Investigating Vacuum Pump Techniques in Space Exploration Equipment

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Space Vacuum Pump Evolution and Objectives

Vacuum pump technology has played a crucial role in space exploration since the early days of the space race. The evolution of these pumps has been closely tied to the advancement of space exploration equipment, with each new generation addressing the unique challenges posed by the harsh environment of space.

In the 1950s and 1960s, early space missions relied on basic mechanical pumps to create and maintain vacuum conditions for testing and simulating space environments on Earth. These pumps were primarily used in ground-based facilities to test spacecraft components and systems. As space exploration progressed, the need for more sophisticated vacuum pumps became apparent, particularly for use in space-based applications.

The 1970s and 1980s saw significant advancements in vacuum pump technology, with the development of turbomolecular pumps and cryogenic pumps. These innovations allowed for higher vacuum levels and improved reliability, critical factors for the success of long-duration space missions. The Space Shuttle program, in particular, drove the development of more compact and efficient vacuum pumps for use in various onboard systems.

In recent decades, the focus has shifted towards developing vacuum pumps that are not only highly efficient but also lightweight and capable of operating in microgravity environments. This has led to the exploration of novel pump designs, such as getter pumps and ion pumps, which offer advantages in terms of power consumption and longevity in space applications.

The objectives of current vacuum pump technology research in space exploration are multifaceted. Firstly, there is a push to develop pumps with higher pumping speeds and lower ultimate pressures, enabling more precise scientific experiments and improved environmental control in spacecraft and space stations. Secondly, researchers are working on increasing the reliability and lifespan of vacuum pumps to support extended deep space missions and reduce the need for maintenance or replacement.

Another key objective is the miniaturization of vacuum pump systems without compromising performance. This is particularly important for small satellites and CubeSats, where space and weight are at a premium. Additionally, there is ongoing research into developing vacuum pumps that can operate effectively in extreme temperature ranges and withstand the radiation environment of space.

As space exploration ventures further into the solar system, with plans for lunar bases and Mars missions, the demands on vacuum pump technology continue to evolve. Future objectives include developing pumps capable of extracting and processing resources from planetary atmospheres and surfaces, as well as creating closed-loop life support systems for long-duration space habitation.

In the 1950s and 1960s, early space missions relied on basic mechanical pumps to create and maintain vacuum conditions for testing and simulating space environments on Earth. These pumps were primarily used in ground-based facilities to test spacecraft components and systems. As space exploration progressed, the need for more sophisticated vacuum pumps became apparent, particularly for use in space-based applications.

The 1970s and 1980s saw significant advancements in vacuum pump technology, with the development of turbomolecular pumps and cryogenic pumps. These innovations allowed for higher vacuum levels and improved reliability, critical factors for the success of long-duration space missions. The Space Shuttle program, in particular, drove the development of more compact and efficient vacuum pumps for use in various onboard systems.

In recent decades, the focus has shifted towards developing vacuum pumps that are not only highly efficient but also lightweight and capable of operating in microgravity environments. This has led to the exploration of novel pump designs, such as getter pumps and ion pumps, which offer advantages in terms of power consumption and longevity in space applications.

The objectives of current vacuum pump technology research in space exploration are multifaceted. Firstly, there is a push to develop pumps with higher pumping speeds and lower ultimate pressures, enabling more precise scientific experiments and improved environmental control in spacecraft and space stations. Secondly, researchers are working on increasing the reliability and lifespan of vacuum pumps to support extended deep space missions and reduce the need for maintenance or replacement.

Another key objective is the miniaturization of vacuum pump systems without compromising performance. This is particularly important for small satellites and CubeSats, where space and weight are at a premium. Additionally, there is ongoing research into developing vacuum pumps that can operate effectively in extreme temperature ranges and withstand the radiation environment of space.

As space exploration ventures further into the solar system, with plans for lunar bases and Mars missions, the demands on vacuum pump technology continue to evolve. Future objectives include developing pumps capable of extracting and processing resources from planetary atmospheres and surfaces, as well as creating closed-loop life support systems for long-duration space habitation.

Space Exploration Equipment Market Analysis

The space exploration equipment market has been experiencing significant growth in recent years, driven by increased government and private sector investments in space missions. This market encompasses a wide range of products, including spacecraft, rovers, satellites, and various scientific instruments used for exploring celestial bodies and conducting research in space environments.

The global space exploration equipment market was valued at approximately $20 billion in 2020 and is projected to reach $30 billion by 2025, growing at a compound annual growth rate (CAGR) of 8.5%. This growth is primarily attributed to the rising number of space missions, advancements in technology, and the increasing participation of private companies in space exploration activities.

Key market segments include orbital infrastructure, lunar and planetary exploration equipment, and deep space exploration systems. The orbital infrastructure segment, which includes satellites and space stations, currently holds the largest market share due to the increasing demand for communication and Earth observation satellites. However, the lunar and planetary exploration equipment segment is expected to witness the highest growth rate in the coming years, driven by ambitious missions to the Moon, Mars, and other celestial bodies.

Geographically, North America dominates the space exploration equipment market, accounting for over 40% of the global market share. This is largely due to the presence of major space agencies like NASA and prominent private companies such as SpaceX and Blue Origin. Europe and Asia-Pacific follow closely, with countries like Russia, China, India, and Japan making significant investments in their space programs.

The market for vacuum pump technologies in space exploration equipment is a crucial subset of this broader market. Vacuum pumps play a vital role in maintaining the necessary pressure conditions for various space systems and instruments. The demand for advanced vacuum pump technologies is expected to grow as space missions become more complex and require more sophisticated equipment.

Key drivers for the vacuum pump market in space exploration include the need for lightweight and efficient pumping systems, increased focus on long-duration missions, and the growing emphasis on in-situ resource utilization (ISRU) technologies. The market is also influenced by the trend towards miniaturization of space systems and the development of CubeSats and other small satellites.

Challenges in this market include the high costs associated with developing and testing space-grade vacuum pumps, stringent reliability requirements, and the need for pumps that can operate in extreme space environments. Despite these challenges, the market is expected to grow steadily as space exploration activities continue to expand and diversify.

The global space exploration equipment market was valued at approximately $20 billion in 2020 and is projected to reach $30 billion by 2025, growing at a compound annual growth rate (CAGR) of 8.5%. This growth is primarily attributed to the rising number of space missions, advancements in technology, and the increasing participation of private companies in space exploration activities.

Key market segments include orbital infrastructure, lunar and planetary exploration equipment, and deep space exploration systems. The orbital infrastructure segment, which includes satellites and space stations, currently holds the largest market share due to the increasing demand for communication and Earth observation satellites. However, the lunar and planetary exploration equipment segment is expected to witness the highest growth rate in the coming years, driven by ambitious missions to the Moon, Mars, and other celestial bodies.

Geographically, North America dominates the space exploration equipment market, accounting for over 40% of the global market share. This is largely due to the presence of major space agencies like NASA and prominent private companies such as SpaceX and Blue Origin. Europe and Asia-Pacific follow closely, with countries like Russia, China, India, and Japan making significant investments in their space programs.

The market for vacuum pump technologies in space exploration equipment is a crucial subset of this broader market. Vacuum pumps play a vital role in maintaining the necessary pressure conditions for various space systems and instruments. The demand for advanced vacuum pump technologies is expected to grow as space missions become more complex and require more sophisticated equipment.

Key drivers for the vacuum pump market in space exploration include the need for lightweight and efficient pumping systems, increased focus on long-duration missions, and the growing emphasis on in-situ resource utilization (ISRU) technologies. The market is also influenced by the trend towards miniaturization of space systems and the development of CubeSats and other small satellites.

Challenges in this market include the high costs associated with developing and testing space-grade vacuum pumps, stringent reliability requirements, and the need for pumps that can operate in extreme space environments. Despite these challenges, the market is expected to grow steadily as space exploration activities continue to expand and diversify.

Current Vacuum Pump Technologies and Challenges

Vacuum pump technologies play a crucial role in space exploration equipment, enabling the creation and maintenance of low-pressure environments essential for various space applications. Currently, several types of vacuum pumps are employed in space-related contexts, each with its own strengths and limitations.

Mechanical pumps, such as rotary vane and scroll pumps, are commonly used for initial vacuum creation. These pumps are robust and reliable, capable of operating over extended periods. However, they face challenges in achieving ultra-high vacuum levels and may introduce contamination due to lubricants.

Turbomolecular pumps are widely utilized for achieving high and ultra-high vacuum conditions. These pumps operate on the principle of momentum transfer, using high-speed rotating blades to direct gas molecules towards the exhaust. While highly effective, turbomolecular pumps are sensitive to vibration and require precise alignment, which can be problematic in the dynamic environment of space missions.

Ion pumps, which ionize gas molecules and trap them on a titanium surface, are favored for their ability to maintain ultra-high vacuum without moving parts. This makes them ideal for long-duration space missions. However, ion pumps have limited pumping speed and capacity, and their performance can degrade over time due to saturation of the titanium surface.

Cryogenic pumps, which condense gases on extremely cold surfaces, are effective for pumping large volumes quickly and achieving very low pressures. These pumps are particularly useful for simulating space environments on Earth. The main challenges with cryogenic pumps include high power consumption and the need for periodic regeneration.

One of the primary challenges in vacuum pump technology for space exploration is miniaturization without compromising performance. As space missions become more ambitious and complex, there is a growing need for compact, lightweight pumps that can deliver high vacuum levels while consuming minimal power.

Another significant challenge is the development of pumps that can operate reliably in the harsh conditions of space, including extreme temperature fluctuations, radiation exposure, and microgravity environments. Materials used in vacuum pumps must withstand these conditions without degradation or outgassing, which could compromise the vacuum integrity.

Furthermore, contamination control remains a critical issue. Even minute amounts of organic compounds or particulates released by pump components can interfere with sensitive scientific instruments or compromise the purity of samples collected during space missions.

Lastly, the integration of smart technologies and predictive maintenance capabilities into vacuum pumps is an emerging challenge. As space missions become longer and more autonomous, there is a need for pumps that can self-diagnose, adapt to changing conditions, and operate efficiently with minimal human intervention.

Mechanical pumps, such as rotary vane and scroll pumps, are commonly used for initial vacuum creation. These pumps are robust and reliable, capable of operating over extended periods. However, they face challenges in achieving ultra-high vacuum levels and may introduce contamination due to lubricants.

Turbomolecular pumps are widely utilized for achieving high and ultra-high vacuum conditions. These pumps operate on the principle of momentum transfer, using high-speed rotating blades to direct gas molecules towards the exhaust. While highly effective, turbomolecular pumps are sensitive to vibration and require precise alignment, which can be problematic in the dynamic environment of space missions.

Ion pumps, which ionize gas molecules and trap them on a titanium surface, are favored for their ability to maintain ultra-high vacuum without moving parts. This makes them ideal for long-duration space missions. However, ion pumps have limited pumping speed and capacity, and their performance can degrade over time due to saturation of the titanium surface.

Cryogenic pumps, which condense gases on extremely cold surfaces, are effective for pumping large volumes quickly and achieving very low pressures. These pumps are particularly useful for simulating space environments on Earth. The main challenges with cryogenic pumps include high power consumption and the need for periodic regeneration.

One of the primary challenges in vacuum pump technology for space exploration is miniaturization without compromising performance. As space missions become more ambitious and complex, there is a growing need for compact, lightweight pumps that can deliver high vacuum levels while consuming minimal power.

Another significant challenge is the development of pumps that can operate reliably in the harsh conditions of space, including extreme temperature fluctuations, radiation exposure, and microgravity environments. Materials used in vacuum pumps must withstand these conditions without degradation or outgassing, which could compromise the vacuum integrity.

Furthermore, contamination control remains a critical issue. Even minute amounts of organic compounds or particulates released by pump components can interfere with sensitive scientific instruments or compromise the purity of samples collected during space missions.

Lastly, the integration of smart technologies and predictive maintenance capabilities into vacuum pumps is an emerging challenge. As space missions become longer and more autonomous, there is a need for pumps that can self-diagnose, adapt to changing conditions, and operate efficiently with minimal human intervention.

Existing Vacuum Pump Solutions for Space

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include novel rotor configurations, advanced sealing mechanisms, or optimized flow paths to achieve better vacuum levels and energy efficiency.- Improved vacuum pump designs: Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.

- Energy-efficient vacuum pump systems: Development of energy-efficient vacuum pump systems focuses on reducing power consumption while maintaining high performance. These systems may incorporate advanced control algorithms, variable speed drives, or heat recovery mechanisms to minimize energy waste and improve overall efficiency.

- Vacuum pump cooling and lubrication: Innovations in cooling and lubrication systems for vacuum pumps aim to extend pump life, reduce maintenance requirements, and improve overall reliability. These may include advanced cooling techniques, self-lubricating materials, or intelligent lubrication systems that optimize oil distribution.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs combine different pump types or stages to achieve higher vacuum levels or improved pumping speeds. These configurations may integrate various pump technologies, such as rotary vane, scroll, or turbomolecular pumps, to optimize performance across a wide range of pressure conditions.

- Smart vacuum pump control systems: Integration of smart control systems in vacuum pumps enables advanced monitoring, diagnostics, and optimization of pump performance. These systems may incorporate sensors, IoT connectivity, and machine learning algorithms to predict maintenance needs, adjust operating parameters, and improve overall pump efficiency and reliability.

02 Vacuum pump control systems

Advanced control systems for vacuum pumps focus on optimizing operation, monitoring performance, and adjusting parameters in real-time. These systems may incorporate sensors, microprocessors, and software algorithms to enhance pump efficiency, extend lifespan, and reduce energy consumption.Expand Specific Solutions03 Specialized vacuum pumps for specific applications

Vacuum pumps designed for specific industries or applications, such as semiconductor manufacturing, medical devices, or food processing. These pumps may have unique features tailored to the requirements of their intended use, including corrosion resistance, contamination prevention, or ultra-high vacuum capabilities.Expand Specific Solutions04 Energy-efficient vacuum pump technologies

Innovations focused on reducing energy consumption in vacuum pumps, including the use of variable speed drives, regenerative technologies, and heat recovery systems. These advancements aim to minimize operational costs and environmental impact while maintaining high performance.Expand Specific Solutions05 Vacuum pump maintenance and monitoring systems

Technologies for predictive maintenance, condition monitoring, and remote diagnostics of vacuum pumps. These systems may use sensors, data analytics, and IoT connectivity to detect potential issues, schedule maintenance, and optimize pump performance over time.Expand Specific Solutions

Key Players in Space Vacuum Pump Industry

The vacuum pump technology in space exploration equipment is in a mature stage, with a competitive landscape dominated by established players. The market size is substantial, driven by increasing space missions and satellite deployments. Companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and Agilent Technologies are at the forefront, leveraging their extensive experience in vacuum technology. The industry is characterized by high entry barriers due to the specialized nature of space-grade equipment. Technological advancements focus on improving efficiency, reducing weight, and enhancing reliability for space applications. Collaboration between aerospace companies and vacuum pump specialists is common, fostering innovation in this niche yet critical sector.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for space exploration equipment. Their innovative approach includes the use of dry pumping technology, which eliminates the need for oil lubrication, making it ideal for the clean and contamination-sensitive environments of space[1]. The company's XDS scroll pumps, designed for space applications, offer high reliability and low power consumption, crucial for long-duration space missions[2]. Edwards has also pioneered the development of turbomolecular pumps with magnetic bearings, which provide oil-free, low-vibration operation, essential for sensitive scientific instruments in space[3]. Their vacuum systems incorporate intelligent control features that allow for remote monitoring and adjustment, enhancing the autonomy of space exploration equipment[4].

Strengths: Oil-free operation, high reliability, low power consumption, and remote monitoring capabilities. Weaknesses: Potentially higher initial costs and complexity compared to traditional vacuum technologies.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum GmbH has made significant strides in vacuum pump technology for space exploration. Their HiPace turbomolecular pumps are designed to achieve ultra-high vacuum levels, crucial for simulating space conditions during equipment testing[5]. The company has developed hybrid bearing technology that combines ceramic ball bearings with magnetic bearings, resulting in extended operational lifetimes and reduced maintenance requirements[6]. Pfeiffer's vacuum solutions also feature advanced rotor designs that optimize pumping speed and compression ratios, enabling efficient gas removal in space-like environments[7]. Additionally, their pumps incorporate innovative coating technologies that enhance corrosion resistance and reduce outgassing, addressing key challenges in space applications[8].

Strengths: Ultra-high vacuum capability, long operational lifetimes, and advanced materials for space conditions. Weaknesses: Specialized nature may limit broader applications outside of high-tech and space industries.

Core Innovations in Space Vacuum Pump Technology

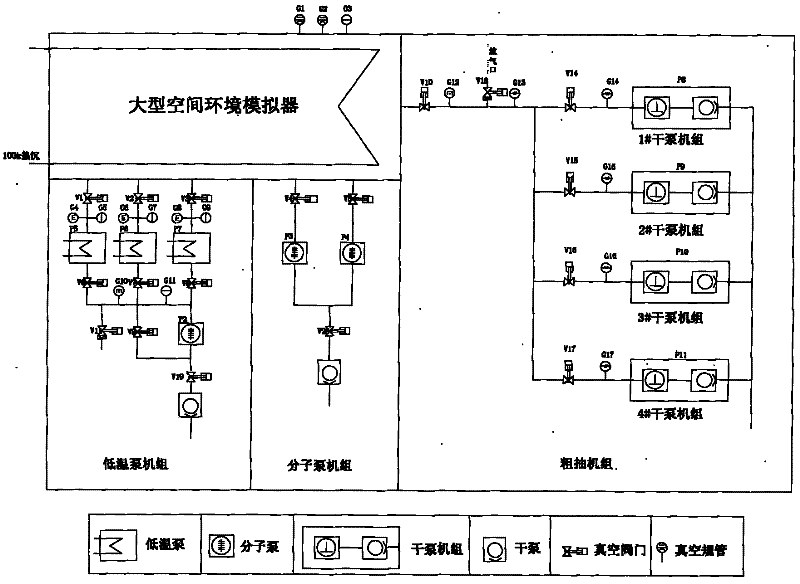

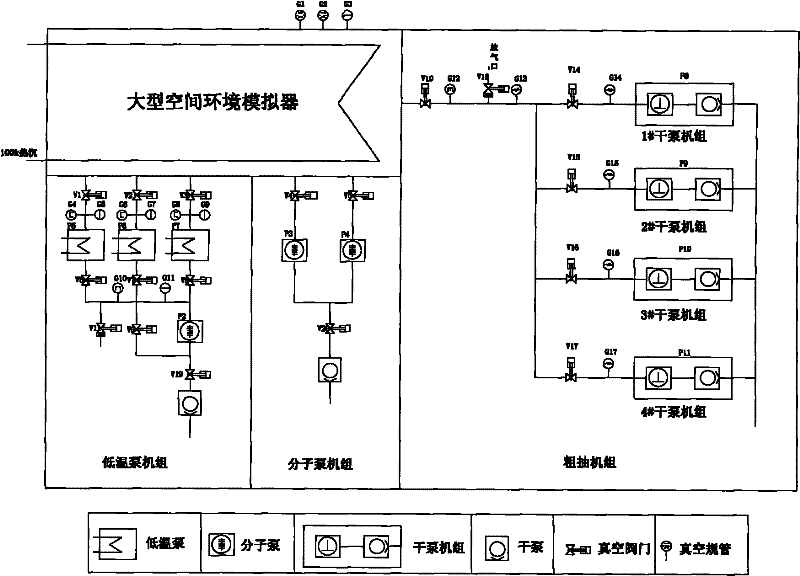

Cleaning vacuum air exhaust technology for large-sized space environmental simulator

PatentInactiveCN102536735A

Innovation

- Oil-free dry pump Roots pump, magnetic levitation molecular pump and refrigerator cryogenic pump are used to form the rough pumping, molecular pump and cryogenic pump system. Automatic control and measurement are realized through PLC and host computer to ensure that there is no oil pollution in the pumping process.

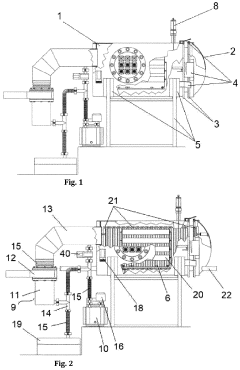

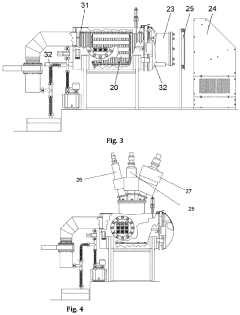

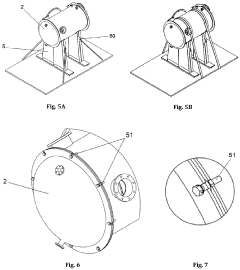

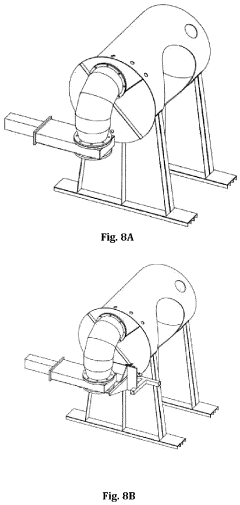

Movable space test facility

PatentActiveEP3988456A1

Innovation

- A mobile space test facility with structural features such as bellows connections, flexible tubing, vibration-absorbing elements like spring isolators and plates, and secure mounting systems to prevent damage and maintain functional integrity during transport and storage, allowing for quick relocation.

Space Environment Impact on Vacuum Pump Performance

The space environment presents unique challenges for vacuum pump performance in space exploration equipment. The extreme conditions encountered beyond Earth's atmosphere significantly impact the functionality and efficiency of these critical components. In the vacuum of space, traditional pumping mechanisms may face difficulties due to the absence of atmospheric pressure and the presence of various forms of radiation.

One of the primary factors affecting vacuum pump performance is the lack of gravity. In terrestrial applications, gravity assists in the movement of fluids and gases within pump systems. However, in microgravity environments, this natural force is absent, requiring alternative methods to ensure proper fluid dynamics and gas flow within the pump mechanisms. This necessitates the development of specialized pump designs that can operate effectively without relying on gravitational forces.

Thermal management is another crucial aspect influenced by the space environment. The extreme temperature fluctuations experienced in space can affect the materials used in vacuum pumps, potentially leading to thermal expansion or contraction issues. These temperature variations can impact seal integrity, bearing performance, and overall pump efficiency. Engineers must carefully select materials and implement thermal control systems to maintain optimal operating conditions for vacuum pumps in space exploration equipment.

Radiation exposure is a significant concern for vacuum pump performance in space. High-energy particles and electromagnetic radiation can degrade pump components over time, affecting their reliability and longevity. Shielding techniques and radiation-resistant materials must be incorporated into pump designs to mitigate these effects and ensure sustained performance throughout extended space missions.

The vacuum of space itself presents both advantages and challenges for pump operation. While the absence of atmospheric pressure reduces the workload on pumps in terms of creating a vacuum, it also eliminates the possibility of using certain pumping mechanisms that rely on atmospheric pressure differentials. This necessitates the development of novel pumping techniques specifically tailored for space applications.

Outgassing, the release of trapped gases from materials in vacuum conditions, is another factor that impacts vacuum pump performance in space. Materials used in pump construction and surrounding equipment must be carefully selected to minimize outgassing, which can contaminate sensitive instruments and affect the overall vacuum quality achieved by the pumps.

In conclusion, the space environment significantly influences vacuum pump performance in space exploration equipment. Addressing these challenges requires innovative design approaches, advanced materials, and specialized testing procedures to ensure reliable and efficient operation of vacuum pumps in the harsh conditions of space.

One of the primary factors affecting vacuum pump performance is the lack of gravity. In terrestrial applications, gravity assists in the movement of fluids and gases within pump systems. However, in microgravity environments, this natural force is absent, requiring alternative methods to ensure proper fluid dynamics and gas flow within the pump mechanisms. This necessitates the development of specialized pump designs that can operate effectively without relying on gravitational forces.

Thermal management is another crucial aspect influenced by the space environment. The extreme temperature fluctuations experienced in space can affect the materials used in vacuum pumps, potentially leading to thermal expansion or contraction issues. These temperature variations can impact seal integrity, bearing performance, and overall pump efficiency. Engineers must carefully select materials and implement thermal control systems to maintain optimal operating conditions for vacuum pumps in space exploration equipment.

Radiation exposure is a significant concern for vacuum pump performance in space. High-energy particles and electromagnetic radiation can degrade pump components over time, affecting their reliability and longevity. Shielding techniques and radiation-resistant materials must be incorporated into pump designs to mitigate these effects and ensure sustained performance throughout extended space missions.

The vacuum of space itself presents both advantages and challenges for pump operation. While the absence of atmospheric pressure reduces the workload on pumps in terms of creating a vacuum, it also eliminates the possibility of using certain pumping mechanisms that rely on atmospheric pressure differentials. This necessitates the development of novel pumping techniques specifically tailored for space applications.

Outgassing, the release of trapped gases from materials in vacuum conditions, is another factor that impacts vacuum pump performance in space. Materials used in pump construction and surrounding equipment must be carefully selected to minimize outgassing, which can contaminate sensitive instruments and affect the overall vacuum quality achieved by the pumps.

In conclusion, the space environment significantly influences vacuum pump performance in space exploration equipment. Addressing these challenges requires innovative design approaches, advanced materials, and specialized testing procedures to ensure reliable and efficient operation of vacuum pumps in the harsh conditions of space.

Reliability and Maintenance of Space Vacuum Pumps

The reliability and maintenance of space vacuum pumps are critical aspects of space exploration equipment. These pumps play a vital role in maintaining the necessary vacuum conditions for various spacecraft systems and scientific instruments. Ensuring their long-term performance and durability in the harsh space environment is paramount to mission success.

Space vacuum pumps are designed to operate in extreme conditions, including microgravity, intense radiation, and extreme temperature fluctuations. These factors pose significant challenges to their reliability and longevity. To address these challenges, space agencies and manufacturers employ rigorous testing and qualification processes to validate pump performance and durability before deployment.

Maintenance of space vacuum pumps is a complex task due to the inaccessibility of spacecraft once in orbit. As a result, redundancy and fault-tolerant designs are often incorporated to mitigate the risk of pump failure. Multiple pumps may be installed in parallel, allowing for continued operation even if one unit malfunctions. Additionally, advanced monitoring systems are integrated to detect early signs of degradation or potential failures.

Preventive maintenance strategies are crucial for extending the operational life of space vacuum pumps. These strategies include regular performance checks, thermal management, and periodic calibration of control systems. Remote diagnostics and telemetry data analysis enable ground crews to assess pump health and make necessary adjustments to operational parameters.

Material selection plays a significant role in enhancing pump reliability. Advanced materials such as titanium alloys, ceramics, and specialized polymers are used to withstand the harsh space environment and minimize wear and tear. Coatings and surface treatments are applied to reduce friction and improve resistance to atomic oxygen erosion, a common issue in low Earth orbit.

Lubrication is another critical aspect of vacuum pump maintenance in space. Traditional oil-based lubricants are unsuitable due to outgassing concerns and potential contamination of sensitive instruments. Instead, dry lubrication techniques, such as molybdenum disulfide coatings or self-lubricating materials, are employed to ensure smooth operation without compromising the vacuum environment.

The development of next-generation space vacuum pumps focuses on improving reliability and reducing maintenance requirements. Emerging technologies, such as magnetically levitated turbomolecular pumps and getter pumps, offer the potential for extended operational lifetimes and reduced mechanical wear. These advancements aim to support long-duration space missions and reduce the need for in-orbit servicing or replacement.

Space vacuum pumps are designed to operate in extreme conditions, including microgravity, intense radiation, and extreme temperature fluctuations. These factors pose significant challenges to their reliability and longevity. To address these challenges, space agencies and manufacturers employ rigorous testing and qualification processes to validate pump performance and durability before deployment.

Maintenance of space vacuum pumps is a complex task due to the inaccessibility of spacecraft once in orbit. As a result, redundancy and fault-tolerant designs are often incorporated to mitigate the risk of pump failure. Multiple pumps may be installed in parallel, allowing for continued operation even if one unit malfunctions. Additionally, advanced monitoring systems are integrated to detect early signs of degradation or potential failures.

Preventive maintenance strategies are crucial for extending the operational life of space vacuum pumps. These strategies include regular performance checks, thermal management, and periodic calibration of control systems. Remote diagnostics and telemetry data analysis enable ground crews to assess pump health and make necessary adjustments to operational parameters.

Material selection plays a significant role in enhancing pump reliability. Advanced materials such as titanium alloys, ceramics, and specialized polymers are used to withstand the harsh space environment and minimize wear and tear. Coatings and surface treatments are applied to reduce friction and improve resistance to atomic oxygen erosion, a common issue in low Earth orbit.

Lubrication is another critical aspect of vacuum pump maintenance in space. Traditional oil-based lubricants are unsuitable due to outgassing concerns and potential contamination of sensitive instruments. Instead, dry lubrication techniques, such as molybdenum disulfide coatings or self-lubricating materials, are employed to ensure smooth operation without compromising the vacuum environment.

The development of next-generation space vacuum pumps focuses on improving reliability and reducing maintenance requirements. Emerging technologies, such as magnetically levitated turbomolecular pumps and getter pumps, offer the potential for extended operational lifetimes and reduced mechanical wear. These advancements aim to support long-duration space missions and reduce the need for in-orbit servicing or replacement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!