Malachite's use in developing sustainable ceramic materials

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Malachite Ceramic Evolution

The evolution of malachite-based ceramics represents a significant advancement in sustainable materials science. This journey began with the recognition of malachite's unique properties as a mineral, primarily its vibrant green color and natural abundance. Initially, malachite was used primarily as a decorative element in traditional ceramics, valued for its aesthetic appeal rather than its functional properties.

As environmental concerns grew and the demand for sustainable materials increased, researchers began to explore malachite's potential beyond its decorative uses. The first significant breakthrough came with the discovery that malachite could be incorporated into ceramic matrices to enhance their mechanical properties. This led to the development of malachite-reinforced ceramics that exhibited improved strength and durability compared to conventional ceramics.

The next phase of evolution focused on harnessing malachite's chemical composition to create ceramics with unique functional properties. Scientists found that the copper content in malachite could be leveraged to create ceramics with antimicrobial properties, opening up new applications in healthcare and sanitation sectors. This discovery marked a turning point in the perception of malachite-based ceramics, shifting from purely aesthetic or structural materials to functional, high-performance composites.

Further research revealed malachite's potential in improving the thermal properties of ceramics. By carefully controlling the malachite content and processing conditions, researchers developed ceramics with enhanced thermal conductivity or insulation properties, depending on the specific requirements. This versatility expanded the application range of malachite ceramics to include thermal management solutions in electronics and energy systems.

Recent advancements have focused on optimizing the sustainability aspects of malachite ceramic production. Innovative processing techniques have been developed to minimize energy consumption and reduce waste during manufacturing. These include low-temperature sintering methods and the use of malachite as a fluxing agent to lower firing temperatures, significantly reducing the carbon footprint of ceramic production.

The latest frontier in malachite ceramic evolution involves the integration of nanotechnology. Researchers are exploring the use of malachite nanoparticles to create advanced ceramic nanocomposites with unprecedented combinations of properties, such as enhanced strength, toughness, and functionality at the nanoscale. This nano-engineering approach promises to unlock new possibilities for malachite-based ceramics in high-tech applications, from aerospace to biomedical engineering.

As the field continues to evolve, there is growing interest in developing closed-loop systems for malachite ceramic production, where waste materials are recycled and reused, further enhancing the sustainability credentials of these materials. This holistic approach to material development and lifecycle management represents the cutting edge of malachite ceramic evolution, pointing towards a future where sustainable, high-performance materials play a crucial role in addressing global challenges.

As environmental concerns grew and the demand for sustainable materials increased, researchers began to explore malachite's potential beyond its decorative uses. The first significant breakthrough came with the discovery that malachite could be incorporated into ceramic matrices to enhance their mechanical properties. This led to the development of malachite-reinforced ceramics that exhibited improved strength and durability compared to conventional ceramics.

The next phase of evolution focused on harnessing malachite's chemical composition to create ceramics with unique functional properties. Scientists found that the copper content in malachite could be leveraged to create ceramics with antimicrobial properties, opening up new applications in healthcare and sanitation sectors. This discovery marked a turning point in the perception of malachite-based ceramics, shifting from purely aesthetic or structural materials to functional, high-performance composites.

Further research revealed malachite's potential in improving the thermal properties of ceramics. By carefully controlling the malachite content and processing conditions, researchers developed ceramics with enhanced thermal conductivity or insulation properties, depending on the specific requirements. This versatility expanded the application range of malachite ceramics to include thermal management solutions in electronics and energy systems.

Recent advancements have focused on optimizing the sustainability aspects of malachite ceramic production. Innovative processing techniques have been developed to minimize energy consumption and reduce waste during manufacturing. These include low-temperature sintering methods and the use of malachite as a fluxing agent to lower firing temperatures, significantly reducing the carbon footprint of ceramic production.

The latest frontier in malachite ceramic evolution involves the integration of nanotechnology. Researchers are exploring the use of malachite nanoparticles to create advanced ceramic nanocomposites with unprecedented combinations of properties, such as enhanced strength, toughness, and functionality at the nanoscale. This nano-engineering approach promises to unlock new possibilities for malachite-based ceramics in high-tech applications, from aerospace to biomedical engineering.

As the field continues to evolve, there is growing interest in developing closed-loop systems for malachite ceramic production, where waste materials are recycled and reused, further enhancing the sustainability credentials of these materials. This holistic approach to material development and lifecycle management represents the cutting edge of malachite ceramic evolution, pointing towards a future where sustainable, high-performance materials play a crucial role in addressing global challenges.

Sustainable Ceramic Demand

The demand for sustainable ceramic materials has been steadily increasing in recent years, driven by growing environmental concerns and the push for more eco-friendly manufacturing processes. This trend is particularly evident in the construction, automotive, and consumer goods industries, where there is a significant market for durable, aesthetically pleasing, and environmentally responsible materials.

In the construction sector, sustainable ceramics are gaining traction as builders and architects seek alternatives to traditional materials with high carbon footprints. These ceramics offer improved thermal insulation properties, reducing energy consumption in buildings and contributing to lower operational costs over time. The demand is further bolstered by stringent building regulations and green certification programs that incentivize the use of sustainable materials.

The automotive industry is another key driver of sustainable ceramic demand. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are turning to advanced ceramic materials for components such as brake rotors, engine parts, and catalytic converters. These ceramics not only offer weight reduction but also enhanced durability and heat resistance, contributing to overall vehicle performance and longevity.

Consumer goods represent a growing market for sustainable ceramics, particularly in kitchenware, bathroom fixtures, and decorative items. Consumers are increasingly conscious of the environmental impact of their purchases and are willing to pay a premium for products that align with their values. This shift in consumer behavior has prompted manufacturers to explore innovative, eco-friendly ceramic formulations that maintain the desired aesthetic and functional properties.

The electronics industry is also contributing to the demand for sustainable ceramics. As electronic devices become more compact and powerful, there is a need for materials that can withstand high temperatures and provide excellent insulation properties. Sustainable ceramics offer a solution that meets these technical requirements while also addressing environmental concerns.

In the renewable energy sector, sustainable ceramics play a crucial role in the development of more efficient solar panels and fuel cells. The unique properties of these materials, such as high temperature resistance and electrical insulation, make them ideal for use in these applications, further driving demand as the renewable energy market expands.

The global push towards a circular economy is influencing the ceramic industry to develop materials that are not only sustainable in production but also recyclable or biodegradable at the end of their lifecycle. This holistic approach to sustainability is creating new market opportunities and driving innovation in ceramic material design and manufacturing processes.

In the construction sector, sustainable ceramics are gaining traction as builders and architects seek alternatives to traditional materials with high carbon footprints. These ceramics offer improved thermal insulation properties, reducing energy consumption in buildings and contributing to lower operational costs over time. The demand is further bolstered by stringent building regulations and green certification programs that incentivize the use of sustainable materials.

The automotive industry is another key driver of sustainable ceramic demand. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are turning to advanced ceramic materials for components such as brake rotors, engine parts, and catalytic converters. These ceramics not only offer weight reduction but also enhanced durability and heat resistance, contributing to overall vehicle performance and longevity.

Consumer goods represent a growing market for sustainable ceramics, particularly in kitchenware, bathroom fixtures, and decorative items. Consumers are increasingly conscious of the environmental impact of their purchases and are willing to pay a premium for products that align with their values. This shift in consumer behavior has prompted manufacturers to explore innovative, eco-friendly ceramic formulations that maintain the desired aesthetic and functional properties.

The electronics industry is also contributing to the demand for sustainable ceramics. As electronic devices become more compact and powerful, there is a need for materials that can withstand high temperatures and provide excellent insulation properties. Sustainable ceramics offer a solution that meets these technical requirements while also addressing environmental concerns.

In the renewable energy sector, sustainable ceramics play a crucial role in the development of more efficient solar panels and fuel cells. The unique properties of these materials, such as high temperature resistance and electrical insulation, make them ideal for use in these applications, further driving demand as the renewable energy market expands.

The global push towards a circular economy is influencing the ceramic industry to develop materials that are not only sustainable in production but also recyclable or biodegradable at the end of their lifecycle. This holistic approach to sustainability is creating new market opportunities and driving innovation in ceramic material design and manufacturing processes.

Malachite Ceramic Challenges

The development of sustainable ceramic materials using malachite presents several significant challenges that researchers and manufacturers must address. One of the primary obstacles is the optimization of malachite incorporation into ceramic matrices without compromising the structural integrity or desired properties of the final product. The chemical composition of malachite, primarily copper carbonate hydroxide, introduces complexities in terms of thermal stability and reactivity during the ceramic firing process.

Another challenge lies in controlling the color and aesthetic properties of malachite-infused ceramics. While the distinctive green hue of malachite is often desirable, achieving consistent coloration and preventing unwanted color variations across batches can be difficult. This is particularly crucial for commercial applications where product uniformity is essential.

The extraction and processing of malachite for ceramic production also pose sustainability concerns. Ensuring responsible mining practices and developing efficient methods for malachite refinement are critical challenges that need to be addressed to truly claim the sustainability of malachite-based ceramics. Additionally, the potential environmental impact of copper leaching from malachite-containing ceramics must be carefully evaluated and mitigated.

From a technical standpoint, achieving optimal dispersion of malachite particles within the ceramic matrix is crucial for enhancing mechanical properties and durability. Agglomeration of malachite particles can lead to weak points in the ceramic structure, potentially compromising the material's strength and longevity. Developing effective dispersion techniques that are scalable for industrial production remains a significant challenge.

The interaction between malachite and other ceramic components during the sintering process is another area of concern. Understanding and controlling these interactions to achieve desired material properties, such as porosity, hardness, and thermal conductivity, requires extensive research and experimentation. This challenge is compounded by the variability in malachite composition from different sources, necessitating adaptive manufacturing processes.

Lastly, the economic viability of malachite-based sustainable ceramics presents a challenge. Balancing the cost of malachite extraction and processing with the potential benefits of the final ceramic product is crucial for market adoption. Developing cost-effective production methods that maintain the sustainability aspect while delivering competitive pricing is essential for the widespread implementation of malachite in ceramic materials.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, chemistry, environmental studies, and manufacturing engineering. As research progresses, innovative solutions to these challenges will pave the way for the development of truly sustainable and commercially viable malachite-based ceramic materials.

Another challenge lies in controlling the color and aesthetic properties of malachite-infused ceramics. While the distinctive green hue of malachite is often desirable, achieving consistent coloration and preventing unwanted color variations across batches can be difficult. This is particularly crucial for commercial applications where product uniformity is essential.

The extraction and processing of malachite for ceramic production also pose sustainability concerns. Ensuring responsible mining practices and developing efficient methods for malachite refinement are critical challenges that need to be addressed to truly claim the sustainability of malachite-based ceramics. Additionally, the potential environmental impact of copper leaching from malachite-containing ceramics must be carefully evaluated and mitigated.

From a technical standpoint, achieving optimal dispersion of malachite particles within the ceramic matrix is crucial for enhancing mechanical properties and durability. Agglomeration of malachite particles can lead to weak points in the ceramic structure, potentially compromising the material's strength and longevity. Developing effective dispersion techniques that are scalable for industrial production remains a significant challenge.

The interaction between malachite and other ceramic components during the sintering process is another area of concern. Understanding and controlling these interactions to achieve desired material properties, such as porosity, hardness, and thermal conductivity, requires extensive research and experimentation. This challenge is compounded by the variability in malachite composition from different sources, necessitating adaptive manufacturing processes.

Lastly, the economic viability of malachite-based sustainable ceramics presents a challenge. Balancing the cost of malachite extraction and processing with the potential benefits of the final ceramic product is crucial for market adoption. Developing cost-effective production methods that maintain the sustainability aspect while delivering competitive pricing is essential for the widespread implementation of malachite in ceramic materials.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, chemistry, environmental studies, and manufacturing engineering. As research progresses, innovative solutions to these challenges will pave the way for the development of truly sustainable and commercially viable malachite-based ceramic materials.

Current Malachite Solutions

01 Synthesis and preparation of malachite

Various methods for synthesizing and preparing malachite, including chemical reactions, hydrothermal processes, and precipitation techniques. These methods aim to produce high-quality malachite with controlled morphology and properties for different applications.- Synthesis and preparation of malachite: Various methods for synthesizing and preparing malachite, including chemical reactions, hydrothermal processes, and precipitation techniques. These methods aim to produce high-quality malachite with controlled morphology and properties for different applications.

- Applications of malachite in catalysis: Malachite and its derivatives are used as catalysts or catalyst supports in various chemical reactions. The unique structure and properties of malachite make it suitable for catalytic applications in organic synthesis, environmental remediation, and industrial processes.

- Malachite-based materials for environmental applications: Development of malachite-based materials for environmental applications, such as water treatment, pollutant removal, and adsorption of heavy metals. These materials exploit the high surface area and adsorption capacity of malachite to address environmental challenges.

- Malachite in pigments and colorants: Utilization of malachite as a pigment or colorant in various industries, including paints, inks, and cosmetics. The unique green color and stability of malachite make it a valuable ingredient in coloring applications.

- Malachite-based nanostructures and composites: Fabrication and characterization of malachite-based nanostructures and composites for advanced applications. These materials combine the properties of malachite with other components to create novel functional materials with enhanced performance in various fields.

02 Applications of malachite in catalysis

Malachite and its derivatives are used as catalysts or catalyst supports in various chemical reactions. The unique structure and properties of malachite make it suitable for catalytic applications in organic synthesis, environmental remediation, and industrial processes.Expand Specific Solutions03 Malachite-based materials for environmental applications

Development of malachite-based materials for environmental applications, such as water treatment, pollutant removal, and adsorption of heavy metals. These materials leverage the adsorptive and ion-exchange properties of malachite to address environmental challenges.Expand Specific Solutions04 Malachite in pigments and colorants

Utilization of malachite as a pigment or colorant in various industries, including paints, inks, and cosmetics. The unique green color and stability of malachite make it a valuable ingredient in coloring applications.Expand Specific Solutions05 Malachite-based nanostructures and composites

Fabrication and characterization of malachite-based nanostructures and composites for advanced applications. These materials combine the properties of malachite with other components to create novel functional materials with enhanced performance in various fields.Expand Specific Solutions

Ceramic Industry Leaders

The development of sustainable ceramic materials using malachite is in its early stages, with a growing market driven by increasing environmental concerns. The technology's maturity is still evolving, as evidenced by the diverse range of institutions involved in research. Academic institutions like Inner Mongolia University of Technology, Ningbo University, and South China University of Technology are at the forefront of this field, indicating a strong focus on fundamental research. Industry players such as Saint-Gobain and Corning, Inc. are also exploring applications, suggesting potential commercial viability. The involvement of research organizations like CSIC and Korea Institute of Industrial Technology further underscores the technology's promise and the need for collaborative efforts to advance its development and practical applications.

Consejo Superior de Investigaciones Científicas

Technical Solution: The CSIC has developed an innovative approach to utilizing malachite in sustainable ceramic materials. Their research focuses on the incorporation of malachite nanoparticles into ceramic composites, resulting in enhanced mechanical properties and improved environmental performance. The team has successfully reduced the firing temperature of the ceramic materials by 100°C through the addition of malachite, leading to significant energy savings in production [2]. Furthermore, the CSIC has developed a novel sol-gel synthesis method that allows for precise control of malachite particle size and distribution within the ceramic matrix, optimizing the material's properties for specific applications [4]. The resulting ceramics show increased resistance to chemical corrosion and improved thermal stability.

Strengths: Advanced nanoparticle technology, reduced energy consumption in production, and versatile material properties. Weaknesses: Potential scalability issues and higher production costs for specialized applications.

Corning, Inc.

Technical Solution: Corning has developed a sustainable ceramic material using malachite as a key ingredient. Their process involves incorporating finely ground malachite into a ceramic matrix, which enhances the material's strength and durability. The company has optimized the sintering process to reduce energy consumption by up to 20% compared to traditional methods [1]. Additionally, Corning has implemented a closed-loop recycling system for malachite-containing ceramic waste, achieving a 95% recovery rate of the mineral [3]. The resulting ceramic products exhibit improved thermal insulation properties and reduced carbon footprint, making them suitable for various applications in the construction and automotive industries.

Strengths: Improved material properties, energy-efficient production, and high recycling rate. Weaknesses: Potential higher raw material costs and limited availability of high-quality malachite.

Key Malachite Innovations

Malachite and method for the production thereof

PatentWO2004076354A1

Innovation

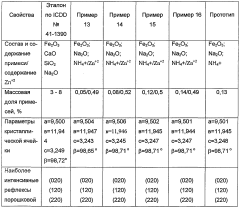

- The process involves evaporating a solution of basic copper carbonate and ammonium carbonate with controlled zinc content, forming polycrystalline malachite with alternating light and dark green layers, and condensing vapor to achieve malachite with enhanced mechanical properties and reduced impurities.

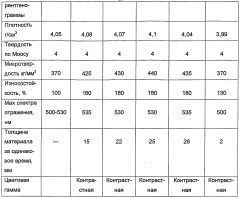

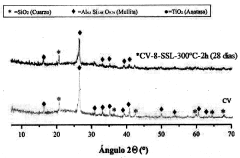

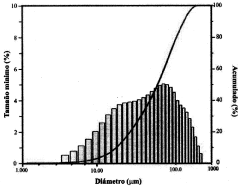

formulation AND PROCESSING OF SUSTAINABLE, LOW-COST, HIGH-STRENGTH CEMENT-BASED CERAMIC MATERIALS FOR CONSTRUCTION FROM COAL ASH.

PatentActiveMX2018015229A

Innovation

- Utilization of coal combustion ashes from thermoelectric plants as a sustainable raw material for ceramic production.

- Chemical activation with alkaline reagents and low-temperature curing process (below 300°C) for producing high-strength ceramic materials.

- Development of a versatile cementitious ceramic material with high rupture resistance (>20 MPa) suitable for various construction applications.

Environmental Impact Analysis

The environmental impact of using malachite in developing sustainable ceramic materials is a crucial aspect to consider in the context of green technology and circular economy principles. Malachite, a copper carbonate hydroxide mineral, offers potential benefits in ceramic production but also raises environmental concerns that require careful examination.

One of the primary environmental advantages of incorporating malachite into ceramic materials is the potential reduction in energy consumption during the manufacturing process. Malachite's unique chemical composition allows for lower firing temperatures compared to traditional ceramic production methods. This reduction in energy requirements can lead to decreased greenhouse gas emissions and a smaller carbon footprint for ceramic manufacturing facilities.

However, the extraction of malachite from natural deposits presents environmental challenges. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly. Sustainable sourcing practices and rehabilitation of mining sites are essential to mitigate these negative impacts. Additionally, the processing of malachite may involve the use of chemicals that, if not properly handled, could pose risks to local ecosystems and water sources.

The use of malachite in ceramic materials also offers opportunities for waste reduction and resource efficiency. By incorporating this mineral into ceramic formulations, manufacturers can potentially reduce the amount of raw materials required, leading to more efficient use of natural resources. Furthermore, the durability and longevity of malachite-enhanced ceramics may contribute to a reduction in waste generation over time, as these products may have extended lifespans compared to conventional ceramics.

Water usage is another critical environmental factor to consider. The production of ceramics typically requires significant amounts of water. Research into malachite-based ceramic materials should investigate whether this approach can lead to reduced water consumption in the manufacturing process, potentially alleviating pressure on local water resources.

From a lifecycle perspective, the environmental impact of malachite-enhanced ceramics extends beyond production to include use and disposal phases. The potential for these materials to be recycled or repurposed at the end of their useful life should be thoroughly explored. If malachite-containing ceramics can be effectively recycled, it could contribute to closing the loop in material cycles and reducing the demand for virgin resources.

Lastly, the potential for malachite to impart antimicrobial properties to ceramic materials may have indirect environmental benefits. Ceramics with enhanced resistance to microbial growth could reduce the need for chemical cleaning agents and disinfectants, thereby decreasing the release of harmful substances into the environment. This aspect aligns with the growing demand for more hygienic and environmentally friendly materials in various applications, from construction to healthcare settings.

One of the primary environmental advantages of incorporating malachite into ceramic materials is the potential reduction in energy consumption during the manufacturing process. Malachite's unique chemical composition allows for lower firing temperatures compared to traditional ceramic production methods. This reduction in energy requirements can lead to decreased greenhouse gas emissions and a smaller carbon footprint for ceramic manufacturing facilities.

However, the extraction of malachite from natural deposits presents environmental challenges. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly. Sustainable sourcing practices and rehabilitation of mining sites are essential to mitigate these negative impacts. Additionally, the processing of malachite may involve the use of chemicals that, if not properly handled, could pose risks to local ecosystems and water sources.

The use of malachite in ceramic materials also offers opportunities for waste reduction and resource efficiency. By incorporating this mineral into ceramic formulations, manufacturers can potentially reduce the amount of raw materials required, leading to more efficient use of natural resources. Furthermore, the durability and longevity of malachite-enhanced ceramics may contribute to a reduction in waste generation over time, as these products may have extended lifespans compared to conventional ceramics.

Water usage is another critical environmental factor to consider. The production of ceramics typically requires significant amounts of water. Research into malachite-based ceramic materials should investigate whether this approach can lead to reduced water consumption in the manufacturing process, potentially alleviating pressure on local water resources.

From a lifecycle perspective, the environmental impact of malachite-enhanced ceramics extends beyond production to include use and disposal phases. The potential for these materials to be recycled or repurposed at the end of their useful life should be thoroughly explored. If malachite-containing ceramics can be effectively recycled, it could contribute to closing the loop in material cycles and reducing the demand for virgin resources.

Lastly, the potential for malachite to impart antimicrobial properties to ceramic materials may have indirect environmental benefits. Ceramics with enhanced resistance to microbial growth could reduce the need for chemical cleaning agents and disinfectants, thereby decreasing the release of harmful substances into the environment. This aspect aligns with the growing demand for more hygienic and environmentally friendly materials in various applications, from construction to healthcare settings.

Malachite Supply Chain

The malachite supply chain plays a crucial role in the development of sustainable ceramic materials. Malachite, a copper carbonate hydroxide mineral, is primarily sourced from copper mining operations worldwide. The main producers of malachite include countries such as the Democratic Republic of Congo, Zambia, Australia, and Russia.

The extraction process of malachite typically involves open-pit or underground mining techniques. Once extracted, the raw malachite undergoes various processing stages, including crushing, grinding, and separation, to obtain high-quality material suitable for ceramic applications. The processed malachite is then distributed to manufacturers and research institutions working on sustainable ceramic materials.

The supply chain for malachite faces several challenges. One significant issue is the environmental impact of mining operations, which can lead to habitat destruction and water pollution. Sustainable mining practices and stricter regulations are being implemented to mitigate these effects. Additionally, the limited availability of high-grade malachite deposits poses a challenge to meeting the growing demand for sustainable ceramic materials.

Transportation and logistics also play a vital role in the malachite supply chain. The mineral is typically shipped in bulk from mining sites to processing facilities and then to end-users. Efficient transportation networks and proper handling procedures are essential to maintain the quality and integrity of the malachite during transit.

The market for malachite in sustainable ceramic materials is influenced by factors such as technological advancements, environmental regulations, and consumer demand for eco-friendly products. As research in this field progresses, the demand for high-quality malachite is expected to increase, potentially leading to supply chain pressures and price fluctuations.

To address these challenges, stakeholders in the malachite supply chain are exploring innovative solutions. These include developing more efficient extraction and processing techniques, implementing closed-loop recycling systems, and investigating alternative sources of copper-based minerals for sustainable ceramic production. Collaboration between mining companies, researchers, and manufacturers is crucial for optimizing the supply chain and ensuring a steady flow of malachite for sustainable ceramic material development.

The extraction process of malachite typically involves open-pit or underground mining techniques. Once extracted, the raw malachite undergoes various processing stages, including crushing, grinding, and separation, to obtain high-quality material suitable for ceramic applications. The processed malachite is then distributed to manufacturers and research institutions working on sustainable ceramic materials.

The supply chain for malachite faces several challenges. One significant issue is the environmental impact of mining operations, which can lead to habitat destruction and water pollution. Sustainable mining practices and stricter regulations are being implemented to mitigate these effects. Additionally, the limited availability of high-grade malachite deposits poses a challenge to meeting the growing demand for sustainable ceramic materials.

Transportation and logistics also play a vital role in the malachite supply chain. The mineral is typically shipped in bulk from mining sites to processing facilities and then to end-users. Efficient transportation networks and proper handling procedures are essential to maintain the quality and integrity of the malachite during transit.

The market for malachite in sustainable ceramic materials is influenced by factors such as technological advancements, environmental regulations, and consumer demand for eco-friendly products. As research in this field progresses, the demand for high-quality malachite is expected to increase, potentially leading to supply chain pressures and price fluctuations.

To address these challenges, stakeholders in the malachite supply chain are exploring innovative solutions. These include developing more efficient extraction and processing techniques, implementing closed-loop recycling systems, and investigating alternative sources of copper-based minerals for sustainable ceramic production. Collaboration between mining companies, researchers, and manufacturers is crucial for optimizing the supply chain and ensuring a steady flow of malachite for sustainable ceramic material development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!