SiC high dV/dt effects on motor insulation and mitigation techniques

SEP 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC dV/dt Effects Overview

Silicon Carbide (SiC) power devices have emerged as a revolutionary technology in power electronics, offering superior performance characteristics compared to traditional silicon-based devices. One of the most significant advantages of SiC devices is their ability to operate at higher switching frequencies and voltages, which leads to improved efficiency and power density in various applications, including motor drives.

However, the high-speed switching capability of SiC devices introduces a new challenge: the high dV/dt effect. This phenomenon refers to the rapid voltage changes that occur during device switching, which can have detrimental effects on motor insulation systems. The high dV/dt rates associated with SiC devices can reach up to 100 V/ns, significantly higher than those of traditional silicon devices.

The high dV/dt effect can cause several issues in motor systems. Firstly, it can lead to increased electromagnetic interference (EMI) and radio frequency interference (RFI), potentially affecting the operation of nearby electronic components and systems. Secondly, the rapid voltage changes can create voltage reflections and standing waves in the cables connecting the inverter to the motor, resulting in overvoltage stress on the motor windings.

Moreover, the high dV/dt can cause non-uniform voltage distribution across the motor winding turns, leading to increased stress on the inter-turn insulation. This stress can accelerate the aging process of the insulation material and potentially cause premature failure of the motor. The problem is particularly acute in older motors or those not specifically designed for use with SiC-based inverters.

The severity of the high dV/dt effects depends on various factors, including the switching speed of the SiC devices, the cable length between the inverter and the motor, and the characteristics of the motor insulation system. As the adoption of SiC technology in motor drive applications continues to grow, understanding and mitigating these effects have become crucial areas of research and development in the power electronics industry.

To address these challenges, researchers and engineers are exploring various mitigation techniques. These include the development of advanced gate driver circuits to control the switching speed of SiC devices, the use of output filters to reduce the dV/dt at the motor terminals, and the design of improved motor insulation systems capable of withstanding higher voltage stresses. Additionally, there is ongoing research into the long-term effects of high dV/dt on motor reliability and performance, aiming to establish new standards and guidelines for SiC-based motor drive systems.

However, the high-speed switching capability of SiC devices introduces a new challenge: the high dV/dt effect. This phenomenon refers to the rapid voltage changes that occur during device switching, which can have detrimental effects on motor insulation systems. The high dV/dt rates associated with SiC devices can reach up to 100 V/ns, significantly higher than those of traditional silicon devices.

The high dV/dt effect can cause several issues in motor systems. Firstly, it can lead to increased electromagnetic interference (EMI) and radio frequency interference (RFI), potentially affecting the operation of nearby electronic components and systems. Secondly, the rapid voltage changes can create voltage reflections and standing waves in the cables connecting the inverter to the motor, resulting in overvoltage stress on the motor windings.

Moreover, the high dV/dt can cause non-uniform voltage distribution across the motor winding turns, leading to increased stress on the inter-turn insulation. This stress can accelerate the aging process of the insulation material and potentially cause premature failure of the motor. The problem is particularly acute in older motors or those not specifically designed for use with SiC-based inverters.

The severity of the high dV/dt effects depends on various factors, including the switching speed of the SiC devices, the cable length between the inverter and the motor, and the characteristics of the motor insulation system. As the adoption of SiC technology in motor drive applications continues to grow, understanding and mitigating these effects have become crucial areas of research and development in the power electronics industry.

To address these challenges, researchers and engineers are exploring various mitigation techniques. These include the development of advanced gate driver circuits to control the switching speed of SiC devices, the use of output filters to reduce the dV/dt at the motor terminals, and the design of improved motor insulation systems capable of withstanding higher voltage stresses. Additionally, there is ongoing research into the long-term effects of high dV/dt on motor reliability and performance, aiming to establish new standards and guidelines for SiC-based motor drive systems.

Motor Insulation Market Trends

The motor insulation market is experiencing significant growth and transformation, driven by the increasing adoption of electric vehicles (EVs) and the rapid advancement of power electronics technologies. The market is witnessing a shift towards high-performance insulation materials capable of withstanding the challenges posed by wide bandgap semiconductors, particularly Silicon Carbide (SiC) devices.

The demand for motor insulation solutions is on the rise, particularly in the automotive sector, where the transition to electric powertrains is accelerating. This trend is further amplified by stringent environmental regulations and government incentives promoting the adoption of EVs. As a result, the motor insulation market is expected to grow substantially in the coming years, with a focus on materials that can withstand higher operating temperatures and voltage stress.

The advent of SiC-based power electronics has introduced new challenges for motor insulation systems. The high dV/dt (rate of voltage change) characteristics of SiC devices can lead to increased electrical stress on motor windings, potentially compromising the insulation integrity. This has created a need for advanced insulation materials and designs that can mitigate these effects while maintaining motor efficiency and reliability.

In response to these challenges, the market is seeing a surge in research and development activities focused on innovative insulation solutions. Manufacturers are investing in the development of high-performance materials, such as corona-resistant enamels, nanocomposite insulation systems, and advanced impregnation techniques. These solutions aim to enhance the voltage endurance and thermal capabilities of motor insulation systems.

The market is also witnessing a trend towards the integration of sensor technologies and smart insulation systems. These advanced solutions enable real-time monitoring of insulation health, allowing for predictive maintenance and improved motor reliability. This trend aligns with the broader Industry 4.0 movement, emphasizing data-driven decision-making and operational efficiency.

Geographically, the motor insulation market is experiencing robust growth in regions with strong EV manufacturing bases, such as Asia-Pacific, North America, and Europe. China, in particular, is emerging as a key player in both EV production and insulation material development, driving significant market growth in the region.

As the market evolves, there is an increasing focus on sustainability and environmental considerations. Manufacturers are exploring eco-friendly insulation materials and production processes to align with global sustainability goals. This trend is likely to shape the future direction of the motor insulation market, influencing material choices and manufacturing practices.

The demand for motor insulation solutions is on the rise, particularly in the automotive sector, where the transition to electric powertrains is accelerating. This trend is further amplified by stringent environmental regulations and government incentives promoting the adoption of EVs. As a result, the motor insulation market is expected to grow substantially in the coming years, with a focus on materials that can withstand higher operating temperatures and voltage stress.

The advent of SiC-based power electronics has introduced new challenges for motor insulation systems. The high dV/dt (rate of voltage change) characteristics of SiC devices can lead to increased electrical stress on motor windings, potentially compromising the insulation integrity. This has created a need for advanced insulation materials and designs that can mitigate these effects while maintaining motor efficiency and reliability.

In response to these challenges, the market is seeing a surge in research and development activities focused on innovative insulation solutions. Manufacturers are investing in the development of high-performance materials, such as corona-resistant enamels, nanocomposite insulation systems, and advanced impregnation techniques. These solutions aim to enhance the voltage endurance and thermal capabilities of motor insulation systems.

The market is also witnessing a trend towards the integration of sensor technologies and smart insulation systems. These advanced solutions enable real-time monitoring of insulation health, allowing for predictive maintenance and improved motor reliability. This trend aligns with the broader Industry 4.0 movement, emphasizing data-driven decision-making and operational efficiency.

Geographically, the motor insulation market is experiencing robust growth in regions with strong EV manufacturing bases, such as Asia-Pacific, North America, and Europe. China, in particular, is emerging as a key player in both EV production and insulation material development, driving significant market growth in the region.

As the market evolves, there is an increasing focus on sustainability and environmental considerations. Manufacturers are exploring eco-friendly insulation materials and production processes to align with global sustainability goals. This trend is likely to shape the future direction of the motor insulation market, influencing material choices and manufacturing practices.

SiC Inverter Challenges

Silicon Carbide (SiC) inverters have emerged as a promising technology in power electronics, offering significant advantages over traditional silicon-based inverters. However, their implementation comes with a set of unique challenges that need to be addressed for widespread adoption and optimal performance.

One of the primary challenges associated with SiC inverters is the high dV/dt (rate of voltage change) they produce. The fast switching speeds of SiC devices, while beneficial for efficiency, can lead to increased electromagnetic interference (EMI) and potential insulation stress in connected components, particularly motors. This high dV/dt can cause premature aging of motor insulation systems and may lead to partial discharge events, ultimately reducing the overall reliability and lifespan of the motor.

Another significant challenge is the increased complexity of gate driver design for SiC devices. The higher switching speeds and lower gate charge requirements of SiC MOSFETs necessitate more sophisticated gate driver circuits. These drivers must be capable of providing precise voltage levels and timing control to ensure optimal switching performance while preventing parasitic turn-on events that can occur due to the device's sensitivity to voltage transients.

Thermal management presents another hurdle in SiC inverter design. Although SiC devices can operate at higher temperatures than their silicon counterparts, the increased power density and faster switching speeds result in more concentrated heat generation. This requires innovative cooling solutions and careful thermal design to maintain device reliability and performance under various operating conditions.

The higher operating frequencies enabled by SiC devices also introduce challenges in terms of PCB layout and system integration. Parasitic inductances and capacitances become more critical at these frequencies, necessitating careful consideration of power loop design, component placement, and interconnect strategies to minimize losses and maintain signal integrity.

Cost remains a significant barrier to widespread adoption of SiC inverters. While the price of SiC devices has been decreasing, they are still considerably more expensive than silicon alternatives. This cost premium must be justified through improved system-level performance, efficiency gains, and potential reductions in passive component sizes.

Lastly, the relative novelty of SiC technology in power electronics applications means that there is a learning curve for engineers and designers. Established design practices and simulation models for silicon-based systems may not directly apply to SiC inverters, requiring new tools, methodologies, and expertise to fully leverage the benefits of this technology.

One of the primary challenges associated with SiC inverters is the high dV/dt (rate of voltage change) they produce. The fast switching speeds of SiC devices, while beneficial for efficiency, can lead to increased electromagnetic interference (EMI) and potential insulation stress in connected components, particularly motors. This high dV/dt can cause premature aging of motor insulation systems and may lead to partial discharge events, ultimately reducing the overall reliability and lifespan of the motor.

Another significant challenge is the increased complexity of gate driver design for SiC devices. The higher switching speeds and lower gate charge requirements of SiC MOSFETs necessitate more sophisticated gate driver circuits. These drivers must be capable of providing precise voltage levels and timing control to ensure optimal switching performance while preventing parasitic turn-on events that can occur due to the device's sensitivity to voltage transients.

Thermal management presents another hurdle in SiC inverter design. Although SiC devices can operate at higher temperatures than their silicon counterparts, the increased power density and faster switching speeds result in more concentrated heat generation. This requires innovative cooling solutions and careful thermal design to maintain device reliability and performance under various operating conditions.

The higher operating frequencies enabled by SiC devices also introduce challenges in terms of PCB layout and system integration. Parasitic inductances and capacitances become more critical at these frequencies, necessitating careful consideration of power loop design, component placement, and interconnect strategies to minimize losses and maintain signal integrity.

Cost remains a significant barrier to widespread adoption of SiC inverters. While the price of SiC devices has been decreasing, they are still considerably more expensive than silicon alternatives. This cost premium must be justified through improved system-level performance, efficiency gains, and potential reductions in passive component sizes.

Lastly, the relative novelty of SiC technology in power electronics applications means that there is a learning curve for engineers and designers. Established design practices and simulation models for silicon-based systems may not directly apply to SiC inverters, requiring new tools, methodologies, and expertise to fully leverage the benefits of this technology.

Current Mitigation Techniques

01 dV/dt control in SiC devices

SiC devices often require careful control of dV/dt (rate of voltage change) to manage switching behavior and reduce electromagnetic interference. Various techniques are employed to optimize dV/dt, including gate drive circuit design, device structure modifications, and external circuit components.- dV/dt control in SiC devices: SiC devices often require careful control of dV/dt (rate of change of voltage) to manage switching behavior and reduce electromagnetic interference. Various techniques are employed to optimize dV/dt, including gate drive circuit design, device structure modifications, and external circuit components.

- Impact of high dV/dt on SiC device reliability: High dV/dt in SiC devices can lead to reliability issues, such as increased stress on gate oxides and potential device degradation. Research focuses on understanding these effects and developing strategies to mitigate them, including improved materials and device designs.

- SiC device structure optimization for dV/dt control: Modifications to SiC device structures, such as field plate designs, trench structures, and doping profiles, can help manage dV/dt effects. These optimizations aim to balance switching speed with EMI reduction and overall device performance.

- Gate drive techniques for SiC dV/dt management: Advanced gate drive techniques are crucial for controlling dV/dt in SiC devices. These may include active gate driving, multi-level gate voltage control, and intelligent gate driver ICs designed specifically for SiC devices to optimize switching behavior.

- EMI reduction strategies related to SiC dV/dt: High dV/dt in SiC devices can lead to increased electromagnetic interference. Strategies to reduce EMI include optimized PCB layout, use of common mode chokes, snubber circuits, and shielding techniques, all designed to mitigate the effects of rapid voltage transitions.

02 SiC device structure for improved dV/dt characteristics

Modifications to SiC device structures, such as optimized doping profiles, buffer layers, and field-limiting rings, can enhance dV/dt performance. These structural improvements aim to control electric field distribution and reduce parasitic capacitances, leading to better switching behavior.Expand Specific Solutions03 Gate drive techniques for SiC dV/dt management

Advanced gate drive circuits and techniques are crucial for managing dV/dt in SiC devices. These may include active gate driving, multi-level gate voltage control, and impedance-matched gate drivers to optimize switching speed and reduce ringing and overshoots.Expand Specific Solutions04 Thermal management related to dV/dt effects in SiC devices

High dV/dt in SiC devices can lead to increased power losses and thermal stress. Effective thermal management strategies, including advanced packaging techniques and cooling solutions, are essential to mitigate these effects and maintain device reliability.Expand Specific Solutions05 EMI reduction techniques for SiC devices with high dV/dt

The high dV/dt capability of SiC devices can lead to increased electromagnetic interference (EMI). Various EMI reduction techniques are employed, including optimized PCB layout, shielding, and the use of common-mode chokes and filters to mitigate the effects of rapid voltage transitions.Expand Specific Solutions

Key SiC Device Manufacturers

The research on SiC high dV/dt effects on motor insulation and mitigation techniques is in a developing stage, with growing market potential due to the increasing adoption of wide bandgap semiconductors in power electronics. The technology is maturing, with key players like Wolfspeed, Hitachi, and Mitsubishi Electric leading innovation. Companies such as DENSO, Fuji Electric, and ABB are also actively contributing to advancements in this field. The competitive landscape is characterized by a mix of established semiconductor manufacturers and power electronics companies, with universities and research institutions playing crucial roles in fundamental research and development.

Wolfspeed, Inc.

Technical Solution: Wolfspeed, as a leading manufacturer of SiC power devices, has developed strategies to address the high dV/dt effects associated with their products. Their approach includes the development of advanced SiC MOSFET structures with optimized internal capacitances and gate charge characteristics, which allow for better control of switching transients[1]. Wolfspeed has also introduced innovative packaging technologies that minimize parasitic inductances, enabling cleaner switching waveforms with reduced voltage overshoot[2]. Additionally, they have developed application-specific design guidelines and reference designs that demonstrate best practices for mitigating dV/dt effects in motor drive applications[3]. Wolfspeed's research extends to collaborative efforts with motor manufacturers to develop SiC-compatible insulation systems and winding designs that can withstand the increased stress from high dV/dt[4].

Strengths: Deep expertise in SiC device technology; holistic approach considering both device and system-level solutions. Weaknesses: Primary focus on semiconductor aspects may limit direct motor insulation solutions; reliance on partnerships for motor-specific developments.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a comprehensive strategy to address SiC high dV/dt effects on motor insulation. Their approach includes the implementation of advanced gate drive circuits with precise control over switching transients, allowing for optimized dV/dt levels without significant compromise to switching speed[1]. Mitsubishi has also introduced innovative motor winding designs that incorporate distributed capacitance to help absorb high-frequency components of the voltage waveform[2]. Additionally, they have developed specialized insulation materials with improved high-frequency characteristics and resistance to partial discharge[3]. Mitsubishi's research extends to the development of intelligent power modules (IPMs) that integrate SiC devices with optimized protection and control circuits, providing a balance between performance and motor insulation stress[4].

Strengths: Strong integration of power semiconductor and motor technologies; focus on practical, system-level solutions. Weaknesses: Potential increased cost due to specialized motor designs; may require significant changes to existing manufacturing processes.

Innovative Insulation Materials

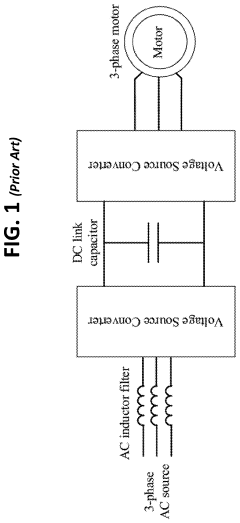

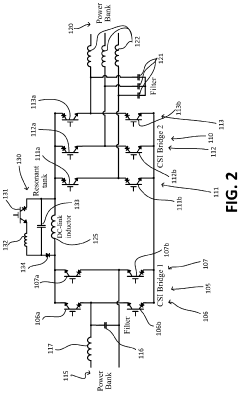

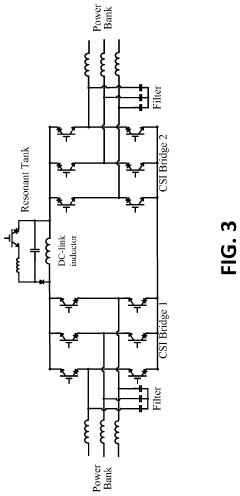

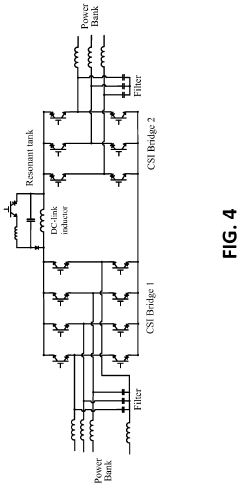

Soft-switching current source inverters

PatentActiveUS20240014749A1

Innovation

- The development of a soft-switching current source inverter (SSCSI) topology, comprising a first and second CSI bridge, a DC-link inductor, and a resonant tank, which enables zero-voltage switching and bi-directional power flow, reducing common-mode voltage, and improving efficiency and dynamic performance.

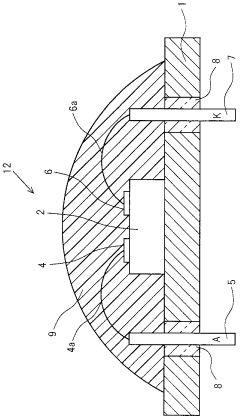

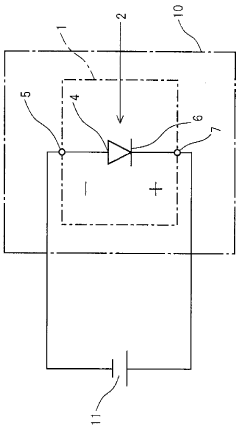

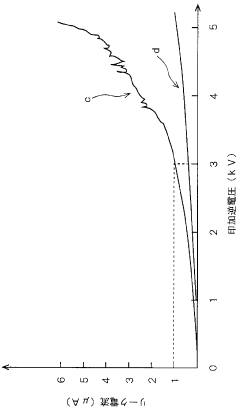

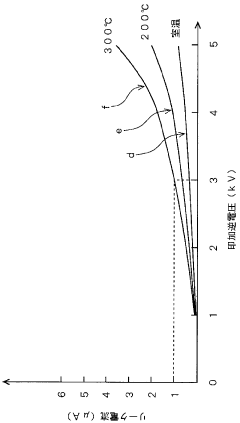

High withstand voltage semiconductor device covered with resin and process for producing the same

PatentWO2006038644A1

Innovation

- Applying a predetermined DC voltage between electrodes covered with uncured resin to align molecules in the direction of the electric field, which is then fixed upon cooling, enhancing the electrical resistance of the polymer compound.

EMI/EMC Considerations

The high dV/dt effects associated with SiC devices in motor drive applications pose significant challenges in terms of electromagnetic interference (EMI) and electromagnetic compatibility (EMC). The rapid switching of SiC MOSFETs, while beneficial for efficiency, generates high-frequency noise that can propagate throughout the system, affecting both the motor and surrounding electronics.

One of the primary EMI concerns is conducted emissions, which can travel along power cables and interfere with other equipment connected to the same power source. The fast rise and fall times of SiC switches create high-frequency harmonics that extend well into the MHz range. These emissions can exceed regulatory limits and cause malfunctions in nearby sensitive electronics.

Radiated emissions are another critical issue, as the high dV/dt can cause motor cables to act as antennas, radiating electromagnetic energy into the surrounding environment. This can lead to interference with wireless communications, control systems, and other electronic devices in the vicinity of the motor drive system.

Common mode (CM) noise is particularly problematic in SiC-based motor drives. The high dV/dt creates significant CM currents that flow through parasitic capacitances in the motor windings, bearings, and chassis. These currents can lead to premature bearing failure, motor insulation stress, and increased EMI.

To mitigate these EMI/EMC issues, several techniques can be employed. Proper shielding of motor cables and drive components is essential to contain radiated emissions. The use of EMI filters, both at the input and output of the drive, can significantly reduce conducted emissions and CM noise.

Careful PCB layout and component placement are crucial in minimizing parasitic inductances and capacitances that can exacerbate EMI issues. Implementing soft-switching techniques or using active gate drivers to control the dV/dt can help reduce the generation of high-frequency noise at the source.

Advanced modulation strategies, such as random PWM or spread spectrum techniques, can help distribute the EMI energy across a wider frequency range, potentially reducing peak emissions and easing compliance with regulatory standards.

Addressing EMI/EMC considerations is critical for the successful implementation of SiC-based motor drives. It requires a holistic approach that considers the entire system, from the power electronics to the motor and its environment. As SiC technology continues to evolve, ongoing research and development of EMI mitigation techniques will be essential to fully leverage the benefits of these high-performance devices in motor drive applications.

One of the primary EMI concerns is conducted emissions, which can travel along power cables and interfere with other equipment connected to the same power source. The fast rise and fall times of SiC switches create high-frequency harmonics that extend well into the MHz range. These emissions can exceed regulatory limits and cause malfunctions in nearby sensitive electronics.

Radiated emissions are another critical issue, as the high dV/dt can cause motor cables to act as antennas, radiating electromagnetic energy into the surrounding environment. This can lead to interference with wireless communications, control systems, and other electronic devices in the vicinity of the motor drive system.

Common mode (CM) noise is particularly problematic in SiC-based motor drives. The high dV/dt creates significant CM currents that flow through parasitic capacitances in the motor windings, bearings, and chassis. These currents can lead to premature bearing failure, motor insulation stress, and increased EMI.

To mitigate these EMI/EMC issues, several techniques can be employed. Proper shielding of motor cables and drive components is essential to contain radiated emissions. The use of EMI filters, both at the input and output of the drive, can significantly reduce conducted emissions and CM noise.

Careful PCB layout and component placement are crucial in minimizing parasitic inductances and capacitances that can exacerbate EMI issues. Implementing soft-switching techniques or using active gate drivers to control the dV/dt can help reduce the generation of high-frequency noise at the source.

Advanced modulation strategies, such as random PWM or spread spectrum techniques, can help distribute the EMI energy across a wider frequency range, potentially reducing peak emissions and easing compliance with regulatory standards.

Addressing EMI/EMC considerations is critical for the successful implementation of SiC-based motor drives. It requires a holistic approach that considers the entire system, from the power electronics to the motor and its environment. As SiC technology continues to evolve, ongoing research and development of EMI mitigation techniques will be essential to fully leverage the benefits of these high-performance devices in motor drive applications.

Thermal Management Strategies

Thermal management strategies play a crucial role in mitigating the high dV/dt effects of SiC devices on motor insulation. As SiC power electronics operate at higher switching frequencies and voltages, they generate significant heat that can exacerbate insulation degradation. Effective thermal management is essential to maintain the reliability and longevity of motor systems.

One primary approach to thermal management is the implementation of advanced cooling techniques. Liquid cooling systems, utilizing coolants with high thermal conductivity, can efficiently dissipate heat from SiC devices and motor windings. These systems often incorporate micro-channel heat sinks or cold plates to maximize heat transfer. Additionally, forced-air cooling with optimized heat sink designs and high-performance fans can provide effective thermal management for less demanding applications.

Thermal interface materials (TIMs) are another critical component in managing heat transfer. Advanced TIMs, such as phase-change materials or metal-based composites, offer improved thermal conductivity and reduced thermal resistance between SiC devices and heat sinks. These materials help to minimize hot spots and ensure more uniform heat distribution.

Innovative packaging techniques also contribute to enhanced thermal management. Direct-bonded copper (DBC) substrates and advanced ceramic materials provide superior thermal conductivity and electrical isolation. Three-dimensional packaging solutions, such as stacked die configurations, can optimize heat dissipation pathways and reduce overall thermal resistance.

Active thermal management techniques, including dynamic power cycling and intelligent thermal monitoring, can further mitigate the impact of high dV/dt on motor insulation. These strategies involve real-time adjustment of switching frequencies and power levels based on temperature feedback, ensuring optimal performance while preventing thermal runaway.

Thermal modeling and simulation tools are invaluable for designing effective thermal management strategies. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable engineers to predict thermal behavior and optimize cooling solutions before physical prototyping. These tools help identify potential hot spots and validate the effectiveness of various thermal management approaches.

Integration of wide-bandgap materials beyond SiC, such as gallium nitride (GaN), can complement thermal management efforts. GaN devices offer even higher switching speeds and lower losses, potentially reducing overall heat generation in motor drive systems. This can alleviate some of the thermal stress on motor insulation while maintaining high performance.

One primary approach to thermal management is the implementation of advanced cooling techniques. Liquid cooling systems, utilizing coolants with high thermal conductivity, can efficiently dissipate heat from SiC devices and motor windings. These systems often incorporate micro-channel heat sinks or cold plates to maximize heat transfer. Additionally, forced-air cooling with optimized heat sink designs and high-performance fans can provide effective thermal management for less demanding applications.

Thermal interface materials (TIMs) are another critical component in managing heat transfer. Advanced TIMs, such as phase-change materials or metal-based composites, offer improved thermal conductivity and reduced thermal resistance between SiC devices and heat sinks. These materials help to minimize hot spots and ensure more uniform heat distribution.

Innovative packaging techniques also contribute to enhanced thermal management. Direct-bonded copper (DBC) substrates and advanced ceramic materials provide superior thermal conductivity and electrical isolation. Three-dimensional packaging solutions, such as stacked die configurations, can optimize heat dissipation pathways and reduce overall thermal resistance.

Active thermal management techniques, including dynamic power cycling and intelligent thermal monitoring, can further mitigate the impact of high dV/dt on motor insulation. These strategies involve real-time adjustment of switching frequencies and power levels based on temperature feedback, ensuring optimal performance while preventing thermal runaway.

Thermal modeling and simulation tools are invaluable for designing effective thermal management strategies. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable engineers to predict thermal behavior and optimize cooling solutions before physical prototyping. These tools help identify potential hot spots and validate the effectiveness of various thermal management approaches.

Integration of wide-bandgap materials beyond SiC, such as gallium nitride (GaN), can complement thermal management efforts. GaN devices offer even higher switching speeds and lower losses, potentially reducing overall heat generation in motor drive systems. This can alleviate some of the thermal stress on motor insulation while maintaining high performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!