SiC short-circuit withstand time and protection in traction inverters

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Technology Evolution

Silicon carbide (SiC) technology has undergone significant evolution since its inception, particularly in the context of traction inverters for electric vehicles. The journey of SiC in power electronics began in the early 2000s when researchers recognized its potential to overcome the limitations of silicon-based devices.

Initially, SiC Schottky diodes were the first commercially available SiC power devices, offering superior switching characteristics and lower losses compared to their silicon counterparts. This breakthrough paved the way for the development of SiC MOSFETs, which emerged in the late 2000s and early 2010s.

The evolution of SiC technology in traction inverters has been driven by the demand for higher efficiency, power density, and reliability in electric vehicle powertrains. As SiC devices matured, their adoption in traction inverters gained momentum, offering significant advantages over traditional silicon-based solutions.

One of the key milestones in SiC technology evolution was the improvement in device quality and reliability. Early SiC devices faced challenges related to defects in the crystal structure and oxide interface, which limited their performance and reliability. However, continuous research and development efforts led to substantial improvements in material quality and device fabrication techniques.

The focus on enhancing short-circuit withstand capability became a critical aspect of SiC technology evolution for traction inverter applications. As the power density of inverters increased, the ability of SiC devices to withstand short-circuit conditions for longer durations became paramount. This led to the development of advanced device structures and protection schemes specifically designed for SiC MOSFETs in traction inverters.

Parallel to device improvements, packaging technologies for SiC power modules also evolved. The higher switching speeds and thermal requirements of SiC devices necessitated innovations in module design, including advanced cooling solutions and low-inductance layouts. These advancements contributed to the overall performance and reliability of SiC-based traction inverters.

Recent years have seen a focus on optimizing the gate drive and control strategies for SiC devices in traction inverters. This includes the development of intelligent gate drivers capable of faster switching and better protection against short-circuit events. Additionally, advancements in real-time monitoring and fault detection techniques have further enhanced the robustness of SiC-based traction inverter systems.

Looking ahead, the evolution of SiC technology in traction inverters is expected to continue, with emphasis on further improving short-circuit withstand capabilities, reducing on-state resistance, and enhancing overall system reliability. The integration of SiC devices with advanced control algorithms and system-level optimization approaches is likely to drive the next phase of innovation in this field.

Initially, SiC Schottky diodes were the first commercially available SiC power devices, offering superior switching characteristics and lower losses compared to their silicon counterparts. This breakthrough paved the way for the development of SiC MOSFETs, which emerged in the late 2000s and early 2010s.

The evolution of SiC technology in traction inverters has been driven by the demand for higher efficiency, power density, and reliability in electric vehicle powertrains. As SiC devices matured, their adoption in traction inverters gained momentum, offering significant advantages over traditional silicon-based solutions.

One of the key milestones in SiC technology evolution was the improvement in device quality and reliability. Early SiC devices faced challenges related to defects in the crystal structure and oxide interface, which limited their performance and reliability. However, continuous research and development efforts led to substantial improvements in material quality and device fabrication techniques.

The focus on enhancing short-circuit withstand capability became a critical aspect of SiC technology evolution for traction inverter applications. As the power density of inverters increased, the ability of SiC devices to withstand short-circuit conditions for longer durations became paramount. This led to the development of advanced device structures and protection schemes specifically designed for SiC MOSFETs in traction inverters.

Parallel to device improvements, packaging technologies for SiC power modules also evolved. The higher switching speeds and thermal requirements of SiC devices necessitated innovations in module design, including advanced cooling solutions and low-inductance layouts. These advancements contributed to the overall performance and reliability of SiC-based traction inverters.

Recent years have seen a focus on optimizing the gate drive and control strategies for SiC devices in traction inverters. This includes the development of intelligent gate drivers capable of faster switching and better protection against short-circuit events. Additionally, advancements in real-time monitoring and fault detection techniques have further enhanced the robustness of SiC-based traction inverter systems.

Looking ahead, the evolution of SiC technology in traction inverters is expected to continue, with emphasis on further improving short-circuit withstand capabilities, reducing on-state resistance, and enhancing overall system reliability. The integration of SiC devices with advanced control algorithms and system-level optimization approaches is likely to drive the next phase of innovation in this field.

Traction Inverter Demands

The demand for traction inverters in electric vehicles (EVs) has been rapidly increasing due to the global shift towards sustainable transportation. Traction inverters play a crucial role in converting DC power from batteries to AC power for driving electric motors, making them a key component in EV powertrains. As the automotive industry continues to electrify, the requirements for traction inverters are becoming more stringent, particularly in terms of efficiency, power density, and reliability.

One of the primary demands for traction inverters is improved efficiency. Higher efficiency translates to extended driving range, which is a critical factor for EV adoption. Manufacturers are constantly seeking ways to reduce power losses in traction inverters, with a focus on advanced semiconductor technologies such as Silicon Carbide (SiC). SiC-based inverters have demonstrated significant improvements in efficiency compared to traditional Silicon-based inverters, particularly at high switching frequencies.

Power density is another crucial demand for traction inverters. As vehicle designers strive to maximize interior space and minimize weight, there is a growing need for compact and lightweight inverter solutions. This demand has led to the development of integrated power modules and advanced cooling technologies, allowing for more power output in smaller form factors.

Reliability and durability are paramount in traction inverter design, especially considering the harsh operating conditions in automotive applications. Inverters must withstand wide temperature ranges, vibrations, and potential short-circuit events. This has led to increased focus on robust packaging techniques, thermal management solutions, and protection mechanisms to ensure long-term reliability and safety.

The demand for higher voltage systems is also shaping traction inverter development. As EVs move towards 800V and even higher voltage architectures, inverters must be designed to handle these increased voltage levels safely and efficiently. This shift is driven by the need for faster charging capabilities and improved overall system efficiency.

Lastly, there is a growing demand for traction inverters with advanced control capabilities. This includes features such as sensorless motor control, which can reduce system complexity and cost, as well as improved torque control for enhanced vehicle performance and driving experience. Additionally, inverters are expected to integrate seamlessly with vehicle control systems, supporting functions like regenerative braking and traction control.

One of the primary demands for traction inverters is improved efficiency. Higher efficiency translates to extended driving range, which is a critical factor for EV adoption. Manufacturers are constantly seeking ways to reduce power losses in traction inverters, with a focus on advanced semiconductor technologies such as Silicon Carbide (SiC). SiC-based inverters have demonstrated significant improvements in efficiency compared to traditional Silicon-based inverters, particularly at high switching frequencies.

Power density is another crucial demand for traction inverters. As vehicle designers strive to maximize interior space and minimize weight, there is a growing need for compact and lightweight inverter solutions. This demand has led to the development of integrated power modules and advanced cooling technologies, allowing for more power output in smaller form factors.

Reliability and durability are paramount in traction inverter design, especially considering the harsh operating conditions in automotive applications. Inverters must withstand wide temperature ranges, vibrations, and potential short-circuit events. This has led to increased focus on robust packaging techniques, thermal management solutions, and protection mechanisms to ensure long-term reliability and safety.

The demand for higher voltage systems is also shaping traction inverter development. As EVs move towards 800V and even higher voltage architectures, inverters must be designed to handle these increased voltage levels safely and efficiently. This shift is driven by the need for faster charging capabilities and improved overall system efficiency.

Lastly, there is a growing demand for traction inverters with advanced control capabilities. This includes features such as sensorless motor control, which can reduce system complexity and cost, as well as improved torque control for enhanced vehicle performance and driving experience. Additionally, inverters are expected to integrate seamlessly with vehicle control systems, supporting functions like regenerative braking and traction control.

SiC Short-Circuit Issues

Silicon carbide (SiC) power devices have emerged as a promising technology for traction inverters in electric vehicles due to their superior performance characteristics compared to traditional silicon-based devices. However, the short-circuit behavior of SiC devices presents unique challenges that require careful consideration and mitigation strategies.

SiC MOSFETs exhibit significantly shorter short-circuit withstand times compared to their silicon counterparts. While silicon IGBTs typically have short-circuit withstand times of 10-20 μs, SiC MOSFETs can only withstand short circuits for 2-5 μs before failure. This reduced time window poses a significant challenge for protection circuits, which must detect and respond to fault conditions much more rapidly.

The primary reason for the shorter withstand time in SiC devices is their higher current density and smaller die size. During a short-circuit event, the device experiences extreme thermal stress due to the high voltage and current. The smaller thermal mass of SiC chips leads to faster temperature rise and reduced ability to absorb and dissipate heat, ultimately resulting in device failure if not addressed promptly.

Another critical issue is the potential for thermal runaway in SiC devices. As the temperature increases during a short-circuit event, the on-state resistance of the device decreases, leading to higher current flow and further temperature increase. This positive feedback loop can rapidly escalate, causing catastrophic failure if not interrupted in time.

The gate oxide in SiC MOSFETs is also more susceptible to damage during short-circuit events. The high electric field and temperature can lead to oxide breakdown, resulting in permanent device failure. This vulnerability necessitates careful gate drive design and protection strategies to ensure the long-term reliability of SiC-based traction inverters.

To address these challenges, advanced protection schemes are required. Traditional overcurrent protection methods may not be sufficient due to the extremely short response time needed. Novel approaches, such as desaturation detection, di/dt sensing, and active Miller clamping, are being explored to provide faster and more reliable short-circuit protection for SiC devices in traction inverter applications.

Furthermore, the development of robust short-circuit withstand time models for SiC devices is crucial. These models must accurately predict device behavior under various operating conditions and fault scenarios, enabling designers to optimize protection circuits and system-level safeguards. Ongoing research focuses on improving these models to account for the unique characteristics of SiC devices and their behavior in traction inverter environments.

SiC MOSFETs exhibit significantly shorter short-circuit withstand times compared to their silicon counterparts. While silicon IGBTs typically have short-circuit withstand times of 10-20 μs, SiC MOSFETs can only withstand short circuits for 2-5 μs before failure. This reduced time window poses a significant challenge for protection circuits, which must detect and respond to fault conditions much more rapidly.

The primary reason for the shorter withstand time in SiC devices is their higher current density and smaller die size. During a short-circuit event, the device experiences extreme thermal stress due to the high voltage and current. The smaller thermal mass of SiC chips leads to faster temperature rise and reduced ability to absorb and dissipate heat, ultimately resulting in device failure if not addressed promptly.

Another critical issue is the potential for thermal runaway in SiC devices. As the temperature increases during a short-circuit event, the on-state resistance of the device decreases, leading to higher current flow and further temperature increase. This positive feedback loop can rapidly escalate, causing catastrophic failure if not interrupted in time.

The gate oxide in SiC MOSFETs is also more susceptible to damage during short-circuit events. The high electric field and temperature can lead to oxide breakdown, resulting in permanent device failure. This vulnerability necessitates careful gate drive design and protection strategies to ensure the long-term reliability of SiC-based traction inverters.

To address these challenges, advanced protection schemes are required. Traditional overcurrent protection methods may not be sufficient due to the extremely short response time needed. Novel approaches, such as desaturation detection, di/dt sensing, and active Miller clamping, are being explored to provide faster and more reliable short-circuit protection for SiC devices in traction inverter applications.

Furthermore, the development of robust short-circuit withstand time models for SiC devices is crucial. These models must accurately predict device behavior under various operating conditions and fault scenarios, enabling designers to optimize protection circuits and system-level safeguards. Ongoing research focuses on improving these models to account for the unique characteristics of SiC devices and their behavior in traction inverter environments.

Current Protection Methods

01 SiC device structure optimization

Optimizing the structure of SiC devices to enhance their short-circuit withstand time. This includes improving the gate oxide quality, refining the channel design, and enhancing the overall device layout to better distribute heat and current during short-circuit events.- Improved gate driver design for SiC devices: Enhanced gate driver designs can significantly increase the short-circuit withstand time of SiC devices. These designs often include advanced protection circuits, optimized gate voltage control, and faster response times to detect and mitigate short-circuit events. By implementing these improvements, the overall reliability and robustness of SiC devices under short-circuit conditions can be greatly enhanced.

- Thermal management techniques for SiC devices: Effective thermal management is crucial for extending the short-circuit withstand time of SiC devices. This includes advanced cooling solutions, improved packaging designs, and thermal interface materials that help dissipate heat more efficiently. By managing the thermal stress during short-circuit events, these techniques can significantly increase the device's ability to withstand such conditions for longer periods.

- Structural improvements in SiC device design: Modifications to the internal structure of SiC devices can lead to improved short-circuit withstand capabilities. This may include optimized cell designs, enhanced current spreading techniques, and improved edge termination structures. These structural improvements help distribute current more evenly and reduce localized heating during short-circuit events, thereby increasing the device's overall robustness.

- Advanced protection and detection circuits: Implementing sophisticated protection and detection circuits can significantly enhance the short-circuit withstand time of SiC devices. These circuits may include fast-acting current sensors, intelligent fault detection algorithms, and rapid shutdown mechanisms. By quickly identifying and responding to short-circuit conditions, these advanced circuits can prevent device failure and extend the safe operating time under fault conditions.

- Optimization of device parameters and materials: Careful optimization of device parameters and materials can lead to improved short-circuit withstand capabilities in SiC devices. This includes fine-tuning doping profiles, optimizing channel designs, and exploring novel materials for device fabrication. By enhancing the intrinsic properties of the device, these optimizations can result in increased robustness and longer short-circuit withstand times.

02 Thermal management techniques

Implementing advanced thermal management techniques to improve the short-circuit withstand time of SiC devices. This involves using novel heat dissipation methods, integrating efficient cooling systems, and employing materials with superior thermal conductivity to manage the heat generated during short-circuit conditions.Expand Specific Solutions03 Protection circuit design

Developing sophisticated protection circuits specifically designed for SiC devices to enhance their short-circuit withstand time. These circuits may include fast-acting current limiters, intelligent gate drivers, and advanced sensing mechanisms to quickly detect and respond to short-circuit events.Expand Specific Solutions04 Material improvements

Enhancing the quality and properties of SiC materials used in device fabrication to increase short-circuit withstand time. This includes refining the crystal growth process, reducing defects in the SiC substrate, and exploring novel doping techniques to improve the material's electrical and thermal characteristics.Expand Specific Solutions05 Advanced packaging solutions

Developing innovative packaging solutions for SiC devices to improve their short-circuit withstand time. This involves using advanced materials for die attach and encapsulation, optimizing the package design for better heat dissipation, and integrating sensors for real-time monitoring of device conditions during short-circuit events.Expand Specific Solutions

Key SiC Device Players

The research on SiC short-circuit withstand time and protection in traction inverters is in a rapidly developing phase, driven by the growing demand for high-efficiency power electronics in electric vehicles and rail systems. The market for SiC-based traction inverters is expanding, with a projected compound annual growth rate of over 30% in the coming years. Technologically, SiC devices are maturing, but challenges remain in optimizing their short-circuit performance and protection mechanisms. Key players like Infineon Technologies, Wolfspeed, and ROHM are leading the development, while automotive and rail companies such as Siemens Mobility, Toyota, and CRRC are actively integrating these technologies into their systems, indicating a collaborative industry approach to advancing SiC applications in traction inverters.

Zhuzhou CRRC Times Electric Co., Ltd.

Technical Solution: Zhuzhou CRRC Times Electric Co., Ltd. has developed a comprehensive approach to SiC short-circuit protection in traction inverters, focusing on both device-level and system-level solutions. Their SiC MOSFETs feature an optimized cell structure that enhances the device's ability to withstand high current densities during short-circuit events. The company has implemented a multi-tiered protection strategy, combining fast hardware detection circuits with advanced software algorithms for fault identification and system response[6]. CRRC's solution includes a novel gate driver design that incorporates active Miller clamping and controlled turn-off techniques to minimize the energy dissipated during short-circuit events. They have also developed a predictive maintenance system that monitors device degradation over time, allowing for preemptive action before critical failures occur[7].

Strengths: Integrated system-level approach to short-circuit protection; Experience in traction applications. Weaknesses: Limited global market presence compared to international competitors; Potential concerns about intellectual property protection.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has invested significantly in SiC technology for traction inverters, with a focus on enhancing short-circuit withstand capabilities. Their approach combines advanced SiC MOSFET designs with intelligent protection schemes tailored for automotive applications. Bosch's SiC devices feature a robust cell structure and optimized current distribution to improve short-circuit resilience. They have developed a proprietary gate driver solution that incorporates ultra-fast fault detection and soft turn-off techniques to minimize stress on the device during short-circuit events[8]. Bosch's protection strategy also includes a machine learning-based algorithm that can predict and prevent potential short-circuit scenarios based on real-time system data and historical patterns. This predictive approach allows for proactive measures to be taken before a critical fault occurs, significantly enhancing system reliability[9].

Strengths: Extensive automotive industry experience; Advanced predictive protection algorithms. Weaknesses: Relatively new entrant in SiC device manufacturing; Higher system complexity due to advanced features.

SiC Short-Circuit Patents

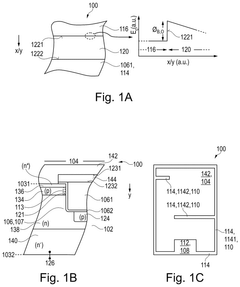

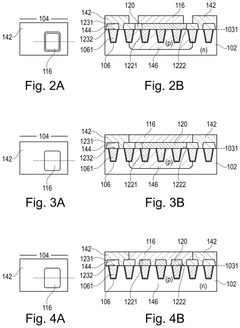

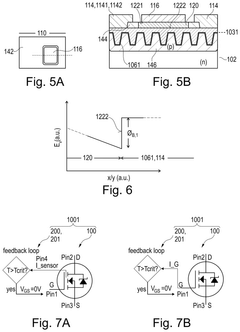

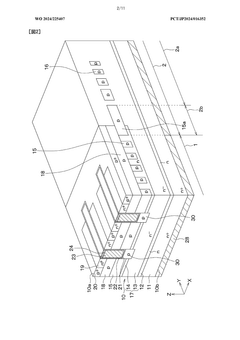

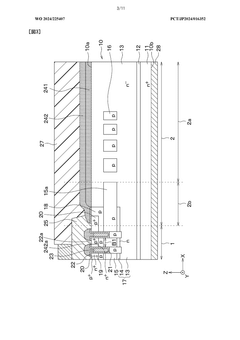

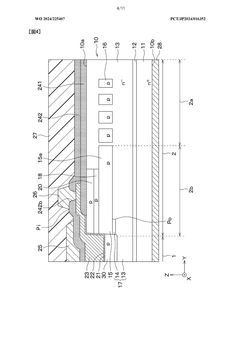

Vertical power semiconductor device including a sensor electrode

PatentPendingUS20250151324A1

Innovation

- A vertical power semiconductor device is designed with a silicon carbide (SiC) semiconductor body, including a transistor cell area, gate structures, and a sensor electrode. The device incorporates interlayer dielectrics with specific band offsets to manage thermal leakage currents, enabling a fast feedback loop to turn off the device during short circuits.

Silicon carbide semiconductor device

PatentWO2024225407A1

Innovation

- The SiC semiconductor device incorporates a cell region with a trench gate structure, an outer withstand voltage structure, and a gap between the outer withstand voltage structure and the cell region, featuring a JFET layer only on the cell region side, reducing impurity concentration in the pn junction to alleviate electric field concentration and prevent gate insulating film breakdown.

Thermal Management

Thermal management is a critical aspect of SiC-based traction inverters, particularly in the context of short-circuit withstand time and protection. The high power density and fast switching capabilities of SiC devices lead to increased heat generation, necessitating advanced cooling strategies to maintain optimal performance and reliability.

One of the primary challenges in thermal management for SiC inverters is the rapid temperature rise during short-circuit events. SiC devices can withstand higher temperatures compared to their silicon counterparts, but the thermal stress during short-circuits can still be significant. To address this, researchers have developed innovative cooling techniques that combine active and passive methods.

Advanced liquid cooling systems have emerged as a promising solution for SiC inverters in traction applications. These systems utilize high-performance coolants and optimized flow channels to efficiently dissipate heat from the power modules. Some designs incorporate two-phase cooling, where the coolant undergoes a phase change to absorb more heat, further enhancing the cooling efficiency.

Another approach to thermal management involves the use of advanced thermal interface materials (TIMs) between the SiC devices and the heat sink. These materials, such as phase-change metals or graphene-based composites, offer superior thermal conductivity and help reduce the thermal resistance at the interface, allowing for more effective heat dissipation.

Researchers have also explored the integration of thermal sensors and real-time temperature monitoring systems within SiC inverters. These sensors provide crucial data on the thermal state of the devices, enabling dynamic adjustment of cooling parameters and triggering protective measures when temperature thresholds are approached during short-circuit events.

The design of power module packaging plays a significant role in thermal management. Novel packaging techniques, such as double-sided cooling and embedded heat spreading layers, have been developed to enhance heat dissipation from SiC devices. These approaches aim to reduce thermal resistance and improve the overall thermal performance of the inverter system.

Furthermore, advanced thermal modeling and simulation tools have become indispensable in the design process of SiC inverters. These tools allow engineers to predict thermal behavior under various operating conditions, including short-circuit events, and optimize the thermal management system accordingly. By leveraging these simulation capabilities, designers can evaluate different cooling strategies and identify potential thermal bottlenecks before physical prototyping.

One of the primary challenges in thermal management for SiC inverters is the rapid temperature rise during short-circuit events. SiC devices can withstand higher temperatures compared to their silicon counterparts, but the thermal stress during short-circuits can still be significant. To address this, researchers have developed innovative cooling techniques that combine active and passive methods.

Advanced liquid cooling systems have emerged as a promising solution for SiC inverters in traction applications. These systems utilize high-performance coolants and optimized flow channels to efficiently dissipate heat from the power modules. Some designs incorporate two-phase cooling, where the coolant undergoes a phase change to absorb more heat, further enhancing the cooling efficiency.

Another approach to thermal management involves the use of advanced thermal interface materials (TIMs) between the SiC devices and the heat sink. These materials, such as phase-change metals or graphene-based composites, offer superior thermal conductivity and help reduce the thermal resistance at the interface, allowing for more effective heat dissipation.

Researchers have also explored the integration of thermal sensors and real-time temperature monitoring systems within SiC inverters. These sensors provide crucial data on the thermal state of the devices, enabling dynamic adjustment of cooling parameters and triggering protective measures when temperature thresholds are approached during short-circuit events.

The design of power module packaging plays a significant role in thermal management. Novel packaging techniques, such as double-sided cooling and embedded heat spreading layers, have been developed to enhance heat dissipation from SiC devices. These approaches aim to reduce thermal resistance and improve the overall thermal performance of the inverter system.

Furthermore, advanced thermal modeling and simulation tools have become indispensable in the design process of SiC inverters. These tools allow engineers to predict thermal behavior under various operating conditions, including short-circuit events, and optimize the thermal management system accordingly. By leveraging these simulation capabilities, designers can evaluate different cooling strategies and identify potential thermal bottlenecks before physical prototyping.

Reliability Standards

Reliability standards play a crucial role in ensuring the safe and efficient operation of SiC-based traction inverters in electric vehicles. These standards are designed to address the unique challenges posed by SiC devices, particularly their short-circuit withstand time and protection mechanisms.

The International Electrotechnical Commission (IEC) has developed specific standards for power electronic systems in railway applications, such as IEC 61287-1. This standard outlines the requirements for power converters installed on board rolling stock, including traction inverters. It addresses aspects like electrical, thermal, and mechanical performance, as well as safety and reliability considerations.

For SiC devices in traction inverters, the focus is on their ability to withstand short-circuit conditions. The JEDEC JC-70 committee has been working on developing standards specifically for wide bandgap power semiconductors, including SiC devices. These standards aim to establish uniform test methods and reliability criteria for SiC MOSFETs and diodes.

The automotive industry has also developed its own set of standards for electronic components, including those used in traction inverters. The AEC-Q101 qualification for discrete semiconductors and AEC-Q100 for integrated circuits are widely adopted. These standards define stress tests and qualification requirements to ensure the reliability of components in automotive applications.

Specific to short-circuit protection, standards like IEC 60747-9 for insulated-gate bipolar transistors (IGBTs) provide a framework that can be adapted for SiC devices. This standard defines methods for measuring short-circuit safe operating area (SCSOA) and provides guidelines for specifying short-circuit withstand time.

As SiC technology continues to evolve, new standards are being developed to address its unique characteristics. The JEDEC JC-70.1 subcommittee is working on standards for SiC power MOSFETs, including guidelines for short-circuit ruggedness testing. These standards aim to establish consistent methods for evaluating the short-circuit withstand capability of SiC devices and defining acceptable performance criteria.

Reliability standards also encompass protection strategies for SiC devices in traction inverters. This includes guidelines for implementing fast-acting protection circuits, such as desaturation detection and overcurrent protection. Standards may specify response times, fault detection thresholds, and coordination between protection mechanisms to ensure the overall reliability of the traction inverter system.

The International Electrotechnical Commission (IEC) has developed specific standards for power electronic systems in railway applications, such as IEC 61287-1. This standard outlines the requirements for power converters installed on board rolling stock, including traction inverters. It addresses aspects like electrical, thermal, and mechanical performance, as well as safety and reliability considerations.

For SiC devices in traction inverters, the focus is on their ability to withstand short-circuit conditions. The JEDEC JC-70 committee has been working on developing standards specifically for wide bandgap power semiconductors, including SiC devices. These standards aim to establish uniform test methods and reliability criteria for SiC MOSFETs and diodes.

The automotive industry has also developed its own set of standards for electronic components, including those used in traction inverters. The AEC-Q101 qualification for discrete semiconductors and AEC-Q100 for integrated circuits are widely adopted. These standards define stress tests and qualification requirements to ensure the reliability of components in automotive applications.

Specific to short-circuit protection, standards like IEC 60747-9 for insulated-gate bipolar transistors (IGBTs) provide a framework that can be adapted for SiC devices. This standard defines methods for measuring short-circuit safe operating area (SCSOA) and provides guidelines for specifying short-circuit withstand time.

As SiC technology continues to evolve, new standards are being developed to address its unique characteristics. The JEDEC JC-70.1 subcommittee is working on standards for SiC power MOSFETs, including guidelines for short-circuit ruggedness testing. These standards aim to establish consistent methods for evaluating the short-circuit withstand capability of SiC devices and defining acceptable performance criteria.

Reliability standards also encompass protection strategies for SiC devices in traction inverters. This includes guidelines for implementing fast-acting protection circuits, such as desaturation detection and overcurrent protection. Standards may specify response times, fault detection thresholds, and coordination between protection mechanisms to ensure the overall reliability of the traction inverter system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!