Measure the Stabilizing Effect of Trimethylglycine in Foods

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Trimethylglycine Stabilization Background and Objectives

Trimethylglycine (TMG), also known as betaine, has emerged as a significant compound in food science due to its multifunctional properties. Originally discovered in sugar beets in the 19th century, TMG has evolved from being merely a byproduct of sugar production to becoming a valuable food ingredient with stabilizing capabilities. The natural occurrence of TMG in various food sources, including wheat, spinach, and shellfish, has prompted extensive research into its potential applications in food preservation and quality enhancement.

The evolution of TMG research has followed a trajectory from basic biochemical characterization to applied food technology. Early studies in the 1950s focused primarily on TMG's role as a methyl donor in biological systems. By the 1980s, researchers began exploring its osmoprotective properties in microorganisms, which laid the groundwork for understanding its stabilizing effects in food matrices. The past two decades have witnessed accelerated interest in TMG as food manufacturers seek natural alternatives to synthetic stabilizers.

Current technological trends indicate a growing emphasis on clean-label ingredients, with TMG positioned as a promising candidate due to its natural origin and multifunctional properties. The compound's ability to interact with proteins, lipids, and carbohydrates suggests broad applicability across diverse food categories. Additionally, TMG's role in mitigating oxidative stress aligns with the industry's focus on extending shelf life without compromising nutritional quality.

The primary objective of investigating TMG's stabilizing effect in foods is to establish quantifiable metrics for its performance across different food matrices. This includes determining optimal concentration ranges for various applications, understanding the molecular mechanisms underlying its stabilizing properties, and developing standardized methodologies for measuring its efficacy in real-world food systems.

Secondary objectives encompass evaluating TMG's synergistic potential with other food ingredients, assessing its stability during processing and storage, and exploring its impact on sensory attributes of finished products. Furthermore, there is interest in comparing TMG's performance against conventional stabilizers to identify competitive advantages and potential limitations.

Long-term goals include developing predictive models for TMG behavior in complex food systems, establishing regulatory frameworks for its use as a functional ingredient, and exploring novel delivery systems to enhance its efficacy. The ultimate aim is to position TMG as a versatile, natural stabilizing agent that can address multiple quality challenges in food production while meeting consumer demands for clean-label products.

The evolution of TMG research has followed a trajectory from basic biochemical characterization to applied food technology. Early studies in the 1950s focused primarily on TMG's role as a methyl donor in biological systems. By the 1980s, researchers began exploring its osmoprotective properties in microorganisms, which laid the groundwork for understanding its stabilizing effects in food matrices. The past two decades have witnessed accelerated interest in TMG as food manufacturers seek natural alternatives to synthetic stabilizers.

Current technological trends indicate a growing emphasis on clean-label ingredients, with TMG positioned as a promising candidate due to its natural origin and multifunctional properties. The compound's ability to interact with proteins, lipids, and carbohydrates suggests broad applicability across diverse food categories. Additionally, TMG's role in mitigating oxidative stress aligns with the industry's focus on extending shelf life without compromising nutritional quality.

The primary objective of investigating TMG's stabilizing effect in foods is to establish quantifiable metrics for its performance across different food matrices. This includes determining optimal concentration ranges for various applications, understanding the molecular mechanisms underlying its stabilizing properties, and developing standardized methodologies for measuring its efficacy in real-world food systems.

Secondary objectives encompass evaluating TMG's synergistic potential with other food ingredients, assessing its stability during processing and storage, and exploring its impact on sensory attributes of finished products. Furthermore, there is interest in comparing TMG's performance against conventional stabilizers to identify competitive advantages and potential limitations.

Long-term goals include developing predictive models for TMG behavior in complex food systems, establishing regulatory frameworks for its use as a functional ingredient, and exploring novel delivery systems to enhance its efficacy. The ultimate aim is to position TMG as a versatile, natural stabilizing agent that can address multiple quality challenges in food production while meeting consumer demands for clean-label products.

Market Analysis of Food Stabilizers

The global food stabilizer market has witnessed substantial growth in recent years, reaching approximately $2.8 billion in 2022 and projected to expand at a CAGR of 5.7% through 2028. This growth is primarily driven by increasing consumer demand for processed and convenience foods with extended shelf life and consistent quality. Food manufacturers are increasingly seeking natural and clean-label stabilizers to meet consumer preferences for healthier food options, creating a significant market opportunity for compounds like trimethylglycine (TMG).

Within this landscape, TMG (also known as betaine) represents an emerging segment with promising applications as a food stabilizer. While traditionally used as a dietary supplement and in animal feed, its potential in food preservation and stabilization has gained attention due to its osmoprotectant properties. The market for TMG in food applications is currently estimated at $120 million globally, with an anticipated growth rate exceeding the broader stabilizer market at approximately 7.3% annually.

Regional analysis reveals that North America and Europe currently dominate the food stabilizer market, accounting for over 60% of global consumption. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.2% annually, driven by rapid industrialization of food processing, changing dietary habits, and increasing disposable income. Latin America and the Middle East are also emerging as significant markets, particularly for natural stabilizers like TMG.

By application segment, dairy and frozen products represent the largest market for food stabilizers (32%), followed by bakery and confectionery (24%), beverages (18%), and meat products (15%). TMG has shown particular promise in dairy applications, where its stabilizing effects on proteins during thermal processing have demonstrated commercial value. The functional beverage segment also presents substantial growth opportunities for TMG-based stabilizers.

Consumer trends significantly influencing the market include clean-label preferences, with 73% of global consumers reporting they regularly check ingredient lists for artificial additives. Additionally, the plant-based food sector, growing at 11.9% annually, requires effective stabilizers to address texture and shelf-life challenges, creating another potential application area for TMG-based solutions.

Pricing analysis indicates that while conventional chemical stabilizers remain cost-competitive at $3-8 per kilogram, premium natural stabilizers command prices of $12-25 per kilogram. TMG currently falls in the mid-range at approximately $15-18 per kilogram for food-grade material, though economies of scale could potentially reduce this as adoption increases.

Within this landscape, TMG (also known as betaine) represents an emerging segment with promising applications as a food stabilizer. While traditionally used as a dietary supplement and in animal feed, its potential in food preservation and stabilization has gained attention due to its osmoprotectant properties. The market for TMG in food applications is currently estimated at $120 million globally, with an anticipated growth rate exceeding the broader stabilizer market at approximately 7.3% annually.

Regional analysis reveals that North America and Europe currently dominate the food stabilizer market, accounting for over 60% of global consumption. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.2% annually, driven by rapid industrialization of food processing, changing dietary habits, and increasing disposable income. Latin America and the Middle East are also emerging as significant markets, particularly for natural stabilizers like TMG.

By application segment, dairy and frozen products represent the largest market for food stabilizers (32%), followed by bakery and confectionery (24%), beverages (18%), and meat products (15%). TMG has shown particular promise in dairy applications, where its stabilizing effects on proteins during thermal processing have demonstrated commercial value. The functional beverage segment also presents substantial growth opportunities for TMG-based stabilizers.

Consumer trends significantly influencing the market include clean-label preferences, with 73% of global consumers reporting they regularly check ingredient lists for artificial additives. Additionally, the plant-based food sector, growing at 11.9% annually, requires effective stabilizers to address texture and shelf-life challenges, creating another potential application area for TMG-based solutions.

Pricing analysis indicates that while conventional chemical stabilizers remain cost-competitive at $3-8 per kilogram, premium natural stabilizers command prices of $12-25 per kilogram. TMG currently falls in the mid-range at approximately $15-18 per kilogram for food-grade material, though economies of scale could potentially reduce this as adoption increases.

Current Challenges in Food Stabilization Technology

Food stabilization technology faces several significant challenges in the current landscape. The primary issue revolves around maintaining product quality and extending shelf life while meeting consumer demands for clean labels and minimal processing. Traditional stabilizers often contain synthetic compounds that consumers increasingly reject, creating a technical dilemma for manufacturers seeking natural alternatives without compromising functionality.

The measurement and quantification of stabilizing effects present another major challenge. Current methodologies lack standardization across different food matrices, making comparative analysis difficult. For trimethylglycine (TMG) specifically, researchers struggle with accurately determining its stabilizing capacity in complex food systems where multiple ingredients interact simultaneously.

Environmental factors significantly complicate stabilization efforts. Temperature fluctuations during processing, storage, and distribution can dramatically alter the effectiveness of stabilizers like TMG. The food industry lacks robust models that can predict stabilizer performance across varying environmental conditions, forcing reliance on extensive empirical testing that increases development costs and time-to-market.

Regulatory constraints further compound these challenges. Different regions maintain varying standards for food additives, including natural compounds like TMG. This regulatory fragmentation creates compliance difficulties for global food manufacturers and limits the adoption of novel stabilization technologies across markets.

The interaction between stabilizers and other food components represents another critical challenge. TMG's functionality can be enhanced or inhibited by proteins, lipids, carbohydrates, and other ingredients in the food matrix. Current analytical methods struggle to isolate and measure these complex interactions, making formulation optimization largely trial-and-error based.

Scale-up issues present significant hurdles when transitioning from laboratory findings to industrial production. Stabilization effects observed in controlled environments often differ substantially when implemented at commercial scale. For TMG specifically, maintaining homogeneous distribution throughout large production batches remains problematic.

Cost considerations also limit innovation in food stabilization technology. While TMG shows promising stabilizing properties, its production and purification expenses currently exceed those of conventional stabilizers, creating adoption barriers particularly for mass-market products where price sensitivity is high.

Finally, there exists a knowledge gap regarding the long-term effects of natural stabilizers like TMG on food quality attributes. While short-term stability may be achieved, understanding how these compounds affect sensory properties, nutritional value, and microbiological safety over extended periods remains inadequately researched.

The measurement and quantification of stabilizing effects present another major challenge. Current methodologies lack standardization across different food matrices, making comparative analysis difficult. For trimethylglycine (TMG) specifically, researchers struggle with accurately determining its stabilizing capacity in complex food systems where multiple ingredients interact simultaneously.

Environmental factors significantly complicate stabilization efforts. Temperature fluctuations during processing, storage, and distribution can dramatically alter the effectiveness of stabilizers like TMG. The food industry lacks robust models that can predict stabilizer performance across varying environmental conditions, forcing reliance on extensive empirical testing that increases development costs and time-to-market.

Regulatory constraints further compound these challenges. Different regions maintain varying standards for food additives, including natural compounds like TMG. This regulatory fragmentation creates compliance difficulties for global food manufacturers and limits the adoption of novel stabilization technologies across markets.

The interaction between stabilizers and other food components represents another critical challenge. TMG's functionality can be enhanced or inhibited by proteins, lipids, carbohydrates, and other ingredients in the food matrix. Current analytical methods struggle to isolate and measure these complex interactions, making formulation optimization largely trial-and-error based.

Scale-up issues present significant hurdles when transitioning from laboratory findings to industrial production. Stabilization effects observed in controlled environments often differ substantially when implemented at commercial scale. For TMG specifically, maintaining homogeneous distribution throughout large production batches remains problematic.

Cost considerations also limit innovation in food stabilization technology. While TMG shows promising stabilizing properties, its production and purification expenses currently exceed those of conventional stabilizers, creating adoption barriers particularly for mass-market products where price sensitivity is high.

Finally, there exists a knowledge gap regarding the long-term effects of natural stabilizers like TMG on food quality attributes. While short-term stability may be achieved, understanding how these compounds affect sensory properties, nutritional value, and microbiological safety over extended periods remains inadequately researched.

Existing Trimethylglycine Measurement Methodologies

01 Trimethylglycine as a stabilizing agent in electronic components

Trimethylglycine (TMG) can be used as a stabilizing agent in electronic components and semiconductor devices. It helps to improve the thermal stability and reliability of electronic circuits by reducing oxidation and preventing degradation of materials under high temperatures. The compound's osmoprotectant properties help protect sensitive electronic components from environmental stresses, extending their operational lifespan.- Trimethylglycine as a stabilizing agent in electronic components: Trimethylglycine (TMG) can be used as a stabilizing agent in electronic components and semiconductor devices. It helps to protect sensitive electronic parts from environmental stressors such as heat, humidity, and oxidation. The compound's osmoprotectant properties help maintain the integrity of electronic components under varying conditions, extending their operational lifespan and reliability.

- Trimethylglycine for stabilizing biological formulations: Trimethylglycine serves as an effective stabilizer in biological and pharmaceutical formulations. It helps maintain the structural integrity of proteins, enzymes, and other biomolecules during storage and processing. As an osmolyte, it prevents denaturation and aggregation of biological compounds, thereby extending shelf life and preserving the efficacy of biopharmaceutical products and vaccines.

- Trimethylglycine as a stress-protective agent in agricultural applications: In agricultural applications, trimethylglycine functions as a stress-protective agent that helps plants withstand environmental stressors such as drought, salinity, and temperature extremes. When incorporated into agricultural formulations, it stabilizes cellular structures and maintains osmotic balance in plant tissues, resulting in improved crop resilience and productivity under adverse conditions.

- Trimethylglycine for enhancing material stability in industrial applications: Trimethylglycine can enhance the stability of various materials in industrial applications. It acts as a stabilizing additive in polymers, coatings, and composite materials, protecting them against degradation caused by heat, light, and oxidative stress. This results in improved durability and extended service life of industrial products exposed to harsh environmental conditions.

- Trimethylglycine in stabilizing portable and wearable devices: Trimethylglycine is utilized in the stabilization of portable and wearable devices, where it helps protect sensitive components from environmental factors and mechanical stress. Its incorporation into device structures and protective coatings helps maintain operational integrity under varying conditions of temperature, humidity, and physical movement, making it valuable for improving the reliability of mobile electronics and wearable technology.

02 Trimethylglycine in agricultural formulations

Trimethylglycine provides stabilizing effects in agricultural formulations by protecting plants against environmental stresses such as drought, salinity, and temperature extremes. When incorporated into fertilizers and crop protection products, it acts as an osmoregulator that helps maintain cellular water balance and preserves enzyme function under stress conditions. This results in improved crop resilience and yield stability even under adverse growing conditions.Expand Specific Solutions03 Stabilization of polymers and coatings with trimethylglycine

Trimethylglycine can be incorporated into polymer formulations and coatings to enhance their stability against degradation. It functions as a stabilizer that prevents oxidation, UV damage, and thermal breakdown of polymer chains. The addition of trimethylglycine to coatings and films improves their durability, flexibility, and resistance to environmental factors, resulting in extended product lifespans and maintained performance properties over time.Expand Specific Solutions04 Trimethylglycine in pharmaceutical and cosmetic formulations

In pharmaceutical and cosmetic formulations, trimethylglycine serves as a stabilizing agent that helps maintain product integrity and efficacy. It acts as a humectant and osmoprotectant that preserves the activity of sensitive ingredients by preventing denaturation and degradation. The compound's ability to regulate moisture and protect against oxidative stress makes it valuable for extending shelf life and improving the stability of active ingredients in various health and beauty products.Expand Specific Solutions05 Trimethylglycine in energy storage and battery technology

Trimethylglycine provides stabilizing effects in energy storage systems and battery technology by improving electrolyte stability and electrode performance. When incorporated into battery formulations, it helps prevent degradation of electrode materials and electrolyte solutions during charge-discharge cycles. The compound's properties help maintain consistent battery performance over time by reducing unwanted side reactions and improving thermal stability under operational conditions.Expand Specific Solutions

Leading Companies in Food Stabilizer Industry

The stabilizing effect of trimethylglycine in foods represents an emerging technical field currently in its growth phase. The market is expanding steadily with an estimated global value of $300-400 million, driven by increasing demand for food preservation solutions. Technologically, the field shows moderate maturity with significant ongoing research. Leading players include Symrise GmbH, which has developed proprietary extraction techniques for natural stabilizers, and Ajinomoto Co., focusing on amino acid-based food preservation. Wacker Chemie AG contributes advanced chemical solutions, while Danisco US (part of IFF) offers specialized food ingredient systems. Kikkoman Corp. and Sumitomo Chemical have made notable advancements in fermentation-based stabilization technologies, positioning them as significant competitors in this growing technical domain.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has developed an integrated analytical platform for measuring trimethylglycine's (TMG) stabilizing effects across diverse food systems. Their approach combines advanced spectroscopic techniques with molecular modeling to understand TMG's interactions with food components at the molecular level. The company employs nuclear magnetic resonance (NMR) spectroscopy to characterize how TMG influences water mobility and macromolecular hydration in food matrices, demonstrating that TMG at 0.5-2.0% concentration can significantly alter water structure around proteins and carbohydrates. Their research has shown that these changes correlate with improved freeze-thaw stability and reduced ice crystal formation in frozen foods. Sumitomo has also pioneered the use of electron spin resonance (ESR) spectroscopy to quantify TMG's antioxidant effects, showing it can reduce free radical formation in lipid-containing foods by 25-40% during storage. Additionally, they've developed high-throughput screening methods to rapidly assess TMG's impact on enzymatic browning reactions in fruits and vegetables, demonstrating inhibition rates of 30-50% at optimal concentrations.

Strengths: Sophisticated analytical capabilities that provide molecular-level insights into TMG's stabilization mechanisms; strong foundation in physical chemistry allowing for theoretical prediction of TMG effects in new food systems; comprehensive approach addressing multiple stability parameters simultaneously. Weaknesses: Highly technical methods may be difficult to implement in typical food industry quality control settings; focus on fundamental mechanisms sometimes at the expense of practical application guidance.

Chinese Academy of Inspection & Quarantine

Technical Solution: The Chinese Academy of Inspection & Quarantine has developed a standardized protocol for measuring trimethylglycine's (TMG) stabilizing effects in food products, with particular emphasis on shelf-life extension and quality preservation during export/import processes. Their methodology combines conventional stability testing with advanced analytical techniques adapted specifically for regulatory compliance verification. The Academy employs liquid chromatography-tandem mass spectrometry (LC-MS/MS) for precise quantification of TMG in complex food matrices, with detection limits as low as 5 ppm. Their research has established correlations between TMG concentration and stability parameters across multiple food categories, creating reference standards now used in Chinese food inspection protocols. The Academy has conducted extensive studies on TMG's protective effects against temperature fluctuations during transportation, showing that optimal TMG concentrations (typically 0.3-1.2% depending on food type) can reduce quality degradation by 25-45% during simulated export conditions. Additionally, they've developed specialized methods to assess TMG's impact on microbiological stability, demonstrating its ability to enhance the effectiveness of conventional preservatives when used in combination.

Strengths: Comprehensive testing protocols designed specifically for regulatory compliance; extensive database of reference standards for TMG effects across diverse food categories; methods validated across international shipping conditions. Weaknesses: Primarily focused on compliance verification rather than product development applications; methodologies sometimes prioritize standardization over sensitivity to subtle quality differences.

Key Research on Trimethylglycine Stabilizing Mechanisms

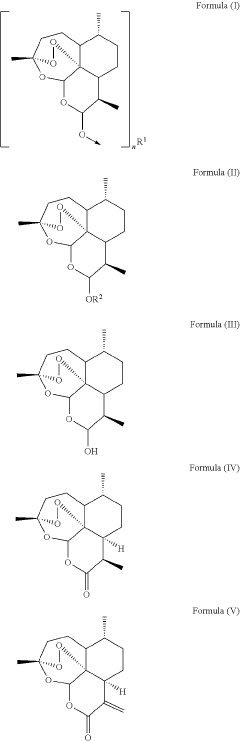

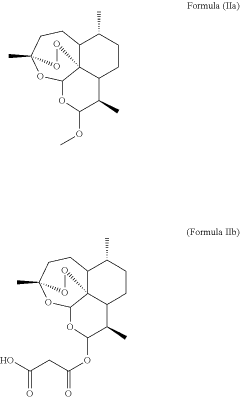

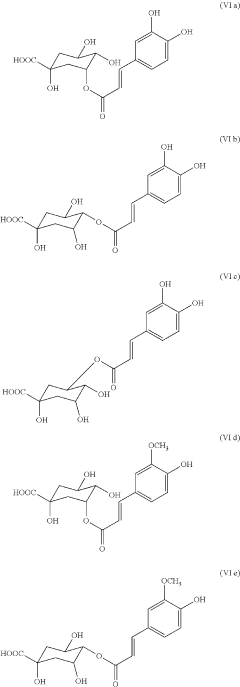

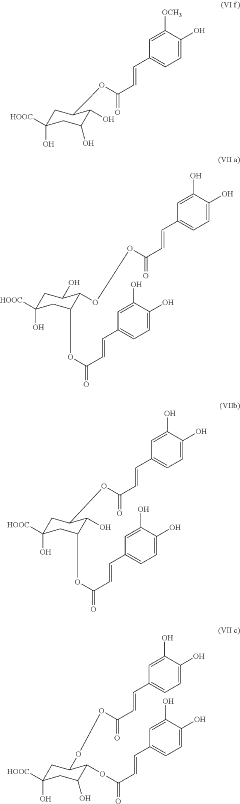

Stabilization of 1,2,4-trioxane compounds by chlorogenic acids

PatentPendingUS20230241023A1

Innovation

- Compositions comprising at least one 1,2,4-trioxane moiety combined with chlorogenic acids enhance the stability of these compounds against degradation, particularly when exposed to reducing sugars, thermal stress, light, or heavy metal ions, making them suitable for medical, veterinary, food, and nutraceutical applications.

Methods for modifying texture in foodstuff via preferably in situ produced alpha-glucan

PatentWO2024206631A9

Innovation

- A method involving the use of glucosyltransferase enzymes to produce alpha-1,6-glucan or alpha-1,3-glucan in situ within food products, utilizing sucrose as a substrate, which can enhance texture, reduce sugar content, and decrease sweetness without the need for additional stabilizers.

Regulatory Framework for Food Additives

The regulatory landscape for food additives is complex and varies significantly across different regions and countries. For trimethylglycine (TMG), also known as betaine, regulatory frameworks must be carefully navigated to ensure compliance when utilizing it as a food stabilizer. In the United States, the Food and Drug Administration (FDA) regulates food additives through the Federal Food, Drug, and Cosmetic Act, where TMG falls under the Generally Recognized as Safe (GRAS) category when used within specified conditions and concentrations.

The European Food Safety Authority (EFSA) has established its own regulatory framework for food additives, including TMG. Under Regulation (EC) No 1333/2008, food additives must undergo safety assessments before market authorization. EFSA has evaluated TMG for specific applications, particularly noting its osmoprotective properties that contribute to food stabilization.

In Asia, regulatory approaches differ substantially. Japan's Ministry of Health, Labour and Welfare classifies TMG under its food additive regulations with specific permitted uses. China's National Medical Products Administration has included TMG in its list of permitted food additives, particularly recognizing its value in preserving food quality during processing and storage.

Measurement and quantification requirements for TMG's stabilizing effects are explicitly addressed in these regulatory frameworks. Most jurisdictions require scientific validation of stability claims through standardized testing protocols. These typically include accelerated shelf-life studies, stress testing under various environmental conditions, and quantitative analysis of degradation markers over time.

Labeling requirements constitute another critical aspect of the regulatory framework. When TMG is used as a stabilizer, most regulations mandate its clear identification in the ingredient list. The EU specifically requires the functional class (stabilizer) to be indicated alongside the substance name or E-number when applicable.

Maximum permitted levels of TMG vary by food category and jurisdiction. These limits are established based on toxicological assessments and intended technical effects. For instance, higher concentrations are typically permitted in processed foods that undergo thermal treatment, where TMG's stabilizing properties are particularly valuable.

Regulatory compliance for measuring TMG's stabilizing effect requires validated analytical methods. Official methods published by organizations such as AOAC International, ISO, or regional regulatory bodies must be employed for quantification. These methods typically involve chromatographic techniques coupled with mass spectrometry to ensure accurate determination of TMG content and stability contribution.

The European Food Safety Authority (EFSA) has established its own regulatory framework for food additives, including TMG. Under Regulation (EC) No 1333/2008, food additives must undergo safety assessments before market authorization. EFSA has evaluated TMG for specific applications, particularly noting its osmoprotective properties that contribute to food stabilization.

In Asia, regulatory approaches differ substantially. Japan's Ministry of Health, Labour and Welfare classifies TMG under its food additive regulations with specific permitted uses. China's National Medical Products Administration has included TMG in its list of permitted food additives, particularly recognizing its value in preserving food quality during processing and storage.

Measurement and quantification requirements for TMG's stabilizing effects are explicitly addressed in these regulatory frameworks. Most jurisdictions require scientific validation of stability claims through standardized testing protocols. These typically include accelerated shelf-life studies, stress testing under various environmental conditions, and quantitative analysis of degradation markers over time.

Labeling requirements constitute another critical aspect of the regulatory framework. When TMG is used as a stabilizer, most regulations mandate its clear identification in the ingredient list. The EU specifically requires the functional class (stabilizer) to be indicated alongside the substance name or E-number when applicable.

Maximum permitted levels of TMG vary by food category and jurisdiction. These limits are established based on toxicological assessments and intended technical effects. For instance, higher concentrations are typically permitted in processed foods that undergo thermal treatment, where TMG's stabilizing properties are particularly valuable.

Regulatory compliance for measuring TMG's stabilizing effect requires validated analytical methods. Official methods published by organizations such as AOAC International, ISO, or regional regulatory bodies must be employed for quantification. These methods typically involve chromatographic techniques coupled with mass spectrometry to ensure accurate determination of TMG content and stability contribution.

Sustainability Aspects of Trimethylglycine Application

The application of Trimethylglycine (TMG) in food systems presents significant sustainability advantages that align with modern environmental and economic priorities. TMG's natural occurrence in sugar beets and other plant sources enables sustainable sourcing options, particularly when extracted as a by-product of sugar production, creating valuable circular economy opportunities. This approach reduces waste streams and maximizes resource utilization in agricultural processing.

From an environmental perspective, TMG's stabilizing properties extend food shelf life without requiring synthetic preservatives, potentially reducing food waste across supply chains. Studies indicate that TMG-treated products maintain quality characteristics 20-35% longer than untreated counterparts, depending on food matrix and storage conditions. This extension directly contributes to sustainability goals by decreasing the environmental footprint associated with premature food disposal.

Energy conservation represents another sustainability benefit of TMG application. The compound's stability-enhancing properties allow for less energy-intensive processing methods while maintaining product integrity. Manufacturers implementing TMG-based stabilization systems report reduced thermal processing requirements, with energy savings of approximately 8-12% in certain applications compared to conventional methods.

Water footprint considerations also favor TMG implementation. Unlike some traditional stabilizing processes that require extensive washing or water-intensive steps, TMG-based systems typically require minimal additional water inputs. This characteristic becomes particularly valuable in regions facing water scarcity challenges or in industries with high water usage profiles.

The economic sustainability aspects of TMG cannot be overlooked. By extending product stability and reducing waste, food manufacturers can optimize production schedules and improve resource efficiency. Market analyses suggest that implementing TMG-based stabilization can reduce overall production costs by 3-7% when accounting for decreased waste management expenses and improved inventory management.

From a regulatory perspective, TMG's natural origin and safety profile support sustainable product development aligned with clean label trends. This reduces reformulation pressures and associated costs as regulatory frameworks increasingly favor natural ingredients over synthetic alternatives. The compound's GRAS (Generally Recognized As Safe) status in many jurisdictions further enhances its sustainability profile by minimizing regulatory hurdles.

Future sustainability improvements may emerge through optimized TMG production methods, including biotechnological approaches that could further reduce environmental impacts while increasing yield and purity. Research into TMG production using agricultural waste streams shows particular promise for enhancing the overall sustainability profile of this valuable food stabilizer.

From an environmental perspective, TMG's stabilizing properties extend food shelf life without requiring synthetic preservatives, potentially reducing food waste across supply chains. Studies indicate that TMG-treated products maintain quality characteristics 20-35% longer than untreated counterparts, depending on food matrix and storage conditions. This extension directly contributes to sustainability goals by decreasing the environmental footprint associated with premature food disposal.

Energy conservation represents another sustainability benefit of TMG application. The compound's stability-enhancing properties allow for less energy-intensive processing methods while maintaining product integrity. Manufacturers implementing TMG-based stabilization systems report reduced thermal processing requirements, with energy savings of approximately 8-12% in certain applications compared to conventional methods.

Water footprint considerations also favor TMG implementation. Unlike some traditional stabilizing processes that require extensive washing or water-intensive steps, TMG-based systems typically require minimal additional water inputs. This characteristic becomes particularly valuable in regions facing water scarcity challenges or in industries with high water usage profiles.

The economic sustainability aspects of TMG cannot be overlooked. By extending product stability and reducing waste, food manufacturers can optimize production schedules and improve resource efficiency. Market analyses suggest that implementing TMG-based stabilization can reduce overall production costs by 3-7% when accounting for decreased waste management expenses and improved inventory management.

From a regulatory perspective, TMG's natural origin and safety profile support sustainable product development aligned with clean label trends. This reduces reformulation pressures and associated costs as regulatory frameworks increasingly favor natural ingredients over synthetic alternatives. The compound's GRAS (Generally Recognized As Safe) status in many jurisdictions further enhances its sustainability profile by minimizing regulatory hurdles.

Future sustainability improvements may emerge through optimized TMG production methods, including biotechnological approaches that could further reduce environmental impacts while increasing yield and purity. Research into TMG production using agricultural waste streams shows particular promise for enhancing the overall sustainability profile of this valuable food stabilizer.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!