Reliability Testing And Long-Term Stability Of EUV Resist Chemistries

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EUV Resist Evolution and Testing Objectives

Extreme Ultraviolet (EUV) lithography represents a revolutionary advancement in semiconductor manufacturing, enabling the production of increasingly smaller and more complex integrated circuits. The evolution of EUV resist chemistries has been marked by significant milestones since the early 2000s, transitioning from conceptual research to commercial implementation in high-volume manufacturing environments.

The development trajectory of EUV resists has progressed through several distinct phases. Initially, researchers adapted existing 193nm resist platforms, which proved inadequate due to the fundamentally different photochemical mechanisms involved with EUV's 13.5nm wavelength. This led to the second generation of purpose-designed chemically amplified resists (CARs) specifically engineered for EUV exposure. The current third generation focuses on metal-oxide hybrid resists that offer enhanced sensitivity and resolution capabilities.

Industry trends indicate a clear movement toward non-chemically amplified resist (non-CAR) technologies, which promise reduced line edge roughness and improved pattern fidelity at smaller feature sizes. Simultaneously, there is growing interest in multi-trigger resist mechanisms that combine aspects of both CAR and non-CAR approaches to optimize performance across multiple parameters.

The primary technical objectives for EUV resist development center around the resolution-linewidth roughness-sensitivity (RLS) trade-off triangle. Current targets aim to achieve sub-10nm half-pitch resolution with line edge roughness below 2nm (3σ) while maintaining practical sensitivity levels below 30mJ/cm². Additionally, pattern collapse prevention at high aspect ratios and etch resistance improvement represent critical secondary objectives.

Long-term stability testing has emerged as a crucial evaluation metric, with industry standards now requiring resist formulations to maintain consistent performance characteristics for at least 6-12 months under controlled storage conditions. This includes stability of chemical composition, sensitivity parameters, and resolution capabilities over time.

Outgassing behavior during exposure represents another key testing objective, as volatile compounds released during the EUV exposure process can contaminate expensive optics within the lithography system. Standardized testing protocols have been established to quantify and minimize this effect.

The evolution of testing methodologies has paralleled resist development, with advanced analytical techniques including time-resolved spectroscopy, synchrotron-based analysis, and high-resolution electron microscopy becoming essential tools for understanding fundamental resist behavior at the molecular level.

The development trajectory of EUV resists has progressed through several distinct phases. Initially, researchers adapted existing 193nm resist platforms, which proved inadequate due to the fundamentally different photochemical mechanisms involved with EUV's 13.5nm wavelength. This led to the second generation of purpose-designed chemically amplified resists (CARs) specifically engineered for EUV exposure. The current third generation focuses on metal-oxide hybrid resists that offer enhanced sensitivity and resolution capabilities.

Industry trends indicate a clear movement toward non-chemically amplified resist (non-CAR) technologies, which promise reduced line edge roughness and improved pattern fidelity at smaller feature sizes. Simultaneously, there is growing interest in multi-trigger resist mechanisms that combine aspects of both CAR and non-CAR approaches to optimize performance across multiple parameters.

The primary technical objectives for EUV resist development center around the resolution-linewidth roughness-sensitivity (RLS) trade-off triangle. Current targets aim to achieve sub-10nm half-pitch resolution with line edge roughness below 2nm (3σ) while maintaining practical sensitivity levels below 30mJ/cm². Additionally, pattern collapse prevention at high aspect ratios and etch resistance improvement represent critical secondary objectives.

Long-term stability testing has emerged as a crucial evaluation metric, with industry standards now requiring resist formulations to maintain consistent performance characteristics for at least 6-12 months under controlled storage conditions. This includes stability of chemical composition, sensitivity parameters, and resolution capabilities over time.

Outgassing behavior during exposure represents another key testing objective, as volatile compounds released during the EUV exposure process can contaminate expensive optics within the lithography system. Standardized testing protocols have been established to quantify and minimize this effect.

The evolution of testing methodologies has paralleled resist development, with advanced analytical techniques including time-resolved spectroscopy, synchrotron-based analysis, and high-resolution electron microscopy becoming essential tools for understanding fundamental resist behavior at the molecular level.

Market Demand Analysis for EUV Lithography Materials

The global market for EUV lithography materials, particularly photoresists, has experienced exponential growth driven by the semiconductor industry's relentless pursuit of Moore's Law. As chip manufacturers transition to sub-7nm nodes, EUV lithography has emerged as the critical enabling technology, creating substantial demand for specialized resist chemistries capable of meeting extreme performance requirements.

Market analysis indicates that the EUV photoresist market is projected to grow at a compound annual growth rate of 19% through 2027, significantly outpacing the broader semiconductor materials sector. This acceleration stems from the widespread adoption of EUV technology by major foundries including TSMC, Samsung, and Intel, who collectively plan to install over 100 EUV scanners by 2025.

The demand for reliable EUV resist chemistries is primarily driven by three key market factors. First, the economics of advanced semiconductor manufacturing necessitates materials that can deliver consistent performance with minimal defects, as the cost of yield loss at advanced nodes exceeds $50,000 per wafer. Second, the increasing complexity of chip designs requires resists with superior resolution capabilities and pattern fidelity. Third, high-volume manufacturing environments demand materials with demonstrated long-term stability to ensure production continuity.

Regional market assessment reveals Asia-Pacific dominates demand, accounting for approximately 70% of the global EUV materials market, with Taiwan and South Korea leading consumption due to their concentrated advanced foundry capacity. North America and Europe represent smaller but growing markets as they invest in reshoring semiconductor manufacturing capabilities.

Customer segmentation shows that leading-edge foundries constitute the primary market, followed by memory manufacturers who are increasingly adopting EUV for critical layers. Both segments emphasize reliability testing data when qualifying new resist formulations, with particular focus on batch-to-batch consistency and shelf-life stability.

Market research indicates that customers are willing to pay premium prices for resist chemistries with comprehensive reliability data. The average selling price for EUV resists is 5-7 times higher than traditional ArF resists, reflecting both the advanced chemistry required and the value of demonstrated stability.

Industry surveys reveal that semiconductor manufacturers rank long-term stability as the third most important selection criterion for EUV resists, following resolution capability and sensitivity. This prioritization underscores the critical nature of reliability testing in the commercial adoption cycle of new resist formulations.

Market analysis indicates that the EUV photoresist market is projected to grow at a compound annual growth rate of 19% through 2027, significantly outpacing the broader semiconductor materials sector. This acceleration stems from the widespread adoption of EUV technology by major foundries including TSMC, Samsung, and Intel, who collectively plan to install over 100 EUV scanners by 2025.

The demand for reliable EUV resist chemistries is primarily driven by three key market factors. First, the economics of advanced semiconductor manufacturing necessitates materials that can deliver consistent performance with minimal defects, as the cost of yield loss at advanced nodes exceeds $50,000 per wafer. Second, the increasing complexity of chip designs requires resists with superior resolution capabilities and pattern fidelity. Third, high-volume manufacturing environments demand materials with demonstrated long-term stability to ensure production continuity.

Regional market assessment reveals Asia-Pacific dominates demand, accounting for approximately 70% of the global EUV materials market, with Taiwan and South Korea leading consumption due to their concentrated advanced foundry capacity. North America and Europe represent smaller but growing markets as they invest in reshoring semiconductor manufacturing capabilities.

Customer segmentation shows that leading-edge foundries constitute the primary market, followed by memory manufacturers who are increasingly adopting EUV for critical layers. Both segments emphasize reliability testing data when qualifying new resist formulations, with particular focus on batch-to-batch consistency and shelf-life stability.

Market research indicates that customers are willing to pay premium prices for resist chemistries with comprehensive reliability data. The average selling price for EUV resists is 5-7 times higher than traditional ArF resists, reflecting both the advanced chemistry required and the value of demonstrated stability.

Industry surveys reveal that semiconductor manufacturers rank long-term stability as the third most important selection criterion for EUV resists, following resolution capability and sensitivity. This prioritization underscores the critical nature of reliability testing in the commercial adoption cycle of new resist formulations.

Current Challenges in EUV Resist Reliability

Despite significant advancements in EUV lithography technology, resist materials continue to present substantial reliability challenges that impede widespread industrial adoption. The fundamental issue stems from the high-energy photons (13.5 nm wavelength) in EUV lithography, which generate secondary electrons that can cause unintended chemical reactions in resist materials. These reactions often lead to pattern degradation, line edge roughness (LER), and structural instability over time.

Current EUV resists face significant sensitivity-resolution-LER trade-off limitations. When optimized for high sensitivity to accommodate the relatively low power output of EUV sources, resists typically sacrifice resolution quality and exhibit increased LER. Conversely, when formulated for superior resolution, they require longer exposure times, reducing throughput and increasing production costs.

Post-exposure stability represents another critical challenge. Many EUV resist formulations demonstrate pattern degradation within hours or days after exposure, creating significant complications for manufacturing environments where processing delays may occur between lithography and subsequent steps. This instability manifests as dimensional changes, feature collapse, or complete pattern loss.

Environmental factors further complicate reliability testing. Humidity, temperature fluctuations, and atmospheric contaminants can dramatically affect resist performance, with some formulations showing up to 30% variation in critical dimensions under different environmental conditions. This sensitivity necessitates strictly controlled manufacturing environments, adding complexity and cost.

Outgassing during exposure presents both tool contamination and pattern quality concerns. Volatile components released from resists can deposit on expensive EUV optics, requiring frequent maintenance cycles. Additionally, these outgassed materials can redeposit on the wafer surface, causing defects and further compromising reliability.

The chemical complexity of EUV resist systems makes comprehensive reliability testing exceptionally challenging. Modern EUV resists contain photoacid generators, quenchers, base polymers, and various additives, each with potential degradation pathways. Understanding the interaction between these components during and after exposure requires sophisticated analytical techniques that are still evolving.

Accelerated aging tests often fail to accurately predict long-term stability, as the degradation mechanisms under accelerated conditions may differ fundamentally from those occurring during normal aging. This disconnect creates uncertainty in reliability projections and complicates qualification processes for new resist formulations in production environments.

Current EUV resists face significant sensitivity-resolution-LER trade-off limitations. When optimized for high sensitivity to accommodate the relatively low power output of EUV sources, resists typically sacrifice resolution quality and exhibit increased LER. Conversely, when formulated for superior resolution, they require longer exposure times, reducing throughput and increasing production costs.

Post-exposure stability represents another critical challenge. Many EUV resist formulations demonstrate pattern degradation within hours or days after exposure, creating significant complications for manufacturing environments where processing delays may occur between lithography and subsequent steps. This instability manifests as dimensional changes, feature collapse, or complete pattern loss.

Environmental factors further complicate reliability testing. Humidity, temperature fluctuations, and atmospheric contaminants can dramatically affect resist performance, with some formulations showing up to 30% variation in critical dimensions under different environmental conditions. This sensitivity necessitates strictly controlled manufacturing environments, adding complexity and cost.

Outgassing during exposure presents both tool contamination and pattern quality concerns. Volatile components released from resists can deposit on expensive EUV optics, requiring frequent maintenance cycles. Additionally, these outgassed materials can redeposit on the wafer surface, causing defects and further compromising reliability.

The chemical complexity of EUV resist systems makes comprehensive reliability testing exceptionally challenging. Modern EUV resists contain photoacid generators, quenchers, base polymers, and various additives, each with potential degradation pathways. Understanding the interaction between these components during and after exposure requires sophisticated analytical techniques that are still evolving.

Accelerated aging tests often fail to accurately predict long-term stability, as the degradation mechanisms under accelerated conditions may differ fundamentally from those occurring during normal aging. This disconnect creates uncertainty in reliability projections and complicates qualification processes for new resist formulations in production environments.

Established Methodologies for EUV Resist Testing

01 Chemical composition for EUV resist stability

Specific chemical compositions can enhance the long-term stability of EUV resists. These formulations typically include polymers with acid-labile groups, photoacid generators, and stabilizing additives that prevent degradation over time. The chemical structure of these components is designed to maintain sensitivity to EUV radiation while resisting breakdown during storage and handling. These compositions often incorporate antioxidants and radical scavengers to prevent unwanted reactions that could compromise resist performance.- Chemical composition for EUV resist stability: Specific chemical compositions can enhance the long-term stability of EUV resists. These formulations typically include polymer matrices with acid-labile groups, photoacid generators, and stabilizing additives that prevent degradation over time. The chemical structure of these components is designed to maintain sensitivity to EUV radiation while resisting breakdown during storage and handling. Advanced polymer designs incorporate cross-linking agents that activate only during exposure, preserving the resist's integrity until processing.

- Storage and environmental control methods: Environmental factors significantly impact EUV resist reliability. Controlled storage conditions including temperature regulation, humidity control, and protection from light exposure can extend shelf life and maintain performance characteristics. Specialized packaging systems with inert atmospheres prevent oxidation and contamination. Some formulations incorporate environmental stabilizers that act as scavengers for reactive species that might otherwise degrade the resist components during storage, ensuring consistent performance even after extended periods.

- Testing and quality control protocols: Comprehensive testing methodologies have been developed to evaluate the long-term stability of EUV resist formulations. These include accelerated aging tests, chemical analysis techniques, and performance evaluation under simulated production conditions. Quality control protocols involve regular monitoring of key parameters such as sensitivity, resolution, and line edge roughness over time. Advanced analytical techniques can detect early signs of degradation before they affect lithographic performance, allowing for timely intervention and formulation adjustments.

- Radiation damage mitigation strategies: EUV resists are susceptible to radiation damage that can compromise their long-term stability. Specialized additives and structural modifications can enhance resistance to radiation-induced degradation. These include radical scavengers, energy transfer agents, and protective compounds that absorb harmful radiation without compromising the resist's sensitivity to EUV wavelengths. Some formulations incorporate self-healing mechanisms that can repair radiation damage, extending the useful life of the resist material even under repeated exposure conditions.

- Processing condition optimization: The reliability of EUV resists is significantly influenced by processing conditions. Optimized pre-bake and post-exposure bake parameters can enhance stability by controlling diffusion rates and chemical reactions within the resist. Development processes designed specifically for EUV resists can minimize pattern collapse and maintain feature integrity. Advanced processing techniques include controlled atmosphere development and specialized rinse procedures that preserve the chemical integrity of the resist structures, contributing to improved reliability and reproducibility in nanoscale patterning.

02 Storage conditions for EUV resist materials

Proper storage conditions significantly impact the reliability and shelf life of EUV resist materials. Temperature-controlled environments, typically below room temperature, help prevent premature chemical reactions within the resist. Protection from light exposure, particularly UV wavelengths, is essential to avoid unintended photochemical reactions. Humidity control and oxygen-free storage environments can also prevent degradation mechanisms that affect resist performance. Specialized packaging materials and containers are often employed to maintain these conditions during transportation and storage.Expand Specific Solutions03 Testing methods for EUV resist reliability

Advanced testing methodologies have been developed to evaluate the long-term stability and reliability of EUV resist materials. These include accelerated aging tests under controlled temperature and humidity conditions, followed by performance evaluation. Spectroscopic techniques monitor chemical changes in the resist over time. Lithographic performance tests assess pattern fidelity, line edge roughness, and sensitivity after storage periods. Mechanical property testing evaluates film integrity and adhesion characteristics. These comprehensive testing protocols help predict resist behavior throughout its usable lifetime.Expand Specific Solutions04 Contamination control in EUV resist systems

Contamination control is critical for maintaining EUV resist reliability. Particulate matter, metallic ions, and organic contaminants can catalyze degradation reactions or interfere with exposure processes. Advanced filtration systems and clean room protocols minimize contamination during resist formulation and application. Purification techniques remove trace impurities from resist components that could affect stability. Specialized coating equipment and handling procedures prevent the introduction of contaminants during the lithographic process. These measures collectively ensure consistent performance and extended shelf life of EUV resist materials.Expand Specific Solutions05 Stabilizing additives for EUV resist formulations

Specific stabilizing additives can significantly improve the long-term reliability of EUV resist formulations. These include radical scavengers that prevent unwanted chain reactions, quenchers that control acid diffusion, and thermal stabilizers that maintain performance across temperature variations. Antioxidants protect sensitive components from oxidative degradation during storage. Surfactants and leveling agents ensure consistent film formation and adhesion properties over time. The careful selection and concentration of these additives balance stability requirements with lithographic performance, ensuring that resist materials maintain their critical properties throughout their shelf life.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The EUV resist chemistry reliability testing market is in a growth phase, driven by increasing semiconductor manufacturing demands for advanced nodes. The market is expanding as EUV lithography becomes essential for sub-7nm processes, with projections showing significant growth potential. Technologically, the field remains challenging with ongoing development needed for long-term stability solutions. Key players include semiconductor giants (Samsung Electronics, TSMC) driving requirements, equipment manufacturers (ASML, Tokyo Electron, Applied Materials) providing testing platforms, and specialized chemical suppliers (JSR, TOK, FUJIFILM, Shin-Etsu Chemical) developing advanced resist formulations. Research institutions like IMEC and various universities collaborate with industry to address fundamental stability issues in these complex photochemical systems.

FUJIFILM Corp.

Technical Solution: FUJIFILM has developed a comprehensive EUV resist reliability testing framework that addresses both chemical stability and performance consistency over time. Their approach includes multi-parameter stress testing where resist materials undergo controlled exposure to varying temperatures (10-40°C), humidity levels (20-80% RH), and storage durations (up to 12 months). FUJIFILM's proprietary molecular stabilizers prevent acid diffusion during post-exposure delay, maintaining critical dimension control even with delays of up to 24 hours between exposure and development. Their metal-organic hybrid resist formulations incorporate specially designed ligand structures that resist oxidative degradation, extending shelf life to over 8 months while maintaining sensitivity within ±5% of initial values. FUJIFILM has implemented automated inspection systems that quantify pattern fidelity changes over time, generating statistical models that predict long-term performance based on accelerated aging data.

Strengths: Industry-leading shelf life stability with minimal sensitivity drift. Comprehensive multi-parameter testing methodology provides accurate performance predictions. Weaknesses: Higher material costs compared to conventional resists, and requires specialized handling protocols that may increase manufacturing complexity.

TOKYO OHKA KOGYO CO., LTD.

Technical Solution: Tokyo Ohka Kogyo (TOK) has pioneered metal-containing resist systems specifically engineered for EUV lithography reliability. Their technology incorporates metal-oxide clusters within polymer matrices to enhance absorption efficiency and pattern resolution. TOK's EUV resist formulations feature proprietary stabilizing additives that maintain chemical integrity during extended storage periods, with documented shelf life exceeding 9 months under controlled conditions. Their reliability testing protocol includes exposure to varying humidity levels (30-70% RH) and temperature cycling (15-30°C) to simulate real-world manufacturing environments. TOK has developed specialized dissolution inhibitors that prevent pattern degradation during development, resulting in consistent critical dimension uniformity even after extended periods between exposure and development. Their resists demonstrate less than 3% sensitivity variation after accelerated aging equivalent to 6 months of storage.

Strengths: Exceptional stability under varying environmental conditions with minimal sensitivity drift over time. Advanced metal-oxide technology provides superior absorption efficiency. Weaknesses: Requires precise temperature control during processing, and integration challenges with certain substrate materials may necessitate additional process optimization.

Critical Patents in EUV Resist Stability Enhancement

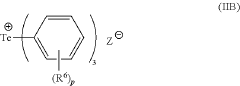

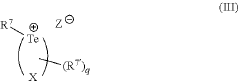

Salts and photoresists comprising same

PatentActiveUS11880134B2

Innovation

- Development of new photoactive tellurium salt compounds that function as acid generators, specifically designed for extreme ultraviolet lithography, which can enhance imaging capabilities and improve resist sensitivity by acting as photoacid generators or photodecomposable quenchers in photoresist compositions.

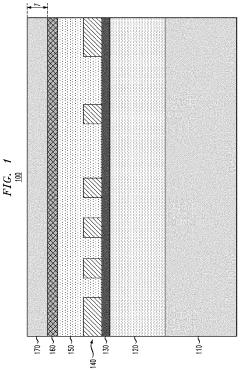

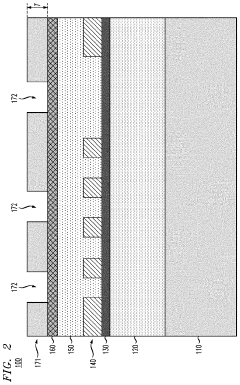

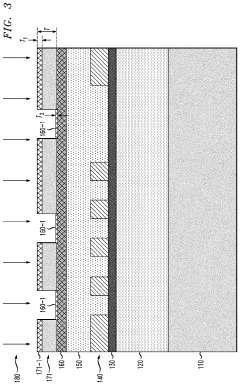

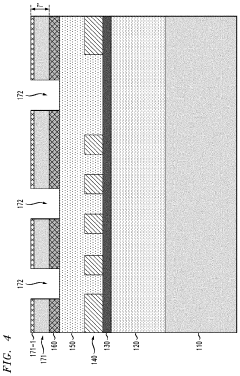

Extreme ultraviolet (EUV) lithography patterning methods utilizing EUV resist hardening

PatentInactiveUS10901317B2

Innovation

- Implementing a surface-hardened EUV resist mask with an etch-resistant layer formed by a neutral atom beam process that implants metallic or chemical species into the upper surface of the EUV resist mask to enhance etch resistance, allowing for patterning of sub-36 nm pitch features without significant mask thickness reduction.

Environmental Impact Assessment of EUV Materials

The environmental impact of Extreme Ultraviolet (EUV) lithography materials, particularly resist chemistries, represents a critical consideration in semiconductor manufacturing sustainability. EUV resists contain complex chemical compounds including metal-organic frameworks, photoacid generators, and various polymers that pose potential environmental concerns throughout their lifecycle.

Primary environmental challenges arise during the production phase, where the synthesis of EUV resist components requires energy-intensive processes and hazardous precursors. Manufacturing these specialized materials generates significant carbon emissions, with estimates suggesting that advanced resist production can contribute up to 15-20% of a semiconductor fab's material-related carbon footprint.

Waste management presents another substantial environmental challenge. Used EUV resists and their byproducts contain heavy metals such as tin, antimony, or hafnium that require specialized disposal protocols. Current industry data indicates that only 30-40% of resist materials are effectively recycled, with the remainder requiring treatment as hazardous waste. This creates long-term environmental liability concerns for manufacturing facilities.

Water consumption and contamination represent additional environmental considerations. The development and rinsing processes for EUV resists typically require ultra-pure water in substantial quantities. Post-process wastewater contains trace amounts of resist components that conventional treatment systems may not fully remove, potentially impacting aquatic ecosystems if not properly managed.

Recent toxicological studies have identified potential bioaccumulation risks associated with certain metal-organic components in EUV resists. While acute toxicity appears limited, the long-term environmental persistence of these compounds remains inadequately characterized, creating uncertainty regarding their ecological impact pathways.

Regulatory frameworks addressing EUV materials vary significantly by region, with the European Union implementing the most stringent requirements through REACH regulations and RoHS directives. These regulations increasingly mandate detailed environmental impact assessments and lifecycle analyses for new resist formulations before market approval.

Industry initiatives to develop more environmentally sustainable EUV resist chemistries are emerging, including bio-inspired alternatives and metal-free formulations that maintain performance while reducing environmental footprint. These green chemistry approaches could potentially reduce hazardous waste generation by up to 50% while maintaining the reliability and stability requirements essential for semiconductor manufacturing.

Primary environmental challenges arise during the production phase, where the synthesis of EUV resist components requires energy-intensive processes and hazardous precursors. Manufacturing these specialized materials generates significant carbon emissions, with estimates suggesting that advanced resist production can contribute up to 15-20% of a semiconductor fab's material-related carbon footprint.

Waste management presents another substantial environmental challenge. Used EUV resists and their byproducts contain heavy metals such as tin, antimony, or hafnium that require specialized disposal protocols. Current industry data indicates that only 30-40% of resist materials are effectively recycled, with the remainder requiring treatment as hazardous waste. This creates long-term environmental liability concerns for manufacturing facilities.

Water consumption and contamination represent additional environmental considerations. The development and rinsing processes for EUV resists typically require ultra-pure water in substantial quantities. Post-process wastewater contains trace amounts of resist components that conventional treatment systems may not fully remove, potentially impacting aquatic ecosystems if not properly managed.

Recent toxicological studies have identified potential bioaccumulation risks associated with certain metal-organic components in EUV resists. While acute toxicity appears limited, the long-term environmental persistence of these compounds remains inadequately characterized, creating uncertainty regarding their ecological impact pathways.

Regulatory frameworks addressing EUV materials vary significantly by region, with the European Union implementing the most stringent requirements through REACH regulations and RoHS directives. These regulations increasingly mandate detailed environmental impact assessments and lifecycle analyses for new resist formulations before market approval.

Industry initiatives to develop more environmentally sustainable EUV resist chemistries are emerging, including bio-inspired alternatives and metal-free formulations that maintain performance while reducing environmental footprint. These green chemistry approaches could potentially reduce hazardous waste generation by up to 50% while maintaining the reliability and stability requirements essential for semiconductor manufacturing.

Standardization Efforts for Resist Reliability Metrics

The standardization of reliability metrics for EUV resist materials represents a critical frontier in semiconductor manufacturing. Industry consortia, including SEMI and IRDS (International Roadmap for Devices and Systems), have initiated collaborative efforts to establish uniform testing protocols and performance benchmarks specifically for EUV resist reliability. These standardization initiatives aim to create a common language for evaluating resist stability across different manufacturing environments and research institutions.

Key standardization bodies like ASTM International and the International Organization for Standardization (ISO) have formed technical committees dedicated to developing comprehensive standards for EUV lithography materials. These committees bring together experts from leading semiconductor manufacturers, material suppliers, and research institutions to define parameters such as outgassing limits, pattern collapse thresholds, and post-exposure stability metrics.

The SEMI Standards Program has made significant progress in developing test methods for quantifying resist reliability factors. Standard E95-18, for instance, provides guidelines for measuring resist outgassing during exposure, while newer standards address line edge roughness measurement protocols and shelf-life determination methodologies. These standards enable meaningful comparison of resist performance across different platforms and exposure conditions.

Consortium-based initiatives like IMEC's EUV Resist Performance Testing Program have established round-robin testing frameworks where multiple facilities evaluate identical resist formulations using standardized protocols. This approach has proven valuable in identifying measurement variabilities and establishing reproducible benchmarks for long-term stability assessment.

The emergence of reliability qualification matrices represents another important standardization trend. These matrices define minimum performance thresholds across multiple parameters including chemical stability during storage, sensitivity to environmental contaminants, and performance consistency across multiple processing cycles. Leading chip manufacturers have begun incorporating these standardized qualification requirements into their material approval processes.

Academic-industry partnerships have contributed significantly to standardization efforts through the development of accelerated aging protocols. These protocols simulate extended storage and processing conditions to predict long-term stability characteristics within compressed timeframes. The resulting data helps establish industry-accepted shelf-life specifications and storage recommendations for EUV resist materials.

Despite progress, challenges remain in standardizing metrics for novel resist chemistries. The rapid evolution of EUV resist technology necessitates continuous refinement of testing methodologies. Industry stakeholders continue to work toward consensus on critical parameters like chemical stability under repeated exposure, sensitivity to airborne molecular contamination, and performance degradation mechanisms during extended storage periods.

Key standardization bodies like ASTM International and the International Organization for Standardization (ISO) have formed technical committees dedicated to developing comprehensive standards for EUV lithography materials. These committees bring together experts from leading semiconductor manufacturers, material suppliers, and research institutions to define parameters such as outgassing limits, pattern collapse thresholds, and post-exposure stability metrics.

The SEMI Standards Program has made significant progress in developing test methods for quantifying resist reliability factors. Standard E95-18, for instance, provides guidelines for measuring resist outgassing during exposure, while newer standards address line edge roughness measurement protocols and shelf-life determination methodologies. These standards enable meaningful comparison of resist performance across different platforms and exposure conditions.

Consortium-based initiatives like IMEC's EUV Resist Performance Testing Program have established round-robin testing frameworks where multiple facilities evaluate identical resist formulations using standardized protocols. This approach has proven valuable in identifying measurement variabilities and establishing reproducible benchmarks for long-term stability assessment.

The emergence of reliability qualification matrices represents another important standardization trend. These matrices define minimum performance thresholds across multiple parameters including chemical stability during storage, sensitivity to environmental contaminants, and performance consistency across multiple processing cycles. Leading chip manufacturers have begun incorporating these standardized qualification requirements into their material approval processes.

Academic-industry partnerships have contributed significantly to standardization efforts through the development of accelerated aging protocols. These protocols simulate extended storage and processing conditions to predict long-term stability characteristics within compressed timeframes. The resulting data helps establish industry-accepted shelf-life specifications and storage recommendations for EUV resist materials.

Despite progress, challenges remain in standardizing metrics for novel resist chemistries. The rapid evolution of EUV resist technology necessitates continuous refinement of testing methodologies. Industry stakeholders continue to work toward consensus on critical parameters like chemical stability under repeated exposure, sensitivity to airborne molecular contamination, and performance degradation mechanisms during extended storage periods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!