Reliability Metrics for Solenoid Valves in Semiconductor Manufacturing

JUL 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Reliability Background and Objectives

Solenoid valves play a critical role in semiconductor manufacturing processes, serving as essential components in various systems such as gas delivery, vacuum control, and fluid management. The reliability of these valves is paramount to ensuring consistent and high-quality semiconductor production. Over the past few decades, the semiconductor industry has witnessed significant advancements in manufacturing technologies, leading to increased demands on the performance and reliability of solenoid valves.

The evolution of solenoid valve technology in semiconductor manufacturing can be traced back to the early days of the industry. Initially, these valves were relatively simple devices with limited control capabilities. As semiconductor processes became more complex and precise, the need for more sophisticated and reliable valve systems grew. This led to the development of advanced solenoid valves with improved materials, enhanced sealing technologies, and more precise actuation mechanisms.

In recent years, the focus on solenoid valve reliability has intensified due to the increasing miniaturization of semiconductor devices and the adoption of more stringent manufacturing processes. The industry has recognized the need for comprehensive reliability metrics to assess and predict the performance of solenoid valves in semiconductor manufacturing environments. These metrics aim to quantify various aspects of valve reliability, including cycle life, response time consistency, leak rates, and resistance to harsh chemicals and extreme temperatures.

The primary objective of developing reliability metrics for solenoid valves in semiconductor manufacturing is to establish standardized methods for evaluating and comparing valve performance across different manufacturers and applications. These metrics serve multiple purposes, including guiding valve selection for specific processes, optimizing maintenance schedules, and driving continuous improvement in valve design and manufacturing.

Furthermore, reliability metrics play a crucial role in risk management and quality control within semiconductor fabs. By accurately assessing valve reliability, manufacturers can minimize downtime, reduce scrap rates, and improve overall yield. This is particularly important as the industry moves towards more advanced process nodes and larger wafer sizes, where the cost of equipment failures and production interruptions becomes increasingly significant.

The development of comprehensive reliability metrics for solenoid valves also aligns with the broader trend of Industry 4.0 and smart manufacturing in the semiconductor sector. These metrics provide valuable data for predictive maintenance systems, enabling proactive replacement of valves before failure occurs and optimizing overall equipment effectiveness (OEE).

As the semiconductor industry continues to evolve, the importance of solenoid valve reliability metrics is expected to grow. Future research and development efforts are likely to focus on refining existing metrics and developing new ones to address emerging challenges in semiconductor manufacturing, such as the integration of new materials and the adoption of more extreme process conditions.

The evolution of solenoid valve technology in semiconductor manufacturing can be traced back to the early days of the industry. Initially, these valves were relatively simple devices with limited control capabilities. As semiconductor processes became more complex and precise, the need for more sophisticated and reliable valve systems grew. This led to the development of advanced solenoid valves with improved materials, enhanced sealing technologies, and more precise actuation mechanisms.

In recent years, the focus on solenoid valve reliability has intensified due to the increasing miniaturization of semiconductor devices and the adoption of more stringent manufacturing processes. The industry has recognized the need for comprehensive reliability metrics to assess and predict the performance of solenoid valves in semiconductor manufacturing environments. These metrics aim to quantify various aspects of valve reliability, including cycle life, response time consistency, leak rates, and resistance to harsh chemicals and extreme temperatures.

The primary objective of developing reliability metrics for solenoid valves in semiconductor manufacturing is to establish standardized methods for evaluating and comparing valve performance across different manufacturers and applications. These metrics serve multiple purposes, including guiding valve selection for specific processes, optimizing maintenance schedules, and driving continuous improvement in valve design and manufacturing.

Furthermore, reliability metrics play a crucial role in risk management and quality control within semiconductor fabs. By accurately assessing valve reliability, manufacturers can minimize downtime, reduce scrap rates, and improve overall yield. This is particularly important as the industry moves towards more advanced process nodes and larger wafer sizes, where the cost of equipment failures and production interruptions becomes increasingly significant.

The development of comprehensive reliability metrics for solenoid valves also aligns with the broader trend of Industry 4.0 and smart manufacturing in the semiconductor sector. These metrics provide valuable data for predictive maintenance systems, enabling proactive replacement of valves before failure occurs and optimizing overall equipment effectiveness (OEE).

As the semiconductor industry continues to evolve, the importance of solenoid valve reliability metrics is expected to grow. Future research and development efforts are likely to focus on refining existing metrics and developing new ones to address emerging challenges in semiconductor manufacturing, such as the integration of new materials and the adoption of more extreme process conditions.

Market Demand Analysis for High-Reliability Valves

The semiconductor manufacturing industry has witnessed a significant surge in demand for high-reliability valves, particularly solenoid valves, due to the increasing complexity and precision requirements of semiconductor fabrication processes. This market demand is driven by several key factors that underscore the critical role of reliable valve systems in maintaining production efficiency and product quality.

Firstly, the continuous miniaturization of semiconductor components has led to more stringent requirements for process control. High-reliability valves are essential in ensuring precise fluid and gas flow management, which directly impacts the quality and consistency of semiconductor production. As chip manufacturers push the boundaries of transistor density and performance, the tolerance for errors in fluid handling systems has dramatically decreased, creating a strong market pull for valves with superior reliability metrics.

Moreover, the semiconductor industry's shift towards more advanced manufacturing processes, such as extreme ultraviolet (EUV) lithography and atomic layer deposition (ALD), has intensified the need for valves that can operate flawlessly under extreme conditions. These processes often involve corrosive chemicals, high temperatures, and ultra-high vacuum environments, all of which demand valves with exceptional durability and consistent performance over extended periods.

The market for high-reliability valves is also being driven by the semiconductor industry's focus on reducing downtime and improving overall equipment effectiveness (OEE). Unplanned shutdowns due to valve failures can result in substantial production losses and increased maintenance costs. Consequently, semiconductor manufacturers are willing to invest in premium valve solutions that offer enhanced reliability, longer service life, and predictive maintenance capabilities.

Furthermore, the global expansion of semiconductor manufacturing capacity, particularly in regions like Asia and North America, is creating new opportunities for valve suppliers. As new fabs are constructed and existing facilities are upgraded, there is a growing demand for state-of-the-art valve systems that can meet the industry's evolving reliability standards.

The market is also seeing increased interest in smart valve solutions that incorporate sensors and diagnostic capabilities. These advanced valves enable real-time monitoring of performance parameters, facilitating predictive maintenance strategies and reducing the risk of unexpected failures. This trend aligns with the broader Industry 4.0 initiatives in semiconductor manufacturing, where data-driven decision-making and automation are becoming increasingly important.

In conclusion, the market demand for high-reliability valves in semiconductor manufacturing is robust and growing. Valve manufacturers that can demonstrate superior reliability metrics, innovative designs, and advanced monitoring capabilities are well-positioned to capture significant market share in this critical and expanding segment of the semiconductor supply chain.

Firstly, the continuous miniaturization of semiconductor components has led to more stringent requirements for process control. High-reliability valves are essential in ensuring precise fluid and gas flow management, which directly impacts the quality and consistency of semiconductor production. As chip manufacturers push the boundaries of transistor density and performance, the tolerance for errors in fluid handling systems has dramatically decreased, creating a strong market pull for valves with superior reliability metrics.

Moreover, the semiconductor industry's shift towards more advanced manufacturing processes, such as extreme ultraviolet (EUV) lithography and atomic layer deposition (ALD), has intensified the need for valves that can operate flawlessly under extreme conditions. These processes often involve corrosive chemicals, high temperatures, and ultra-high vacuum environments, all of which demand valves with exceptional durability and consistent performance over extended periods.

The market for high-reliability valves is also being driven by the semiconductor industry's focus on reducing downtime and improving overall equipment effectiveness (OEE). Unplanned shutdowns due to valve failures can result in substantial production losses and increased maintenance costs. Consequently, semiconductor manufacturers are willing to invest in premium valve solutions that offer enhanced reliability, longer service life, and predictive maintenance capabilities.

Furthermore, the global expansion of semiconductor manufacturing capacity, particularly in regions like Asia and North America, is creating new opportunities for valve suppliers. As new fabs are constructed and existing facilities are upgraded, there is a growing demand for state-of-the-art valve systems that can meet the industry's evolving reliability standards.

The market is also seeing increased interest in smart valve solutions that incorporate sensors and diagnostic capabilities. These advanced valves enable real-time monitoring of performance parameters, facilitating predictive maintenance strategies and reducing the risk of unexpected failures. This trend aligns with the broader Industry 4.0 initiatives in semiconductor manufacturing, where data-driven decision-making and automation are becoming increasingly important.

In conclusion, the market demand for high-reliability valves in semiconductor manufacturing is robust and growing. Valve manufacturers that can demonstrate superior reliability metrics, innovative designs, and advanced monitoring capabilities are well-positioned to capture significant market share in this critical and expanding segment of the semiconductor supply chain.

Current Challenges in Solenoid Valve Reliability

The reliability of solenoid valves in semiconductor manufacturing faces several critical challenges that impact production efficiency and product quality. One of the primary issues is the harsh operating environment, characterized by extreme temperatures, corrosive gases, and high-purity requirements. These conditions accelerate wear and tear on valve components, leading to premature failures and reduced lifespan.

Contamination control presents another significant challenge. Even minute particles can compromise the integrity of semiconductor processes, necessitating stringent cleanliness standards for solenoid valves. Achieving and maintaining these standards throughout the valve's operational life is a constant struggle, requiring advanced materials and design innovations.

The demand for increasingly precise flow control in semiconductor manufacturing processes exacerbates reliability concerns. As feature sizes in semiconductors continue to shrink, the tolerance for flow variations becomes tighter. This places greater stress on solenoid valves to maintain consistent performance over extended periods, pushing the limits of current designs and materials.

Thermal management is a critical factor affecting solenoid valve reliability. The heat generated during operation can lead to thermal expansion, altering valve dimensions and affecting sealing properties. This thermal cycling can cause fatigue and eventual failure of valve components, particularly in high-frequency switching applications common in semiconductor manufacturing.

The complexity of modern semiconductor processes also introduces challenges in valve diagnostics and predictive maintenance. Traditional reliability metrics may not adequately capture the nuanced performance requirements of these advanced manufacturing environments. Developing more sophisticated monitoring and analysis tools is crucial for predicting valve failures before they impact production.

Electromagnetic interference (EMI) poses another reliability concern, particularly in the highly sensitive semiconductor manufacturing environment. Solenoid valves, by nature of their operation, can both generate and be affected by EMI, potentially disrupting nearby electronic systems or compromising their own performance.

Lastly, the industry's push towards miniaturization and increased integration of components presents challenges in maintaining reliability while reducing valve size. Smaller valves must deliver the same or better performance and longevity as their larger counterparts, often with less material and in more confined spaces, pushing the boundaries of current design and manufacturing capabilities.

Addressing these challenges requires a multifaceted approach, combining advancements in materials science, design engineering, and process control. The development of new reliability metrics and testing methodologies specific to semiconductor manufacturing environments is essential to overcome these hurdles and ensure the continued evolution of solenoid valve technology in this critical industry.

Contamination control presents another significant challenge. Even minute particles can compromise the integrity of semiconductor processes, necessitating stringent cleanliness standards for solenoid valves. Achieving and maintaining these standards throughout the valve's operational life is a constant struggle, requiring advanced materials and design innovations.

The demand for increasingly precise flow control in semiconductor manufacturing processes exacerbates reliability concerns. As feature sizes in semiconductors continue to shrink, the tolerance for flow variations becomes tighter. This places greater stress on solenoid valves to maintain consistent performance over extended periods, pushing the limits of current designs and materials.

Thermal management is a critical factor affecting solenoid valve reliability. The heat generated during operation can lead to thermal expansion, altering valve dimensions and affecting sealing properties. This thermal cycling can cause fatigue and eventual failure of valve components, particularly in high-frequency switching applications common in semiconductor manufacturing.

The complexity of modern semiconductor processes also introduces challenges in valve diagnostics and predictive maintenance. Traditional reliability metrics may not adequately capture the nuanced performance requirements of these advanced manufacturing environments. Developing more sophisticated monitoring and analysis tools is crucial for predicting valve failures before they impact production.

Electromagnetic interference (EMI) poses another reliability concern, particularly in the highly sensitive semiconductor manufacturing environment. Solenoid valves, by nature of their operation, can both generate and be affected by EMI, potentially disrupting nearby electronic systems or compromising their own performance.

Lastly, the industry's push towards miniaturization and increased integration of components presents challenges in maintaining reliability while reducing valve size. Smaller valves must deliver the same or better performance and longevity as their larger counterparts, often with less material and in more confined spaces, pushing the boundaries of current design and manufacturing capabilities.

Addressing these challenges requires a multifaceted approach, combining advancements in materials science, design engineering, and process control. The development of new reliability metrics and testing methodologies specific to semiconductor manufacturing environments is essential to overcome these hurdles and ensure the continued evolution of solenoid valve technology in this critical industry.

Existing Reliability Measurement Techniques

01 Improved valve design for enhanced reliability

Solenoid valve reliability can be improved through advanced design features such as optimized flow paths, reinforced components, and precision manufacturing techniques. These enhancements reduce wear, minimize leakage, and extend the operational lifespan of the valve.- Improved valve design for enhanced reliability: Solenoid valve reliability can be improved through advanced design features such as optimized flow paths, reinforced components, and enhanced sealing mechanisms. These design improvements help reduce wear, prevent leakage, and ensure consistent operation over extended periods.

- Material selection for durability: Selecting appropriate materials for solenoid valve components is crucial for reliability. High-quality, corrosion-resistant materials such as stainless steel or specialized alloys can significantly extend the valve's lifespan and maintain performance in challenging environments.

- Advanced testing and quality control methods: Implementing rigorous testing procedures and quality control measures during manufacturing can greatly enhance solenoid valve reliability. This includes pressure testing, cycle testing, and environmental stress screening to identify potential weaknesses before deployment.

- Predictive maintenance and condition monitoring: Incorporating sensors and diagnostic systems for real-time monitoring of solenoid valve performance can help predict potential failures and schedule maintenance proactively. This approach significantly improves reliability by addressing issues before they lead to valve failure.

- Redundancy and fail-safe mechanisms: Implementing redundant systems or fail-safe mechanisms in critical applications can enhance overall system reliability. This may include dual solenoid configurations or mechanical backup systems to ensure continued operation in case of primary valve failure.

02 Fault detection and diagnostic systems

Implementing fault detection and diagnostic systems in solenoid valves can significantly improve their reliability. These systems monitor valve performance, detect anomalies, and provide early warnings of potential failures, allowing for proactive maintenance and reducing unexpected downtime.Expand Specific Solutions03 Material selection for harsh environments

Choosing appropriate materials for solenoid valve components is crucial for reliability in challenging operating conditions. Corrosion-resistant alloys, high-temperature polymers, and durable coatings can enhance valve performance and longevity in harsh industrial environments.Expand Specific Solutions04 Smart control and monitoring systems

Integrating smart control and monitoring systems into solenoid valves can improve their reliability. These systems enable real-time performance tracking, predictive maintenance, and remote diagnostics, leading to optimized valve operation and reduced failure rates.Expand Specific Solutions05 Testing and quality assurance procedures

Implementing rigorous testing and quality assurance procedures during manufacturing and installation can significantly enhance solenoid valve reliability. This includes pressure testing, cycle testing, and environmental stress screening to identify potential weaknesses and ensure consistent performance.Expand Specific Solutions

Key Players in Semiconductor Valve Manufacturing

The reliability metrics for solenoid valves in semiconductor manufacturing represent a critical aspect of the industry's technological landscape. This field is in a mature stage of development, with established players like Tokyo Electron, Samsung Electronics, and FUJIFILM Corp. dominating the market. The global semiconductor manufacturing equipment market, which includes solenoid valve systems, is projected to reach significant scale, driven by increasing demand for advanced electronics. Technologically, companies such as MKS, Inc. and Renesas Electronics Corp. are at the forefront, continuously improving valve reliability through innovations in materials, design, and control systems. The competition is intense, with firms like SK hynix and Semiconductor Manufacturing International (Shanghai) Corp. also making substantial investments in enhancing solenoid valve performance and longevity.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron Ltd. has pioneered a holistic approach to solenoid valve reliability in semiconductor manufacturing. They have developed a proprietary Valve Health Index (VHI) that combines multiple performance metrics into a single, easy-to-interpret score[2]. This index incorporates data from embedded sensors that monitor valve temperature, pressure differentials, and electromagnetic characteristics[4]. Tokyo Electron's reliability system also includes a unique "self-healing" feature that can make minor adjustments to valve parameters in real-time to optimize performance and extend operational life[6]. Additionally, they have implemented a cloud-based analytics platform that aggregates data from multiple fabs, enabling cross-facility comparisons and continuous improvement of reliability metrics[8].

Strengths: Comprehensive Valve Health Index, self-healing capabilities, and cross-facility data analytics. Weaknesses: Potential complexity in implementation and integration with existing systems, and possible data security concerns with cloud-based analytics.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an innovative reliability metric system for solenoid valves used in their semiconductor manufacturing processes. Their approach focuses on a multi-dimensional reliability assessment that includes both traditional metrics and novel indicators. Samsung's system incorporates real-time monitoring of valve actuation speed, power consumption, and temperature profiles[1]. They have also implemented advanced acoustic sensors to detect early signs of wear or malfunction based on changes in the valve's sound signature during operation[3]. Samsung's reliability metrics are integrated into their overall fab management system, allowing for predictive maintenance scheduling and optimization of valve replacement intervals[5]. Furthermore, they have developed a unique "valve twinning" technology that creates digital replicas of each valve, enabling detailed simulation and analysis of performance under various operating conditions[7].

Strengths: Multi-dimensional reliability assessment, acoustic monitoring for early fault detection, and digital twin technology for advanced simulation. Weaknesses: Potentially high implementation costs and complexity in integrating the system across diverse manufacturing lines.

Core Innovations in Valve Reliability Testing

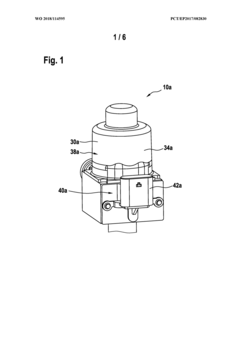

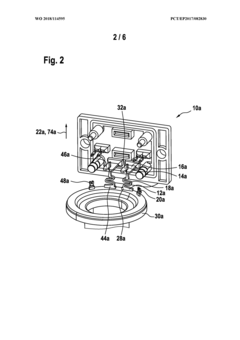

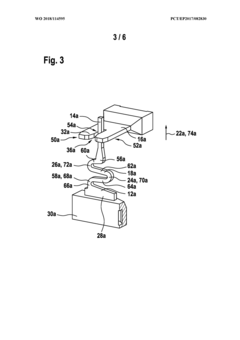

Valve device

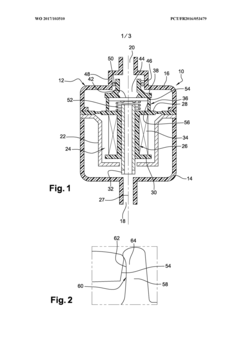

PatentWO2018114595A1

Innovation

- A solenoid valve device with a contact element and a compensating section of higher deformability, made from metallic materials like copper alloys, which compensates for thermal and mechanical deformations, ensuring a stable electrical connection by being reversibly deformable and designed to maintain contact integrity under various conditions.

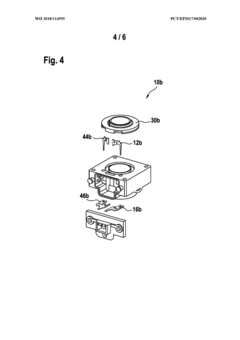

Solenoid valve

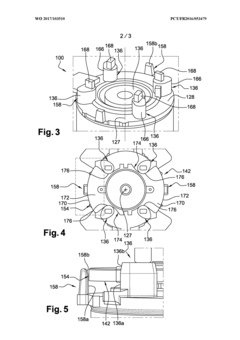

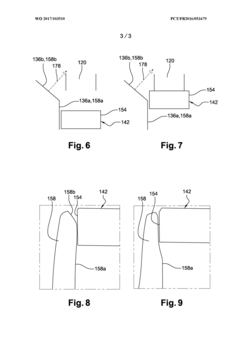

PatentWO2017103510A1

Innovation

- The solenoid valve design incorporates guide faces with obliquely inclined surfaces to prevent the formation of hooked parts, ensuring smooth operation by guiding the shutter member without inducing wear that leads to hook formation, and features a central hub with annular flanges and distributed studs for sliding guidance.

Semiconductor Industry Standards and Regulations

The semiconductor industry operates under stringent standards and regulations to ensure the quality, reliability, and safety of its products and processes. These standards are crucial for maintaining consistency across the global semiconductor supply chain and meeting the demanding requirements of various applications, including those involving solenoid valves in semiconductor manufacturing.

One of the primary organizations setting standards for the semiconductor industry is the Semiconductor Equipment and Materials International (SEMI). SEMI develops and maintains a comprehensive set of global standards that cover various aspects of semiconductor manufacturing, including equipment specifications, materials, safety, and environmental considerations. These standards are regularly updated to keep pace with technological advancements and industry needs.

In the context of solenoid valves used in semiconductor manufacturing, several SEMI standards are particularly relevant. For instance, SEMI S2 provides guidelines for environmental, health, and safety (EHS) requirements in semiconductor manufacturing equipment. This standard encompasses aspects such as chemical handling, electrical safety, and mechanical hazards, which are all pertinent to the operation of solenoid valves in semiconductor fabrication processes.

Another important standard is SEMI E6, which focuses on facilities interface specifications. This standard is crucial for ensuring compatibility and interoperability between various components and systems in semiconductor manufacturing facilities, including the integration of solenoid valves into complex manufacturing equipment.

The International Electrotechnical Commission (IEC) also plays a significant role in setting standards that impact solenoid valve reliability in semiconductor manufacturing. IEC 60747, for example, provides specifications for semiconductor devices, which can include components used in solenoid valve control systems.

Additionally, the International Organization for Standardization (ISO) contributes to the regulatory framework with standards such as ISO 14644, which defines cleanroom classifications and associated controlled environments. This standard is critical for maintaining the ultra-clean conditions required in semiconductor manufacturing, where solenoid valves must operate without introducing contaminants.

Specific to reliability metrics, standards like IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) provide guidelines for assessing and ensuring the reliability of safety-critical components, which can be applied to solenoid valves in semiconductor manufacturing processes where precision and safety are paramount.

Furthermore, regional regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impact the materials and manufacturing processes used in solenoid valves for semiconductor applications. Compliance with these regulations is essential for global market access and environmental responsibility.

One of the primary organizations setting standards for the semiconductor industry is the Semiconductor Equipment and Materials International (SEMI). SEMI develops and maintains a comprehensive set of global standards that cover various aspects of semiconductor manufacturing, including equipment specifications, materials, safety, and environmental considerations. These standards are regularly updated to keep pace with technological advancements and industry needs.

In the context of solenoid valves used in semiconductor manufacturing, several SEMI standards are particularly relevant. For instance, SEMI S2 provides guidelines for environmental, health, and safety (EHS) requirements in semiconductor manufacturing equipment. This standard encompasses aspects such as chemical handling, electrical safety, and mechanical hazards, which are all pertinent to the operation of solenoid valves in semiconductor fabrication processes.

Another important standard is SEMI E6, which focuses on facilities interface specifications. This standard is crucial for ensuring compatibility and interoperability between various components and systems in semiconductor manufacturing facilities, including the integration of solenoid valves into complex manufacturing equipment.

The International Electrotechnical Commission (IEC) also plays a significant role in setting standards that impact solenoid valve reliability in semiconductor manufacturing. IEC 60747, for example, provides specifications for semiconductor devices, which can include components used in solenoid valve control systems.

Additionally, the International Organization for Standardization (ISO) contributes to the regulatory framework with standards such as ISO 14644, which defines cleanroom classifications and associated controlled environments. This standard is critical for maintaining the ultra-clean conditions required in semiconductor manufacturing, where solenoid valves must operate without introducing contaminants.

Specific to reliability metrics, standards like IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) provide guidelines for assessing and ensuring the reliability of safety-critical components, which can be applied to solenoid valves in semiconductor manufacturing processes where precision and safety are paramount.

Furthermore, regional regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impact the materials and manufacturing processes used in solenoid valves for semiconductor applications. Compliance with these regulations is essential for global market access and environmental responsibility.

Environmental Impact of Valve Manufacturing

The environmental impact of valve manufacturing, particularly for solenoid valves used in semiconductor production, is a critical consideration in the industry's sustainability efforts. The production process involves various materials and energy-intensive steps that contribute to the overall environmental footprint. Raw material extraction, primarily metals like brass, stainless steel, and copper, requires significant energy and can lead to habitat disruption and water pollution. The manufacturing phase itself consumes substantial energy for machining, assembly, and testing processes.

Electroplating and surface treatment of valve components often involve hazardous chemicals, potentially resulting in toxic waste if not properly managed. The use of plastics and rubber in valve seals and gaskets introduces additional environmental concerns, as these materials are derived from non-renewable resources and can persist in the environment for extended periods. Moreover, the precision required in semiconductor manufacturing necessitates stringent quality control measures, which may lead to increased material waste from rejected components.

Energy consumption during valve operation is another significant factor. While solenoid valves are generally energy-efficient compared to other valve types, the cumulative energy use across numerous valves in a semiconductor fabrication facility can be substantial. This operational energy demand indirectly contributes to greenhouse gas emissions, depending on the energy source.

End-of-life considerations for solenoid valves also present environmental challenges. The complex nature of these components, often containing a mix of materials, can make recycling difficult. Improper disposal may lead to electronic waste issues, particularly for valves with integrated electronic controls. However, advancements in design for disassembly and recycling are gradually improving the recyclability of these components.

The semiconductor industry's push for miniaturization has implications for valve manufacturing as well. While smaller valves may require less material, the increased complexity and precision demands can lead to more energy-intensive manufacturing processes. Additionally, the use of rare earth elements in some advanced valve designs introduces concerns about resource scarcity and the environmental impact of mining these materials.

To address these environmental concerns, valve manufacturers are increasingly adopting sustainable practices. These include implementing closed-loop manufacturing systems to reduce waste, utilizing renewable energy sources, and exploring alternative materials with lower environmental impacts. Some companies are also focusing on developing valves with longer lifespans and improved reliability, which can reduce the frequency of replacements and associated environmental costs.

Electroplating and surface treatment of valve components often involve hazardous chemicals, potentially resulting in toxic waste if not properly managed. The use of plastics and rubber in valve seals and gaskets introduces additional environmental concerns, as these materials are derived from non-renewable resources and can persist in the environment for extended periods. Moreover, the precision required in semiconductor manufacturing necessitates stringent quality control measures, which may lead to increased material waste from rejected components.

Energy consumption during valve operation is another significant factor. While solenoid valves are generally energy-efficient compared to other valve types, the cumulative energy use across numerous valves in a semiconductor fabrication facility can be substantial. This operational energy demand indirectly contributes to greenhouse gas emissions, depending on the energy source.

End-of-life considerations for solenoid valves also present environmental challenges. The complex nature of these components, often containing a mix of materials, can make recycling difficult. Improper disposal may lead to electronic waste issues, particularly for valves with integrated electronic controls. However, advancements in design for disassembly and recycling are gradually improving the recyclability of these components.

The semiconductor industry's push for miniaturization has implications for valve manufacturing as well. While smaller valves may require less material, the increased complexity and precision demands can lead to more energy-intensive manufacturing processes. Additionally, the use of rare earth elements in some advanced valve designs introduces concerns about resource scarcity and the environmental impact of mining these materials.

To address these environmental concerns, valve manufacturers are increasingly adopting sustainable practices. These include implementing closed-loop manufacturing systems to reduce waste, utilizing renewable energy sources, and exploring alternative materials with lower environmental impacts. Some companies are also focusing on developing valves with longer lifespans and improved reliability, which can reduce the frequency of replacements and associated environmental costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!