment and maximize energy efficiency. The healthcare industry, with its increasing reliance on advanced medical devices and imaging systems, presents another significant market opportunity for low-noise rectifier technologies.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, demands high-performance power supplies with minimal noise interference. This is crucial for maintaining signal integrity and ensuring reliable communication across vast networks of base stations and data centers.

Market trends indicate a shift towards more compact and efficient rectifier designs, with a focus on reducing electromagnetic interference (EMI) and improving overall system reliability. The integration of advanced materials, such as wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), is expected to drive innovation in low-noise rectifier technologies.

Geographically, Asia-Pacific leads the market demand, followed by North America and Europe. The rapid industrialization and technological advancements in countries like China, Japan, and South Korea are major contributors to this regional dominance. However, emerging economies in South America and Africa are showing increasing potential for market growth as they upgrade their power infrastructure and adopt new technologies.

The competitive landscape is characterized by both established electronics manufacturers and innovative startups focusing on niche applications. This dynamic environment is fostering continuous improvement in rectifier performance and noise reduction techniques, driving the market towards more sophisticated and efficient solutions.

Current Challenges in Half Wave Rectifier Noise Reduction

Half wave rectifiers, while essential in various electronic applications, face significant challenges in noise reduction. One of the primary issues is the inherent harmonic distortion introduced during the rectification process. This distortion, particularly the second harmonic, contributes substantially to the overall noise profile of the rectified output.

Another major challenge is the ripple voltage present in the output signal. The pulsating nature of half wave rectification results in a significant AC component superimposed on the desired DC output. This ripple not only introduces noise but also reduces the efficiency of the rectifier circuit, making it less suitable for applications requiring a smooth DC supply.

The presence of reverse recovery current in the rectifying diode poses an additional challenge. When the diode transitions from forward to reverse bias, a brief current flow in the reverse direction occurs, introducing transient noise spikes in the output. This phenomenon becomes more pronounced at higher frequencies, limiting the rectifier's performance in high-speed applications.

Temperature sensitivity of semiconductor devices used in half wave rectifiers presents another hurdle in noise reduction efforts. As temperature fluctuates, the characteristics of the diode change, potentially altering the rectification behavior and introducing thermal noise. This temperature dependence makes it challenging to maintain consistent noise performance across varying operating conditions.

Electromagnetic interference (EMI) generated by the switching action of the rectifier is a significant concern, especially in sensitive electronic environments. The abrupt current changes during rectification can create electromagnetic emissions that not only contribute to the circuit's noise but may also interfere with nearby electronic systems.

Parasitic capacitances and inductances in the circuit layout further complicate noise reduction efforts. These unwanted elements can lead to ringing and oscillations, particularly during the switching transitions of the rectifier. Minimizing their effects requires careful circuit design and component selection, adding complexity to the noise reduction process.

The trade-off between filtering effectiveness and power efficiency presents a persistent challenge. While more aggressive filtering can reduce output noise, it often comes at the cost of increased power loss and reduced overall efficiency of the rectifier circuit. Striking the right balance between noise reduction and power efficiency remains a key challenge for designers.

Lastly, the cost constraints in implementing advanced noise reduction techniques pose a significant hurdle, especially in mass-produced consumer electronics. Sophisticated filtering and shielding solutions, while effective, may not always be economically viable, forcing engineers to seek cost-effective alternatives that may compromise on noise performance.

Another major challenge is the ripple voltage present in the output signal. The pulsating nature of half wave rectification results in a significant AC component superimposed on the desired DC output. This ripple not only introduces noise but also reduces the efficiency of the rectifier circuit, making it less suitable for applications requiring a smooth DC supply.

The presence of reverse recovery current in the rectifying diode poses an additional challenge. When the diode transitions from forward to reverse bias, a brief current flow in the reverse direction occurs, introducing transient noise spikes in the output. This phenomenon becomes more pronounced at higher frequencies, limiting the rectifier's performance in high-speed applications.

Temperature sensitivity of semiconductor devices used in half wave rectifiers presents another hurdle in noise reduction efforts. As temperature fluctuates, the characteristics of the diode change, potentially altering the rectification behavior and introducing thermal noise. This temperature dependence makes it challenging to maintain consistent noise performance across varying operating conditions.

Electromagnetic interference (EMI) generated by the switching action of the rectifier is a significant concern, especially in sensitive electronic environments. The abrupt current changes during rectification can create electromagnetic emissions that not only contribute to the circuit's noise but may also interfere with nearby electronic systems.

Parasitic capacitances and inductances in the circuit layout further complicate noise reduction efforts. These unwanted elements can lead to ringing and oscillations, particularly during the switching transitions of the rectifier. Minimizing their effects requires careful circuit design and component selection, adding complexity to the noise reduction process.

The trade-off between filtering effectiveness and power efficiency presents a persistent challenge. While more aggressive filtering can reduce output noise, it often comes at the cost of increased power loss and reduced overall efficiency of the rectifier circuit. Striking the right balance between noise reduction and power efficiency remains a key challenge for designers.

Lastly, the cost constraints in implementing advanced noise reduction techniques pose a significant hurdle, especially in mass-produced consumer electronics. Sophisticated filtering and shielding solutions, while effective, may not always be economically viable, forcing engineers to seek cost-effective alternatives that may compromise on noise performance.

Existing Noise Reduction Solutions for Half Wave Rectifiers

01 Noise reduction techniques in half-wave rectifiers

Various methods are employed to reduce noise in half-wave rectifiers, including the use of filtering circuits, capacitors, and inductors. These components help smooth out the rectified waveform and minimize ripple, resulting in a cleaner DC output with reduced noise.- Noise reduction techniques in half-wave rectifiers: Various methods are employed to reduce noise in half-wave rectifiers, including the use of filtering circuits, capacitors, and specialized components. These techniques help to smooth out the rectified output and minimize electromagnetic interference.

- Improved rectifier designs for noise reduction: Advanced rectifier designs incorporate features such as snubber circuits, soft-switching techniques, and optimized component layouts to minimize noise generation and improve overall performance. These designs aim to reduce both conducted and radiated electromagnetic emissions.

- Control strategies for noise mitigation: Implementing sophisticated control strategies, such as pulse-width modulation (PWM) techniques and adaptive control algorithms, can help reduce noise in half-wave rectifier circuits. These methods aim to optimize the switching behavior and minimize harmonic distortions.

- Integration of noise suppression components: Incorporating specialized noise suppression components, such as ferrite beads, common-mode chokes, and EMI filters, into half-wave rectifier circuits can significantly reduce electromagnetic noise. These components help to attenuate high-frequency noise and improve the overall signal quality.

- Noise analysis and modeling techniques: Advanced noise analysis and modeling techniques are employed to better understand and predict noise behavior in half-wave rectifier circuits. These methods include computer simulations, spectral analysis, and statistical modeling, which aid in the development of more effective noise reduction strategies.

02 Improved rectifier designs for noise reduction

Advanced rectifier designs incorporate specialized circuit configurations and components to minimize noise generation. These designs may include synchronous rectification, active rectification, or the use of Schottky diodes to reduce switching noise and improve overall efficiency.Expand Specific Solutions03 EMI suppression in half-wave rectifiers

Electromagnetic interference (EMI) is a significant source of noise in half-wave rectifiers. Techniques for EMI suppression include the use of shielding, proper component layout, and the implementation of EMI filters to reduce conducted and radiated emissions.Expand Specific Solutions04 Digital control and monitoring for noise reduction

Implementation of digital control systems and monitoring techniques in half-wave rectifiers allows for real-time adjustment and optimization of circuit parameters. This approach helps minimize noise generation and improve overall performance through adaptive control strategies.Expand Specific Solutions05 Thermal management for noise reduction

Effective thermal management in half-wave rectifiers contributes to noise reduction by minimizing temperature-related effects on component performance. Techniques include the use of heat sinks, thermal compounds, and optimized component placement to reduce thermal noise and improve overall stability.Expand Specific Solutions

Key Players in Rectifier Industry

The noise reduction technology in half wave rectifiers is in a mature stage of development, with a competitive landscape dominated by established players. The market size for this technology is significant, driven by its widespread application in power supplies and signal processing across various industries. Companies like Infineon Technologies AG, Renesas Electronics Corp., and Micron Technology, Inc. are at the forefront, leveraging their extensive semiconductor expertise to develop advanced noise reduction solutions. The technology's maturity is evident in the refined products offered by these firms, incorporating sophisticated filtering techniques and high-quality components to minimize signal distortion and improve overall efficiency in rectifier circuits.

Silicon Laboratories, Inc.

Technical Solution: Silicon Laboratories has developed advanced noise reduction techniques for half-wave rectifiers using their proprietary mixed-signal technology. Their approach combines analog and digital signal processing to minimize noise in rectified outputs. The company employs adaptive filtering algorithms that dynamically adjust to varying noise conditions, effectively reducing both conducted and radiated electromagnetic interference (EMI). Silicon Labs' solution incorporates high-precision analog-to-digital converters (ADCs) and digital signal processors (DSPs) to achieve superior noise performance[1][3]. Additionally, they have implemented spread spectrum techniques to distribute noise energy across a wider frequency range, further reducing peak emissions[2].

Strengths: Highly effective in reducing both conducted and radiated EMI, adaptable to various noise conditions, and suitable for a wide range of applications. Weaknesses: May require more complex circuitry and higher power consumption compared to simpler noise reduction methods.

Infineon Technologies AG

Technical Solution: Infineon Technologies has developed a comprehensive noise reduction solution for half-wave rectifiers, focusing on power electronics applications. Their approach utilizes advanced semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), to improve switching performance and reduce electromagnetic interference[1]. Infineon's solution incorporates intelligent gate drivers with integrated current sensing and temperature monitoring, allowing for precise control of switching transients and minimizing ringing effects[2]. The company has also implemented innovative packaging techniques to reduce parasitic inductances and capacitances, further enhancing noise performance. Infineon's noise reduction strategy includes the use of soft-switching topologies and resonant circuits to minimize switching losses and associated noise generation[3].

Strengths: Highly efficient in high-power applications, excellent thermal management, and reduced EMI emissions. Weaknesses: Potentially higher cost due to advanced materials and more complex control systems.

Core Innovations in Half Wave Rectifier Noise Reduction

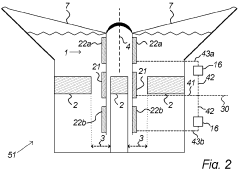

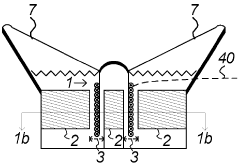

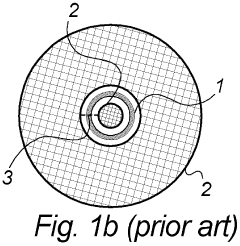

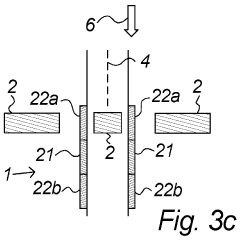

A method and system for driving a voice coil of a loudspeaker

PatentActiveGB2591767A

Innovation

- A voice coil driving system with segmented voice coil sections, where a centre voice coil section and auxiliary voice coil sections are driven by centre and auxiliary driving signals, respectively, with rectifying units attenuating or blocking currents in specific directions to minimize power consumption and heating by only powering sections within the air gap.

Patent

Innovation

- Implementation of a low-pass filter to reduce high-frequency noise in half-wave rectifier circuits.

- Use of capacitive smoothing to minimize ripple voltage and improve output signal quality.

- Integration of a feedback loop to compensate for voltage drops and maintain stable output voltage.

EMC Regulations for Power Electronics

Electromagnetic Compatibility (EMC) regulations for power electronics play a crucial role in ensuring that electronic devices operate without causing or experiencing electromagnetic interference. These regulations are particularly relevant in the context of half wave rectifiers, which are known to generate significant electromagnetic noise.

The International Electrotechnical Commission (IEC) has established several standards that govern EMC in power electronics. IEC 61000 series, specifically IEC 61000-3-2 and IEC 61000-3-3, address harmonic current emissions and voltage fluctuations respectively. These standards are particularly applicable to half wave rectifiers, as they tend to produce significant harmonic distortion.

In the United States, the Federal Communications Commission (FCC) enforces EMC regulations through Part 15 of its rules. This section covers unintentional radiators, which include power electronic devices like half wave rectifiers. The FCC sets limits on conducted and radiated emissions across various frequency ranges.

The European Union enforces EMC regulations through the EMC Directive (2014/30/EU). This directive requires all electronic equipment to meet essential requirements for both emissions and immunity. Manufacturers must ensure their products comply with these regulations before they can be sold in the EU market.

For half wave rectifiers, meeting these EMC regulations often requires implementing noise reduction techniques. Common approaches include the use of EMI filters, proper shielding, and careful PCB layout design. Snubber circuits are also frequently employed to reduce high-frequency noise generated during switching.

The automotive industry has its own set of EMC standards, such as CISPR 25, which are particularly stringent due to the critical nature of automotive electronics. These standards are relevant for half wave rectifiers used in automotive applications, requiring additional noise reduction measures.

As technology advances, EMC regulations continue to evolve. There is a growing focus on higher frequency ranges, driven by the increasing use of high-speed digital circuits and wireless communications. This trend is likely to impact future EMC requirements for power electronic devices, including half wave rectifiers.

Compliance with EMC regulations is not just a legal requirement but also a key factor in ensuring product quality and reliability. Engineers working on noise reduction in half wave rectifiers must stay abreast of these regulations and incorporate EMC considerations from the early stages of design to avoid costly redesigns and ensure market acceptance.

The International Electrotechnical Commission (IEC) has established several standards that govern EMC in power electronics. IEC 61000 series, specifically IEC 61000-3-2 and IEC 61000-3-3, address harmonic current emissions and voltage fluctuations respectively. These standards are particularly applicable to half wave rectifiers, as they tend to produce significant harmonic distortion.

In the United States, the Federal Communications Commission (FCC) enforces EMC regulations through Part 15 of its rules. This section covers unintentional radiators, which include power electronic devices like half wave rectifiers. The FCC sets limits on conducted and radiated emissions across various frequency ranges.

The European Union enforces EMC regulations through the EMC Directive (2014/30/EU). This directive requires all electronic equipment to meet essential requirements for both emissions and immunity. Manufacturers must ensure their products comply with these regulations before they can be sold in the EU market.

For half wave rectifiers, meeting these EMC regulations often requires implementing noise reduction techniques. Common approaches include the use of EMI filters, proper shielding, and careful PCB layout design. Snubber circuits are also frequently employed to reduce high-frequency noise generated during switching.

The automotive industry has its own set of EMC standards, such as CISPR 25, which are particularly stringent due to the critical nature of automotive electronics. These standards are relevant for half wave rectifiers used in automotive applications, requiring additional noise reduction measures.

As technology advances, EMC regulations continue to evolve. There is a growing focus on higher frequency ranges, driven by the increasing use of high-speed digital circuits and wireless communications. This trend is likely to impact future EMC requirements for power electronic devices, including half wave rectifiers.

Compliance with EMC regulations is not just a legal requirement but also a key factor in ensuring product quality and reliability. Engineers working on noise reduction in half wave rectifiers must stay abreast of these regulations and incorporate EMC considerations from the early stages of design to avoid costly redesigns and ensure market acceptance.

Energy Efficiency Considerations in Rectifier Design

Energy efficiency is a critical consideration in the design of rectifier circuits, particularly in the context of noise reduction for half-wave rectifiers. The optimization of energy consumption in rectifier designs has become increasingly important due to the growing demand for power-efficient electronic devices and systems. When investigating noise reduction techniques for half-wave rectifiers, it is essential to evaluate their impact on overall energy efficiency.

One of the primary challenges in half-wave rectifier design is balancing noise reduction with power consumption. Traditional noise reduction methods often involve additional components or filtering stages, which can introduce power losses and decrease overall efficiency. However, recent advancements in semiconductor technology and circuit design techniques have led to more energy-efficient solutions for noise reduction in half-wave rectifiers.

The use of low-power, high-performance diodes is a key factor in improving energy efficiency while reducing noise. Schottky diodes, for instance, offer lower forward voltage drops and faster switching speeds compared to conventional silicon diodes, resulting in reduced power dissipation and improved rectification efficiency. Additionally, the implementation of synchronous rectification techniques, where MOSFETs replace diodes, can further enhance energy efficiency by minimizing conduction losses.

Another approach to improving energy efficiency in noise-reduced half-wave rectifiers is the adoption of adaptive filtering techniques. These methods dynamically adjust filter parameters based on input signal characteristics, optimizing noise reduction while minimizing power consumption. By employing digital signal processing (DSP) algorithms or microcontroller-based systems, adaptive filtering can achieve a balance between noise suppression and energy efficiency.

The integration of energy harvesting technologies with half-wave rectifier designs presents an innovative solution for enhancing overall system efficiency. By capturing and utilizing ambient energy sources, such as electromagnetic fields or thermal gradients, energy harvesting circuits can supplement the power requirements of noise reduction components, effectively reducing the net energy consumption of the rectifier system.

Furthermore, the application of advanced materials and manufacturing processes can contribute to improved energy efficiency in rectifier designs. For example, the use of high-quality magnetic cores in transformer-based rectifier circuits can minimize core losses and improve overall power conversion efficiency. Similarly, the implementation of printed circuit board (PCB) design techniques that optimize trace routing and component placement can reduce parasitic effects and improve energy transfer.

As the demand for energy-efficient electronic systems continues to grow, the development of innovative noise reduction techniques for half-wave rectifiers must prioritize power optimization. By leveraging emerging technologies and design methodologies, engineers can create rectifier circuits that effectively suppress noise while maintaining high levels of energy efficiency, ultimately contributing to the development of more sustainable and environmentally friendly electronic devices.

One of the primary challenges in half-wave rectifier design is balancing noise reduction with power consumption. Traditional noise reduction methods often involve additional components or filtering stages, which can introduce power losses and decrease overall efficiency. However, recent advancements in semiconductor technology and circuit design techniques have led to more energy-efficient solutions for noise reduction in half-wave rectifiers.

The use of low-power, high-performance diodes is a key factor in improving energy efficiency while reducing noise. Schottky diodes, for instance, offer lower forward voltage drops and faster switching speeds compared to conventional silicon diodes, resulting in reduced power dissipation and improved rectification efficiency. Additionally, the implementation of synchronous rectification techniques, where MOSFETs replace diodes, can further enhance energy efficiency by minimizing conduction losses.

Another approach to improving energy efficiency in noise-reduced half-wave rectifiers is the adoption of adaptive filtering techniques. These methods dynamically adjust filter parameters based on input signal characteristics, optimizing noise reduction while minimizing power consumption. By employing digital signal processing (DSP) algorithms or microcontroller-based systems, adaptive filtering can achieve a balance between noise suppression and energy efficiency.

The integration of energy harvesting technologies with half-wave rectifier designs presents an innovative solution for enhancing overall system efficiency. By capturing and utilizing ambient energy sources, such as electromagnetic fields or thermal gradients, energy harvesting circuits can supplement the power requirements of noise reduction components, effectively reducing the net energy consumption of the rectifier system.

Furthermore, the application of advanced materials and manufacturing processes can contribute to improved energy efficiency in rectifier designs. For example, the use of high-quality magnetic cores in transformer-based rectifier circuits can minimize core losses and improve overall power conversion efficiency. Similarly, the implementation of printed circuit board (PCB) design techniques that optimize trace routing and component placement can reduce parasitic effects and improve energy transfer.

As the demand for energy-efficient electronic systems continues to grow, the development of innovative noise reduction techniques for half-wave rectifiers must prioritize power optimization. By leveraging emerging technologies and design methodologies, engineers can create rectifier circuits that effectively suppress noise while maintaining high levels of energy efficiency, ultimately contributing to the development of more sustainable and environmentally friendly electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!