SiC current sensing and desaturation protection under fast transients

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Power Electronics Background and Objectives

Silicon carbide (SiC) power electronics have emerged as a revolutionary technology in the field of power conversion and management. The development of SiC-based devices has been driven by the increasing demand for high-efficiency, high-power density, and high-temperature operation in various applications, including electric vehicles, renewable energy systems, and industrial motor drives.

The primary objective of research on SiC current sensing and desaturation protection under fast transients is to address the unique challenges posed by the rapid switching capabilities of SiC power devices. As SiC MOSFETs and other SiC-based switches can operate at much higher frequencies and with faster switching speeds compared to their silicon counterparts, traditional current sensing and protection mechanisms may not be sufficient to ensure reliable and safe operation.

Current sensing in SiC power electronics is crucial for implementing various control and protection functions, such as overcurrent protection, short-circuit detection, and current-mode control. However, the fast transients associated with SiC devices can lead to significant electromagnetic interference (EMI) and noise, making accurate current measurement challenging. Therefore, developing robust and high-bandwidth current sensing techniques is essential for fully leveraging the benefits of SiC technology.

Desaturation protection is another critical aspect of SiC power electronics, particularly in applications where the devices are subjected to high-stress conditions. SiC MOSFETs, when operating in their saturation region, can experience rapid temperature increases due to their high current density capabilities. This phenomenon, known as desaturation, can lead to device failure if not properly managed. The fast switching nature of SiC devices necessitates the development of advanced desaturation protection schemes that can respond quickly to potential fault conditions.

The research aims to explore innovative approaches to current sensing and desaturation protection that can keep pace with the rapid transients of SiC devices. This includes investigating new sensor technologies, signal processing techniques, and protection circuit topologies that offer improved bandwidth, accuracy, and response times. Additionally, the research seeks to address the integration challenges of these protection mechanisms within SiC-based power converters, ensuring minimal impact on overall system performance and efficiency.

By advancing the state-of-the-art in current sensing and desaturation protection for SiC power electronics, this research contributes to the broader goal of enabling more widespread adoption of SiC technology across various industries. The outcomes of this research are expected to enhance the reliability, safety, and performance of SiC-based power systems, ultimately leading to more efficient and compact power electronic solutions for next-generation applications.

The primary objective of research on SiC current sensing and desaturation protection under fast transients is to address the unique challenges posed by the rapid switching capabilities of SiC power devices. As SiC MOSFETs and other SiC-based switches can operate at much higher frequencies and with faster switching speeds compared to their silicon counterparts, traditional current sensing and protection mechanisms may not be sufficient to ensure reliable and safe operation.

Current sensing in SiC power electronics is crucial for implementing various control and protection functions, such as overcurrent protection, short-circuit detection, and current-mode control. However, the fast transients associated with SiC devices can lead to significant electromagnetic interference (EMI) and noise, making accurate current measurement challenging. Therefore, developing robust and high-bandwidth current sensing techniques is essential for fully leveraging the benefits of SiC technology.

Desaturation protection is another critical aspect of SiC power electronics, particularly in applications where the devices are subjected to high-stress conditions. SiC MOSFETs, when operating in their saturation region, can experience rapid temperature increases due to their high current density capabilities. This phenomenon, known as desaturation, can lead to device failure if not properly managed. The fast switching nature of SiC devices necessitates the development of advanced desaturation protection schemes that can respond quickly to potential fault conditions.

The research aims to explore innovative approaches to current sensing and desaturation protection that can keep pace with the rapid transients of SiC devices. This includes investigating new sensor technologies, signal processing techniques, and protection circuit topologies that offer improved bandwidth, accuracy, and response times. Additionally, the research seeks to address the integration challenges of these protection mechanisms within SiC-based power converters, ensuring minimal impact on overall system performance and efficiency.

By advancing the state-of-the-art in current sensing and desaturation protection for SiC power electronics, this research contributes to the broader goal of enabling more widespread adoption of SiC technology across various industries. The outcomes of this research are expected to enhance the reliability, safety, and performance of SiC-based power systems, ultimately leading to more efficient and compact power electronic solutions for next-generation applications.

Market Demand for SiC-based Power Systems

The market demand for Silicon Carbide (SiC) based power systems has been experiencing significant growth in recent years, driven by the increasing need for high-efficiency, high-power density solutions across various industries. The automotive sector, particularly electric vehicles (EVs), has emerged as a primary driver for SiC adoption. As automakers strive to extend driving ranges and reduce charging times, SiC-based power electronics offer substantial advantages over traditional silicon-based systems.

In the EV market, SiC devices are being increasingly utilized in onboard chargers, DC-DC converters, and traction inverters. The superior thermal conductivity and higher breakdown field strength of SiC allow for more compact and efficient power systems, directly addressing the automotive industry's demands for lighter, more energy-efficient vehicles. This trend is expected to continue as governments worldwide implement stricter emissions regulations and push for greater EV adoption.

Beyond automotive applications, the industrial sector is also showing strong interest in SiC-based power systems. Factory automation, robotics, and renewable energy systems are key areas where SiC technology is gaining traction. In solar and wind power applications, SiC-based inverters are becoming more prevalent due to their ability to operate at higher frequencies and temperatures, leading to improved energy conversion efficiency and reduced system size.

The aerospace and defense industries are another significant market for SiC power systems. The technology's ability to withstand harsh environments and operate at high temperatures makes it ideal for use in aircraft power systems, satellite technology, and military equipment. As these sectors continue to demand more advanced and reliable power solutions, the market for SiC-based systems is expected to expand further.

Data centers and telecommunications infrastructure represent another growing market for SiC technology. With the increasing demand for data processing and storage, power efficiency has become a critical factor. SiC-based power supplies and converters offer the potential for significant energy savings and improved reliability in these high-demand environments.

As the global focus on energy efficiency and sustainability intensifies, the market demand for SiC-based power systems is projected to continue its upward trajectory. Industry analysts predict a compound annual growth rate (CAGR) of over 30% for the SiC power semiconductor market in the coming years. This growth is supported by ongoing advancements in SiC wafer production technology and device design, which are gradually reducing costs and improving performance, making SiC solutions increasingly competitive with traditional silicon-based alternatives.

In the EV market, SiC devices are being increasingly utilized in onboard chargers, DC-DC converters, and traction inverters. The superior thermal conductivity and higher breakdown field strength of SiC allow for more compact and efficient power systems, directly addressing the automotive industry's demands for lighter, more energy-efficient vehicles. This trend is expected to continue as governments worldwide implement stricter emissions regulations and push for greater EV adoption.

Beyond automotive applications, the industrial sector is also showing strong interest in SiC-based power systems. Factory automation, robotics, and renewable energy systems are key areas where SiC technology is gaining traction. In solar and wind power applications, SiC-based inverters are becoming more prevalent due to their ability to operate at higher frequencies and temperatures, leading to improved energy conversion efficiency and reduced system size.

The aerospace and defense industries are another significant market for SiC power systems. The technology's ability to withstand harsh environments and operate at high temperatures makes it ideal for use in aircraft power systems, satellite technology, and military equipment. As these sectors continue to demand more advanced and reliable power solutions, the market for SiC-based systems is expected to expand further.

Data centers and telecommunications infrastructure represent another growing market for SiC technology. With the increasing demand for data processing and storage, power efficiency has become a critical factor. SiC-based power supplies and converters offer the potential for significant energy savings and improved reliability in these high-demand environments.

As the global focus on energy efficiency and sustainability intensifies, the market demand for SiC-based power systems is projected to continue its upward trajectory. Industry analysts predict a compound annual growth rate (CAGR) of over 30% for the SiC power semiconductor market in the coming years. This growth is supported by ongoing advancements in SiC wafer production technology and device design, which are gradually reducing costs and improving performance, making SiC solutions increasingly competitive with traditional silicon-based alternatives.

Current Challenges in SiC Current Sensing

The current challenges in SiC current sensing primarily stem from the unique characteristics of Silicon Carbide (SiC) power devices and their fast switching capabilities. One of the main issues is the high dv/dt and di/dt rates associated with SiC devices, which can lead to significant electromagnetic interference (EMI) and noise in current sensing circuits. This noise can severely impact the accuracy and reliability of current measurements, potentially leading to false triggering of protection mechanisms or inefficient system operation.

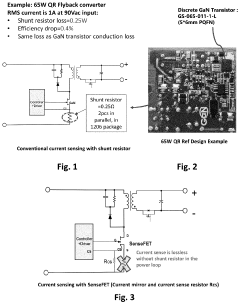

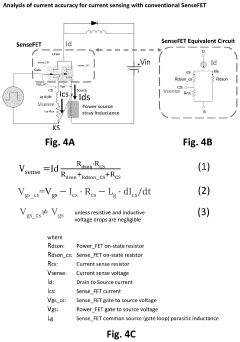

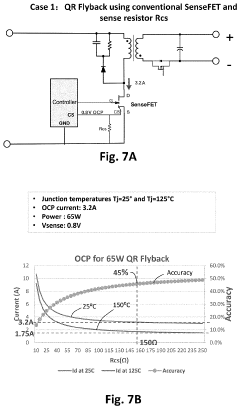

Another critical challenge is the need for high-bandwidth current sensing solutions to keep up with the rapid switching speeds of SiC devices. Traditional current sensing methods, such as shunt resistors or Hall effect sensors, may not provide sufficient bandwidth to accurately capture the fast transients in SiC-based power converters. This limitation can result in distorted current waveforms and inaccurate measurements, particularly during switching events.

The high operating temperatures of SiC devices also pose a significant challenge for current sensing. Many conventional current sensing technologies exhibit temperature-dependent behavior, which can lead to measurement drift and reduced accuracy in high-temperature environments. Developing temperature-stable current sensing solutions that can withstand the extreme operating conditions of SiC power systems is crucial for ensuring reliable operation.

Furthermore, the integration of current sensing and desaturation protection circuits in SiC-based power modules presents unique design challenges. The compact nature of these modules and the need for minimal parasitic inductance require innovative approaches to sensor placement and circuit layout. Balancing the trade-offs between sensing accuracy, protection speed, and overall system performance becomes increasingly complex in these highly integrated designs.

The high common-mode voltage swings and fast edge rates in SiC-based power converters also create challenges for galvanic isolation in current sensing circuits. Ensuring robust isolation while maintaining high bandwidth and low latency is essential for both measurement accuracy and system safety. This requirement often necessitates the use of advanced isolation technologies and careful consideration of circuit topologies to minimize common-mode noise coupling.

Lastly, the cost and complexity of implementing high-performance current sensing solutions for SiC applications remain significant hurdles. As the adoption of SiC technology continues to grow, there is an increasing demand for cost-effective, reliable, and easily implementable current sensing techniques that can meet the stringent requirements of these high-speed, high-power density systems.

Another critical challenge is the need for high-bandwidth current sensing solutions to keep up with the rapid switching speeds of SiC devices. Traditional current sensing methods, such as shunt resistors or Hall effect sensors, may not provide sufficient bandwidth to accurately capture the fast transients in SiC-based power converters. This limitation can result in distorted current waveforms and inaccurate measurements, particularly during switching events.

The high operating temperatures of SiC devices also pose a significant challenge for current sensing. Many conventional current sensing technologies exhibit temperature-dependent behavior, which can lead to measurement drift and reduced accuracy in high-temperature environments. Developing temperature-stable current sensing solutions that can withstand the extreme operating conditions of SiC power systems is crucial for ensuring reliable operation.

Furthermore, the integration of current sensing and desaturation protection circuits in SiC-based power modules presents unique design challenges. The compact nature of these modules and the need for minimal parasitic inductance require innovative approaches to sensor placement and circuit layout. Balancing the trade-offs between sensing accuracy, protection speed, and overall system performance becomes increasingly complex in these highly integrated designs.

The high common-mode voltage swings and fast edge rates in SiC-based power converters also create challenges for galvanic isolation in current sensing circuits. Ensuring robust isolation while maintaining high bandwidth and low latency is essential for both measurement accuracy and system safety. This requirement often necessitates the use of advanced isolation technologies and careful consideration of circuit topologies to minimize common-mode noise coupling.

Lastly, the cost and complexity of implementing high-performance current sensing solutions for SiC applications remain significant hurdles. As the adoption of SiC technology continues to grow, there is an increasing demand for cost-effective, reliable, and easily implementable current sensing techniques that can meet the stringent requirements of these high-speed, high-power density systems.

Existing SiC Current Sensing Solutions

01 Current sensing techniques for SiC devices

Various current sensing methods are employed in SiC devices to accurately measure and monitor current flow. These techniques include shunt resistors, Hall effect sensors, and integrated current sensing elements. Advanced current sensing allows for precise control and protection of SiC-based power electronics, enabling efficient operation and improved reliability.- Current sensing techniques for SiC devices: Various methods are employed for current sensing in SiC devices, including shunt resistors, current transformers, and integrated sensing elements. These techniques allow for accurate monitoring of current flow, which is crucial for protection and control purposes in power electronic applications using SiC technology.

- Desaturation protection for SiC power devices: Desaturation protection is a critical feature in SiC power devices to prevent damage from overcurrent conditions. This protection method monitors the collector-emitter voltage to detect when the device enters the desaturation region, triggering a rapid shutdown to safeguard the device from thermal runaway and failure.

- Gate driver circuits for SiC MOSFETs: Specialized gate driver circuits are designed for SiC MOSFETs to ensure optimal switching performance and protection. These circuits often incorporate features such as adjustable drive strength, temperature compensation, and integrated protection mechanisms to enhance the reliability and efficiency of SiC-based power systems.

- Overcurrent and short-circuit protection in SiC devices: SiC devices require robust overcurrent and short-circuit protection due to their fast switching speeds and high power density. Advanced protection schemes may include fast-acting current limiters, intelligent power modules with integrated sensors, and coordinated protection algorithms to ensure device safety under fault conditions.

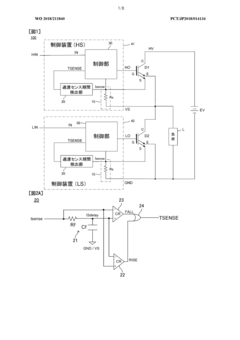

- Temperature monitoring and thermal management for SiC devices: Effective temperature monitoring and thermal management are essential for maintaining the reliability of SiC devices. This includes the use of temperature sensors, advanced cooling techniques, and thermal modeling to optimize device performance and prevent overheating in high-power applications.

02 Desaturation protection for SiC devices

Desaturation protection is crucial for SiC devices to prevent damage from overcurrent conditions. This protection scheme monitors the collector-emitter voltage to detect when the device enters the desaturation region. Fast-acting circuitry is implemented to quickly turn off the device when desaturation is detected, safeguarding it from potential failure.Expand Specific Solutions03 Integration of current sensing and desaturation protection

Advanced SiC device designs incorporate both current sensing and desaturation protection features into a single integrated solution. This approach enhances overall device performance and reliability while reducing component count and system complexity. The integrated solution provides comprehensive protection against various fault conditions in SiC-based power systems.Expand Specific Solutions04 Temperature compensation in SiC device protection

Temperature compensation techniques are implemented in SiC device protection circuits to ensure accurate current sensing and desaturation detection across a wide operating temperature range. These methods account for the temperature-dependent characteristics of SiC devices, maintaining consistent protection performance under varying thermal conditions.Expand Specific Solutions05 Fast response and fault handling in SiC protection circuits

SiC protection circuits are designed with emphasis on fast response times and efficient fault handling capabilities. Advanced gate driver designs, high-speed comparators, and optimized circuit topologies are employed to quickly detect and respond to overcurrent and desaturation events. This rapid response helps prevent device damage and enhances the overall reliability of SiC-based power systems.Expand Specific Solutions

Key Players in SiC Power Electronics Industry

The research on SiC current sensing and desaturation protection under fast transients is in a developing stage, with increasing market potential due to the growing demand for high-performance power electronics. The market size is expanding as SiC technology gains traction in various applications. Technologically, it's progressing rapidly, with companies like Infineon Technologies AG, NXP USA, Inc., and ROHM Co., Ltd. leading the way. These firms are investing heavily in R&D to overcome challenges related to fast transients in SiC devices. The competition is intensifying as more players enter the field, driving innovation and pushing the boundaries of SiC technology's capabilities in power electronics applications.

Infineon Technologies AG

Technical Solution: Infineon has developed advanced SiC current sensing and desaturation protection solutions for fast transients. Their approach utilizes high-speed analog-to-digital converters (ADCs) and sophisticated digital signal processing algorithms to accurately measure current in SiC power devices during rapid switching events. The company's CoolSiC™ MOSFET technology incorporates integrated current sensing and desaturation protection features, enabling precise current monitoring and fault detection within nanoseconds[1]. Infineon's solution also employs advanced gate driver ICs with built-in protection mechanisms, capable of responding to overcurrent and desaturation events in less than 200ns[2]. This rapid response time is crucial for protecting SiC devices from damage during fast transient conditions.

Strengths: Industry-leading response times, high integration of sensing and protection features. Weaknesses: Potentially higher cost due to advanced technology, may require specialized design knowledge to implement effectively.

NXP USA, Inc.

Technical Solution: NXP has developed a comprehensive SiC current sensing and desaturation protection solution for fast transients. Their approach combines high-speed current sensing amplifiers with advanced digital signal processing techniques. NXP's solution utilizes a proprietary algorithm that can accurately detect and respond to desaturation events within 100ns[3]. The company's GD3160 smart gate driver IC incorporates both current sensing and desaturation protection features, offering a highly integrated solution for SiC power devices[4]. NXP's technology also includes adaptive blanking time control to minimize false triggering during normal switching transients, enhancing overall system reliability.

Strengths: Highly integrated solution, fast response time, adaptive protection features. Weaknesses: May have limited flexibility for customization in some applications.

Innovations in Fast Transient Protection

HIGH ACCURACY CURRENT SENSING FOR GaN POWER SWITCHING DEVICES

PatentActiveUS20220182048A1

Innovation

- A current sensing circuit using a GaN sense transistor in parallel with a GaN power transistor, along with a sampling circuit comprising operational amplifiers, ensures that the gate-to-source voltage of both transistors is matched, allowing for accurate current sensing by converting and amplifying the current sense input to provide a high accuracy current sense voltage, independent of junction temperature.

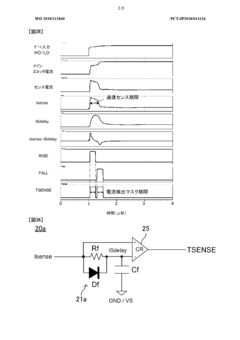

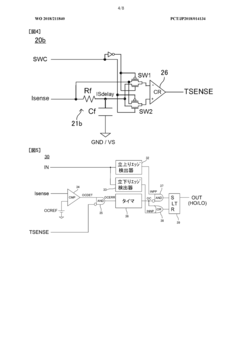

Control device and semiconductor apparatus

PatentWO2018211840A1

Innovation

- A control device with a current detection unit, transient sense period detection section, and control unit that accurately detects transient rises and falls in the sense current, distinguishing between transient and steady states to prevent false overcurrent detection, thereby enabling timely protection of semiconductor elements.

Reliability and Robustness Considerations

Reliability and robustness are critical considerations in the development and implementation of SiC current sensing and desaturation protection systems, especially under fast transient conditions. The high-speed switching capabilities of SiC devices introduce unique challenges that must be addressed to ensure consistent and dependable operation.

One of the primary concerns is the susceptibility of sensing circuits to electromagnetic interference (EMI) and noise. The rapid voltage and current transitions in SiC-based power converters can generate significant electromagnetic disturbances, potentially leading to false triggering or measurement inaccuracies. To mitigate these issues, careful shielding and layout techniques must be employed, along with the use of differential signaling and common-mode rejection strategies.

Temperature stability is another crucial factor affecting the reliability of current sensing and desaturation protection systems. SiC devices can operate at higher temperatures compared to traditional silicon-based semiconductors, necessitating robust sensing elements and protection circuits that maintain accuracy and performance across a wide temperature range. This may involve the use of temperature-compensated components and advanced calibration techniques.

The fast switching speeds of SiC devices also place stringent requirements on the response time of protection circuits. Desaturation detection systems must be capable of identifying fault conditions and initiating protective actions within extremely short timeframes, often in the order of nanoseconds. This demands high-speed comparators, fast-acting gate drivers, and optimized signal paths to minimize propagation delays.

Aging and degradation effects must be considered to ensure long-term reliability. The high electric fields and temperatures experienced by SiC devices can accelerate certain failure mechanisms, potentially impacting the performance of sensing and protection circuits over time. Comprehensive reliability testing, including accelerated life testing and stress testing under various operating conditions, is essential to validate the robustness of these systems.

Furthermore, the integration of advanced diagnostics and self-monitoring capabilities can significantly enhance the overall reliability of SiC-based power systems. Implementing real-time monitoring of critical parameters, such as junction temperature and switching characteristics, allows for early detection of potential issues and enables predictive maintenance strategies.

In conclusion, addressing the reliability and robustness considerations for SiC current sensing and desaturation protection under fast transients requires a multifaceted approach. This encompasses careful circuit design, advanced materials selection, comprehensive testing methodologies, and the integration of intelligent monitoring systems. By focusing on these aspects, developers can create resilient and dependable solutions that fully leverage the benefits of SiC technology in high-performance power electronics applications.

One of the primary concerns is the susceptibility of sensing circuits to electromagnetic interference (EMI) and noise. The rapid voltage and current transitions in SiC-based power converters can generate significant electromagnetic disturbances, potentially leading to false triggering or measurement inaccuracies. To mitigate these issues, careful shielding and layout techniques must be employed, along with the use of differential signaling and common-mode rejection strategies.

Temperature stability is another crucial factor affecting the reliability of current sensing and desaturation protection systems. SiC devices can operate at higher temperatures compared to traditional silicon-based semiconductors, necessitating robust sensing elements and protection circuits that maintain accuracy and performance across a wide temperature range. This may involve the use of temperature-compensated components and advanced calibration techniques.

The fast switching speeds of SiC devices also place stringent requirements on the response time of protection circuits. Desaturation detection systems must be capable of identifying fault conditions and initiating protective actions within extremely short timeframes, often in the order of nanoseconds. This demands high-speed comparators, fast-acting gate drivers, and optimized signal paths to minimize propagation delays.

Aging and degradation effects must be considered to ensure long-term reliability. The high electric fields and temperatures experienced by SiC devices can accelerate certain failure mechanisms, potentially impacting the performance of sensing and protection circuits over time. Comprehensive reliability testing, including accelerated life testing and stress testing under various operating conditions, is essential to validate the robustness of these systems.

Furthermore, the integration of advanced diagnostics and self-monitoring capabilities can significantly enhance the overall reliability of SiC-based power systems. Implementing real-time monitoring of critical parameters, such as junction temperature and switching characteristics, allows for early detection of potential issues and enables predictive maintenance strategies.

In conclusion, addressing the reliability and robustness considerations for SiC current sensing and desaturation protection under fast transients requires a multifaceted approach. This encompasses careful circuit design, advanced materials selection, comprehensive testing methodologies, and the integration of intelligent monitoring systems. By focusing on these aspects, developers can create resilient and dependable solutions that fully leverage the benefits of SiC technology in high-performance power electronics applications.

Thermal Management Strategies for SiC Devices

Thermal management is a critical aspect of SiC device operation, particularly in high-power and high-frequency applications. As SiC devices operate at higher temperatures and power densities compared to traditional silicon devices, effective thermal management strategies are essential to ensure optimal performance and reliability.

One key approach to thermal management for SiC devices is the use of advanced packaging materials and techniques. These include the development of high thermal conductivity substrates, such as aluminum nitride (AlN) or silicon nitride (Si3N4), which can efficiently dissipate heat from the device. Additionally, novel die-attach materials, like silver sintering or transient liquid phase bonding, are being employed to improve thermal conductivity between the SiC chip and the substrate.

Active cooling methods play a crucial role in SiC thermal management. Liquid cooling systems, utilizing coolants with high thermal conductivity and heat capacity, are increasingly being adopted for high-power SiC applications. These systems can efficiently remove heat from the device, allowing for higher power densities and improved performance. Furthermore, advanced heat sink designs, incorporating microchannels or jet impingement cooling, are being developed to enhance heat dissipation from SiC devices.

Thermal simulation and modeling tools are becoming indispensable in the design and optimization of SiC thermal management systems. These tools allow engineers to predict hot spots, analyze thermal gradients, and optimize cooling strategies before physical prototyping. Advanced thermal models that account for the unique properties of SiC, such as its anisotropic thermal conductivity, are being developed to improve the accuracy of these simulations.

The integration of temperature sensors and intelligent thermal management systems is another emerging trend in SiC device applications. These systems can dynamically adjust cooling parameters based on real-time temperature measurements, ensuring optimal thermal performance under varying operating conditions. This approach is particularly valuable in applications with rapidly changing power profiles, such as electric vehicle inverters or renewable energy converters.

Lastly, the development of novel thermal interface materials (TIMs) is an active area of research for SiC thermal management. Advanced TIMs, such as graphene-based composites or phase-change materials, are being explored to reduce thermal resistance between the SiC device and the cooling system, further enhancing overall thermal performance.

One key approach to thermal management for SiC devices is the use of advanced packaging materials and techniques. These include the development of high thermal conductivity substrates, such as aluminum nitride (AlN) or silicon nitride (Si3N4), which can efficiently dissipate heat from the device. Additionally, novel die-attach materials, like silver sintering or transient liquid phase bonding, are being employed to improve thermal conductivity between the SiC chip and the substrate.

Active cooling methods play a crucial role in SiC thermal management. Liquid cooling systems, utilizing coolants with high thermal conductivity and heat capacity, are increasingly being adopted for high-power SiC applications. These systems can efficiently remove heat from the device, allowing for higher power densities and improved performance. Furthermore, advanced heat sink designs, incorporating microchannels or jet impingement cooling, are being developed to enhance heat dissipation from SiC devices.

Thermal simulation and modeling tools are becoming indispensable in the design and optimization of SiC thermal management systems. These tools allow engineers to predict hot spots, analyze thermal gradients, and optimize cooling strategies before physical prototyping. Advanced thermal models that account for the unique properties of SiC, such as its anisotropic thermal conductivity, are being developed to improve the accuracy of these simulations.

The integration of temperature sensors and intelligent thermal management systems is another emerging trend in SiC device applications. These systems can dynamically adjust cooling parameters based on real-time temperature measurements, ensuring optimal thermal performance under varying operating conditions. This approach is particularly valuable in applications with rapidly changing power profiles, such as electric vehicle inverters or renewable energy converters.

Lastly, the development of novel thermal interface materials (TIMs) is an active area of research for SiC thermal management. Advanced TIMs, such as graphene-based composites or phase-change materials, are being explored to reduce thermal resistance between the SiC device and the cooling system, further enhancing overall thermal performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!