Advanced Solenoid Valve Coatings for Harsh Chemical Environments

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Coating Evolution and Objectives

Solenoid valve coatings have undergone significant evolution since their inception, driven by the increasing demands of harsh chemical environments in various industries. The development of these coatings has been closely tied to advancements in materials science and surface engineering technologies. Initially, basic metallic coatings were used to provide a minimal barrier against corrosion and wear. However, as industrial processes became more complex and aggressive, the need for more robust and specialized coatings became apparent.

The progression of solenoid valve coatings can be traced through several key stages. Early coatings primarily focused on basic corrosion resistance, utilizing simple electroplating techniques with materials such as nickel or chrome. As the understanding of material interactions in chemical environments improved, more sophisticated multi-layer coatings emerged. These coatings combined different materials to provide enhanced protection against both chemical attack and mechanical wear.

A significant leap forward came with the introduction of polymer-based coatings, such as PTFE (Polytetrafluoroethylene), which offered superior chemical resistance and non-stick properties. This innovation greatly extended the lifespan of solenoid valves in corrosive environments. Subsequently, the development of ceramic coatings marked another milestone, providing exceptional hardness and resistance to extreme temperatures and chemical exposure.

Recent years have seen the emergence of advanced nanocomposite coatings, which combine the benefits of multiple materials at the nanoscale. These coatings offer unprecedented levels of protection and functionality, including self-healing properties and the ability to withstand a wider range of chemical environments.

The primary objective of current research in solenoid valve coatings is to develop solutions that can withstand increasingly aggressive chemical environments while maintaining optimal valve performance. This includes improving coating adhesion to the substrate, enhancing chemical resistance across a broader spectrum of substances, and increasing the overall durability of the coating under repeated cycling and exposure.

Another key goal is to develop coatings that are environmentally friendly and comply with stringent regulations. This involves finding alternatives to traditional coating materials that may contain harmful substances, without compromising on performance. Additionally, there is a focus on creating coatings that can be applied more efficiently, reducing production costs and environmental impact.

Looking forward, the objectives for advanced solenoid valve coatings include the development of smart coatings that can adapt to changing environmental conditions, self-diagnostic capabilities to predict coating failure, and the integration of nanotechnology to achieve molecular-level protection. These advancements aim to push the boundaries of what is possible in harsh chemical environments, enabling solenoid valves to operate reliably in conditions that were previously considered too extreme.

The progression of solenoid valve coatings can be traced through several key stages. Early coatings primarily focused on basic corrosion resistance, utilizing simple electroplating techniques with materials such as nickel or chrome. As the understanding of material interactions in chemical environments improved, more sophisticated multi-layer coatings emerged. These coatings combined different materials to provide enhanced protection against both chemical attack and mechanical wear.

A significant leap forward came with the introduction of polymer-based coatings, such as PTFE (Polytetrafluoroethylene), which offered superior chemical resistance and non-stick properties. This innovation greatly extended the lifespan of solenoid valves in corrosive environments. Subsequently, the development of ceramic coatings marked another milestone, providing exceptional hardness and resistance to extreme temperatures and chemical exposure.

Recent years have seen the emergence of advanced nanocomposite coatings, which combine the benefits of multiple materials at the nanoscale. These coatings offer unprecedented levels of protection and functionality, including self-healing properties and the ability to withstand a wider range of chemical environments.

The primary objective of current research in solenoid valve coatings is to develop solutions that can withstand increasingly aggressive chemical environments while maintaining optimal valve performance. This includes improving coating adhesion to the substrate, enhancing chemical resistance across a broader spectrum of substances, and increasing the overall durability of the coating under repeated cycling and exposure.

Another key goal is to develop coatings that are environmentally friendly and comply with stringent regulations. This involves finding alternatives to traditional coating materials that may contain harmful substances, without compromising on performance. Additionally, there is a focus on creating coatings that can be applied more efficiently, reducing production costs and environmental impact.

Looking forward, the objectives for advanced solenoid valve coatings include the development of smart coatings that can adapt to changing environmental conditions, self-diagnostic capabilities to predict coating failure, and the integration of nanotechnology to achieve molecular-level protection. These advancements aim to push the boundaries of what is possible in harsh chemical environments, enabling solenoid valves to operate reliably in conditions that were previously considered too extreme.

Chemical Industry Demand for Corrosion-Resistant Valves

The chemical industry's demand for corrosion-resistant valves has been steadily increasing due to the harsh operating environments and stringent safety requirements in chemical processing plants. Solenoid valves, in particular, play a crucial role in controlling fluid flow and are often exposed to corrosive chemicals, high temperatures, and extreme pressures. This has created a significant market need for advanced coatings that can protect these valves from degradation and extend their operational lifespan.

Chemical manufacturers are constantly seeking ways to improve process efficiency and reduce maintenance costs. Corrosion-resistant valves are essential in achieving these goals, as they minimize downtime, prevent leaks, and ensure the integrity of chemical processes. The demand is particularly high in sectors dealing with aggressive chemicals, such as chlorine production, sulfuric acid manufacturing, and petrochemical processing.

The market for corrosion-resistant valves in the chemical industry is driven by several factors. Firstly, there is an increasing focus on safety and environmental regulations, which require more reliable and durable valve components. Secondly, the trend towards process intensification in chemical plants has led to more extreme operating conditions, necessitating valves with enhanced corrosion resistance.

Furthermore, the growing adoption of automation and smart manufacturing concepts in the chemical industry has heightened the importance of reliable valve performance. Solenoid valves, being electronically controlled, are integral to these automated systems. Any failure due to corrosion can lead to significant production losses and safety hazards.

The demand for corrosion-resistant valves is not limited to new installations. There is also a substantial market for retrofitting existing chemical plants with more durable valve solutions. This retrofit market is driven by the need to upgrade aging infrastructure and improve overall plant reliability.

Geographically, the demand is particularly strong in regions with a high concentration of chemical manufacturing facilities, such as North America, Western Europe, and East Asia. Emerging economies with rapidly growing chemical industries, like India and China, are also showing increased demand for advanced corrosion-resistant valve technologies.

In terms of specific requirements, the chemical industry is looking for valve coatings that can withstand a wide range of corrosive media, including acids, bases, and organic solvents. The coatings must also maintain their integrity under varying temperature and pressure conditions. Additionally, there is a growing interest in coatings that offer not only corrosion resistance but also other functional properties such as improved flow characteristics or anti-fouling capabilities.

Chemical manufacturers are constantly seeking ways to improve process efficiency and reduce maintenance costs. Corrosion-resistant valves are essential in achieving these goals, as they minimize downtime, prevent leaks, and ensure the integrity of chemical processes. The demand is particularly high in sectors dealing with aggressive chemicals, such as chlorine production, sulfuric acid manufacturing, and petrochemical processing.

The market for corrosion-resistant valves in the chemical industry is driven by several factors. Firstly, there is an increasing focus on safety and environmental regulations, which require more reliable and durable valve components. Secondly, the trend towards process intensification in chemical plants has led to more extreme operating conditions, necessitating valves with enhanced corrosion resistance.

Furthermore, the growing adoption of automation and smart manufacturing concepts in the chemical industry has heightened the importance of reliable valve performance. Solenoid valves, being electronically controlled, are integral to these automated systems. Any failure due to corrosion can lead to significant production losses and safety hazards.

The demand for corrosion-resistant valves is not limited to new installations. There is also a substantial market for retrofitting existing chemical plants with more durable valve solutions. This retrofit market is driven by the need to upgrade aging infrastructure and improve overall plant reliability.

Geographically, the demand is particularly strong in regions with a high concentration of chemical manufacturing facilities, such as North America, Western Europe, and East Asia. Emerging economies with rapidly growing chemical industries, like India and China, are also showing increased demand for advanced corrosion-resistant valve technologies.

In terms of specific requirements, the chemical industry is looking for valve coatings that can withstand a wide range of corrosive media, including acids, bases, and organic solvents. The coatings must also maintain their integrity under varying temperature and pressure conditions. Additionally, there is a growing interest in coatings that offer not only corrosion resistance but also other functional properties such as improved flow characteristics or anti-fouling capabilities.

Current Challenges in Harsh Chemical Environment Coatings

The development of advanced coatings for solenoid valves operating in harsh chemical environments faces several significant challenges. These challenges stem from the extreme conditions these components are subjected to, including exposure to corrosive chemicals, high temperatures, and abrasive materials.

One of the primary challenges is achieving long-term chemical resistance. Coatings must withstand a wide range of aggressive chemicals, including acids, bases, and solvents, without degradation or loss of protective properties. This requires the development of materials with exceptional chemical inertness and stability across a broad pH spectrum.

Thermal stability presents another critical challenge. Coatings must maintain their protective properties at elevated temperatures, often exceeding 200°C in industrial applications. This necessitates the use of advanced polymers or ceramic-based materials that can withstand thermal cycling without cracking, delamination, or loss of adhesion to the substrate.

Wear resistance is equally important, as solenoid valves are subject to mechanical stresses and abrasion from particulates in fluid streams. Coatings must exhibit high hardness and toughness to resist erosion and maintain their protective function over extended operational periods.

The challenge of adhesion to diverse substrate materials cannot be overlooked. Coatings must form strong, durable bonds with various metals used in solenoid valve construction, including stainless steel, brass, and aluminum alloys. This requires careful surface preparation and the development of versatile coating systems that can accommodate different substrate properties.

Permeation resistance is another critical factor. Coatings must provide an effective barrier against the diffusion of small molecules, particularly in applications involving gases or volatile liquids. This demands the development of dense, defect-free coating structures with minimal porosity.

The complexity of coating application processes poses additional challenges. Techniques must be developed that allow for uniform, reproducible coating deposition on complex valve geometries, including internal surfaces and small orifices. This may require innovations in application methods, such as electroless deposition or advanced vapor deposition techniques.

Lastly, there is an ongoing challenge to develop environmentally friendly coating solutions. This involves moving away from traditional coatings that may contain harmful substances like chromates or perfluorinated compounds, towards more sustainable alternatives that maintain or exceed the performance of conventional systems.

One of the primary challenges is achieving long-term chemical resistance. Coatings must withstand a wide range of aggressive chemicals, including acids, bases, and solvents, without degradation or loss of protective properties. This requires the development of materials with exceptional chemical inertness and stability across a broad pH spectrum.

Thermal stability presents another critical challenge. Coatings must maintain their protective properties at elevated temperatures, often exceeding 200°C in industrial applications. This necessitates the use of advanced polymers or ceramic-based materials that can withstand thermal cycling without cracking, delamination, or loss of adhesion to the substrate.

Wear resistance is equally important, as solenoid valves are subject to mechanical stresses and abrasion from particulates in fluid streams. Coatings must exhibit high hardness and toughness to resist erosion and maintain their protective function over extended operational periods.

The challenge of adhesion to diverse substrate materials cannot be overlooked. Coatings must form strong, durable bonds with various metals used in solenoid valve construction, including stainless steel, brass, and aluminum alloys. This requires careful surface preparation and the development of versatile coating systems that can accommodate different substrate properties.

Permeation resistance is another critical factor. Coatings must provide an effective barrier against the diffusion of small molecules, particularly in applications involving gases or volatile liquids. This demands the development of dense, defect-free coating structures with minimal porosity.

The complexity of coating application processes poses additional challenges. Techniques must be developed that allow for uniform, reproducible coating deposition on complex valve geometries, including internal surfaces and small orifices. This may require innovations in application methods, such as electroless deposition or advanced vapor deposition techniques.

Lastly, there is an ongoing challenge to develop environmentally friendly coating solutions. This involves moving away from traditional coatings that may contain harmful substances like chromates or perfluorinated compounds, towards more sustainable alternatives that maintain or exceed the performance of conventional systems.

Existing Chemical-Resistant Coating Technologies

01 Fluoropolymer coatings for chemical resistance

Fluoropolymer coatings, such as PTFE or PFA, are applied to solenoid valve components to enhance chemical resistance. These coatings provide excellent protection against corrosive substances and harsh chemicals, extending the lifespan of the valve and ensuring reliable operation in challenging environments.- Fluoropolymer coatings for chemical resistance: Fluoropolymer coatings, such as PTFE or PFA, are applied to solenoid valve components to enhance chemical resistance. These coatings provide excellent protection against corrosive substances and harsh chemicals, extending the lifespan of the valve and ensuring reliable operation in challenging environments.

- Ceramic coatings for improved durability: Ceramic coatings are utilized on solenoid valve parts to increase chemical resistance and wear resistance. These coatings offer superior hardness and can withstand aggressive chemicals and high temperatures, making them suitable for applications in harsh industrial environments.

- Composite coatings for enhanced protection: Composite coatings combining multiple materials are applied to solenoid valve components to provide a balance of chemical resistance and other desirable properties. These coatings may incorporate ceramic particles in a polymer matrix or utilize layered structures to achieve optimal performance in various chemical environments.

- Surface treatment techniques for improved coating adhesion: Various surface treatment techniques are employed to enhance the adhesion of chemical-resistant coatings on solenoid valve components. These methods may include plasma treatment, chemical etching, or mechanical roughening to create a suitable surface for coating application, ensuring long-lasting protection against chemical attack.

- Specialized coatings for specific chemical environments: Tailored coating formulations are developed to address specific chemical resistance requirements in different industries. These coatings may be optimized for resistance to particular solvents, acids, or other aggressive substances commonly encountered in certain applications, providing targeted protection for solenoid valves in specialized environments.

02 Ceramic coatings for improved durability

Ceramic coatings are utilized on solenoid valve parts to increase chemical resistance and wear resistance. These coatings offer superior hardness and can withstand aggressive chemicals and high temperatures, making them suitable for applications in demanding industrial settings.Expand Specific Solutions03 Composite coatings for enhanced performance

Composite coatings combining multiple materials are applied to solenoid valve components to achieve optimal chemical resistance and other desirable properties. These coatings may incorporate nanoparticles or layered structures to provide a balance of chemical resistance, wear resistance, and thermal stability.Expand Specific Solutions04 Surface treatment techniques for improved adhesion

Various surface treatment techniques are employed to enhance the adhesion of chemical-resistant coatings to solenoid valve surfaces. These methods may include plasma treatment, chemical etching, or the application of primer layers to ensure strong bonding between the coating and the substrate, thereby improving the overall chemical resistance of the valve.Expand Specific Solutions05 Specialized coatings for specific chemical environments

Tailored coating formulations are developed to address specific chemical resistance requirements in different industries. These coatings may be designed to withstand particular solvents, acids, or other aggressive substances commonly encountered in certain applications, ensuring optimal performance and longevity of solenoid valves in specialized chemical environments.Expand Specific Solutions

Key Players in Advanced Coating Solutions

The research on advanced solenoid valve coatings for harsh chemical environments is in a growth phase, with increasing market demand driven by industrial automation and stringent environmental regulations. The global market for specialty coatings is projected to reach $39 billion by 2025, with solenoid valve coatings representing a significant segment. Technologically, the field is advancing rapidly, with companies like Robert Bosch GmbH, Parker-Hannifin Corp., and Praxair Technology, Inc. leading innovation. These firms are developing high-performance coatings that offer enhanced chemical resistance and durability. Emerging players such as Ningbo Institute of Industrial Technology and Foshan Zhongzhizhu New Material Technology Co., Ltd. are also contributing to technological advancements, particularly in nanomaterials and surface treatments for extreme conditions.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced solenoid valve coatings for harsh chemical environments using a multi-layer approach. Their technology involves a base layer of nickel-phosphorus alloy for corrosion resistance, followed by a ceramic layer (e.g., aluminum oxide or zirconium oxide) for thermal insulation and wear resistance. The final layer consists of a fluoropolymer coating (e.g., PTFE) for chemical resistance and low friction. This combination provides excellent protection against aggressive chemicals, high temperatures, and abrasive wear[1][3]. The coating process utilizes plasma-enhanced chemical vapor deposition (PECVD) for precise control of layer thickness and composition, resulting in uniform and durable coatings[2].

Strengths: Excellent chemical resistance, high temperature tolerance, and wear resistance. The multi-layer approach provides comprehensive protection. Weaknesses: Complex and potentially costly manufacturing process, may require specialized equipment for application.

Parker-Hannifin Corp.

Technical Solution: Parker-Hannifin Corp. has developed a proprietary coating technology for solenoid valves in harsh chemical environments called "ChemShield". This coating system utilizes a combination of electroless nickel plating and a specialized polymer overlay. The electroless nickel provides a uniform, corrosion-resistant base layer, while the polymer overlay offers superior chemical resistance and low friction properties. The coating is applied using a multi-step process that includes surface preparation, electroless nickel deposition, and polymer application through a proprietary spraying technique[4]. Parker-Hannifin's coating technology also incorporates nano-scale additives to enhance wear resistance and thermal stability, allowing the coated valves to operate efficiently in temperatures up to 200°C[5].

Strengths: High chemical resistance, good wear properties, and thermal stability. The coating process is scalable for mass production. Weaknesses: May have limitations in extremely high-temperature applications compared to ceramic-based coatings.

Innovative Coating Materials for Harsh Environments

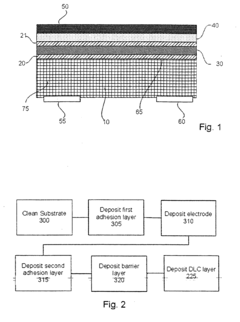

Coating for harsh environments and sensors using same

PatentInactiveEP1891429B1

Innovation

- A coating system comprising a thin Diamond-Like Carbon (DLC) layer with a thicker adhesion/barrier metal system, including niobium or tantalum, and a conductive electrode layer, optimized for smoothness and stability, applied to piezoelectric sensors to enhance durability and operational reliability in extreme conditions.

Coating for harsh environments and sensors using the same

PatentInactiveKR1020080007218A

Innovation

- A multi-layer coating system comprising a barrier layer of tantalum or niobium, an adhesive layer of titanium or chromium, and a DLC layer, along with optional conductive electrodes, provides enhanced adhesion, wear resistance, and chemical resistance, suitable for extreme temperatures.

Environmental Impact of Advanced Coating Materials

The environmental impact of advanced coating materials for solenoid valves in harsh chemical environments is a critical consideration in the development and application of these technologies. These coatings, while designed to enhance the performance and longevity of solenoid valves, may have both positive and negative effects on the environment throughout their lifecycle.

One of the primary environmental benefits of advanced coatings is their potential to extend the operational life of solenoid valves. By protecting valve components from corrosion and wear in harsh chemical environments, these coatings can significantly reduce the frequency of valve replacements. This, in turn, leads to a decrease in raw material consumption and energy expenditure associated with manufacturing and replacing valve components, thereby reducing the overall environmental footprint of industrial processes that rely on these valves.

However, the production of advanced coating materials often involves complex chemical processes and the use of potentially hazardous substances. Some coating formulations may contain volatile organic compounds (VOCs), heavy metals, or other environmentally persistent chemicals. The manufacturing processes for these coatings can result in air and water pollution if not properly managed, necessitating stringent environmental controls and waste management practices.

The disposal of coated valve components at the end of their lifecycle presents another environmental challenge. While the coatings extend the life of the valves, they may also complicate recycling efforts. Some advanced coatings can be difficult to separate from the base materials, potentially reducing the recyclability of the valve components. This could lead to increased landfill waste or require specialized recycling processes, which may have their own environmental impacts.

On the other hand, the development of environmentally friendly coating materials is an emerging trend in the field. Researchers are exploring bio-based and water-based coating formulations that aim to reduce the environmental impact of both production and disposal. These eco-friendly alternatives often have lower VOC emissions and reduced toxicity, aligning with global efforts to minimize the environmental footprint of industrial processes.

The application method of these coatings also plays a role in their environmental impact. Advanced techniques such as plasma-enhanced chemical vapor deposition (PECVD) or atomic layer deposition (ALD) can provide more uniform and thinner coatings, potentially reducing material usage and improving efficiency. However, these processes may be energy-intensive, highlighting the need for a holistic approach to assessing environmental impact.

In conclusion, while advanced solenoid valve coatings offer significant benefits in terms of equipment longevity and performance in harsh chemical environments, their environmental impact is complex and multifaceted. Balancing the positive effects of extended component life against the potential negative impacts of production and disposal is crucial. Ongoing research and development in this field should prioritize not only performance enhancements but also the minimization of environmental impacts throughout the coating's lifecycle.

One of the primary environmental benefits of advanced coatings is their potential to extend the operational life of solenoid valves. By protecting valve components from corrosion and wear in harsh chemical environments, these coatings can significantly reduce the frequency of valve replacements. This, in turn, leads to a decrease in raw material consumption and energy expenditure associated with manufacturing and replacing valve components, thereby reducing the overall environmental footprint of industrial processes that rely on these valves.

However, the production of advanced coating materials often involves complex chemical processes and the use of potentially hazardous substances. Some coating formulations may contain volatile organic compounds (VOCs), heavy metals, or other environmentally persistent chemicals. The manufacturing processes for these coatings can result in air and water pollution if not properly managed, necessitating stringent environmental controls and waste management practices.

The disposal of coated valve components at the end of their lifecycle presents another environmental challenge. While the coatings extend the life of the valves, they may also complicate recycling efforts. Some advanced coatings can be difficult to separate from the base materials, potentially reducing the recyclability of the valve components. This could lead to increased landfill waste or require specialized recycling processes, which may have their own environmental impacts.

On the other hand, the development of environmentally friendly coating materials is an emerging trend in the field. Researchers are exploring bio-based and water-based coating formulations that aim to reduce the environmental impact of both production and disposal. These eco-friendly alternatives often have lower VOC emissions and reduced toxicity, aligning with global efforts to minimize the environmental footprint of industrial processes.

The application method of these coatings also plays a role in their environmental impact. Advanced techniques such as plasma-enhanced chemical vapor deposition (PECVD) or atomic layer deposition (ALD) can provide more uniform and thinner coatings, potentially reducing material usage and improving efficiency. However, these processes may be energy-intensive, highlighting the need for a holistic approach to assessing environmental impact.

In conclusion, while advanced solenoid valve coatings offer significant benefits in terms of equipment longevity and performance in harsh chemical environments, their environmental impact is complex and multifaceted. Balancing the positive effects of extended component life against the potential negative impacts of production and disposal is crucial. Ongoing research and development in this field should prioritize not only performance enhancements but also the minimization of environmental impacts throughout the coating's lifecycle.

Safety Standards for Coated Solenoid Valves

Safety standards for coated solenoid valves in harsh chemical environments are critical to ensure operational integrity and personnel protection. These standards encompass a range of requirements, from material compatibility to performance testing under extreme conditions. The primary focus is on the coating's ability to withstand corrosive chemicals, high temperatures, and pressure fluctuations without compromising the valve's functionality or safety.

International standards such as IEC 60079 and ATEX directives provide guidelines for equipment used in potentially explosive atmospheres, which often overlap with harsh chemical environments. These standards mandate specific coating properties, including chemical resistance, adhesion strength, and durability under cyclic stress. Compliance with these standards typically requires extensive testing and certification processes.

Material selection for coatings plays a crucial role in meeting safety standards. Advanced fluoropolymers, ceramic composites, and specialized epoxy resins are among the materials that have demonstrated superior performance in harsh chemical environments. These coatings must not only resist chemical attack but also maintain their protective properties over extended periods of exposure.

Testing protocols for coated solenoid valves often include accelerated aging tests, chemical immersion trials, and thermal shock evaluations. These tests aim to simulate long-term exposure to aggressive chemicals and extreme operating conditions. Safety standards may specify minimum performance criteria, such as coating integrity after a defined number of operational cycles or exposure hours.

Electrical safety is another critical aspect addressed by these standards. Coatings must provide adequate insulation properties to prevent electrical failures or sparking, which could be catastrophic in chemically reactive environments. Standards often dictate specific dielectric strength requirements and leakage current limits for coated components.

Maintenance and inspection procedures are integral to safety standards for coated solenoid valves. Regular assessments of coating integrity, along with protocols for reapplication or replacement, are typically outlined. These standards may also specify documentation requirements, including material certifications, test reports, and maintenance records, to ensure traceability and compliance throughout the valve's lifecycle.

International standards such as IEC 60079 and ATEX directives provide guidelines for equipment used in potentially explosive atmospheres, which often overlap with harsh chemical environments. These standards mandate specific coating properties, including chemical resistance, adhesion strength, and durability under cyclic stress. Compliance with these standards typically requires extensive testing and certification processes.

Material selection for coatings plays a crucial role in meeting safety standards. Advanced fluoropolymers, ceramic composites, and specialized epoxy resins are among the materials that have demonstrated superior performance in harsh chemical environments. These coatings must not only resist chemical attack but also maintain their protective properties over extended periods of exposure.

Testing protocols for coated solenoid valves often include accelerated aging tests, chemical immersion trials, and thermal shock evaluations. These tests aim to simulate long-term exposure to aggressive chemicals and extreme operating conditions. Safety standards may specify minimum performance criteria, such as coating integrity after a defined number of operational cycles or exposure hours.

Electrical safety is another critical aspect addressed by these standards. Coatings must provide adequate insulation properties to prevent electrical failures or sparking, which could be catastrophic in chemically reactive environments. Standards often dictate specific dielectric strength requirements and leakage current limits for coated components.

Maintenance and inspection procedures are integral to safety standards for coated solenoid valves. Regular assessments of coating integrity, along with protocols for reapplication or replacement, are typically outlined. These standards may also specify documentation requirements, including material certifications, test reports, and maintenance records, to ensure traceability and compliance throughout the valve's lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!