Lifecycle Analysis of Solenoid Valves in Transportation Infrastructure

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution and Objectives

Solenoid valves have played a crucial role in transportation infrastructure since their inception in the early 20th century. These electromechanical devices have undergone significant evolution, adapting to the changing needs of various transportation systems. The journey of solenoid valves in this sector began with simple on-off control mechanisms and has progressed to sophisticated, precision-controlled units capable of managing complex fluid and gas systems.

The evolution of solenoid valves in transportation infrastructure can be traced through several key phases. Initially, they were primarily used in basic pneumatic and hydraulic systems for trains and early automobiles. As transportation technology advanced, so did the demands placed on these valves. The mid-20th century saw the integration of solenoid valves into more complex vehicle systems, including braking, fuel injection, and transmission control.

In recent decades, the focus has shifted towards enhancing the efficiency, reliability, and longevity of solenoid valves. This has been driven by the increasing complexity of modern transportation systems and the growing emphasis on sustainability and energy efficiency. Manufacturers have invested heavily in research and development to improve valve materials, reduce power consumption, and increase operational lifespan.

The current objectives in solenoid valve development for transportation infrastructure are multifaceted. One primary goal is to improve the durability and reliability of these components, ensuring they can withstand the harsh conditions often encountered in transportation applications. This includes resistance to extreme temperatures, vibrations, and corrosive environments.

Another key objective is to enhance the energy efficiency of solenoid valves. As transportation systems strive for greater sustainability, there is a growing demand for valves that can operate with minimal power consumption while maintaining high performance. This has led to innovations in valve design and materials, as well as the integration of smart control systems.

Miniaturization is also a significant focus, particularly in automotive applications where space is at a premium. Engineers are working to develop compact solenoid valves that can deliver the same or improved performance in a smaller package. This trend is closely tied to the broader move towards electric and hybrid vehicles, where efficient use of space is critical.

Furthermore, there is an increasing emphasis on developing 'smart' solenoid valves capable of self-diagnosis and predictive maintenance. These advanced valves can monitor their own performance, detect potential issues before they become critical, and communicate this information to central control systems. This capability is particularly valuable in large-scale transportation infrastructure, where unplanned maintenance can lead to significant disruptions and costs.

The evolution of solenoid valves in transportation infrastructure can be traced through several key phases. Initially, they were primarily used in basic pneumatic and hydraulic systems for trains and early automobiles. As transportation technology advanced, so did the demands placed on these valves. The mid-20th century saw the integration of solenoid valves into more complex vehicle systems, including braking, fuel injection, and transmission control.

In recent decades, the focus has shifted towards enhancing the efficiency, reliability, and longevity of solenoid valves. This has been driven by the increasing complexity of modern transportation systems and the growing emphasis on sustainability and energy efficiency. Manufacturers have invested heavily in research and development to improve valve materials, reduce power consumption, and increase operational lifespan.

The current objectives in solenoid valve development for transportation infrastructure are multifaceted. One primary goal is to improve the durability and reliability of these components, ensuring they can withstand the harsh conditions often encountered in transportation applications. This includes resistance to extreme temperatures, vibrations, and corrosive environments.

Another key objective is to enhance the energy efficiency of solenoid valves. As transportation systems strive for greater sustainability, there is a growing demand for valves that can operate with minimal power consumption while maintaining high performance. This has led to innovations in valve design and materials, as well as the integration of smart control systems.

Miniaturization is also a significant focus, particularly in automotive applications where space is at a premium. Engineers are working to develop compact solenoid valves that can deliver the same or improved performance in a smaller package. This trend is closely tied to the broader move towards electric and hybrid vehicles, where efficient use of space is critical.

Furthermore, there is an increasing emphasis on developing 'smart' solenoid valves capable of self-diagnosis and predictive maintenance. These advanced valves can monitor their own performance, detect potential issues before they become critical, and communicate this information to central control systems. This capability is particularly valuable in large-scale transportation infrastructure, where unplanned maintenance can lead to significant disruptions and costs.

Market Demand Analysis

The market demand for solenoid valves in transportation infrastructure has been experiencing steady growth, driven by the increasing complexity and automation of modern transportation systems. These valves play a crucial role in controlling fluid flow and pressure in various applications, including braking systems, fuel injection, and pneumatic controls.

In the automotive sector, the rising adoption of electric and hybrid vehicles has created new opportunities for solenoid valve manufacturers. These vehicles require sophisticated cooling systems and battery management, where solenoid valves are essential components. The global automotive solenoid valve market is expected to grow significantly in the coming years, with a particular focus on energy-efficient and compact designs.

The aerospace industry also contributes substantially to the demand for high-performance solenoid valves. As aircraft manufacturers strive for more fuel-efficient and environmentally friendly designs, the need for advanced valve technologies in hydraulic and pneumatic systems has increased. This trend is likely to continue as the industry recovers from the impact of the COVID-19 pandemic and air travel demand rebounds.

In railway infrastructure, the implementation of advanced signaling and control systems has boosted the demand for reliable solenoid valves. These components are critical in ensuring the safe and efficient operation of trains, particularly in high-speed rail networks. As countries invest in upgrading their rail infrastructure, the market for specialized solenoid valves in this sector is projected to expand.

The maritime industry represents another significant market for solenoid valves, particularly in ship propulsion systems and fluid handling applications. With the growing emphasis on reducing emissions and improving fuel efficiency in marine transport, there is an increasing demand for advanced valve technologies that can withstand harsh marine environments while delivering precise control.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the solenoid valve market for transportation infrastructure. This is primarily due to rapid urbanization, increasing investments in public transportation, and the expansion of automotive manufacturing in countries like China and India.

The lifecycle analysis of solenoid valves in transportation infrastructure reveals a growing focus on sustainability and longevity. End-users are increasingly demanding valves with extended service life, reduced maintenance requirements, and improved energy efficiency. This trend is driving innovation in materials science and design optimization to create more durable and eco-friendly valve solutions.

Furthermore, the integration of smart technologies and IoT capabilities into solenoid valves is emerging as a key market driver. Valve manufacturers are developing products with built-in sensors and connectivity features, enabling predictive maintenance and real-time monitoring. This shift towards "smart" valves is expected to create new market opportunities and enhance the overall value proposition of solenoid valves in transportation applications.

In the automotive sector, the rising adoption of electric and hybrid vehicles has created new opportunities for solenoid valve manufacturers. These vehicles require sophisticated cooling systems and battery management, where solenoid valves are essential components. The global automotive solenoid valve market is expected to grow significantly in the coming years, with a particular focus on energy-efficient and compact designs.

The aerospace industry also contributes substantially to the demand for high-performance solenoid valves. As aircraft manufacturers strive for more fuel-efficient and environmentally friendly designs, the need for advanced valve technologies in hydraulic and pneumatic systems has increased. This trend is likely to continue as the industry recovers from the impact of the COVID-19 pandemic and air travel demand rebounds.

In railway infrastructure, the implementation of advanced signaling and control systems has boosted the demand for reliable solenoid valves. These components are critical in ensuring the safe and efficient operation of trains, particularly in high-speed rail networks. As countries invest in upgrading their rail infrastructure, the market for specialized solenoid valves in this sector is projected to expand.

The maritime industry represents another significant market for solenoid valves, particularly in ship propulsion systems and fluid handling applications. With the growing emphasis on reducing emissions and improving fuel efficiency in marine transport, there is an increasing demand for advanced valve technologies that can withstand harsh marine environments while delivering precise control.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the solenoid valve market for transportation infrastructure. This is primarily due to rapid urbanization, increasing investments in public transportation, and the expansion of automotive manufacturing in countries like China and India.

The lifecycle analysis of solenoid valves in transportation infrastructure reveals a growing focus on sustainability and longevity. End-users are increasingly demanding valves with extended service life, reduced maintenance requirements, and improved energy efficiency. This trend is driving innovation in materials science and design optimization to create more durable and eco-friendly valve solutions.

Furthermore, the integration of smart technologies and IoT capabilities into solenoid valves is emerging as a key market driver. Valve manufacturers are developing products with built-in sensors and connectivity features, enabling predictive maintenance and real-time monitoring. This shift towards "smart" valves is expected to create new market opportunities and enhance the overall value proposition of solenoid valves in transportation applications.

Technical Challenges

The lifecycle analysis of solenoid valves in transportation infrastructure faces several significant technical challenges. One of the primary obstacles is the harsh operating conditions these valves are subjected to in transportation systems. Extreme temperatures, vibrations, and exposure to various contaminants can significantly impact the performance and longevity of solenoid valves, making accurate lifecycle predictions difficult.

Another challenge lies in the complexity of failure modes associated with solenoid valves. These components can fail due to various reasons, including mechanical wear, electrical issues, and material degradation. Developing comprehensive models that account for all potential failure mechanisms and their interactions is a formidable task, requiring extensive data collection and analysis.

The variability in usage patterns across different transportation applications further complicates lifecycle analysis. Solenoid valves in high-frequency urban transit systems may experience different wear patterns compared to those in long-haul freight transportation. This diversity in operational profiles necessitates the development of adaptive models capable of accurately predicting lifecycle across various scenarios.

Data acquisition and monitoring present another significant hurdle. While modern transportation systems increasingly incorporate sensors and IoT devices, legacy infrastructure often lacks comprehensive monitoring capabilities. This data gap hinders the collection of real-time performance metrics crucial for accurate lifecycle analysis and predictive maintenance strategies.

The integration of solenoid valves with other components in transportation systems adds another layer of complexity to lifecycle analysis. The interdependencies between valves and other system elements can lead to cascading effects that are challenging to model and predict. Understanding these system-level interactions is crucial for developing holistic lifecycle models.

Environmental factors and regulatory changes also pose challenges to lifecycle analysis. As transportation infrastructure evolves to meet sustainability goals, the operating conditions and requirements for solenoid valves may change. Adapting lifecycle models to account for these shifting environmental and regulatory landscapes requires continuous refinement and updating of analytical approaches.

Lastly, the economic aspects of lifecycle analysis present their own set of challenges. Balancing the cost of maintenance, replacement, and potential system failures against the benefits of extended valve life requires sophisticated economic modeling. This economic dimension adds another layer of complexity to the technical analysis, necessitating interdisciplinary approaches to lifecycle management in transportation infrastructure.

Another challenge lies in the complexity of failure modes associated with solenoid valves. These components can fail due to various reasons, including mechanical wear, electrical issues, and material degradation. Developing comprehensive models that account for all potential failure mechanisms and their interactions is a formidable task, requiring extensive data collection and analysis.

The variability in usage patterns across different transportation applications further complicates lifecycle analysis. Solenoid valves in high-frequency urban transit systems may experience different wear patterns compared to those in long-haul freight transportation. This diversity in operational profiles necessitates the development of adaptive models capable of accurately predicting lifecycle across various scenarios.

Data acquisition and monitoring present another significant hurdle. While modern transportation systems increasingly incorporate sensors and IoT devices, legacy infrastructure often lacks comprehensive monitoring capabilities. This data gap hinders the collection of real-time performance metrics crucial for accurate lifecycle analysis and predictive maintenance strategies.

The integration of solenoid valves with other components in transportation systems adds another layer of complexity to lifecycle analysis. The interdependencies between valves and other system elements can lead to cascading effects that are challenging to model and predict. Understanding these system-level interactions is crucial for developing holistic lifecycle models.

Environmental factors and regulatory changes also pose challenges to lifecycle analysis. As transportation infrastructure evolves to meet sustainability goals, the operating conditions and requirements for solenoid valves may change. Adapting lifecycle models to account for these shifting environmental and regulatory landscapes requires continuous refinement and updating of analytical approaches.

Lastly, the economic aspects of lifecycle analysis present their own set of challenges. Balancing the cost of maintenance, replacement, and potential system failures against the benefits of extended valve life requires sophisticated economic modeling. This economic dimension adds another layer of complexity to the technical analysis, necessitating interdisciplinary approaches to lifecycle management in transportation infrastructure.

Current Lifecycle Solutions

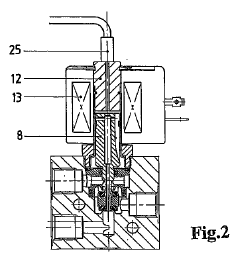

01 Design and construction of solenoid valves

The lifecycle of solenoid valves is significantly influenced by their design and construction. Key factors include the materials used, the quality of components, and the overall assembly. Proper design can enhance durability, reduce wear and tear, and extend the operational life of the valve. Considerations such as the choice of sealing materials, coil design, and plunger mechanism play crucial roles in determining the valve's longevity and performance over time.- Design and construction of solenoid valves: The lifecycle of solenoid valves is significantly influenced by their design and construction. Key factors include the materials used, the precision of manufacturing, and the overall robustness of the valve assembly. Improved designs can lead to longer operational life, reduced wear and tear, and better resistance to environmental factors.

- Maintenance and monitoring of solenoid valves: Regular maintenance and monitoring are crucial for extending the lifecycle of solenoid valves. This includes periodic inspections, cleaning, and replacement of worn parts. Advanced monitoring systems can detect early signs of wear or malfunction, allowing for preventive maintenance and reducing unexpected failures.

- Environmental factors affecting solenoid valve lifespan: The operational environment plays a significant role in determining the lifecycle of solenoid valves. Factors such as temperature, humidity, pressure, and exposure to corrosive substances can impact valve performance and longevity. Selecting valves designed for specific environmental conditions can greatly extend their operational life.

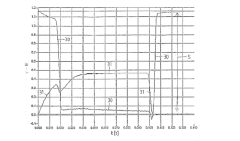

- Operational parameters and valve lifecycle: The way solenoid valves are operated can significantly affect their lifecycle. Factors such as cycling frequency, operating pressure, and fluid characteristics all play a role. Proper sizing and selection of valves for specific applications, along with adherence to recommended operational parameters, can help maximize their lifespan.

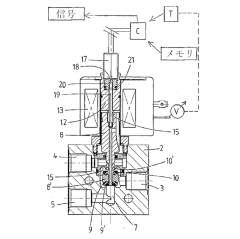

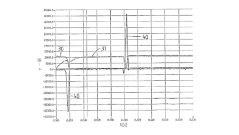

- Technological advancements in solenoid valve lifecycle management: Recent technological advancements have led to improvements in solenoid valve lifecycle management. This includes the development of smart valves with self-diagnostic capabilities, the use of advanced materials for improved durability, and the implementation of predictive maintenance algorithms. These innovations contribute to extended valve lifecycles and improved reliability.

02 Maintenance and servicing of solenoid valves

Regular maintenance and servicing are essential for prolonging the lifecycle of solenoid valves. This includes periodic inspections, cleaning, lubrication, and replacement of worn parts. Proper maintenance practices can prevent premature failure, reduce downtime, and ensure optimal performance throughout the valve's lifespan. Implementing a scheduled maintenance program and following manufacturer guidelines can significantly extend the operational life of solenoid valves.Expand Specific Solutions03 Environmental factors affecting solenoid valve lifecycle

The operating environment plays a crucial role in determining the lifecycle of solenoid valves. Factors such as temperature, humidity, pressure, and exposure to corrosive substances can significantly impact valve performance and longevity. Selecting valves designed for specific environmental conditions and implementing protective measures can help mitigate these effects and extend the valve's useful life.Expand Specific Solutions04 Monitoring and diagnostics for solenoid valves

Implementing monitoring and diagnostic systems can help predict and prevent solenoid valve failures, thereby extending their lifecycle. Advanced sensors and data analysis techniques can be used to monitor valve performance, detect early signs of wear or malfunction, and schedule preventive maintenance. This proactive approach can significantly reduce unexpected failures and extend the overall operational life of solenoid valves.Expand Specific Solutions05 End-of-life considerations and replacement strategies

Proper end-of-life management and replacement strategies are important aspects of the solenoid valve lifecycle. This includes determining the optimal time for valve replacement based on performance degradation, frequency of repairs, and overall system efficiency. Implementing a strategic replacement plan can help minimize downtime, reduce maintenance costs, and ensure consistent system performance. Additionally, considering environmentally friendly disposal methods for old valves contributes to sustainable lifecycle management.Expand Specific Solutions

Key Industry Players

The lifecycle analysis of solenoid valves in transportation infrastructure is in a mature stage, with a well-established market and proven technology. The global market size for solenoid valves is substantial, driven by increasing automation in various industries. Key players like Robert Bosch GmbH, Festo SE & Co. KG, and ZF CV Systems Europe BV demonstrate high technological maturity through their advanced product offerings and extensive industry experience. These companies, along with others such as Knorr-Bremse Systeme für Nutzfahrzeuge GmbH and HL Mando Co., Ltd., are continuously innovating to improve valve efficiency, durability, and performance in transportation applications, indicating a competitive and evolving landscape despite the technology's maturity.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced solenoid valve systems for transportation infrastructure with a focus on lifecycle analysis. Their approach integrates smart diagnostics and predictive maintenance capabilities. The company utilizes IoT sensors and data analytics to monitor valve performance in real-time, allowing for early detection of potential failures and optimized maintenance schedules[1]. Bosch's solenoid valves incorporate energy-efficient designs, reducing power consumption by up to 30% compared to conventional models[2]. Additionally, they have implemented modular designs that facilitate easier repairs and component replacements, extending the overall lifecycle of the valves[3].

Strengths: Advanced IoT integration, energy efficiency, and modular design for easy maintenance. Weaknesses: Higher initial cost and potential complexity in implementation for existing systems.

Festo SE & Co. KG

Technical Solution: Festo SE & Co. KG has developed a comprehensive lifecycle analysis approach for solenoid valves in transportation infrastructure. Their solution incorporates advanced materials and coatings that significantly enhance valve durability and resistance to harsh environmental conditions[4]. Festo's valves feature a unique self-cleaning mechanism that reduces the accumulation of debris and extends operational life[5]. The company has also implemented a digital twin technology that allows for virtual simulation and optimization of valve performance throughout its lifecycle, reducing the need for physical prototyping and testing[6]. Furthermore, Festo's valves are designed with a focus on energy recuperation, capturing and reusing energy from valve actuation to improve overall system efficiency[7].

Strengths: Innovative self-cleaning mechanism, digital twin technology for optimization, and energy recuperation features. Weaknesses: Potentially higher upfront costs and specialized training requirements for maintenance personnel.

Core Innovations

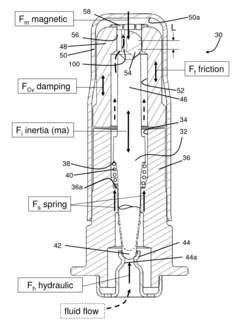

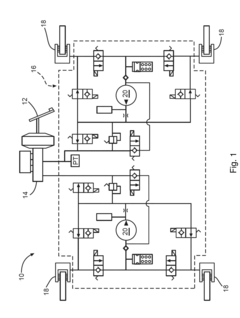

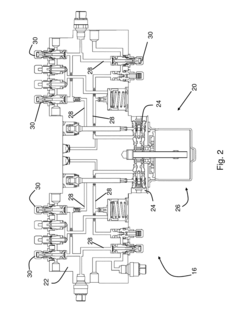

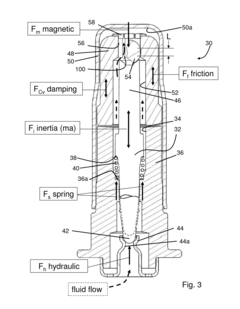

Solenoid Valve Having Hydraulic Damping Mechanism

PatentInactiveUS20150130265A1

Innovation

- A solenoid valve design featuring a damping port with a specific flow groove depth, flow diameter, and effective length ratio, creating turbulent fluid flow characteristics to attenuate vibrations, and an actuating ball that connects the armature to the tappet, enhancing damping and reducing NVH disturbances.

Solenoid valves with sensors for determining the stroke, velocity and/or acceleration of the valve's moving core as an indication of failure mode and health

PatentInactiveJP2012508857A

Innovation

- A solenoid valve equipped with a position sensor and control unit that monitors the axial position, velocity, and acceleration of the valve element, allowing for the analysis of kinematic behavior to detect potential failures before they occur, and provides feedback for maintenance.

Environmental Impact

The environmental impact of solenoid valves in transportation infrastructure is a critical consideration throughout their lifecycle. These components, while small, can have significant cumulative effects on the environment due to their widespread use in various transportation systems.

During the production phase, the manufacturing of solenoid valves involves the extraction and processing of raw materials, primarily metals and plastics. This process contributes to resource depletion and energy consumption. The production of copper wire for coils and steel or brass for valve bodies requires mining activities, which can lead to habitat destruction and water pollution. Additionally, the use of rare earth elements in some high-performance solenoid valves raises concerns about the sustainability of these resources.

The operational phase of solenoid valves in transportation infrastructure presents both challenges and opportunities for environmental impact. On one hand, these valves contribute to the efficient operation of systems such as pneumatic brakes in trains or fluid control in aircraft, potentially reducing overall energy consumption and emissions. However, the continuous operation of these valves requires electrical energy, which, depending on the source, may contribute to greenhouse gas emissions.

Maintenance and replacement of solenoid valves also have environmental implications. Regular maintenance can extend the lifespan of these components, reducing the need for frequent replacements and thus minimizing waste. However, when replacement is necessary, the disposal of old valves becomes an environmental concern. Many solenoid valves contain materials that are not easily biodegradable or recyclable, potentially contributing to landfill waste.

The end-of-life phase for solenoid valves presents significant challenges. The complex composition of these components, often including a mix of metals, plastics, and electronic parts, makes recycling difficult. Improper disposal can lead to the release of harmful substances into the environment. However, advancements in recycling technologies and the implementation of take-back programs by manufacturers are beginning to address these issues.

From a lifecycle perspective, the environmental impact of solenoid valves can be mitigated through several strategies. Design for disassembly and recyclability can facilitate easier end-of-life processing. The use of more sustainable materials, such as recycled metals or bio-based plastics, can reduce the environmental footprint of production. Additionally, improving the energy efficiency of solenoid valves during operation can significantly reduce their long-term environmental impact in transportation infrastructure.

During the production phase, the manufacturing of solenoid valves involves the extraction and processing of raw materials, primarily metals and plastics. This process contributes to resource depletion and energy consumption. The production of copper wire for coils and steel or brass for valve bodies requires mining activities, which can lead to habitat destruction and water pollution. Additionally, the use of rare earth elements in some high-performance solenoid valves raises concerns about the sustainability of these resources.

The operational phase of solenoid valves in transportation infrastructure presents both challenges and opportunities for environmental impact. On one hand, these valves contribute to the efficient operation of systems such as pneumatic brakes in trains or fluid control in aircraft, potentially reducing overall energy consumption and emissions. However, the continuous operation of these valves requires electrical energy, which, depending on the source, may contribute to greenhouse gas emissions.

Maintenance and replacement of solenoid valves also have environmental implications. Regular maintenance can extend the lifespan of these components, reducing the need for frequent replacements and thus minimizing waste. However, when replacement is necessary, the disposal of old valves becomes an environmental concern. Many solenoid valves contain materials that are not easily biodegradable or recyclable, potentially contributing to landfill waste.

The end-of-life phase for solenoid valves presents significant challenges. The complex composition of these components, often including a mix of metals, plastics, and electronic parts, makes recycling difficult. Improper disposal can lead to the release of harmful substances into the environment. However, advancements in recycling technologies and the implementation of take-back programs by manufacturers are beginning to address these issues.

From a lifecycle perspective, the environmental impact of solenoid valves can be mitigated through several strategies. Design for disassembly and recyclability can facilitate easier end-of-life processing. The use of more sustainable materials, such as recycled metals or bio-based plastics, can reduce the environmental footprint of production. Additionally, improving the energy efficiency of solenoid valves during operation can significantly reduce their long-term environmental impact in transportation infrastructure.

Regulatory Compliance

Regulatory compliance plays a crucial role in the lifecycle analysis of solenoid valves used in transportation infrastructure. These components are subject to various regulations and standards to ensure safety, reliability, and environmental sustainability throughout their operational life.

In the United States, the Department of Transportation (DOT) and the Federal Motor Carrier Safety Administration (FMCSA) set forth regulations that directly impact the use of solenoid valves in transportation systems. These regulations cover aspects such as performance requirements, durability standards, and maintenance protocols. Compliance with these regulations is mandatory for manufacturers, installers, and operators of transportation infrastructure.

The National Highway Traffic Safety Administration (NHTSA) also establishes safety standards that indirectly affect solenoid valve design and implementation. These standards often necessitate specific performance characteristics from valves used in critical systems like braking and steering.

Internationally, organizations such as the International Organization for Standardization (ISO) provide guidelines and standards for solenoid valves. ISO 4126, for instance, outlines safety requirements for pressure relief valves, which may include solenoid-operated types used in transportation applications.

Environmental regulations also impact the lifecycle analysis of solenoid valves. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation influence material selection and disposal practices for these components.

Compliance with electromagnetic compatibility (EMC) regulations is another critical aspect, as solenoid valves operate in environments with various electronic systems. Standards such as those set by the Federal Communications Commission (FCC) in the US and the European Union's EMC Directive must be adhered to throughout the valve's lifecycle.

Lifecycle analysis must also consider evolving regulations. For instance, the increasing focus on energy efficiency and carbon footprint reduction may lead to new standards affecting solenoid valve design and operation in transportation infrastructure.

Manufacturers and operators must implement robust quality management systems to ensure ongoing compliance. This includes regular testing, documentation, and reporting processes. Third-party certification bodies often play a role in verifying compliance with relevant standards and regulations.

The regulatory landscape for solenoid valves in transportation infrastructure is complex and multifaceted. A comprehensive lifecycle analysis must account for current regulations and anticipate future changes to ensure long-term compliance and optimal performance of these critical components.

In the United States, the Department of Transportation (DOT) and the Federal Motor Carrier Safety Administration (FMCSA) set forth regulations that directly impact the use of solenoid valves in transportation systems. These regulations cover aspects such as performance requirements, durability standards, and maintenance protocols. Compliance with these regulations is mandatory for manufacturers, installers, and operators of transportation infrastructure.

The National Highway Traffic Safety Administration (NHTSA) also establishes safety standards that indirectly affect solenoid valve design and implementation. These standards often necessitate specific performance characteristics from valves used in critical systems like braking and steering.

Internationally, organizations such as the International Organization for Standardization (ISO) provide guidelines and standards for solenoid valves. ISO 4126, for instance, outlines safety requirements for pressure relief valves, which may include solenoid-operated types used in transportation applications.

Environmental regulations also impact the lifecycle analysis of solenoid valves. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation influence material selection and disposal practices for these components.

Compliance with electromagnetic compatibility (EMC) regulations is another critical aspect, as solenoid valves operate in environments with various electronic systems. Standards such as those set by the Federal Communications Commission (FCC) in the US and the European Union's EMC Directive must be adhered to throughout the valve's lifecycle.

Lifecycle analysis must also consider evolving regulations. For instance, the increasing focus on energy efficiency and carbon footprint reduction may lead to new standards affecting solenoid valve design and operation in transportation infrastructure.

Manufacturers and operators must implement robust quality management systems to ensure ongoing compliance. This includes regular testing, documentation, and reporting processes. Third-party certification bodies often play a role in verifying compliance with relevant standards and regulations.

The regulatory landscape for solenoid valves in transportation infrastructure is complex and multifaceted. A comprehensive lifecycle analysis must account for current regulations and anticipate future changes to ensure long-term compliance and optimal performance of these critical components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!