Material Fatigue Study of Solenoid Valve Components in Aerospace Industry

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Solenoid Valve Fatigue Background

Solenoid valves play a critical role in aerospace systems, controlling the flow of fluids and gases in various applications such as fuel systems, hydraulic systems, and environmental control systems. The study of material fatigue in solenoid valve components is of paramount importance due to the extreme conditions these components face in aerospace environments.

The aerospace industry has long been at the forefront of technological advancements, pushing the boundaries of materials science and engineering. As aircraft and spacecraft designs evolve to meet increasingly demanding performance requirements, the components within these systems must withstand higher pressures, temperatures, and operational cycles. Solenoid valves, being electromechanical devices, are particularly susceptible to fatigue-related failures due to their frequent actuation and exposure to harsh operating conditions.

Material fatigue in solenoid valve components can manifest in various forms, including crack initiation and propagation, surface degradation, and changes in material properties. These fatigue-related issues can lead to reduced performance, increased maintenance requirements, and, in severe cases, catastrophic failures. The consequences of such failures in aerospace applications can be dire, potentially compromising the safety and reliability of the entire system.

The study of material fatigue in solenoid valve components has evolved significantly over the years. Early research focused primarily on empirical testing and observation of failure modes. However, with advancements in materials science, computational modeling, and non-destructive testing techniques, the field has progressed towards a more comprehensive understanding of fatigue mechanisms at the microstructural level.

Current research in this area encompasses a wide range of disciplines, including materials science, mechanical engineering, and aerospace engineering. Scientists and engineers are exploring innovative materials, such as advanced alloys and composites, to enhance the fatigue resistance of solenoid valve components. Additionally, there is a growing emphasis on developing predictive models that can accurately forecast the fatigue life of these components under various operating conditions.

The aerospace industry's stringent safety standards and reliability requirements have driven continuous improvements in material fatigue studies. Regulatory bodies, such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA), have established rigorous certification processes that demand extensive fatigue testing and analysis for critical components like solenoid valves.

As the aerospace industry continues to push technological boundaries, with developments in electric propulsion, hypersonic flight, and space exploration, the demands on solenoid valve components are expected to increase further. This underscores the ongoing importance of material fatigue studies in ensuring the safety, reliability, and performance of aerospace systems for years to come.

The aerospace industry has long been at the forefront of technological advancements, pushing the boundaries of materials science and engineering. As aircraft and spacecraft designs evolve to meet increasingly demanding performance requirements, the components within these systems must withstand higher pressures, temperatures, and operational cycles. Solenoid valves, being electromechanical devices, are particularly susceptible to fatigue-related failures due to their frequent actuation and exposure to harsh operating conditions.

Material fatigue in solenoid valve components can manifest in various forms, including crack initiation and propagation, surface degradation, and changes in material properties. These fatigue-related issues can lead to reduced performance, increased maintenance requirements, and, in severe cases, catastrophic failures. The consequences of such failures in aerospace applications can be dire, potentially compromising the safety and reliability of the entire system.

The study of material fatigue in solenoid valve components has evolved significantly over the years. Early research focused primarily on empirical testing and observation of failure modes. However, with advancements in materials science, computational modeling, and non-destructive testing techniques, the field has progressed towards a more comprehensive understanding of fatigue mechanisms at the microstructural level.

Current research in this area encompasses a wide range of disciplines, including materials science, mechanical engineering, and aerospace engineering. Scientists and engineers are exploring innovative materials, such as advanced alloys and composites, to enhance the fatigue resistance of solenoid valve components. Additionally, there is a growing emphasis on developing predictive models that can accurately forecast the fatigue life of these components under various operating conditions.

The aerospace industry's stringent safety standards and reliability requirements have driven continuous improvements in material fatigue studies. Regulatory bodies, such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA), have established rigorous certification processes that demand extensive fatigue testing and analysis for critical components like solenoid valves.

As the aerospace industry continues to push technological boundaries, with developments in electric propulsion, hypersonic flight, and space exploration, the demands on solenoid valve components are expected to increase further. This underscores the ongoing importance of material fatigue studies in ensuring the safety, reliability, and performance of aerospace systems for years to come.

Market Demand Analysis

The aerospace industry's demand for reliable solenoid valve components has been steadily increasing due to the growing emphasis on safety, efficiency, and performance in aircraft and spacecraft systems. Solenoid valves play a crucial role in various aerospace applications, including fuel systems, hydraulic controls, and environmental control systems. The market for these components is driven by the expansion of commercial aviation, increased defense spending, and the burgeoning space exploration sector.

In commercial aviation, the rise in air travel demand has led to a surge in aircraft production, consequently boosting the need for high-quality solenoid valve components. Major aircraft manufacturers are focusing on developing more fuel-efficient and environmentally friendly aircraft, which requires advanced valve systems capable of withstanding higher pressures and temperatures. This trend is expected to continue, with the global commercial aircraft market projected to grow at a compound annual growth rate (CAGR) of around 3-4% over the next decade.

The defense aerospace sector is another significant driver of demand for solenoid valve components. Governments worldwide are investing in modernizing their military aircraft fleets, which necessitates the integration of cutting-edge valve technologies. These components are essential for enhancing the performance and reliability of military aircraft, particularly in demanding operational environments. The global military aircraft market is anticipated to expand at a CAGR of approximately 2-3% in the coming years, further fueling the demand for advanced solenoid valve components.

Space exploration initiatives, both public and private, are creating new opportunities for solenoid valve manufacturers. The increasing number of satellite launches, lunar missions, and plans for Mars exploration are driving the need for highly specialized valve components capable of operating in extreme conditions. The global space industry is experiencing rapid growth, with some estimates suggesting a CAGR of 5-6% over the next five years, which will significantly impact the demand for aerospace-grade solenoid valves.

The material fatigue study of solenoid valve components is of particular interest to the aerospace industry due to the critical nature of these parts in ensuring system reliability and safety. As aircraft and spacecraft are subjected to extreme temperature fluctuations, high-pressure environments, and constant vibrations, the durability of valve components becomes paramount. Industry stakeholders are increasingly focused on developing materials and designs that can withstand these harsh conditions while maintaining optimal performance throughout the lifespan of the aircraft or spacecraft.

Market analysis indicates a growing preference for lightweight, corrosion-resistant materials that offer superior fatigue resistance. This trend is driven by the industry's push towards weight reduction and increased fuel efficiency. Manufacturers are investing in research and development to create innovative alloys and composite materials that can meet these demanding requirements while also extending the service life of solenoid valve components.

In commercial aviation, the rise in air travel demand has led to a surge in aircraft production, consequently boosting the need for high-quality solenoid valve components. Major aircraft manufacturers are focusing on developing more fuel-efficient and environmentally friendly aircraft, which requires advanced valve systems capable of withstanding higher pressures and temperatures. This trend is expected to continue, with the global commercial aircraft market projected to grow at a compound annual growth rate (CAGR) of around 3-4% over the next decade.

The defense aerospace sector is another significant driver of demand for solenoid valve components. Governments worldwide are investing in modernizing their military aircraft fleets, which necessitates the integration of cutting-edge valve technologies. These components are essential for enhancing the performance and reliability of military aircraft, particularly in demanding operational environments. The global military aircraft market is anticipated to expand at a CAGR of approximately 2-3% in the coming years, further fueling the demand for advanced solenoid valve components.

Space exploration initiatives, both public and private, are creating new opportunities for solenoid valve manufacturers. The increasing number of satellite launches, lunar missions, and plans for Mars exploration are driving the need for highly specialized valve components capable of operating in extreme conditions. The global space industry is experiencing rapid growth, with some estimates suggesting a CAGR of 5-6% over the next five years, which will significantly impact the demand for aerospace-grade solenoid valves.

The material fatigue study of solenoid valve components is of particular interest to the aerospace industry due to the critical nature of these parts in ensuring system reliability and safety. As aircraft and spacecraft are subjected to extreme temperature fluctuations, high-pressure environments, and constant vibrations, the durability of valve components becomes paramount. Industry stakeholders are increasingly focused on developing materials and designs that can withstand these harsh conditions while maintaining optimal performance throughout the lifespan of the aircraft or spacecraft.

Market analysis indicates a growing preference for lightweight, corrosion-resistant materials that offer superior fatigue resistance. This trend is driven by the industry's push towards weight reduction and increased fuel efficiency. Manufacturers are investing in research and development to create innovative alloys and composite materials that can meet these demanding requirements while also extending the service life of solenoid valve components.

Current Challenges in Material Fatigue

Material fatigue remains a critical challenge in the aerospace industry, particularly for solenoid valve components. These components are subjected to extreme conditions, including high-frequency cyclic loading, temperature fluctuations, and exposure to corrosive environments. The current challenges in material fatigue for solenoid valve components are multifaceted and require innovative solutions to ensure the reliability and longevity of aerospace systems.

One of the primary challenges is the accurate prediction of fatigue life under complex loading conditions. Traditional fatigue models often fall short when applied to the unique operational environments of aerospace solenoid valves. The combination of mechanical stress, thermal cycling, and electromagnetic forces creates a complex stress state that is difficult to simulate and predict accurately. This limitation in predictive capabilities can lead to either overly conservative designs or unexpected failures, both of which are undesirable in aerospace applications.

Another significant challenge is the development of advanced materials that can withstand the harsh conditions encountered in aerospace environments. While current materials such as high-strength steels and nickel-based alloys offer good fatigue resistance, there is a constant push for materials with higher strength-to-weight ratios and improved fatigue properties. The development of such materials is hindered by the limited understanding of microstructural evolution during cyclic loading and its impact on fatigue life.

The miniaturization trend in aerospace components poses additional challenges for material fatigue studies. As solenoid valves become smaller and more compact, the effects of surface finish, microstructural defects, and manufacturing processes become increasingly significant. These factors can introduce stress concentrations and initiation sites for fatigue cracks, which are particularly critical in small-scale components where the tolerance for material degradation is minimal.

Furthermore, the aerospace industry faces challenges in non-destructive evaluation (NDE) techniques for detecting early signs of fatigue damage. Current methods often lack the sensitivity to detect micro-cracks or subtle changes in material properties that precede fatigue failure. This limitation hampers the implementation of effective predictive maintenance strategies, which are crucial for ensuring the safety and reliability of aerospace systems.

The integration of smart materials and sensors for real-time fatigue monitoring is another area presenting both opportunities and challenges. While such technologies offer the potential for continuous health monitoring of solenoid valve components, their implementation faces obstacles related to sensor durability, data interpretation, and integration with existing systems.

Lastly, the aerospace industry must address the challenge of accelerated testing methodologies. The long service life expected from aerospace components makes traditional fatigue testing time-consuming and costly. Developing reliable accelerated testing protocols that accurately represent real-world conditions is essential for rapid material evaluation and qualification, but remains a significant technical hurdle.

One of the primary challenges is the accurate prediction of fatigue life under complex loading conditions. Traditional fatigue models often fall short when applied to the unique operational environments of aerospace solenoid valves. The combination of mechanical stress, thermal cycling, and electromagnetic forces creates a complex stress state that is difficult to simulate and predict accurately. This limitation in predictive capabilities can lead to either overly conservative designs or unexpected failures, both of which are undesirable in aerospace applications.

Another significant challenge is the development of advanced materials that can withstand the harsh conditions encountered in aerospace environments. While current materials such as high-strength steels and nickel-based alloys offer good fatigue resistance, there is a constant push for materials with higher strength-to-weight ratios and improved fatigue properties. The development of such materials is hindered by the limited understanding of microstructural evolution during cyclic loading and its impact on fatigue life.

The miniaturization trend in aerospace components poses additional challenges for material fatigue studies. As solenoid valves become smaller and more compact, the effects of surface finish, microstructural defects, and manufacturing processes become increasingly significant. These factors can introduce stress concentrations and initiation sites for fatigue cracks, which are particularly critical in small-scale components where the tolerance for material degradation is minimal.

Furthermore, the aerospace industry faces challenges in non-destructive evaluation (NDE) techniques for detecting early signs of fatigue damage. Current methods often lack the sensitivity to detect micro-cracks or subtle changes in material properties that precede fatigue failure. This limitation hampers the implementation of effective predictive maintenance strategies, which are crucial for ensuring the safety and reliability of aerospace systems.

The integration of smart materials and sensors for real-time fatigue monitoring is another area presenting both opportunities and challenges. While such technologies offer the potential for continuous health monitoring of solenoid valve components, their implementation faces obstacles related to sensor durability, data interpretation, and integration with existing systems.

Lastly, the aerospace industry must address the challenge of accelerated testing methodologies. The long service life expected from aerospace components makes traditional fatigue testing time-consuming and costly. Developing reliable accelerated testing protocols that accurately represent real-world conditions is essential for rapid material evaluation and qualification, but remains a significant technical hurdle.

Existing Fatigue Mitigation Strategies

01 Material selection for solenoid valve components

Proper material selection is crucial for solenoid valve components to prevent material fatigue. Materials with high fatigue resistance, such as stainless steel or specialized alloys, are often used for critical components like valve stems, springs, and housings. These materials can withstand repeated stress cycles and harsh operating conditions, extending the valve's lifespan and reliability.- Material selection for solenoid valve components: Choosing appropriate materials for solenoid valve components is crucial to prevent material fatigue. High-quality, durable materials such as stainless steel, brass, or engineered plastics are often used. These materials offer resistance to corrosion, wear, and fatigue, ensuring longer component life and improved valve performance.

- Design optimization to reduce stress: Optimizing the design of solenoid valve components can significantly reduce stress concentrations and minimize material fatigue. This includes streamlining component shapes, eliminating sharp corners, and ensuring proper load distribution. Advanced computer-aided design and finite element analysis techniques are often employed to identify and mitigate potential stress points.

- Surface treatment and coatings: Applying surface treatments and coatings to solenoid valve components can enhance their resistance to material fatigue. Techniques such as nitriding, carburizing, or applying protective coatings like chrome plating or PVD coatings can improve surface hardness, reduce friction, and increase wear resistance, thereby extending component life.

- Fatigue testing and quality control: Implementing rigorous fatigue testing and quality control measures is essential to ensure the longevity of solenoid valve components. This includes cyclic loading tests, accelerated life testing, and non-destructive testing methods such as ultrasonic or magnetic particle inspection. These processes help identify potential weaknesses and ensure components meet required performance standards.

- Maintenance and replacement strategies: Developing effective maintenance and replacement strategies can help mitigate the effects of material fatigue in solenoid valve components. This includes regular inspections, preventive maintenance schedules, and timely replacement of worn components. Implementing condition monitoring systems can also help detect early signs of fatigue and prevent catastrophic failures.

02 Design optimization to reduce material fatigue

Optimizing the design of solenoid valve components can significantly reduce material fatigue. This includes streamlining fluid flow paths, minimizing stress concentrations, and improving overall component geometry. Advanced design techniques, such as finite element analysis, can be used to identify and mitigate potential fatigue points, resulting in more durable and efficient valve designs.Expand Specific Solutions03 Surface treatment and coating techniques

Various surface treatment and coating techniques can be applied to solenoid valve components to enhance their resistance to material fatigue. These methods include nitriding, carburizing, and the application of wear-resistant coatings. Such treatments can improve the surface hardness, reduce friction, and protect against corrosion, all of which contribute to increased fatigue resistance and extended component life.Expand Specific Solutions04 Innovative sealing and actuation mechanisms

Developing innovative sealing and actuation mechanisms can help reduce the stress on solenoid valve components, thereby minimizing material fatigue. This may include the use of advanced elastomers for seals, balanced poppet designs, or novel electromagnetic actuators. These innovations can distribute forces more evenly, reduce wear, and improve overall valve performance and longevity.Expand Specific Solutions05 Predictive maintenance and condition monitoring

Implementing predictive maintenance strategies and condition monitoring systems can help detect early signs of material fatigue in solenoid valve components. This may involve the use of sensors to monitor valve performance, vibration analysis, or advanced diagnostic algorithms. By identifying potential issues before they lead to failure, maintenance can be performed proactively, extending the life of valve components and preventing unexpected downtime.Expand Specific Solutions

Key Players in Aerospace Valve Industry

The material fatigue study of solenoid valve components in the aerospace industry is in a mature stage, with significant market size and technological advancements. The competitive landscape is characterized by established players like Rolls-Royce Plc, Boeing Co., and General Electric Company, who have extensive experience in aerospace engineering. These companies, along with research institutions such as Nanjing University of Aeronautics & Astronautics and Harbin Institute of Technology, are driving innovation in materials science and fatigue analysis. The market is further enhanced by specialized firms like StressWave, Inc., which focuses on improving structural component longevity. As the aerospace industry continues to grow, the demand for advanced fatigue studies in critical components like solenoid valves is expected to increase, fostering ongoing research and development in this field.

Svenska Kullagerfabriken AB

Technical Solution: SKF has developed a specialized approach to material fatigue studies for bearing components in aerospace solenoid valves. Their method focuses on rolling contact fatigue, which is critical for the performance and reliability of bearings in these applications. SKF utilizes advanced tribological models that account for lubricant behavior, surface roughness, and material microstructure[13]. They have implemented a unique testing facility that simulates the specific loading conditions experienced by bearings in aerospace solenoid valves, including high-frequency cycling and extreme temperatures[15]. SKF's approach also incorporates probabilistic modeling to account for variability in material properties and operating conditions, enhancing the accuracy of fatigue life predictions[17].

Strengths: Specialized expertise in bearing fatigue, advanced tribological modeling. Weaknesses: Focus primarily on bearing components may limit applicability to other solenoid valve parts.

Robert Bosch GmbH

Technical Solution: Bosch has developed a holistic approach to material fatigue studies for solenoid valve components in aerospace applications. Their method combines advanced simulation techniques with in-situ monitoring systems. Bosch utilizes multi-physics simulation models that account for electromagnetic, thermal, and mechanical interactions within solenoid valves[8]. They have implemented a novel sensor system for real-time monitoring of material fatigue in critical components, allowing for predictive maintenance and enhanced safety[10]. Bosch's approach also incorporates materials informatics to guide the selection and development of advanced materials with improved fatigue resistance for aerospace solenoid valves[12].

Strengths: Integrated approach combining simulation, monitoring, and materials informatics. Weaknesses: Complex implementation may be challenging for smaller aerospace companies.

Core Innovations in Material Science

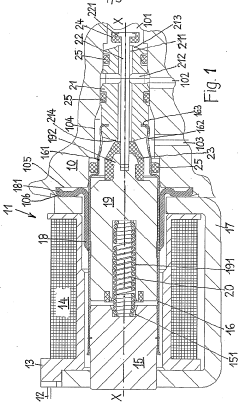

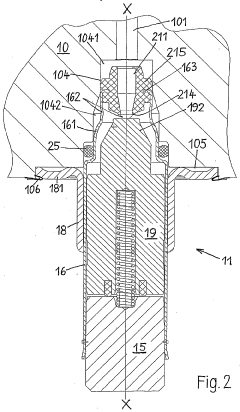

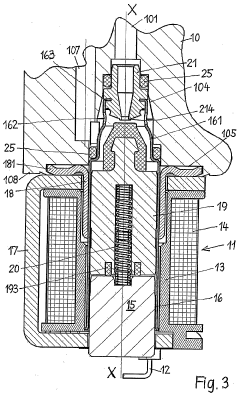

Solenoid valve

PatentWO2005102807A1

Innovation

- A solenoid valve design where the guide tube is made of metal and the sealing seat is overmoulded with a flanged end, allowing for a single operation shaping and attachment, eliminating shape deviations and enabling automated production with injection molding, using materials like plastic or metal for stability and preventing leaks.

Solenoid valve, in particular quantity control valve for a high-pressure fuel pump

PatentActiveEP2798650A1

Innovation

- A solenoid valve design featuring a pole core made of ferritic stainless steel with a hard chrome-plated armature stop, where only the end region is cold-formed to increase hardness and fatigue strength, while maintaining soft-magnetic properties in the rest of the pole core, and a manufacturing method involving sequential processing for precise machining.

Aerospace Industry Standards

The aerospace industry operates under stringent standards to ensure the safety, reliability, and performance of aircraft and spacecraft components. These standards are crucial for the material fatigue study of solenoid valve components, as they provide a framework for design, testing, and certification processes.

Key aerospace industry standards relevant to material fatigue studies include SAE AS1831, which specifies requirements for solenoid-operated valves in aerospace applications. This standard outlines performance criteria, environmental conditions, and durability requirements that directly impact fatigue considerations. Additionally, RTCA DO-160 sets forth environmental test conditions for airborne equipment, including vibration and temperature cycling tests that are essential for assessing material fatigue resistance.

The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established certification requirements that mandate rigorous fatigue testing for critical components. These regulations, such as FAR Part 25 and CS-25, specify the minimum number of cycles and load conditions that must be demonstrated for certification, directly influencing the design and material selection process for solenoid valve components.

Material-specific standards, such as AMS 2759 for heat treatment of steel parts, play a crucial role in ensuring consistent material properties that affect fatigue performance. These standards define processes that can significantly enhance the fatigue resistance of solenoid valve components, such as shot peening and surface hardening treatments.

Fatigue testing methodologies are standardized through ASTM E466 for axial fatigue testing and ASTM E606 for strain-controlled fatigue testing. These standards ensure that fatigue data collected across different laboratories and organizations can be reliably compared and utilized in component design and life prediction models.

The aerospace industry also employs probabilistic approaches to fatigue analysis, as outlined in standards like MMPDS-08, which provides statistical-based material property data. This approach acknowledges the inherent variability in material properties and loading conditions, allowing for more robust fatigue life predictions for solenoid valve components.

Compliance with these standards is typically verified through a combination of analysis, testing, and documentation. Aerospace manufacturers must maintain detailed records of material properties, manufacturing processes, and test results to demonstrate adherence to the relevant standards throughout the product lifecycle.

Key aerospace industry standards relevant to material fatigue studies include SAE AS1831, which specifies requirements for solenoid-operated valves in aerospace applications. This standard outlines performance criteria, environmental conditions, and durability requirements that directly impact fatigue considerations. Additionally, RTCA DO-160 sets forth environmental test conditions for airborne equipment, including vibration and temperature cycling tests that are essential for assessing material fatigue resistance.

The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established certification requirements that mandate rigorous fatigue testing for critical components. These regulations, such as FAR Part 25 and CS-25, specify the minimum number of cycles and load conditions that must be demonstrated for certification, directly influencing the design and material selection process for solenoid valve components.

Material-specific standards, such as AMS 2759 for heat treatment of steel parts, play a crucial role in ensuring consistent material properties that affect fatigue performance. These standards define processes that can significantly enhance the fatigue resistance of solenoid valve components, such as shot peening and surface hardening treatments.

Fatigue testing methodologies are standardized through ASTM E466 for axial fatigue testing and ASTM E606 for strain-controlled fatigue testing. These standards ensure that fatigue data collected across different laboratories and organizations can be reliably compared and utilized in component design and life prediction models.

The aerospace industry also employs probabilistic approaches to fatigue analysis, as outlined in standards like MMPDS-08, which provides statistical-based material property data. This approach acknowledges the inherent variability in material properties and loading conditions, allowing for more robust fatigue life predictions for solenoid valve components.

Compliance with these standards is typically verified through a combination of analysis, testing, and documentation. Aerospace manufacturers must maintain detailed records of material properties, manufacturing processes, and test results to demonstrate adherence to the relevant standards throughout the product lifecycle.

Environmental Impact Considerations

The environmental impact of solenoid valve components in the aerospace industry is a critical consideration in the material fatigue study. These components, while essential for aircraft operation, can have significant environmental implications throughout their lifecycle. The manufacturing process of solenoid valves often involves the use of rare earth metals and other materials that require extensive mining and processing, potentially leading to habitat destruction and pollution. Additionally, the production of these components typically consumes substantial energy, contributing to greenhouse gas emissions.

During the operational phase, the environmental impact of solenoid valves is primarily related to their energy consumption and potential for leakage. While these components are designed for efficiency, any malfunction or degradation due to material fatigue can result in increased energy usage or fluid leakage, both of which can have adverse environmental effects. In the case of hydraulic systems, leaks can lead to soil and water contamination, particularly if the fluids contain hazardous substances.

The disposal of solenoid valve components at the end of their lifecycle presents another environmental challenge. Many of these components contain materials that are not easily recyclable or biodegradable, contributing to the growing problem of electronic waste. Proper disposal and recycling procedures are essential to minimize the environmental impact, but these processes are often complex and energy-intensive.

Climate change and extreme weather conditions can also affect the performance and lifespan of solenoid valve components, potentially exacerbating their environmental impact. Higher temperatures and increased humidity can accelerate material fatigue, leading to more frequent replacements and, consequently, increased waste generation and resource consumption.

To address these environmental concerns, researchers and engineers are exploring several avenues. The development of more durable materials that can withstand fatigue and environmental stressors for longer periods is a key focus area. This approach not only reduces the frequency of replacements but also minimizes the overall environmental footprint of these components. Additionally, efforts are being made to design solenoid valves that are more easily recyclable and use fewer hazardous materials.

Advancements in manufacturing techniques, such as additive manufacturing, are also being investigated to reduce material waste and energy consumption during production. Furthermore, the implementation of predictive maintenance strategies, enabled by sensors and data analytics, can help optimize the lifecycle of solenoid valve components, reducing unnecessary replacements and associated environmental impacts.

During the operational phase, the environmental impact of solenoid valves is primarily related to their energy consumption and potential for leakage. While these components are designed for efficiency, any malfunction or degradation due to material fatigue can result in increased energy usage or fluid leakage, both of which can have adverse environmental effects. In the case of hydraulic systems, leaks can lead to soil and water contamination, particularly if the fluids contain hazardous substances.

The disposal of solenoid valve components at the end of their lifecycle presents another environmental challenge. Many of these components contain materials that are not easily recyclable or biodegradable, contributing to the growing problem of electronic waste. Proper disposal and recycling procedures are essential to minimize the environmental impact, but these processes are often complex and energy-intensive.

Climate change and extreme weather conditions can also affect the performance and lifespan of solenoid valve components, potentially exacerbating their environmental impact. Higher temperatures and increased humidity can accelerate material fatigue, leading to more frequent replacements and, consequently, increased waste generation and resource consumption.

To address these environmental concerns, researchers and engineers are exploring several avenues. The development of more durable materials that can withstand fatigue and environmental stressors for longer periods is a key focus area. This approach not only reduces the frequency of replacements but also minimizes the overall environmental footprint of these components. Additionally, efforts are being made to design solenoid valves that are more easily recyclable and use fewer hazardous materials.

Advancements in manufacturing techniques, such as additive manufacturing, are also being investigated to reduce material waste and energy consumption during production. Furthermore, the implementation of predictive maintenance strategies, enabled by sensors and data analytics, can help optimize the lifecycle of solenoid valve components, reducing unnecessary replacements and associated environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!