Advanced Materials for High-Temperature Solenoid Valve Applications

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temp Solenoid Valve Materials: Background and Objectives

High-temperature solenoid valves have been a critical component in various industries for decades, playing a vital role in controlling fluid flow under extreme temperature conditions. The evolution of these valves has been closely tied to advancements in materials science and engineering. Initially, traditional materials such as stainless steel and certain alloys were used, but as industrial processes became more demanding, the need for more robust and heat-resistant materials became apparent.

The development of high-temperature solenoid valves has been driven by the increasing demands of industries such as aerospace, petrochemical, and power generation. These sectors require valves that can maintain their integrity and functionality in environments where temperatures can exceed 1000°C. The progression of materials used in these valves has seen a shift from conventional metals to more advanced alloys and, more recently, to ceramic and composite materials.

The primary objective of research in this field is to develop materials that can withstand extreme temperatures while maintaining their mechanical properties, chemical resistance, and electromagnetic characteristics. This involves a multidisciplinary approach, combining materials science, mechanical engineering, and electromagnetic theory. The goal is not only to improve temperature resistance but also to enhance overall valve performance, including response time, durability, and energy efficiency.

Current research focuses on several key areas. One is the development of superalloys that can maintain their strength and corrosion resistance at high temperatures. Another area of interest is the exploration of ceramic materials and ceramic matrix composites, which offer excellent thermal stability and wear resistance. Additionally, there is ongoing research into advanced coatings that can provide thermal insulation and protection against oxidation and corrosion.

The technological trajectory in this field is moving towards the integration of smart materials and nanotechnology. This includes the development of shape memory alloys that can respond to temperature changes, potentially revolutionizing valve design. There is also growing interest in nanomaterials that can enhance the thermal and mechanical properties of existing materials.

As industries continue to push the boundaries of operational conditions, the demand for more advanced high-temperature solenoid valve materials is expected to grow. This presents both challenges and opportunities for researchers and engineers in the field. The ultimate aim is to develop materials that not only withstand extreme temperatures but also contribute to improved energy efficiency, reduced maintenance requirements, and enhanced overall system performance.

The development of high-temperature solenoid valves has been driven by the increasing demands of industries such as aerospace, petrochemical, and power generation. These sectors require valves that can maintain their integrity and functionality in environments where temperatures can exceed 1000°C. The progression of materials used in these valves has seen a shift from conventional metals to more advanced alloys and, more recently, to ceramic and composite materials.

The primary objective of research in this field is to develop materials that can withstand extreme temperatures while maintaining their mechanical properties, chemical resistance, and electromagnetic characteristics. This involves a multidisciplinary approach, combining materials science, mechanical engineering, and electromagnetic theory. The goal is not only to improve temperature resistance but also to enhance overall valve performance, including response time, durability, and energy efficiency.

Current research focuses on several key areas. One is the development of superalloys that can maintain their strength and corrosion resistance at high temperatures. Another area of interest is the exploration of ceramic materials and ceramic matrix composites, which offer excellent thermal stability and wear resistance. Additionally, there is ongoing research into advanced coatings that can provide thermal insulation and protection against oxidation and corrosion.

The technological trajectory in this field is moving towards the integration of smart materials and nanotechnology. This includes the development of shape memory alloys that can respond to temperature changes, potentially revolutionizing valve design. There is also growing interest in nanomaterials that can enhance the thermal and mechanical properties of existing materials.

As industries continue to push the boundaries of operational conditions, the demand for more advanced high-temperature solenoid valve materials is expected to grow. This presents both challenges and opportunities for researchers and engineers in the field. The ultimate aim is to develop materials that not only withstand extreme temperatures but also contribute to improved energy efficiency, reduced maintenance requirements, and enhanced overall system performance.

Market Analysis for Advanced High-Temperature Valves

The market for advanced high-temperature valves is experiencing significant growth, driven by increasing demand across various industries such as aerospace, automotive, oil and gas, and power generation. These sectors require valves capable of withstanding extreme temperatures and harsh operating conditions, making advanced materials for high-temperature solenoid valve applications a critical area of focus.

In the aerospace industry, the demand for high-temperature valves is particularly strong due to the need for lightweight, durable components that can operate efficiently in extreme environments. The automotive sector is also driving market growth, especially with the rise of electric vehicles and the development of more efficient internal combustion engines, which require advanced valve technologies to improve performance and reduce emissions.

The oil and gas industry remains a significant consumer of high-temperature valves, particularly in deep-sea drilling operations and refineries where extreme temperatures and pressures are common. Similarly, the power generation sector, including nuclear and renewable energy plants, requires valves that can withstand high temperatures and corrosive environments.

Market analysts project a compound annual growth rate (CAGR) for the high-temperature valve market to be in the range of 5-7% over the next five years. This growth is attributed to increasing industrialization in developing countries, stringent environmental regulations driving the need for more efficient systems, and ongoing technological advancements in material science.

Geographically, North America and Europe currently dominate the market for advanced high-temperature valves, owing to their well-established industrial bases and significant investments in research and development. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization in countries like China and India, and increasing adoption of advanced technologies in manufacturing and energy sectors.

Key market trends include the development of smart valves with integrated sensors and control systems, which allow for real-time monitoring and predictive maintenance. There is also a growing emphasis on sustainability, with manufacturers focusing on developing valves that improve energy efficiency and reduce environmental impact.

The competitive landscape of the high-temperature valve market is characterized by the presence of several large multinational corporations and specialized manufacturers. These companies are investing heavily in research and development to create innovative materials and designs that can withstand increasingly extreme operating conditions while maintaining reliability and efficiency.

In the aerospace industry, the demand for high-temperature valves is particularly strong due to the need for lightweight, durable components that can operate efficiently in extreme environments. The automotive sector is also driving market growth, especially with the rise of electric vehicles and the development of more efficient internal combustion engines, which require advanced valve technologies to improve performance and reduce emissions.

The oil and gas industry remains a significant consumer of high-temperature valves, particularly in deep-sea drilling operations and refineries where extreme temperatures and pressures are common. Similarly, the power generation sector, including nuclear and renewable energy plants, requires valves that can withstand high temperatures and corrosive environments.

Market analysts project a compound annual growth rate (CAGR) for the high-temperature valve market to be in the range of 5-7% over the next five years. This growth is attributed to increasing industrialization in developing countries, stringent environmental regulations driving the need for more efficient systems, and ongoing technological advancements in material science.

Geographically, North America and Europe currently dominate the market for advanced high-temperature valves, owing to their well-established industrial bases and significant investments in research and development. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization in countries like China and India, and increasing adoption of advanced technologies in manufacturing and energy sectors.

Key market trends include the development of smart valves with integrated sensors and control systems, which allow for real-time monitoring and predictive maintenance. There is also a growing emphasis on sustainability, with manufacturers focusing on developing valves that improve energy efficiency and reduce environmental impact.

The competitive landscape of the high-temperature valve market is characterized by the presence of several large multinational corporations and specialized manufacturers. These companies are investing heavily in research and development to create innovative materials and designs that can withstand increasingly extreme operating conditions while maintaining reliability and efficiency.

Current State and Challenges in High-Temp Solenoid Materials

The current state of high-temperature solenoid valve materials presents both significant advancements and persistent challenges. Recent years have seen remarkable progress in developing materials capable of withstanding extreme temperatures, with some alloys and composites now able to operate reliably at temperatures exceeding 800°C. This progress has been driven by the increasing demands of aerospace, automotive, and industrial applications where high-temperature environments are commonplace.

One of the primary materials currently used in high-temperature solenoid valves is Inconel, a family of austenitic nickel-chromium-based superalloys. These alloys offer excellent resistance to oxidation and maintain their strength at high temperatures. However, they face limitations in terms of magnetic properties and cost-effectiveness for large-scale applications.

Ceramic materials, particularly silicon nitride and silicon carbide, have also gained traction due to their exceptional heat resistance and low thermal expansion. These materials can withstand temperatures well above 1000°C, but they present challenges in terms of manufacturability and integration with metallic components.

A significant hurdle in the development of high-temperature solenoid valve materials is the trade-off between magnetic properties and heat resistance. Materials that exhibit excellent magnetic characteristics at room temperature often lose these properties at elevated temperatures, a phenomenon known as the Curie point. This necessitates the development of novel composites or alloys that can maintain their magnetic properties at high temperatures without compromising structural integrity.

Another challenge lies in the thermal cycling and fatigue resistance of these materials. Rapid temperature changes can induce thermal stresses, leading to material degradation over time. This is particularly problematic in applications where frequent cycling between high and low temperatures is expected.

Corrosion resistance at high temperatures remains a critical issue, especially in environments where aggressive gases or fluids are present. While some superalloys offer good corrosion resistance, there is still a need for materials that can withstand both high temperatures and corrosive environments simultaneously.

The cost and scalability of advanced high-temperature materials also present significant challenges. Many of the most promising materials are expensive to produce and difficult to manufacture at scale, limiting their widespread adoption in commercial applications.

Looking ahead, the field is moving towards the development of advanced ceramic matrix composites (CMCs) and intermetallic compounds. These materials show promise in combining high-temperature stability with the necessary mechanical and magnetic properties. However, significant research is still needed to optimize their performance and develop cost-effective manufacturing processes.

One of the primary materials currently used in high-temperature solenoid valves is Inconel, a family of austenitic nickel-chromium-based superalloys. These alloys offer excellent resistance to oxidation and maintain their strength at high temperatures. However, they face limitations in terms of magnetic properties and cost-effectiveness for large-scale applications.

Ceramic materials, particularly silicon nitride and silicon carbide, have also gained traction due to their exceptional heat resistance and low thermal expansion. These materials can withstand temperatures well above 1000°C, but they present challenges in terms of manufacturability and integration with metallic components.

A significant hurdle in the development of high-temperature solenoid valve materials is the trade-off between magnetic properties and heat resistance. Materials that exhibit excellent magnetic characteristics at room temperature often lose these properties at elevated temperatures, a phenomenon known as the Curie point. This necessitates the development of novel composites or alloys that can maintain their magnetic properties at high temperatures without compromising structural integrity.

Another challenge lies in the thermal cycling and fatigue resistance of these materials. Rapid temperature changes can induce thermal stresses, leading to material degradation over time. This is particularly problematic in applications where frequent cycling between high and low temperatures is expected.

Corrosion resistance at high temperatures remains a critical issue, especially in environments where aggressive gases or fluids are present. While some superalloys offer good corrosion resistance, there is still a need for materials that can withstand both high temperatures and corrosive environments simultaneously.

The cost and scalability of advanced high-temperature materials also present significant challenges. Many of the most promising materials are expensive to produce and difficult to manufacture at scale, limiting their widespread adoption in commercial applications.

Looking ahead, the field is moving towards the development of advanced ceramic matrix composites (CMCs) and intermetallic compounds. These materials show promise in combining high-temperature stability with the necessary mechanical and magnetic properties. However, significant research is still needed to optimize their performance and develop cost-effective manufacturing processes.

Existing High-Temperature Solenoid Valve Material Solutions

01 High-temperature resistant ceramic materials

Advanced ceramic materials are developed for applications requiring high temperature resistance. These materials often incorporate specific oxides, nitrides, or carbides to enhance their thermal stability and mechanical properties at elevated temperatures. The manufacturing processes may involve sintering or hot pressing techniques to achieve the desired microstructure and performance characteristics.- High-temperature resistant polymer composites: Advanced materials for temperature resistance often involve polymer composites reinforced with various fillers or additives. These composites are designed to maintain their structural integrity and mechanical properties at elevated temperatures, making them suitable for applications in aerospace, automotive, and industrial sectors.

- Ceramic-based temperature resistant materials: Ceramic materials and ceramic matrix composites are developed for extreme temperature resistance. These advanced materials can withstand very high temperatures while maintaining their mechanical and chemical properties, making them ideal for use in furnaces, engines, and thermal protection systems.

- Nanostructured materials for thermal stability: Nanostructured materials, such as nanocomposites and nanocoatings, are engineered to enhance temperature resistance. These materials leverage the unique properties of nanoscale structures to improve thermal stability, heat dissipation, and overall performance at high temperatures.

- Metal alloys with improved heat resistance: Advanced metal alloys are developed to withstand high temperatures while maintaining their mechanical properties. These alloys often incorporate elements that enhance oxidation resistance and creep strength, making them suitable for use in turbines, heat exchangers, and other high-temperature applications.

- Thermal barrier coatings: Specialized coatings are designed to provide thermal insulation and protection to underlying materials. These advanced coatings can significantly increase the temperature resistance of various substrates, extending the lifespan and performance of components in high-temperature environments.

02 Temperature-resistant polymer composites

Polymer composites with enhanced temperature resistance are formulated by incorporating heat-resistant fillers, fibers, or nanoparticles into the polymer matrix. These composites often utilize high-performance polymers as the base material and may employ cross-linking or other modification techniques to improve their thermal stability and mechanical properties at elevated temperatures.Expand Specific Solutions03 Thermal barrier coatings for high-temperature applications

Advanced thermal barrier coatings are developed to protect underlying materials from extreme temperatures. These coatings often consist of multiple layers with specific compositions and structures designed to minimize heat transfer and resist thermal cycling. The application methods may include plasma spraying, electron beam physical vapor deposition, or other advanced deposition techniques.Expand Specific Solutions04 Heat-resistant alloys and superalloys

Advanced alloys and superalloys are engineered for superior temperature resistance in demanding applications. These materials often incorporate specific combinations of elements to enhance their high-temperature strength, creep resistance, and oxidation resistance. The manufacturing processes may involve precision casting, powder metallurgy, or additive manufacturing techniques to achieve the desired microstructure and properties.Expand Specific Solutions05 Temperature-resistant nanomaterials

Nanomaterials with enhanced temperature resistance are developed for various applications. These materials may include nanoparticles, nanofibers, or nanocomposites designed to maintain their unique properties at elevated temperatures. The synthesis and processing methods often involve specialized techniques to control the nanoscale structure and composition, resulting in improved thermal stability and performance.Expand Specific Solutions

Key Players in Advanced Materials for Solenoid Valves

The research on advanced materials for high-temperature solenoid valve applications is in a growth phase, with increasing market demand driven by industrial and automotive sectors. The global market size for high-temperature solenoid valves is expanding, reflecting the need for more durable and efficient components in extreme environments. Technologically, the field is advancing rapidly, with companies like Robert Bosch GmbH, Parker-Hannifin Corp., and Eaton Corp. leading innovation. These industry giants are investing heavily in R&D to develop materials that can withstand higher temperatures and pressures. Meanwhile, specialized firms such as Anshan Electromagnetic Valve Co. Ltd. and Buschjost GmbH are focusing on niche applications, contributing to the overall technological maturity of the field.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced materials for high-temperature solenoid valve applications, focusing on innovative alloys and ceramics. Their research includes the use of nickel-based superalloys with enhanced creep resistance and oxidation protection for valve components operating in extreme temperatures[1]. They have also explored ceramic matrix composites (CMCs) for valve seats and seals, which offer excellent thermal stability and wear resistance[3]. Bosch's approach integrates computational materials science to predict and optimize material performance under high-temperature conditions, enabling the design of solenoid valves that maintain reliability and efficiency in harsh environments up to 1000°C[5].

Strengths: Extensive R&D capabilities, advanced material science expertise, and a strong track record in automotive and industrial applications. Weaknesses: High development costs and potential challenges in scaling up production of specialized materials.

Parker-Hannifin Corp.

Technical Solution: Parker-Hannifin has focused on developing high-performance polymers and composite materials for high-temperature solenoid valve applications. Their research includes the use of polyetheretherketone (PEEK) and polyimide-based materials, which offer excellent thermal stability and chemical resistance[2]. They have also explored metal-matrix composites reinforced with ceramic particles to enhance the thermal conductivity and wear resistance of valve components[4]. Parker's approach combines material innovation with advanced manufacturing techniques, such as powder metallurgy and additive manufacturing, to create complex valve geometries that optimize flow characteristics and thermal management in high-temperature environments up to 800°C[6].

Strengths: Diverse material portfolio, strong manufacturing capabilities, and extensive experience in fluid control systems. Weaknesses: Potential limitations in extreme high-temperature applications compared to some ceramic-based solutions.

Core Innovations in High-Temp Resistant Materials

Temperature resistant material electromagnet

PatentInactiveEP1808869A3

Innovation

- A solenoid electromagnet design featuring a bobbin and coil made from temperature-resistant materials such as non-magnetic metals or ceramic, with anodized aluminum or glass fiber-coated wire for the coil, allowing for high packing density and reliable magnetic field generation up to 600°C, and optionally encased with magnetizable material for field localization.

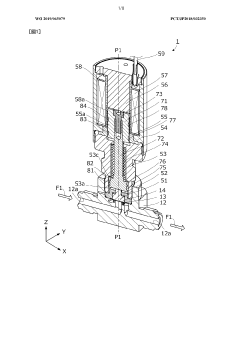

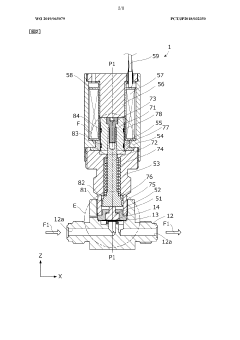

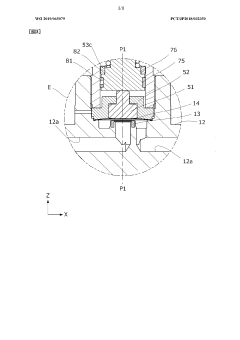

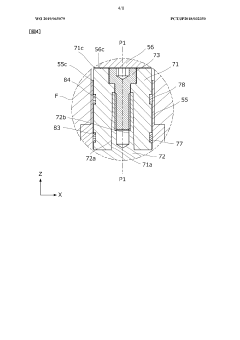

Electromagnetic valve

PatentWO2019065079A1

Innovation

- The solenoid valve employs an electromagnetic drive with annular bearings made of heat-resistant resin to minimize metal powder generation, reduce the air gap for improved responsiveness and durability, and incorporates a cylindrical coil and yoke structure with a movable iron core and push rod to enhance operational longevity and high-temperature performance.

Environmental Impact of Advanced High-Temp Materials

The development and application of advanced materials for high-temperature solenoid valves have significant environmental implications. These materials, designed to withstand extreme temperatures and harsh operating conditions, can contribute to both positive and negative environmental impacts throughout their lifecycle.

One of the primary environmental benefits of advanced high-temperature materials is their potential to improve energy efficiency in various industrial processes. By enabling solenoid valves to operate at higher temperatures, these materials can enhance the overall efficiency of systems in power plants, chemical processing facilities, and aerospace applications. This increased efficiency translates to reduced energy consumption and, consequently, lower greenhouse gas emissions.

However, the production of advanced high-temperature materials often involves energy-intensive processes and the use of rare or toxic elements. The extraction and processing of these raw materials can lead to environmental degradation, including habitat destruction, water pollution, and increased carbon emissions. Manufacturers must carefully consider the environmental trade-offs between the benefits of improved performance and the ecological costs of material production.

The durability and longevity of advanced high-temperature materials can have positive environmental effects by reducing the frequency of component replacements. This extended lifespan results in less waste generation and decreased demand for new materials over time. Additionally, the improved reliability of solenoid valves in high-temperature applications can prevent system failures and potential environmental hazards associated with leaks or malfunctions.

Recycling and end-of-life management present both challenges and opportunities for advanced high-temperature materials. While some components may be recyclable, the complex composition of these materials can make separation and recovery processes difficult. Developing effective recycling technologies and implementing proper disposal methods are crucial to minimizing the environmental impact of these materials at the end of their useful life.

The use of advanced materials in high-temperature solenoid valves can also contribute to the development of cleaner technologies. For instance, these materials enable more efficient and reliable operation in renewable energy systems, such as concentrated solar power plants and geothermal facilities. By supporting the growth of clean energy technologies, advanced high-temperature materials indirectly contribute to reducing reliance on fossil fuels and mitigating climate change.

As research in this field progresses, there is a growing focus on developing environmentally friendly alternatives to traditional high-temperature materials. This includes exploring bio-based materials, reducing the use of rare earth elements, and improving manufacturing processes to minimize environmental impact. These efforts aim to create a new generation of advanced materials that balance high-temperature performance with environmental sustainability.

One of the primary environmental benefits of advanced high-temperature materials is their potential to improve energy efficiency in various industrial processes. By enabling solenoid valves to operate at higher temperatures, these materials can enhance the overall efficiency of systems in power plants, chemical processing facilities, and aerospace applications. This increased efficiency translates to reduced energy consumption and, consequently, lower greenhouse gas emissions.

However, the production of advanced high-temperature materials often involves energy-intensive processes and the use of rare or toxic elements. The extraction and processing of these raw materials can lead to environmental degradation, including habitat destruction, water pollution, and increased carbon emissions. Manufacturers must carefully consider the environmental trade-offs between the benefits of improved performance and the ecological costs of material production.

The durability and longevity of advanced high-temperature materials can have positive environmental effects by reducing the frequency of component replacements. This extended lifespan results in less waste generation and decreased demand for new materials over time. Additionally, the improved reliability of solenoid valves in high-temperature applications can prevent system failures and potential environmental hazards associated with leaks or malfunctions.

Recycling and end-of-life management present both challenges and opportunities for advanced high-temperature materials. While some components may be recyclable, the complex composition of these materials can make separation and recovery processes difficult. Developing effective recycling technologies and implementing proper disposal methods are crucial to minimizing the environmental impact of these materials at the end of their useful life.

The use of advanced materials in high-temperature solenoid valves can also contribute to the development of cleaner technologies. For instance, these materials enable more efficient and reliable operation in renewable energy systems, such as concentrated solar power plants and geothermal facilities. By supporting the growth of clean energy technologies, advanced high-temperature materials indirectly contribute to reducing reliance on fossil fuels and mitigating climate change.

As research in this field progresses, there is a growing focus on developing environmentally friendly alternatives to traditional high-temperature materials. This includes exploring bio-based materials, reducing the use of rare earth elements, and improving manufacturing processes to minimize environmental impact. These efforts aim to create a new generation of advanced materials that balance high-temperature performance with environmental sustainability.

Standardization and Testing Protocols for New Materials

The development of advanced materials for high-temperature solenoid valve applications necessitates robust standardization and testing protocols to ensure reliability, performance, and safety. These protocols are crucial for evaluating new materials and comparing them against existing solutions. A comprehensive approach to standardization and testing should encompass several key areas.

Firstly, thermal performance testing is essential. This includes evaluating the material's ability to withstand extreme temperatures, typically ranging from -40°C to 400°C or higher, depending on the specific application. Thermal cycling tests should be conducted to assess the material's resistance to thermal fatigue and its ability to maintain structural integrity under repeated temperature fluctuations.

Mechanical property testing is another critical aspect. This involves measuring tensile strength, compressive strength, and fatigue resistance at various temperatures. Creep testing is particularly important for high-temperature applications, as it determines the material's ability to resist deformation under constant stress over extended periods.

Chemical resistance testing is vital to ensure the material can withstand exposure to various fluids and gases commonly encountered in solenoid valve applications. This may include tests for corrosion resistance, oxidation resistance, and compatibility with specific working fluids.

Electrical property testing is crucial for solenoid valve materials. This includes evaluating electrical resistivity, dielectric strength, and magnetic permeability across the operational temperature range. These properties directly impact the valve's performance and efficiency.

Durability and longevity testing protocols should be established to simulate real-world operating conditions. This may involve accelerated life testing, where materials are subjected to extreme conditions to predict long-term performance and identify potential failure modes.

Standardized manufacturing process controls are essential to ensure consistency in material properties. This includes specifying acceptable ranges for key process parameters and establishing quality control measures throughout the production process.

Environmental impact and safety testing should also be incorporated into the protocols. This includes assessing the material's recyclability, potential for off-gassing at high temperatures, and compliance with relevant environmental regulations.

Lastly, it is crucial to develop standardized reporting formats and performance metrics. This allows for easy comparison between different materials and ensures that test results are presented in a consistent and meaningful manner across the industry. Collaboration with international standards organizations, such as ASTM International or ISO, can help in developing widely accepted testing protocols and standards for these advanced materials.

Firstly, thermal performance testing is essential. This includes evaluating the material's ability to withstand extreme temperatures, typically ranging from -40°C to 400°C or higher, depending on the specific application. Thermal cycling tests should be conducted to assess the material's resistance to thermal fatigue and its ability to maintain structural integrity under repeated temperature fluctuations.

Mechanical property testing is another critical aspect. This involves measuring tensile strength, compressive strength, and fatigue resistance at various temperatures. Creep testing is particularly important for high-temperature applications, as it determines the material's ability to resist deformation under constant stress over extended periods.

Chemical resistance testing is vital to ensure the material can withstand exposure to various fluids and gases commonly encountered in solenoid valve applications. This may include tests for corrosion resistance, oxidation resistance, and compatibility with specific working fluids.

Electrical property testing is crucial for solenoid valve materials. This includes evaluating electrical resistivity, dielectric strength, and magnetic permeability across the operational temperature range. These properties directly impact the valve's performance and efficiency.

Durability and longevity testing protocols should be established to simulate real-world operating conditions. This may involve accelerated life testing, where materials are subjected to extreme conditions to predict long-term performance and identify potential failure modes.

Standardized manufacturing process controls are essential to ensure consistency in material properties. This includes specifying acceptable ranges for key process parameters and establishing quality control measures throughout the production process.

Environmental impact and safety testing should also be incorporated into the protocols. This includes assessing the material's recyclability, potential for off-gassing at high temperatures, and compliance with relevant environmental regulations.

Lastly, it is crucial to develop standardized reporting formats and performance metrics. This allows for easy comparison between different materials and ensures that test results are presented in a consistent and meaningful manner across the industry. Collaboration with international standards organizations, such as ASTM International or ISO, can help in developing widely accepted testing protocols and standards for these advanced materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!