SiC trench versus planar MOSFETs: conduction, switching, and reliability

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Evolution

The evolution of Silicon Carbide (SiC) MOSFETs represents a significant advancement in power semiconductor technology. This progression has been driven by the increasing demand for high-efficiency, high-power density devices in various applications, including electric vehicles, renewable energy systems, and industrial power supplies.

In the early stages of SiC MOSFET development, planar structures were the primary focus. These devices offered improved performance compared to their silicon counterparts, particularly in terms of higher breakdown voltage and lower on-resistance. However, they also faced challenges related to channel mobility and oxide reliability.

As research and development efforts intensified, the industry witnessed a shift towards trench structures. Trench SiC MOSFETs emerged as a promising alternative, offering several advantages over their planar counterparts. The vertical channel orientation in trench structures allowed for higher channel density and reduced specific on-resistance, leading to improved conduction performance.

The evolution of SiC MOSFETs has been marked by continuous improvements in both planar and trench designs. Manufacturers have focused on optimizing the gate oxide interface, reducing defect densities, and enhancing channel mobility. These efforts have resulted in devices with lower switching losses, improved reliability, and higher current-carrying capabilities.

One of the key milestones in SiC MOSFET evolution was the development of advanced epitaxial growth techniques. These methods enabled the production of high-quality SiC substrates with reduced defect densities, which is crucial for achieving reliable and high-performance devices. Additionally, innovations in device packaging and thermal management have played a vital role in maximizing the potential of SiC MOSFETs.

The comparison between trench and planar SiC MOSFETs has been a subject of extensive research and debate. While trench structures generally offer superior conduction performance, planar devices have shown advantages in terms of manufacturing simplicity and, in some cases, reliability. The choice between the two often depends on specific application requirements and trade-offs between performance, cost, and reliability.

Recent advancements have focused on addressing the reliability concerns associated with both planar and trench SiC MOSFETs. Improved gate oxide formation techniques, novel channel doping profiles, and optimized device structures have contributed to enhancing the long-term stability and robustness of these devices. These developments have been crucial in expanding the adoption of SiC MOSFETs across various high-power applications.

In the early stages of SiC MOSFET development, planar structures were the primary focus. These devices offered improved performance compared to their silicon counterparts, particularly in terms of higher breakdown voltage and lower on-resistance. However, they also faced challenges related to channel mobility and oxide reliability.

As research and development efforts intensified, the industry witnessed a shift towards trench structures. Trench SiC MOSFETs emerged as a promising alternative, offering several advantages over their planar counterparts. The vertical channel orientation in trench structures allowed for higher channel density and reduced specific on-resistance, leading to improved conduction performance.

The evolution of SiC MOSFETs has been marked by continuous improvements in both planar and trench designs. Manufacturers have focused on optimizing the gate oxide interface, reducing defect densities, and enhancing channel mobility. These efforts have resulted in devices with lower switching losses, improved reliability, and higher current-carrying capabilities.

One of the key milestones in SiC MOSFET evolution was the development of advanced epitaxial growth techniques. These methods enabled the production of high-quality SiC substrates with reduced defect densities, which is crucial for achieving reliable and high-performance devices. Additionally, innovations in device packaging and thermal management have played a vital role in maximizing the potential of SiC MOSFETs.

The comparison between trench and planar SiC MOSFETs has been a subject of extensive research and debate. While trench structures generally offer superior conduction performance, planar devices have shown advantages in terms of manufacturing simplicity and, in some cases, reliability. The choice between the two often depends on specific application requirements and trade-offs between performance, cost, and reliability.

Recent advancements have focused on addressing the reliability concerns associated with both planar and trench SiC MOSFETs. Improved gate oxide formation techniques, novel channel doping profiles, and optimized device structures have contributed to enhancing the long-term stability and robustness of these devices. These developments have been crucial in expanding the adoption of SiC MOSFETs across various high-power applications.

Market Demand Analysis

The market demand for Silicon Carbide (SiC) MOSFETs, including both trench and planar structures, has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of electric vehicles (EVs), renewable energy systems, and industrial power applications. The automotive sector, in particular, has emerged as a key driver for SiC MOSFET demand, with major automakers integrating these devices into their EV powertrains to enhance efficiency and range.

The global SiC power semiconductor market is projected to expand rapidly, with compound annual growth rates (CAGR) in double digits for the foreseeable future. This growth is fueled by the superior performance characteristics of SiC MOSFETs compared to traditional silicon-based devices, including higher switching frequencies, lower on-resistance, and better thermal conductivity. These attributes make SiC MOSFETs particularly attractive for high-power and high-temperature applications.

In the context of trench versus planar SiC MOSFETs, market demand is shifting towards trench structures due to their potential for lower on-resistance and higher current density. This trend is especially pronounced in automotive applications, where power density and efficiency are critical factors. However, planar SiC MOSFETs still maintain a significant market share, particularly in applications where reliability and proven performance are prioritized over cutting-edge efficiency gains.

The renewable energy sector, including solar inverters and wind power systems, represents another substantial market for SiC MOSFETs. The ability of these devices to operate at higher frequencies allows for smaller and more efficient power conversion systems, which is driving their adoption in next-generation renewable energy installations.

Industrial power applications, such as motor drives, uninterruptible power supplies (UPS), and power factor correction (PFC) circuits, are also contributing to the growing demand for SiC MOSFETs. The improved efficiency and reduced system size offered by SiC technology are particularly valuable in these applications, where energy savings and space constraints are often critical considerations.

Geographically, the demand for SiC MOSFETs is strongest in regions with advanced automotive and industrial sectors, such as North America, Europe, and parts of Asia. China, in particular, has been investing heavily in SiC technology as part of its push towards electrification and industrial modernization, creating a rapidly expanding market for both domestic and international suppliers.

Despite the growing demand, challenges remain in the widespread adoption of SiC MOSFETs, including higher costs compared to silicon alternatives and the need for specialized packaging and gate driver solutions. However, as production scales up and technology matures, these barriers are expected to diminish, further accelerating market growth and potentially reshaping the competitive landscape between trench and planar SiC MOSFET technologies.

The global SiC power semiconductor market is projected to expand rapidly, with compound annual growth rates (CAGR) in double digits for the foreseeable future. This growth is fueled by the superior performance characteristics of SiC MOSFETs compared to traditional silicon-based devices, including higher switching frequencies, lower on-resistance, and better thermal conductivity. These attributes make SiC MOSFETs particularly attractive for high-power and high-temperature applications.

In the context of trench versus planar SiC MOSFETs, market demand is shifting towards trench structures due to their potential for lower on-resistance and higher current density. This trend is especially pronounced in automotive applications, where power density and efficiency are critical factors. However, planar SiC MOSFETs still maintain a significant market share, particularly in applications where reliability and proven performance are prioritized over cutting-edge efficiency gains.

The renewable energy sector, including solar inverters and wind power systems, represents another substantial market for SiC MOSFETs. The ability of these devices to operate at higher frequencies allows for smaller and more efficient power conversion systems, which is driving their adoption in next-generation renewable energy installations.

Industrial power applications, such as motor drives, uninterruptible power supplies (UPS), and power factor correction (PFC) circuits, are also contributing to the growing demand for SiC MOSFETs. The improved efficiency and reduced system size offered by SiC technology are particularly valuable in these applications, where energy savings and space constraints are often critical considerations.

Geographically, the demand for SiC MOSFETs is strongest in regions with advanced automotive and industrial sectors, such as North America, Europe, and parts of Asia. China, in particular, has been investing heavily in SiC technology as part of its push towards electrification and industrial modernization, creating a rapidly expanding market for both domestic and international suppliers.

Despite the growing demand, challenges remain in the widespread adoption of SiC MOSFETs, including higher costs compared to silicon alternatives and the need for specialized packaging and gate driver solutions. However, as production scales up and technology matures, these barriers are expected to diminish, further accelerating market growth and potentially reshaping the competitive landscape between trench and planar SiC MOSFET technologies.

Trench vs Planar SiC

Silicon carbide (SiC) power MOSFETs have emerged as a promising technology for high-power and high-frequency applications due to their superior material properties compared to traditional silicon-based devices. Within the realm of SiC MOSFETs, two primary structures have gained prominence: trench and planar configurations. Each of these structures offers distinct advantages and challenges in terms of conduction, switching, and reliability characteristics.

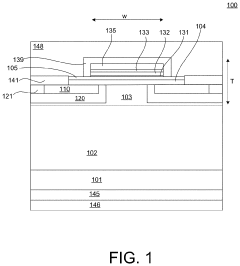

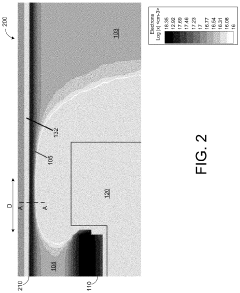

Trench SiC MOSFETs feature a vertical channel structure where the gate is formed in a trench etched into the semiconductor surface. This design allows for higher channel density and reduced on-resistance compared to planar structures. The vertical channel orientation also enables better control of the electric field distribution, potentially leading to improved breakdown voltage capabilities. However, the trench structure introduces challenges in maintaining the integrity of the gate oxide, particularly at the trench corners where electric field crowding can occur.

Planar SiC MOSFETs, on the other hand, employ a horizontal channel structure with the gate formed on the semiconductor surface. This configuration offers simplicity in fabrication and has been the traditional approach in MOSFET design. Planar structures generally exhibit better reliability due to the absence of high-stress regions associated with trench corners. They also tend to have lower gate capacitance, which can be advantageous for high-frequency switching applications.

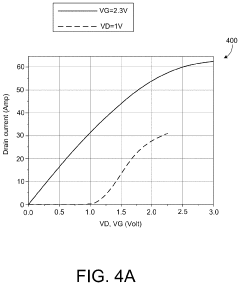

In terms of conduction characteristics, trench SiC MOSFETs typically demonstrate lower on-resistance due to their higher channel density and shorter current path. This translates to reduced conduction losses and improved overall efficiency in power conversion systems. Planar structures, while generally having higher on-resistance, can offer more uniform current distribution across the device, which can be beneficial for thermal management and reliability.

Switching performance is another critical aspect where trench and planar structures differ. Trench MOSFETs often exhibit faster switching speeds due to their lower input and output capacitances. This can lead to reduced switching losses and enable operation at higher frequencies. However, the trade-off is potentially higher electromagnetic interference (EMI) due to faster voltage and current transients. Planar MOSFETs, with their typically higher capacitances, may offer slower switching but can provide smoother transitions and lower EMI.

Reliability considerations play a crucial role in the comparison between trench and planar SiC MOSFETs. The trench structure's vulnerability to oxide breakdown at the trench corners necessitates careful design and advanced processing techniques to mitigate this risk. Planar structures generally offer better long-term reliability due to their simpler geometry and lower stress on the gate oxide. However, advancements in trench design and fabrication processes have significantly narrowed this gap in recent years.

The choice between trench and planar SiC MOSFETs ultimately depends on the specific application requirements and the trade-offs between performance, reliability, and cost. As research and development in SiC technology continue, both structures are likely to see further improvements, potentially leading to hybrid designs that combine the strengths of both approaches.

Trench SiC MOSFETs feature a vertical channel structure where the gate is formed in a trench etched into the semiconductor surface. This design allows for higher channel density and reduced on-resistance compared to planar structures. The vertical channel orientation also enables better control of the electric field distribution, potentially leading to improved breakdown voltage capabilities. However, the trench structure introduces challenges in maintaining the integrity of the gate oxide, particularly at the trench corners where electric field crowding can occur.

Planar SiC MOSFETs, on the other hand, employ a horizontal channel structure with the gate formed on the semiconductor surface. This configuration offers simplicity in fabrication and has been the traditional approach in MOSFET design. Planar structures generally exhibit better reliability due to the absence of high-stress regions associated with trench corners. They also tend to have lower gate capacitance, which can be advantageous for high-frequency switching applications.

In terms of conduction characteristics, trench SiC MOSFETs typically demonstrate lower on-resistance due to their higher channel density and shorter current path. This translates to reduced conduction losses and improved overall efficiency in power conversion systems. Planar structures, while generally having higher on-resistance, can offer more uniform current distribution across the device, which can be beneficial for thermal management and reliability.

Switching performance is another critical aspect where trench and planar structures differ. Trench MOSFETs often exhibit faster switching speeds due to their lower input and output capacitances. This can lead to reduced switching losses and enable operation at higher frequencies. However, the trade-off is potentially higher electromagnetic interference (EMI) due to faster voltage and current transients. Planar MOSFETs, with their typically higher capacitances, may offer slower switching but can provide smoother transitions and lower EMI.

Reliability considerations play a crucial role in the comparison between trench and planar SiC MOSFETs. The trench structure's vulnerability to oxide breakdown at the trench corners necessitates careful design and advanced processing techniques to mitigate this risk. Planar structures generally offer better long-term reliability due to their simpler geometry and lower stress on the gate oxide. However, advancements in trench design and fabrication processes have significantly narrowed this gap in recent years.

The choice between trench and planar SiC MOSFETs ultimately depends on the specific application requirements and the trade-offs between performance, reliability, and cost. As research and development in SiC technology continue, both structures are likely to see further improvements, potentially leading to hybrid designs that combine the strengths of both approaches.

Current SiC Solutions

01 Conduction characteristics of SiC MOSFETs

SiC MOSFETs exhibit superior conduction characteristics compared to traditional silicon-based devices. They have lower on-resistance, which results in reduced conduction losses and improved efficiency. The wide bandgap nature of SiC allows for higher operating temperatures and voltages, enhancing overall performance in power electronics applications.- Conduction characteristics of SiC MOSFETs: SiC MOSFETs exhibit superior conduction characteristics compared to traditional silicon-based devices. They have lower on-resistance, which results in reduced conduction losses and improved efficiency. The wide bandgap nature of SiC allows for higher operating temperatures and voltages, enhancing overall performance in power electronics applications.

- Switching performance of SiC MOSFETs: SiC MOSFETs demonstrate excellent switching performance with faster switching speeds and lower switching losses compared to silicon devices. This enables higher frequency operation and improved efficiency in power conversion systems. Advanced gate driver designs and circuit topologies are often employed to fully utilize the switching capabilities of SiC MOSFETs.

- Reliability and robustness of SiC MOSFETs: SiC MOSFETs offer enhanced reliability and robustness in harsh operating conditions. They exhibit better thermal management, higher breakdown voltages, and improved radiation hardness. Long-term stability and device degradation mechanisms are areas of ongoing research to ensure the longevity of SiC MOSFET-based systems in critical applications.

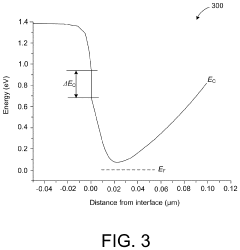

- Gate oxide reliability in SiC MOSFETs: The reliability of the gate oxide is a crucial aspect of SiC MOSFET performance. Researchers focus on improving the quality and stability of the SiC/SiO2 interface to reduce threshold voltage instability and enhance long-term reliability. Various techniques, such as nitridation and post-oxidation annealing, are employed to address these challenges.

- SiC MOSFET packaging and thermal management: Effective packaging and thermal management are essential for maximizing the performance and reliability of SiC MOSFETs. Advanced packaging techniques, such as double-sided cooling and low-inductance designs, are developed to handle the high power density and fast switching speeds of SiC devices. Improved thermal management strategies help to fully utilize the high-temperature capabilities of SiC MOSFETs.

02 Switching performance of SiC MOSFETs

SiC MOSFETs demonstrate excellent switching characteristics, including faster switching speeds and lower switching losses. This enables higher frequency operation and improved efficiency in power conversion systems. Advanced gate driver designs and circuit topologies are often employed to optimize the switching performance of SiC MOSFETs.Expand Specific Solutions03 Reliability and robustness of SiC MOSFETs

SiC MOSFETs offer enhanced reliability and robustness compared to silicon devices. They can withstand higher temperatures, voltages, and current densities, leading to improved long-term stability and reduced failure rates. However, specific reliability concerns such as gate oxide integrity and threshold voltage stability need to be addressed through proper device design and packaging techniques.Expand Specific Solutions04 Thermal management for SiC MOSFETs

Effective thermal management is crucial for maximizing the performance and reliability of SiC MOSFETs. Advanced cooling techniques, such as liquid cooling or advanced heat sink designs, are often employed to dissipate heat efficiently. Proper thermal design ensures optimal operation and prevents thermal runaway, contributing to the overall reliability of SiC MOSFET-based systems.Expand Specific Solutions05 Gate drive optimization for SiC MOSFETs

Optimizing gate drive circuits is essential for fully leveraging the capabilities of SiC MOSFETs. This includes designing appropriate gate voltage levels, rise and fall times, and protection mechanisms. Advanced gate driver ICs and isolation techniques are often used to ensure reliable and efficient switching of SiC MOSFETs across a wide range of operating conditions.Expand Specific Solutions

Key SiC MOSFET Players

The competition landscape for SiC trench versus planar MOSFETs is in a mature growth stage, with a rapidly expanding market driven by demand in power electronics and electric vehicles. The global SiC power device market is projected to reach billions of dollars by 2025. Technologically, both trench and planar structures are well-established, with ongoing research focused on optimizing performance and reliability. Key players like Huawei, Gree Electric, and Chuangxin Semiconductor are actively developing and commercializing SiC MOSFET technologies, while research institutions such as Tsinghua University and Zhejiang University contribute to advancing the field through academic studies and industry collaborations.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei Digital Power Technologies has leveraged its parent company's SiC expertise to develop high-performance power modules utilizing advanced SiC MOSFET technology. Their approach focuses on system-level optimization, integrating SiC trench MOSFETs into intelligent power modules for applications such as electric vehicle chargers and solar inverters. The company has implemented advanced packaging techniques to maximize the thermal performance of their SiC modules, enabling higher power density and improved reliability[10]. Huawei Digital Power's SiC trench MOSFET modules have demonstrated significant efficiency improvements, with reported system-level efficiency gains of up to 3% compared to silicon-based solutions[11]. The company has also developed proprietary gate driver technology optimized for SiC trench MOSFETs, addressing the unique switching characteristics of these devices to minimize losses and EMI[12].

Strengths: System-level optimization, advanced packaging and thermal management, proprietary gate driver technology. Weaknesses: Potential dependency on parent company's SiC technology, may face challenges in competing with established power semiconductor companies.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree Electric Appliances has been actively developing SiC MOSFET technology for use in their high-efficiency air conditioning and home appliance products. The company has focused on both trench and planar SiC MOSFET designs, with an emphasis on optimizing device performance for specific application requirements. Gree's research has led to the development of a specialized SiC trench MOSFET structure tailored for motor drive applications, featuring reduced parasitic capacitance and improved dv/dt immunity[13]. Their planar SiC MOSFET designs have been optimized for lower switching losses, making them suitable for high-frequency operation in power factor correction circuits[14]. Gree has reported energy efficiency improvements of up to 8% in air conditioning systems utilizing their SiC MOSFET technology compared to traditional silicon-based solutions[15].

Strengths: Application-specific optimization, focus on energy efficiency improvements in end products. Weaknesses: Limited experience in semiconductor manufacturing, may rely on foundry partners for production.

Core SiC Innovations

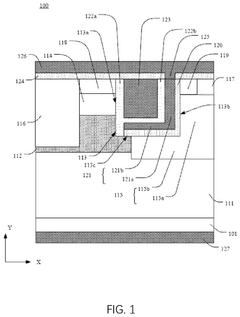

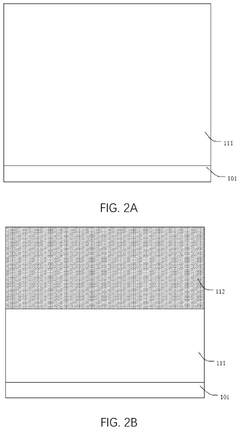

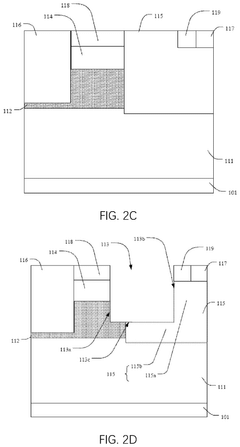

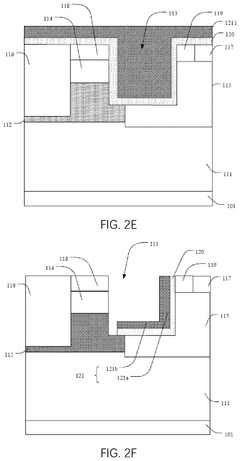

Gate-source structure and manufacturing method thereof, and asymmetric trench mosfet and manufacturing method thereof

PatentPendingUS20240355925A1

Innovation

- The asymmetric trench MOSFET design incorporates a unique gate-source structure with a L-shaped source conductor and optimized dielectric layers to enhance gate-source capacitance, reduce on-resistance, and improve the reliability of the gate dielectric layer, featuring a substrate with epitaxial and current spreading layers, and strategically placed doped regions to shield the gate dielectric.

Silicon carbide field-effect transistors

PatentActiveUS20220013661A1

Innovation

- A silicon carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) design incorporating a substrate, drift region, spreading layer, body region, and source region with a gate structure that includes a gate oxide layer, aluminum nitride, and p-type gallium nitride layers, achieving low on-state specific resistance and high threshold voltage.

Thermal Management

Thermal management is a critical aspect in the comparison of SiC trench and planar MOSFETs, particularly in high-power applications where device performance and reliability are paramount. The unique properties of silicon carbide, including its wide bandgap and high thermal conductivity, offer significant advantages in thermal management compared to traditional silicon-based devices.

SiC trench MOSFETs generally exhibit superior thermal performance compared to their planar counterparts. The trench structure allows for a more efficient current flow and reduced on-resistance, which translates to lower power losses and heat generation during operation. This inherent advantage in heat dissipation contributes to improved overall thermal management of the device.

The thermal conductivity of SiC is approximately three times higher than that of silicon, enabling more efficient heat transfer from the active device region to the package and heat sink. This property is particularly beneficial in high-temperature applications, where SiC MOSFETs can operate reliably at junction temperatures exceeding 200°C, compared to the typical 150°C limit of silicon devices.

In terms of thermal resistance, SiC trench MOSFETs often demonstrate lower values compared to planar structures. This is due to the reduced chip size for a given current rating and the more uniform current distribution in the trench design. Lower thermal resistance results in improved heat dissipation and allows for higher power density in compact designs.

The impact of thermal management on device reliability is significant for both trench and planar SiC MOSFETs. However, the trench structure's inherent advantages in heat dissipation contribute to enhanced long-term reliability. The reduced thermal stress on the device can lead to slower degradation of key parameters such as threshold voltage and on-resistance over time.

Thermal cycling performance is another area where SiC trench MOSFETs excel. The ability to withstand rapid temperature changes without significant degradation is crucial in applications with frequent power cycling, such as electric vehicle powertrains. The trench structure's more uniform current distribution and lower thermal resistance contribute to improved resilience against thermal fatigue.

Advanced packaging techniques play a crucial role in maximizing the thermal management benefits of SiC MOSFETs. Both trench and planar devices benefit from innovations such as double-sided cooling and advanced thermal interface materials. However, the trench structure's inherent thermal advantages often allow for more compact and efficient packaging solutions.

In conclusion, while both SiC trench and planar MOSFETs offer significant thermal management improvements over silicon devices, the trench structure generally provides superior performance in this aspect. The combination of reduced on-resistance, more efficient current distribution, and lower thermal resistance makes SiC trench MOSFETs particularly attractive for high-power, high-temperature applications where thermal management is a critical design consideration.

SiC trench MOSFETs generally exhibit superior thermal performance compared to their planar counterparts. The trench structure allows for a more efficient current flow and reduced on-resistance, which translates to lower power losses and heat generation during operation. This inherent advantage in heat dissipation contributes to improved overall thermal management of the device.

The thermal conductivity of SiC is approximately three times higher than that of silicon, enabling more efficient heat transfer from the active device region to the package and heat sink. This property is particularly beneficial in high-temperature applications, where SiC MOSFETs can operate reliably at junction temperatures exceeding 200°C, compared to the typical 150°C limit of silicon devices.

In terms of thermal resistance, SiC trench MOSFETs often demonstrate lower values compared to planar structures. This is due to the reduced chip size for a given current rating and the more uniform current distribution in the trench design. Lower thermal resistance results in improved heat dissipation and allows for higher power density in compact designs.

The impact of thermal management on device reliability is significant for both trench and planar SiC MOSFETs. However, the trench structure's inherent advantages in heat dissipation contribute to enhanced long-term reliability. The reduced thermal stress on the device can lead to slower degradation of key parameters such as threshold voltage and on-resistance over time.

Thermal cycling performance is another area where SiC trench MOSFETs excel. The ability to withstand rapid temperature changes without significant degradation is crucial in applications with frequent power cycling, such as electric vehicle powertrains. The trench structure's more uniform current distribution and lower thermal resistance contribute to improved resilience against thermal fatigue.

Advanced packaging techniques play a crucial role in maximizing the thermal management benefits of SiC MOSFETs. Both trench and planar devices benefit from innovations such as double-sided cooling and advanced thermal interface materials. However, the trench structure's inherent thermal advantages often allow for more compact and efficient packaging solutions.

In conclusion, while both SiC trench and planar MOSFETs offer significant thermal management improvements over silicon devices, the trench structure generally provides superior performance in this aspect. The combination of reduced on-resistance, more efficient current distribution, and lower thermal resistance makes SiC trench MOSFETs particularly attractive for high-power, high-temperature applications where thermal management is a critical design consideration.

SiC Device Reliability

The reliability of Silicon Carbide (SiC) devices is a critical factor in their adoption for power electronics applications. SiC MOSFETs, both in trench and planar configurations, have shown significant improvements in performance compared to their silicon counterparts. However, their long-term reliability remains a key concern for industry professionals and researchers alike.

Trench SiC MOSFETs have demonstrated superior conduction and switching characteristics compared to planar structures. The trench design allows for higher channel density and reduced on-resistance, leading to improved efficiency. However, this configuration also introduces new reliability challenges, particularly at the trench corners where electric field crowding can occur.

Planar SiC MOSFETs, while offering slightly lower performance in terms of conduction and switching, have shown better reliability in certain aspects. The simpler structure of planar devices results in fewer defects and a more uniform electric field distribution, potentially leading to improved long-term stability.

One of the primary reliability concerns for both trench and planar SiC MOSFETs is the stability of the gate oxide. The high electric fields present in SiC devices can cause stress-induced leakage current (SILC) and time-dependent dielectric breakdown (TDDB). Trench structures may be more susceptible to these issues due to the higher electric fields at the trench corners.

Another critical reliability aspect is the threshold voltage stability. Both trench and planar SiC MOSFETs can experience threshold voltage shifts over time, particularly under high-temperature operation. This shift can affect the device's switching characteristics and overall performance in power electronic systems.

The impact of cosmic radiation on device reliability is also a growing concern, especially for high-voltage SiC MOSFETs. Both trench and planar structures are susceptible to single-event burnout (SEB) caused by cosmic rays, although the trench design may offer some advantages in this regard due to its lower specific on-resistance.

Reliability testing methodologies for SiC devices are still evolving, with accelerated life tests and stress tests being developed to accurately predict long-term performance. These tests must account for the unique properties of SiC, including its wide bandgap and high-temperature capabilities.

In conclusion, while both trench and planar SiC MOSFETs offer significant performance advantages, their reliability characteristics differ. Trench structures provide superior conduction and switching performance but may face greater reliability challenges in certain areas. Planar devices, while slightly less performant, may offer better long-term stability in some applications. Ongoing research and development efforts are focused on addressing these reliability concerns to fully realize the potential of SiC technology in power electronics.

Trench SiC MOSFETs have demonstrated superior conduction and switching characteristics compared to planar structures. The trench design allows for higher channel density and reduced on-resistance, leading to improved efficiency. However, this configuration also introduces new reliability challenges, particularly at the trench corners where electric field crowding can occur.

Planar SiC MOSFETs, while offering slightly lower performance in terms of conduction and switching, have shown better reliability in certain aspects. The simpler structure of planar devices results in fewer defects and a more uniform electric field distribution, potentially leading to improved long-term stability.

One of the primary reliability concerns for both trench and planar SiC MOSFETs is the stability of the gate oxide. The high electric fields present in SiC devices can cause stress-induced leakage current (SILC) and time-dependent dielectric breakdown (TDDB). Trench structures may be more susceptible to these issues due to the higher electric fields at the trench corners.

Another critical reliability aspect is the threshold voltage stability. Both trench and planar SiC MOSFETs can experience threshold voltage shifts over time, particularly under high-temperature operation. This shift can affect the device's switching characteristics and overall performance in power electronic systems.

The impact of cosmic radiation on device reliability is also a growing concern, especially for high-voltage SiC MOSFETs. Both trench and planar structures are susceptible to single-event burnout (SEB) caused by cosmic rays, although the trench design may offer some advantages in this regard due to its lower specific on-resistance.

Reliability testing methodologies for SiC devices are still evolving, with accelerated life tests and stress tests being developed to accurately predict long-term performance. These tests must account for the unique properties of SiC, including its wide bandgap and high-temperature capabilities.

In conclusion, while both trench and planar SiC MOSFETs offer significant performance advantages, their reliability characteristics differ. Trench structures provide superior conduction and switching performance but may face greater reliability challenges in certain areas. Planar devices, while slightly less performant, may offer better long-term stability in some applications. Ongoing research and development efforts are focused on addressing these reliability concerns to fully realize the potential of SiC technology in power electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!