Malachite's role in historical metallurgy and alloy production

AUG 19, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Historical Context

Malachite, a vibrant green copper carbonate hydroxide mineral, has played a significant role in the development of metallurgy and alloy production throughout human history. Its use can be traced back to ancient civilizations, where it served as both a source of copper and a decorative material.

The earliest known use of malachite in metallurgy dates back to the Chalcolithic period, around 5000 BCE, in the Near East and Eastern Europe. During this time, early metalworkers discovered that heating malachite in a fire could produce copper, marking a crucial step in the transition from stone tools to metal implements. This discovery laid the foundation for the Bronze Age, which began around 3300 BCE in the Near East.

As civilizations advanced, the exploitation of malachite for copper production became more sophisticated. Ancient Egyptians, for instance, mined malachite extensively from the Sinai Peninsula as early as 4000 BCE. They not only used it for copper extraction but also ground it into pigments for cosmetics and decorative purposes. The green pigment derived from malachite was highly prized and used in paintings and decorative arts throughout the ancient world.

In China, malachite played a crucial role in the development of bronze technology during the Shang Dynasty (1600-1046 BCE). Chinese metallurgists discovered that combining copper from malachite with tin could produce bronze, a stronger and more durable alloy. This innovation led to the production of sophisticated bronze weapons, tools, and ritual vessels that characterized Chinese civilization for centuries.

The Romans further advanced the use of malachite in metallurgy, developing more efficient smelting techniques to extract copper. They also recognized the potential of malachite in creating alloys, particularly brass, by combining copper with zinc. This knowledge spread throughout the Roman Empire, influencing metallurgical practices across Europe and North Africa.

During the Middle Ages, alchemists and early chemists began to study malachite more closely, attempting to understand its properties and potential uses. These investigations contributed to the development of more advanced metallurgical techniques and a deeper understanding of chemical reactions involved in metal production.

The Industrial Revolution marked a turning point in the use of malachite and other copper ores. The invention of new mining and smelting technologies allowed for large-scale copper production, which in turn fueled the growth of industries relying on copper and its alloys. While malachite's importance as a primary copper ore diminished with the discovery of more abundant sources, its historical significance in the development of metallurgy and alloy production remains undeniable.

The earliest known use of malachite in metallurgy dates back to the Chalcolithic period, around 5000 BCE, in the Near East and Eastern Europe. During this time, early metalworkers discovered that heating malachite in a fire could produce copper, marking a crucial step in the transition from stone tools to metal implements. This discovery laid the foundation for the Bronze Age, which began around 3300 BCE in the Near East.

As civilizations advanced, the exploitation of malachite for copper production became more sophisticated. Ancient Egyptians, for instance, mined malachite extensively from the Sinai Peninsula as early as 4000 BCE. They not only used it for copper extraction but also ground it into pigments for cosmetics and decorative purposes. The green pigment derived from malachite was highly prized and used in paintings and decorative arts throughout the ancient world.

In China, malachite played a crucial role in the development of bronze technology during the Shang Dynasty (1600-1046 BCE). Chinese metallurgists discovered that combining copper from malachite with tin could produce bronze, a stronger and more durable alloy. This innovation led to the production of sophisticated bronze weapons, tools, and ritual vessels that characterized Chinese civilization for centuries.

The Romans further advanced the use of malachite in metallurgy, developing more efficient smelting techniques to extract copper. They also recognized the potential of malachite in creating alloys, particularly brass, by combining copper with zinc. This knowledge spread throughout the Roman Empire, influencing metallurgical practices across Europe and North Africa.

During the Middle Ages, alchemists and early chemists began to study malachite more closely, attempting to understand its properties and potential uses. These investigations contributed to the development of more advanced metallurgical techniques and a deeper understanding of chemical reactions involved in metal production.

The Industrial Revolution marked a turning point in the use of malachite and other copper ores. The invention of new mining and smelting technologies allowed for large-scale copper production, which in turn fueled the growth of industries relying on copper and its alloys. While malachite's importance as a primary copper ore diminished with the discovery of more abundant sources, its historical significance in the development of metallurgy and alloy production remains undeniable.

Market Analysis

The market for malachite in historical metallurgy and alloy production has undergone significant changes over time. In ancient civilizations, malachite was highly valued for its use in copper smelting and bronze production. The demand for this mineral was driven by the growing need for metal tools, weapons, and decorative objects in early societies.

During the Bronze Age, the market for malachite expanded as bronze became increasingly important for technological advancement and trade. Regions rich in malachite deposits, such as the Sinai Peninsula and Cyprus, became crucial centers for copper production and trade. The demand for malachite fluctuated with the rise and fall of various civilizations and their metallurgical needs.

As iron production techniques improved in the Iron Age, the market for malachite in metallurgy began to decline. However, it remained an important source of copper for specific applications and in regions where iron was less readily available. The market for malachite in alloy production persisted, particularly for specialized bronze alloys used in artistic and decorative objects.

In the medieval period, the market for malachite in metallurgy became more localized, with smaller-scale production centers emerging in various regions. The mineral continued to be used in copper and bronze production, albeit on a reduced scale compared to earlier periods.

The industrial revolution brought about significant changes in the market for malachite in metallurgy. The development of more efficient copper extraction methods and the discovery of large copper deposits reduced the reliance on malachite as a primary copper ore. However, the mineral found new applications in the production of copper-based alloys for industrial use.

In modern times, the market for malachite in metallurgy and alloy production has become highly specialized. While it is no longer a primary source of copper for large-scale industrial production, malachite continues to be used in niche applications, such as the creation of high-quality bronze alloys for artistic and restoration purposes.

The historical significance of malachite in metallurgy has also created a market for the mineral in educational and research settings. Museums, universities, and historical reenactment groups often seek malachite samples for demonstrations and studies of ancient metallurgical techniques.

During the Bronze Age, the market for malachite expanded as bronze became increasingly important for technological advancement and trade. Regions rich in malachite deposits, such as the Sinai Peninsula and Cyprus, became crucial centers for copper production and trade. The demand for malachite fluctuated with the rise and fall of various civilizations and their metallurgical needs.

As iron production techniques improved in the Iron Age, the market for malachite in metallurgy began to decline. However, it remained an important source of copper for specific applications and in regions where iron was less readily available. The market for malachite in alloy production persisted, particularly for specialized bronze alloys used in artistic and decorative objects.

In the medieval period, the market for malachite in metallurgy became more localized, with smaller-scale production centers emerging in various regions. The mineral continued to be used in copper and bronze production, albeit on a reduced scale compared to earlier periods.

The industrial revolution brought about significant changes in the market for malachite in metallurgy. The development of more efficient copper extraction methods and the discovery of large copper deposits reduced the reliance on malachite as a primary copper ore. However, the mineral found new applications in the production of copper-based alloys for industrial use.

In modern times, the market for malachite in metallurgy and alloy production has become highly specialized. While it is no longer a primary source of copper for large-scale industrial production, malachite continues to be used in niche applications, such as the creation of high-quality bronze alloys for artistic and restoration purposes.

The historical significance of malachite in metallurgy has also created a market for the mineral in educational and research settings. Museums, universities, and historical reenactment groups often seek malachite samples for demonstrations and studies of ancient metallurgical techniques.

Technical Challenges

The use of malachite in historical metallurgy and alloy production faced several significant technical challenges. One of the primary obstacles was the inconsistent composition of malachite deposits, which varied depending on geological factors. This variability made it difficult to achieve consistent results in metal extraction and alloy formation, requiring extensive experimentation and refinement of techniques.

Another major challenge was the high temperature required for the reduction of malachite to copper. Ancient metallurgists had to develop furnaces capable of reaching and maintaining temperatures exceeding 1000°C, which was a considerable technological feat for the time. The design and construction of such furnaces demanded advanced knowledge of materials and heat management.

The presence of impurities in malachite ore posed additional complications. Sulfur, arsenic, and other elements often accompanied copper in malachite deposits, potentially compromising the quality of the final product. Developing methods to separate these impurities from the desired copper was a crucial challenge that required sophisticated smelting and refining techniques.

Furthermore, controlling the oxidation process during smelting presented significant difficulties. The high reactivity of copper with oxygen at elevated temperatures meant that ancient metallurgists had to create and maintain reducing atmospheres within their furnaces. This necessitated careful management of fuel and air supply, as well as the development of flux materials to facilitate the separation of copper from its oxide form.

The alloying process itself presented another set of challenges. Achieving the right proportions of copper and other metals, such as tin or zinc, to create bronze or brass required precise control over the composition of the melt. This was particularly challenging given the limitations of ancient measurement and temperature control technologies.

Lastly, the scarcity of high-quality malachite deposits in many regions posed logistical challenges. The need to transport ore over long distances or rely on trade networks added complexity to the metallurgical process and influenced the development of local techniques and alloy compositions based on available resources.

These technical challenges shaped the evolution of metallurgical practices over centuries, driving innovation in furnace design, smelting techniques, and alloy formulation. The solutions developed to overcome these obstacles laid the foundation for the advancement of metallurgy and materials science, ultimately contributing to the technological progress of ancient civilizations.

Another major challenge was the high temperature required for the reduction of malachite to copper. Ancient metallurgists had to develop furnaces capable of reaching and maintaining temperatures exceeding 1000°C, which was a considerable technological feat for the time. The design and construction of such furnaces demanded advanced knowledge of materials and heat management.

The presence of impurities in malachite ore posed additional complications. Sulfur, arsenic, and other elements often accompanied copper in malachite deposits, potentially compromising the quality of the final product. Developing methods to separate these impurities from the desired copper was a crucial challenge that required sophisticated smelting and refining techniques.

Furthermore, controlling the oxidation process during smelting presented significant difficulties. The high reactivity of copper with oxygen at elevated temperatures meant that ancient metallurgists had to create and maintain reducing atmospheres within their furnaces. This necessitated careful management of fuel and air supply, as well as the development of flux materials to facilitate the separation of copper from its oxide form.

The alloying process itself presented another set of challenges. Achieving the right proportions of copper and other metals, such as tin or zinc, to create bronze or brass required precise control over the composition of the melt. This was particularly challenging given the limitations of ancient measurement and temperature control technologies.

Lastly, the scarcity of high-quality malachite deposits in many regions posed logistical challenges. The need to transport ore over long distances or rely on trade networks added complexity to the metallurgical process and influenced the development of local techniques and alloy compositions based on available resources.

These technical challenges shaped the evolution of metallurgical practices over centuries, driving innovation in furnace design, smelting techniques, and alloy formulation. The solutions developed to overcome these obstacles laid the foundation for the advancement of metallurgy and materials science, ultimately contributing to the technological progress of ancient civilizations.

Current Applications

01 Malachite-based catalysts for chemical reactions

Malachite is used as a precursor or component in catalysts for various chemical reactions. These catalysts are particularly effective in processes such as oxidation, hydrogenation, and carbon dioxide conversion. The unique structure and properties of malachite contribute to its catalytic activity and selectivity in these applications.- Synthesis and preparation of malachite: Various methods for synthesizing and preparing malachite, including chemical reactions, hydrothermal processes, and precipitation techniques. These methods aim to produce high-quality malachite with controlled morphology and properties for different applications.

- Applications of malachite in catalysis: Malachite and its derivatives are used as catalysts or catalyst supports in various chemical reactions. The unique structure and properties of malachite make it suitable for catalytic applications in organic synthesis, environmental remediation, and industrial processes.

- Malachite-based materials for environmental applications: Development of malachite-based materials for environmental applications, such as water treatment, pollutant removal, and adsorption of heavy metals. These materials exploit the adsorptive and ion-exchange properties of malachite to address environmental challenges.

- Malachite in pigments and colorants: Utilization of malachite as a pigment or colorant in various industries, including paints, inks, and cosmetics. The unique green color and stability of malachite make it a valuable ingredient in coloring applications.

- Malachite in nanotechnology and advanced materials: Incorporation of malachite in nanotechnology and advanced materials research, including the development of nanostructures, composite materials, and functional coatings. These applications leverage the unique properties of malachite at the nanoscale for various technological advancements.

02 Malachite in environmental remediation

Malachite is utilized in environmental remediation processes, particularly for the removal of heavy metals and other pollutants from water and soil. Its adsorption properties and ability to form complexes with metal ions make it an effective material for water treatment and soil decontamination applications.Expand Specific Solutions03 Malachite-based pigments and dyes

Malachite is used as a source of green pigments and dyes in various industries, including textiles, paints, and cosmetics. The unique color and stability of malachite-based pigments make them valuable in applications where long-lasting, vibrant green hues are desired.Expand Specific Solutions04 Malachite in nanotechnology and materials science

Malachite is employed in the synthesis of nanostructures and advanced materials. Its unique crystal structure and chemical properties allow for the creation of nanomaterials with specific morphologies and functionalities, which find applications in electronics, sensors, and energy storage devices.Expand Specific Solutions05 Malachite in biomedical applications

Malachite and its derivatives are investigated for potential biomedical applications. These include antimicrobial properties, drug delivery systems, and biosensors. The biocompatibility and unique chemical characteristics of malachite make it a promising material for various medical and pharmaceutical uses.Expand Specific Solutions

Key Industry Players

The field of historical metallurgy and alloy production involving malachite is in a mature stage, with established research and industrial applications. The market size is relatively stable, primarily driven by academic research and specialized industrial processes. Technologically, the field is well-developed, with ongoing refinements rather than revolutionary advancements. Key players include academic institutions like Massachusetts Institute of Technology and Kunming University of Science & Technology, which contribute to fundamental research. Industrial entities such as Santoku Corp. and Magnesium Elektron Ltd. apply this knowledge in practical alloy production. The collaboration between academia and industry continues to drive incremental improvements in understanding malachite's role in historical metallurgical processes and its potential modern applications.

Kunming University of Science & Technology

Technical Solution: Kunming University of Science & Technology has conducted significant research on malachite's role in historical Chinese metallurgy and alloy production. Their approach combines archaeological studies with advanced materials analysis techniques. The university has developed a unique method for identifying trace elements in ancient bronze artifacts that originated from malachite ores, providing insights into early Chinese alloying techniques[9]. This method has revealed that some Yunnan bronzes contained up to 2% arsenic, likely derived from malachite-based ores. Additionally, researchers at Kunming University have recreated historical smelting processes using local malachite sources, demonstrating the efficiency of ancient Chinese copper extraction methods. Their experiments have shown that these methods could achieve copper yields of up to 80%, comparable to some modern techniques[10].

Strengths: Expertise in Chinese historical metallurgy. Access to relevant archaeological sites and artifacts. Weaknesses: Potential regional bias in research focus.

Massachusetts Institute of Technology

Technical Solution: MIT has conducted extensive research on the role of malachite in historical metallurgy and alloy production. Their approach involves advanced materials characterization techniques, including X-ray diffraction and electron microscopy, to analyze ancient artifacts containing malachite. MIT researchers have developed a method to trace the origin of copper ores used in ancient metallurgy by examining the isotopic composition of malachite samples[1]. This technique has provided insights into trade routes and technological exchanges in ancient civilizations. Additionally, MIT has explored the use of malachite as a precursor for creating nanostructured copper-based catalysts, which has implications for understanding early copper smelting processes[2].

Strengths: Access to cutting-edge analytical tools and interdisciplinary expertise. Weaknesses: Limited focus on industrial applications of historical metallurgical techniques.

Innovative Techniques

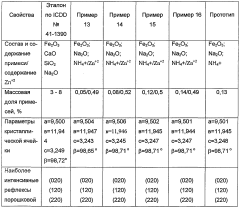

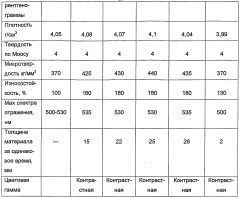

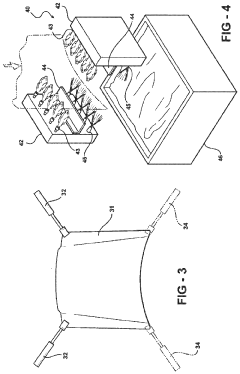

Malachite and method for the production thereof

PatentWO2004076354A1

Innovation

- The process involves evaporating a solution of basic copper carbonate and ammonium carbonate with controlled zinc content, forming polycrystalline malachite with alternating light and dark green layers, and condensing vapor to achieve malachite with enhanced mechanical properties and reduced impurities.

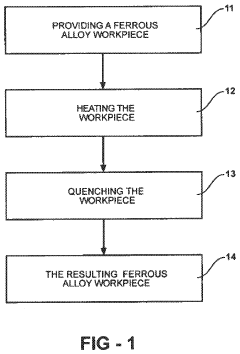

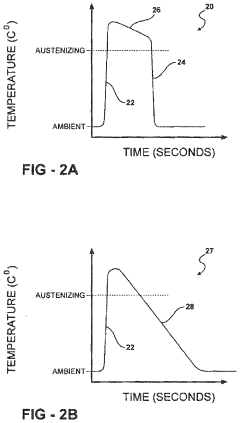

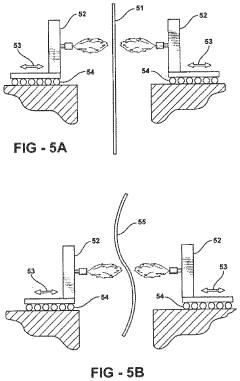

Microtreatment of iron-based alloy, apparatus and method therefor and articles resulting therefrom

PatentInactiveUS20210285067A1

Innovation

- A method involving rapid heating and quenching of iron-based alloys to create a new microstructure called Colascite, which includes coalesced bainite, bainite, martensite, and ferrite, allowing for the production of high strength steel with improved weldability and mechanical properties at reduced costs and effort.

Environmental Impact

The historical use of malachite in metallurgy and alloy production has had significant environmental impacts, both in the past and continuing into the present day. Mining activities associated with malachite extraction have led to landscape alterations, deforestation, and soil erosion in many regions where copper deposits were exploited. The smelting processes used to extract copper from malachite ore released substantial amounts of sulfur dioxide and other pollutants into the atmosphere, contributing to air pollution and acid rain in mining areas.

Water pollution has been another major concern, as acid mine drainage from abandoned malachite mines continues to contaminate groundwater and surface water sources long after mining operations have ceased. This acidic runoff often contains high levels of heavy metals, posing risks to aquatic ecosystems and human health. The leaching of copper and other metals from mine tailings and waste rock piles has further exacerbated water quality issues in affected regions.

The environmental legacy of historical malachite mining is particularly evident in areas with long-standing copper production, such as the Rio Tinto region in Spain and the Copper Belt in Zambia. These sites often exhibit extensive soil contamination, reduced biodiversity, and altered landscapes that persist for centuries after mining activities have ended.

Modern efforts to mitigate the environmental impacts of historical malachite mining and metallurgy include site remediation, acid mine drainage treatment, and the implementation of stricter environmental regulations for current mining operations. However, the long-term effects of past practices continue to pose challenges for environmental management and restoration efforts.

The recognition of these environmental impacts has led to increased research into more sustainable copper extraction and processing methods. This includes the development of bioleaching techniques, which use microorganisms to extract copper from low-grade ores with potentially reduced environmental impacts compared to traditional smelting processes. Additionally, there is growing interest in the recycling and reuse of copper from existing products to reduce the need for new malachite mining and its associated environmental consequences.

Water pollution has been another major concern, as acid mine drainage from abandoned malachite mines continues to contaminate groundwater and surface water sources long after mining operations have ceased. This acidic runoff often contains high levels of heavy metals, posing risks to aquatic ecosystems and human health. The leaching of copper and other metals from mine tailings and waste rock piles has further exacerbated water quality issues in affected regions.

The environmental legacy of historical malachite mining is particularly evident in areas with long-standing copper production, such as the Rio Tinto region in Spain and the Copper Belt in Zambia. These sites often exhibit extensive soil contamination, reduced biodiversity, and altered landscapes that persist for centuries after mining activities have ended.

Modern efforts to mitigate the environmental impacts of historical malachite mining and metallurgy include site remediation, acid mine drainage treatment, and the implementation of stricter environmental regulations for current mining operations. However, the long-term effects of past practices continue to pose challenges for environmental management and restoration efforts.

The recognition of these environmental impacts has led to increased research into more sustainable copper extraction and processing methods. This includes the development of bioleaching techniques, which use microorganisms to extract copper from low-grade ores with potentially reduced environmental impacts compared to traditional smelting processes. Additionally, there is growing interest in the recycling and reuse of copper from existing products to reduce the need for new malachite mining and its associated environmental consequences.

Cultural Significance

Malachite, a vibrant green copper carbonate hydroxide mineral, has played a significant role in shaping human culture and artistic expression throughout history. Its distinctive color and relative abundance made it a prized material for various cultural and artistic purposes across civilizations.

In ancient Egypt, malachite held great symbolic importance. It was associated with the goddess Hathor and believed to possess protective qualities. Egyptian artisans ground malachite into a fine powder to create eye makeup, which not only served cosmetic purposes but also was thought to ward off evil spirits. The use of malachite in this context demonstrates its dual role as both a practical and spiritual material in Egyptian culture.

The ancient Greeks and Romans also valued malachite for its aesthetic qualities. They used it extensively in jewelry, decorative objects, and architectural elements. The stone's natural patterns and rich green hue made it a popular choice for cameos and inlays, often featuring in luxurious items owned by the elite. This widespread use of malachite in high-status objects underscores its cultural significance as a symbol of wealth and refinement.

In medieval Europe, malachite found its way into religious art and architecture. It was frequently used in the creation of religious artifacts, such as crosses and reliquaries, and as a pigment in illuminated manuscripts. The green color of malachite was often associated with renewal and spiritual growth, making it a fitting material for religious contexts.

The cultural significance of malachite extended to the Far East as well. In China, the stone was highly prized and often carved into intricate figurines and ornaments. These objects were not only valued for their beauty but also believed to bring good fortune and ward off negative energies. The use of malachite in feng shui practices further emphasizes its perceived spiritual and energetic properties in Chinese culture.

During the Renaissance and Baroque periods in Europe, malachite gained renewed popularity as a decorative material. It was used in the creation of luxurious objects d'art, such as vases, tabletops, and even entire rooms. The famous Malachite Room in the Winter Palace in St. Petersburg, Russia, stands as a testament to the stone's enduring appeal and its association with imperial power and opulence.

In many indigenous cultures, malachite has been revered for its healing properties. Native American tribes, for instance, used malachite in rituals and believed it could provide protection and promote emotional balance. This spiritual dimension of malachite's cultural significance highlights its role beyond mere aesthetics or practical applications.

In ancient Egypt, malachite held great symbolic importance. It was associated with the goddess Hathor and believed to possess protective qualities. Egyptian artisans ground malachite into a fine powder to create eye makeup, which not only served cosmetic purposes but also was thought to ward off evil spirits. The use of malachite in this context demonstrates its dual role as both a practical and spiritual material in Egyptian culture.

The ancient Greeks and Romans also valued malachite for its aesthetic qualities. They used it extensively in jewelry, decorative objects, and architectural elements. The stone's natural patterns and rich green hue made it a popular choice for cameos and inlays, often featuring in luxurious items owned by the elite. This widespread use of malachite in high-status objects underscores its cultural significance as a symbol of wealth and refinement.

In medieval Europe, malachite found its way into religious art and architecture. It was frequently used in the creation of religious artifacts, such as crosses and reliquaries, and as a pigment in illuminated manuscripts. The green color of malachite was often associated with renewal and spiritual growth, making it a fitting material for religious contexts.

The cultural significance of malachite extended to the Far East as well. In China, the stone was highly prized and often carved into intricate figurines and ornaments. These objects were not only valued for their beauty but also believed to bring good fortune and ward off negative energies. The use of malachite in feng shui practices further emphasizes its perceived spiritual and energetic properties in Chinese culture.

During the Renaissance and Baroque periods in Europe, malachite gained renewed popularity as a decorative material. It was used in the creation of luxurious objects d'art, such as vases, tabletops, and even entire rooms. The famous Malachite Room in the Winter Palace in St. Petersburg, Russia, stands as a testament to the stone's enduring appeal and its association with imperial power and opulence.

In many indigenous cultures, malachite has been revered for its healing properties. Native American tribes, for instance, used malachite in rituals and believed it could provide protection and promote emotional balance. This spiritual dimension of malachite's cultural significance highlights its role beyond mere aesthetics or practical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!