SiC synchronous rectification vs diode rectification in onboard chargers

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Rectification Background and Objectives

Silicon carbide (SiC) technology has emerged as a game-changing innovation in power electronics, particularly in the realm of electric vehicle (EV) onboard chargers. The evolution of SiC-based rectification techniques has been driven by the increasing demand for more efficient and compact power conversion systems in automotive applications.

Historically, diode rectification has been the standard method for AC-DC conversion in onboard chargers. However, as the automotive industry pushes for higher power density and improved efficiency, the limitations of traditional silicon-based diodes have become apparent. This has led to the exploration of SiC-based solutions, including both diode and synchronous rectification techniques.

The primary objective of researching SiC synchronous rectification versus diode rectification in onboard chargers is to determine the most effective approach for maximizing power conversion efficiency while minimizing size and weight. This comparison aims to evaluate the performance characteristics, thermal management requirements, and overall system impact of both rectification methods.

SiC technology offers several advantages over traditional silicon, including higher breakdown voltage, lower on-resistance, and superior thermal conductivity. These properties make SiC an ideal candidate for high-power applications such as EV charging systems. The investigation into SiC rectification techniques seeks to leverage these benefits to push the boundaries of onboard charger performance.

Another key objective of this research is to assess the feasibility of implementing SiC synchronous rectification in mass-produced EVs. This involves analyzing the cost-effectiveness, reliability, and manufacturability of SiC-based solutions compared to traditional diode rectification. The potential for reducing the size and weight of onboard chargers through the use of SiC technology is a critical factor in this evaluation.

Furthermore, this research aims to explore the impact of SiC rectification on the overall EV charging ecosystem. This includes examining how improved efficiency in onboard chargers can contribute to faster charging times, extended battery life, and reduced strain on the electrical grid. The potential for SiC technology to enable bidirectional power flow in vehicle-to-grid (V2G) applications is also a significant area of interest.

As the automotive industry continues to evolve towards electrification, the development of advanced power electronics plays a crucial role in enhancing EV performance and adoption. By thoroughly investigating the merits of SiC synchronous rectification compared to diode rectification, this research seeks to provide valuable insights that will guide the future design and implementation of onboard chargers in electric vehicles.

Historically, diode rectification has been the standard method for AC-DC conversion in onboard chargers. However, as the automotive industry pushes for higher power density and improved efficiency, the limitations of traditional silicon-based diodes have become apparent. This has led to the exploration of SiC-based solutions, including both diode and synchronous rectification techniques.

The primary objective of researching SiC synchronous rectification versus diode rectification in onboard chargers is to determine the most effective approach for maximizing power conversion efficiency while minimizing size and weight. This comparison aims to evaluate the performance characteristics, thermal management requirements, and overall system impact of both rectification methods.

SiC technology offers several advantages over traditional silicon, including higher breakdown voltage, lower on-resistance, and superior thermal conductivity. These properties make SiC an ideal candidate for high-power applications such as EV charging systems. The investigation into SiC rectification techniques seeks to leverage these benefits to push the boundaries of onboard charger performance.

Another key objective of this research is to assess the feasibility of implementing SiC synchronous rectification in mass-produced EVs. This involves analyzing the cost-effectiveness, reliability, and manufacturability of SiC-based solutions compared to traditional diode rectification. The potential for reducing the size and weight of onboard chargers through the use of SiC technology is a critical factor in this evaluation.

Furthermore, this research aims to explore the impact of SiC rectification on the overall EV charging ecosystem. This includes examining how improved efficiency in onboard chargers can contribute to faster charging times, extended battery life, and reduced strain on the electrical grid. The potential for SiC technology to enable bidirectional power flow in vehicle-to-grid (V2G) applications is also a significant area of interest.

As the automotive industry continues to evolve towards electrification, the development of advanced power electronics plays a crucial role in enhancing EV performance and adoption. By thoroughly investigating the merits of SiC synchronous rectification compared to diode rectification, this research seeks to provide valuable insights that will guide the future design and implementation of onboard chargers in electric vehicles.

Market Demand Analysis for Onboard Chargers

The market demand for onboard chargers has been experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) industry. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for efficient and reliable onboard charging solutions has surged. This trend is expected to continue in the coming years, with the global onboard charger market projected to grow at a compound annual growth rate (CAGR) of over 20% through 2026.

The increasing focus on fast charging capabilities and improved power efficiency has led to a growing interest in advanced technologies such as Silicon Carbide (SiC) power devices. SiC-based onboard chargers offer several advantages over traditional silicon-based solutions, including higher power density, improved thermal performance, and enhanced efficiency. These benefits align well with consumer demands for faster charging times and extended EV range.

The automotive industry's shift towards electrification has also created a ripple effect in the supply chain, with tier-1 suppliers and OEMs investing heavily in onboard charger technologies. This has resulted in increased competition and innovation in the market, driving down costs and improving overall product quality. As a result, consumers are benefiting from more affordable and technologically advanced onboard charging solutions.

Regional market dynamics play a crucial role in shaping the demand for onboard chargers. In mature EV markets such as Europe and China, there is a strong emphasis on high-power onboard chargers capable of supporting bi-directional charging and vehicle-to-grid (V2G) functionality. In contrast, emerging markets are focusing on cost-effective solutions that can accelerate EV adoption while maintaining reliability and performance.

The integration of smart charging features and connectivity options in onboard chargers is another key trend driving market demand. Consumers are increasingly seeking chargers that can communicate with smart grids, optimize charging schedules, and provide real-time data on charging status and efficiency. This trend is expected to continue as the automotive industry moves towards more connected and autonomous vehicles.

As the EV market matures, there is a growing demand for standardization in onboard charger technologies. This includes efforts to develop universal charging protocols and interoperable systems that can work across different vehicle brands and models. Such standardization is crucial for reducing consumer anxiety and promoting wider EV adoption, ultimately driving further growth in the onboard charger market.

The increasing focus on fast charging capabilities and improved power efficiency has led to a growing interest in advanced technologies such as Silicon Carbide (SiC) power devices. SiC-based onboard chargers offer several advantages over traditional silicon-based solutions, including higher power density, improved thermal performance, and enhanced efficiency. These benefits align well with consumer demands for faster charging times and extended EV range.

The automotive industry's shift towards electrification has also created a ripple effect in the supply chain, with tier-1 suppliers and OEMs investing heavily in onboard charger technologies. This has resulted in increased competition and innovation in the market, driving down costs and improving overall product quality. As a result, consumers are benefiting from more affordable and technologically advanced onboard charging solutions.

Regional market dynamics play a crucial role in shaping the demand for onboard chargers. In mature EV markets such as Europe and China, there is a strong emphasis on high-power onboard chargers capable of supporting bi-directional charging and vehicle-to-grid (V2G) functionality. In contrast, emerging markets are focusing on cost-effective solutions that can accelerate EV adoption while maintaining reliability and performance.

The integration of smart charging features and connectivity options in onboard chargers is another key trend driving market demand. Consumers are increasingly seeking chargers that can communicate with smart grids, optimize charging schedules, and provide real-time data on charging status and efficiency. This trend is expected to continue as the automotive industry moves towards more connected and autonomous vehicles.

As the EV market matures, there is a growing demand for standardization in onboard charger technologies. This includes efforts to develop universal charging protocols and interoperable systems that can work across different vehicle brands and models. Such standardization is crucial for reducing consumer anxiety and promoting wider EV adoption, ultimately driving further growth in the onboard charger market.

Current State and Challenges in SiC Rectification

Silicon Carbide (SiC) rectification technology has made significant strides in recent years, particularly in the context of onboard chargers for electric vehicles. The current state of SiC rectification is characterized by its superior performance compared to traditional silicon-based solutions, offering higher efficiency, faster switching speeds, and improved thermal management.

In onboard chargers, SiC devices are increasingly being adopted for both synchronous rectification and diode rectification applications. Synchronous rectification using SiC MOSFETs has shown promising results in terms of efficiency improvements, especially at higher switching frequencies. This approach allows for bidirectional power flow, which is beneficial for vehicle-to-grid (V2G) applications.

Diode rectification using SiC Schottky diodes has also demonstrated significant advantages over silicon alternatives. These diodes offer lower forward voltage drop, faster reverse recovery, and better high-temperature performance, contributing to overall system efficiency and reliability.

Despite the advancements, several challenges persist in the widespread adoption of SiC rectification in onboard chargers. Cost remains a primary concern, as SiC devices are generally more expensive than their silicon counterparts. This cost differential can be significant in high-volume automotive applications, where price sensitivity is a critical factor.

Another challenge lies in the design and implementation of SiC-based rectification circuits. The high switching speeds of SiC devices, while beneficial for efficiency, can lead to increased electromagnetic interference (EMI) and parasitic effects. This necessitates careful circuit layout and EMI mitigation strategies, which can increase design complexity and time-to-market.

Reliability and long-term performance of SiC devices in automotive environments are also areas of ongoing research and development. While SiC has inherent advantages in high-temperature operation, ensuring consistent performance over the lifetime of a vehicle under various operating conditions remains a challenge.

The integration of SiC rectification into existing onboard charger designs presents another hurdle. Many manufacturers are faced with the task of redesigning their systems to fully leverage the benefits of SiC technology while maintaining compatibility with existing vehicle architectures and charging infrastructure.

Lastly, the supply chain for SiC devices is still evolving. As demand grows, ensuring a stable and diverse supply of high-quality SiC components becomes crucial for automotive manufacturers. This includes not only the semiconductor devices themselves but also associated packaging and thermal management solutions optimized for SiC's unique characteristics.

In onboard chargers, SiC devices are increasingly being adopted for both synchronous rectification and diode rectification applications. Synchronous rectification using SiC MOSFETs has shown promising results in terms of efficiency improvements, especially at higher switching frequencies. This approach allows for bidirectional power flow, which is beneficial for vehicle-to-grid (V2G) applications.

Diode rectification using SiC Schottky diodes has also demonstrated significant advantages over silicon alternatives. These diodes offer lower forward voltage drop, faster reverse recovery, and better high-temperature performance, contributing to overall system efficiency and reliability.

Despite the advancements, several challenges persist in the widespread adoption of SiC rectification in onboard chargers. Cost remains a primary concern, as SiC devices are generally more expensive than their silicon counterparts. This cost differential can be significant in high-volume automotive applications, where price sensitivity is a critical factor.

Another challenge lies in the design and implementation of SiC-based rectification circuits. The high switching speeds of SiC devices, while beneficial for efficiency, can lead to increased electromagnetic interference (EMI) and parasitic effects. This necessitates careful circuit layout and EMI mitigation strategies, which can increase design complexity and time-to-market.

Reliability and long-term performance of SiC devices in automotive environments are also areas of ongoing research and development. While SiC has inherent advantages in high-temperature operation, ensuring consistent performance over the lifetime of a vehicle under various operating conditions remains a challenge.

The integration of SiC rectification into existing onboard charger designs presents another hurdle. Many manufacturers are faced with the task of redesigning their systems to fully leverage the benefits of SiC technology while maintaining compatibility with existing vehicle architectures and charging infrastructure.

Lastly, the supply chain for SiC devices is still evolving. As demand grows, ensuring a stable and diverse supply of high-quality SiC components becomes crucial for automotive manufacturers. This includes not only the semiconductor devices themselves but also associated packaging and thermal management solutions optimized for SiC's unique characteristics.

Existing SiC Rectification Solutions

01 Efficiency comparison between SiC synchronous rectification and diode rectification

SiC synchronous rectification generally offers higher efficiency compared to diode rectification due to lower conduction losses. The efficiency improvement is particularly significant at higher switching frequencies and lower output voltages. Synchronous rectification can reduce power losses by up to 50% in some applications.- Efficiency comparison between SiC synchronous rectification and diode rectification: SiC synchronous rectification generally offers higher efficiency compared to diode rectification due to lower conduction losses. The efficiency improvement is particularly significant at higher switching frequencies and lower output voltages. Synchronous rectification can reduce power losses by up to 50% in some applications.

- SiC MOSFET characteristics for synchronous rectification: SiC MOSFETs have lower on-resistance and faster switching speeds compared to traditional silicon devices, making them ideal for synchronous rectification. Their ability to operate at higher temperatures and voltages further enhances efficiency in power conversion applications.

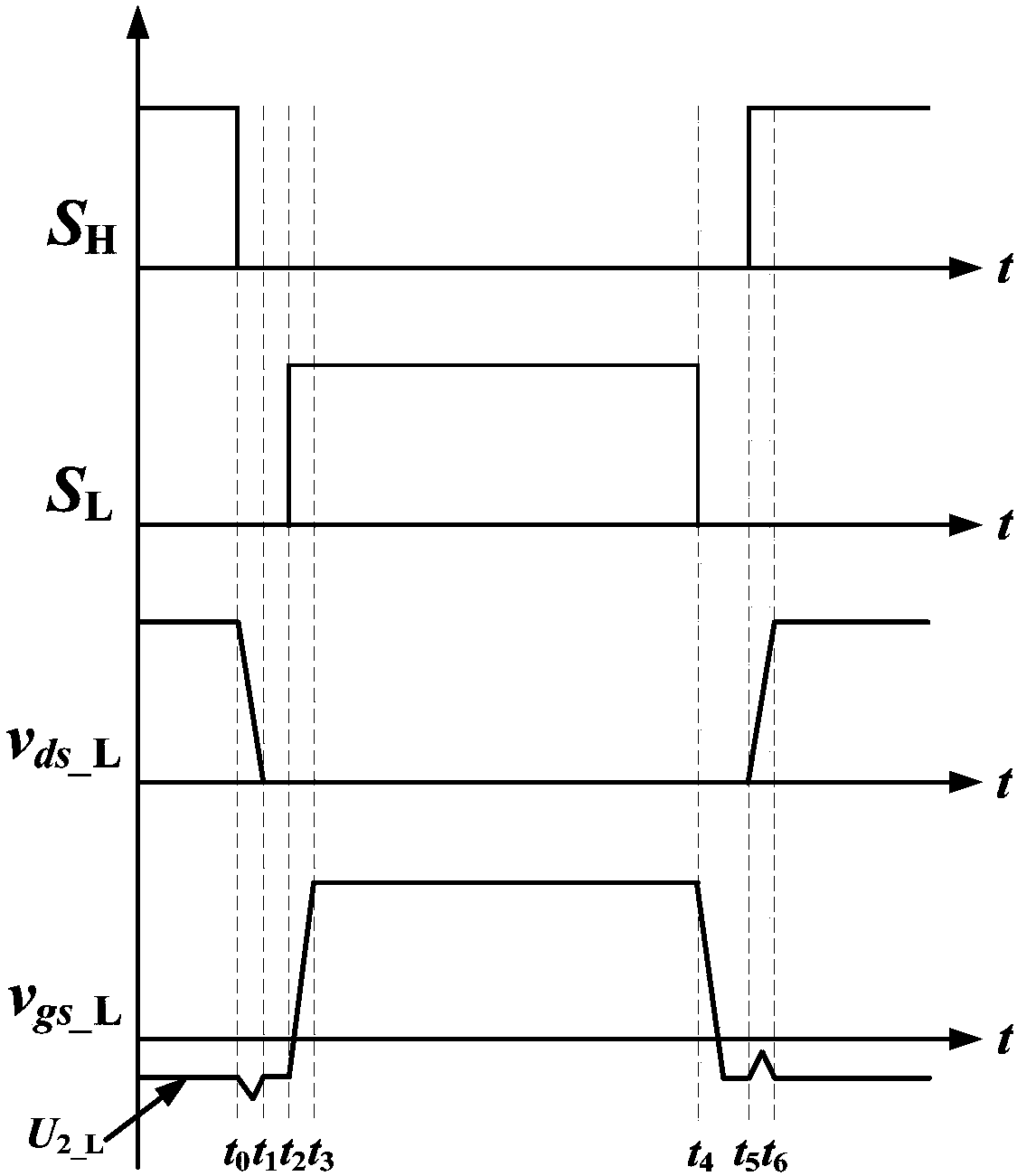

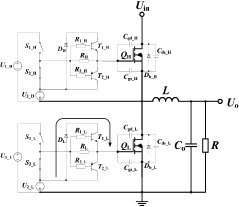

- Control strategies for SiC synchronous rectification: Advanced control strategies, such as adaptive dead-time control and precise timing of gate signals, are crucial for maximizing the efficiency of SiC synchronous rectification. These techniques minimize switching losses and prevent shoot-through current, further improving overall system efficiency.

- Thermal management in SiC rectification systems: Efficient thermal management is essential for maintaining high efficiency in SiC rectification systems. Improved heat dissipation techniques and packaging solutions help to maximize the performance benefits of SiC devices, especially in high-power applications.

- Integration of SiC devices in power conversion topologies: The integration of SiC devices in various power conversion topologies, such as bridgeless PFC and multilevel converters, can lead to significant improvements in efficiency and power density. These topologies leverage the unique properties of SiC to achieve higher performance in rectification and power conversion applications.

02 SiC MOSFET characteristics for synchronous rectification

SiC MOSFETs have lower on-resistance and faster switching speeds compared to traditional silicon devices, making them ideal for synchronous rectification. Their ability to operate at higher temperatures and voltages further enhances efficiency in power conversion applications.Expand Specific Solutions03 Control strategies for SiC synchronous rectification

Advanced control strategies, such as adaptive dead-time control and precise timing of gate signals, are crucial for maximizing the efficiency of SiC synchronous rectification. These techniques minimize switching losses and prevent shoot-through current, further improving overall system efficiency.Expand Specific Solutions04 Thermal management in SiC rectification systems

Efficient thermal management is essential for maintaining high efficiency in SiC rectification systems. Advanced cooling techniques and optimized package designs help dissipate heat effectively, allowing SiC devices to operate at their peak efficiency even under high-power conditions.Expand Specific Solutions05 Integration of SiC rectification in power conversion topologies

Incorporating SiC synchronous rectification into various power conversion topologies, such as buck, boost, and bridge configurations, can significantly improve overall system efficiency. The selection of appropriate topology and optimization of circuit parameters are crucial for maximizing the benefits of SiC rectification.Expand Specific Solutions

Key Players in SiC and Onboard Charger Industry

The research on SiC synchronous rectification vs diode rectification in onboard chargers is in a growth phase, with increasing market size due to the rising demand for electric vehicles. The technology is maturing rapidly, with key players like Texas Instruments, Infineon Technologies, and ROHM Co. leading innovation. These companies are investing heavily in SiC technology, pushing for higher efficiency and power density in onboard chargers. The competitive landscape is intensifying as more automotive and semiconductor firms enter the market, driving advancements in both synchronous and diode rectification techniques for SiC-based solutions.

Texas Instruments Incorporated

Technical Solution: Texas Instruments (TI) has developed advanced SiC-based synchronous rectification solutions for onboard chargers. Their approach utilizes high-performance SiC MOSFETs in place of traditional diodes, significantly improving efficiency and power density. TI's solution incorporates intelligent gate drivers with advanced control algorithms to optimize switching timing and reduce losses. The company has reported efficiency improvements of up to 2% compared to diode rectification, translating to reduced heat generation and smaller cooling requirements[1]. TI's SiC synchronous rectification technology also enables higher switching frequencies, allowing for more compact designs and reduced overall system size[2].

Strengths: Higher efficiency, reduced heat generation, and smaller form factor. Weaknesses: Higher initial component costs and increased control complexity compared to diode rectification.

Infineon Technologies Americas Corp.

Technical Solution: Infineon has pioneered SiC-based synchronous rectification solutions for onboard chargers, focusing on their CoolSiC™ MOSFET technology. Their approach combines high-performance SiC MOSFETs with advanced gate driver ICs to achieve optimal switching performance. Infineon's solution has demonstrated efficiency improvements of up to 3% over traditional diode rectification in onboard charger applications[3]. The company's SiC synchronous rectification technology enables operation at higher frequencies (up to 100 kHz), allowing for significant reductions in passive component sizes and overall charger volume[4]. Infineon has also developed sophisticated control algorithms to mitigate challenges associated with SiC MOSFET body diode recovery, ensuring reliable operation across various operating conditions.

Strengths: High efficiency gains, reduced charger size, and advanced control algorithms. Weaknesses: Higher system complexity and potential EMI challenges at higher switching frequencies.

Core Innovations in SiC Synchronous Rectification

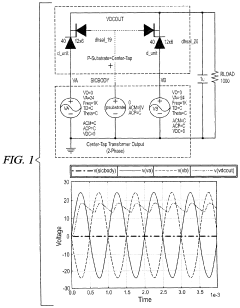

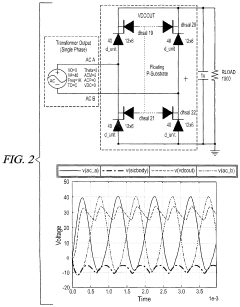

Integrated silicon carbide diode rectifier circuits

PatentActiveUS11251717B1

Innovation

- The development of integrated silicon carbide diode rectifier circuits using an isolation diode from a JFET N-channel to a P-Substrate, which allows for the design of efficient rectification circuits by tying the P-Substrate to the center tap of a transformer for two-phase AC input and allowing it to float for single-phase transformer outputs, enabling effective rectification without affecting performance.

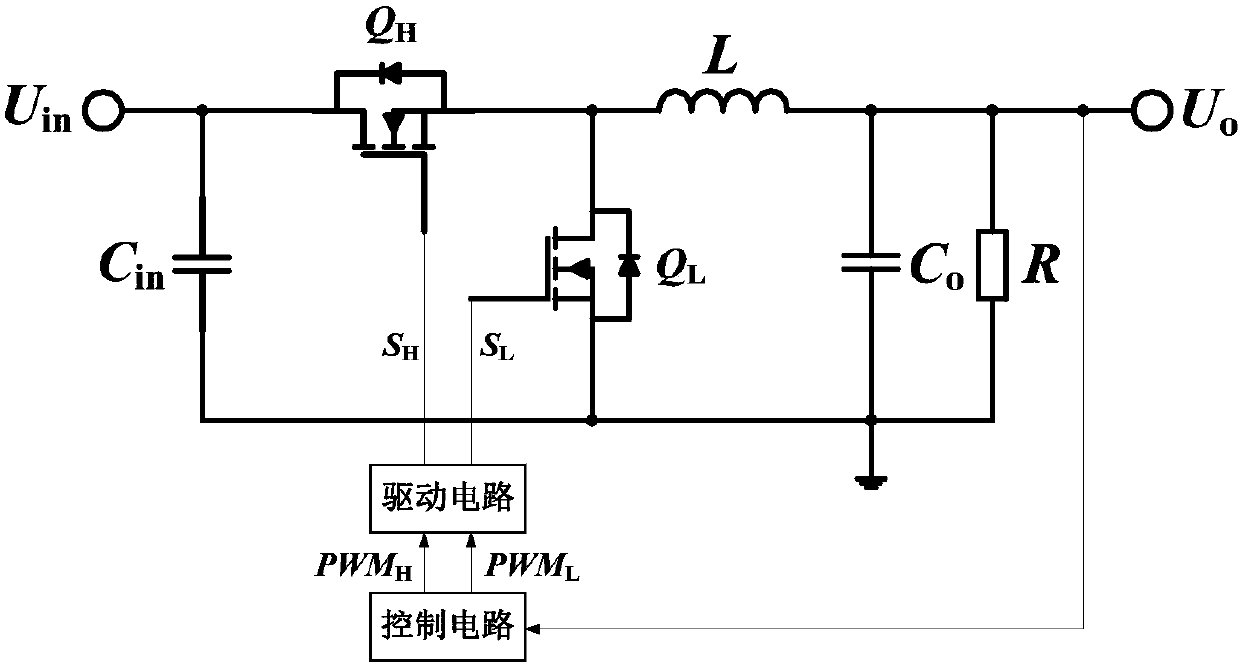

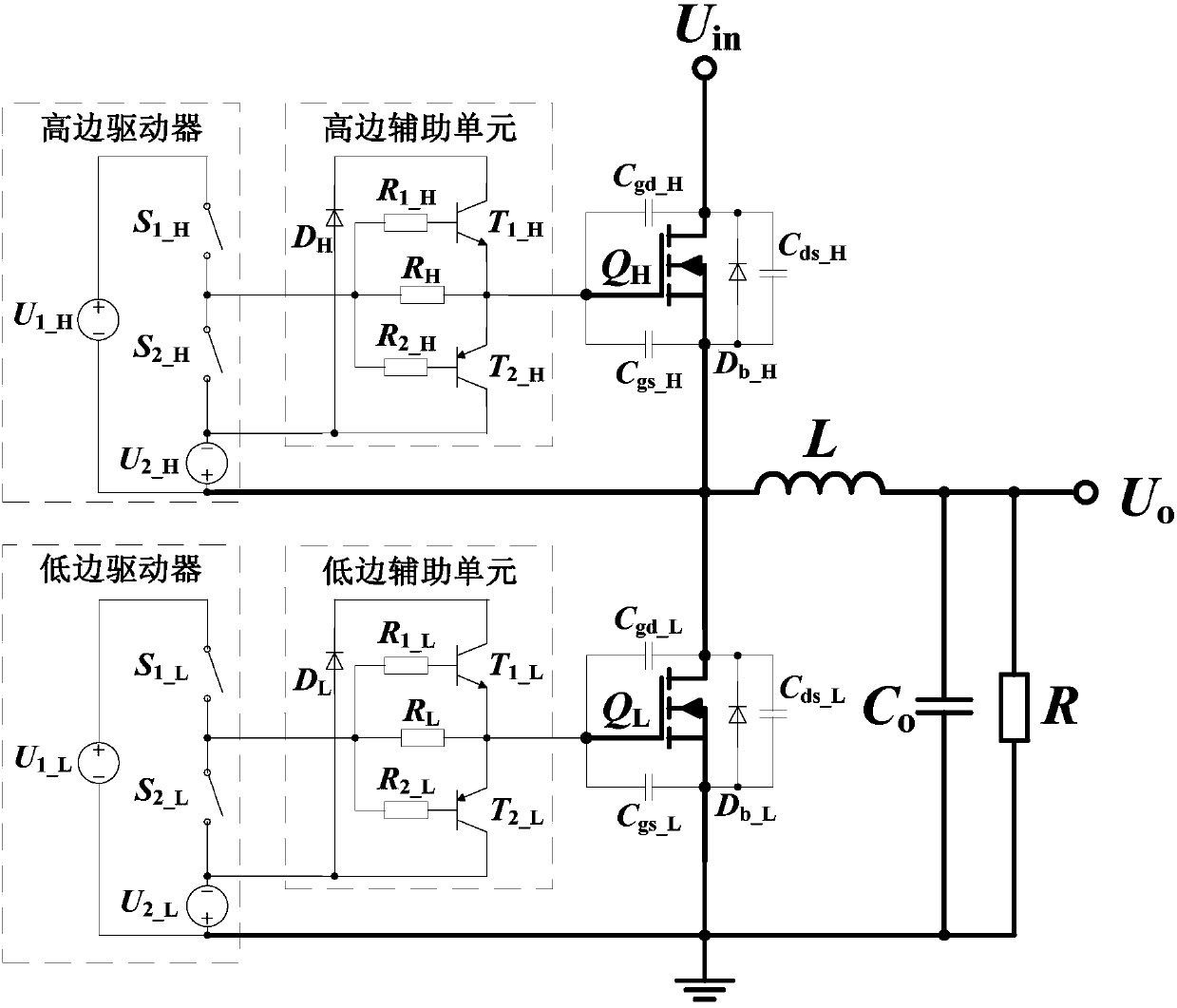

SiC switch tube driving circuit and method of synchronous rectification Buck convertor

PatentActiveCN107769530A

Innovation

- A SiC switch tube driving circuit is designed, including a high-side driver, a low-side driver, a high-side auxiliary unit and a low-side auxiliary unit. Through the on-off control of the auxiliary unit, it is ensured that the gate-source voltage of the low-side switch tube is turned off. At negative pressure, avoid driving signal oscillation.

Efficiency Comparison: SiC vs Diode Rectification

The efficiency comparison between Silicon Carbide (SiC) synchronous rectification and diode rectification in onboard chargers reveals significant advantages for SiC technology. SiC synchronous rectification demonstrates superior performance in terms of power conversion efficiency, particularly at higher switching frequencies and voltages.

In onboard chargers, SiC synchronous rectification typically achieves efficiency levels of 98-99%, compared to 94-96% for traditional diode rectification. This improvement is primarily due to the lower on-state resistance and faster switching capabilities of SiC MOSFETs. The reduced conduction and switching losses translate to less heat generation and improved overall system efficiency.

The efficiency gap between SiC and diode rectification becomes more pronounced at higher power levels and operating temperatures. SiC devices maintain their performance advantages even at elevated temperatures, whereas silicon-based diodes experience increased losses as temperature rises. This characteristic makes SiC particularly suitable for automotive applications where high-temperature operation is common.

Switching losses are another area where SiC outperforms traditional diodes. SiC MOSFETs can switch at much higher frequencies with lower losses, enabling the design of more compact and lightweight onboard chargers. This high-frequency operation also allows for smaller passive components, further reducing system size and cost.

The reverse recovery characteristics of SiC devices are superior to those of silicon diodes. SiC Schottky diodes, often used in synchronous rectification circuits, have virtually no reverse recovery time, eliminating the associated losses and electromagnetic interference (EMI) issues common in silicon-based rectifiers.

However, it is important to note that the efficiency gains of SiC synchronous rectification come at a higher initial cost. SiC devices are generally more expensive than their silicon counterparts, which can impact the overall system cost. Nevertheless, the long-term benefits in terms of improved efficiency, reduced cooling requirements, and potential for system size reduction often justify the higher upfront investment.

The efficiency advantage of SiC synchronous rectification also contributes to improved battery charging times in electric vehicles. The higher efficiency allows for faster power transfer to the battery without excessive heat generation, potentially reducing charging times and improving the overall user experience.

In conclusion, while both SiC synchronous rectification and diode rectification have their place in onboard charger designs, SiC technology offers clear efficiency advantages. As SiC device costs continue to decrease and manufacturing processes improve, the adoption of SiC synchronous rectification in onboard chargers is expected to increase, driving further improvements in electric vehicle charging efficiency and performance.

In onboard chargers, SiC synchronous rectification typically achieves efficiency levels of 98-99%, compared to 94-96% for traditional diode rectification. This improvement is primarily due to the lower on-state resistance and faster switching capabilities of SiC MOSFETs. The reduced conduction and switching losses translate to less heat generation and improved overall system efficiency.

The efficiency gap between SiC and diode rectification becomes more pronounced at higher power levels and operating temperatures. SiC devices maintain their performance advantages even at elevated temperatures, whereas silicon-based diodes experience increased losses as temperature rises. This characteristic makes SiC particularly suitable for automotive applications where high-temperature operation is common.

Switching losses are another area where SiC outperforms traditional diodes. SiC MOSFETs can switch at much higher frequencies with lower losses, enabling the design of more compact and lightweight onboard chargers. This high-frequency operation also allows for smaller passive components, further reducing system size and cost.

The reverse recovery characteristics of SiC devices are superior to those of silicon diodes. SiC Schottky diodes, often used in synchronous rectification circuits, have virtually no reverse recovery time, eliminating the associated losses and electromagnetic interference (EMI) issues common in silicon-based rectifiers.

However, it is important to note that the efficiency gains of SiC synchronous rectification come at a higher initial cost. SiC devices are generally more expensive than their silicon counterparts, which can impact the overall system cost. Nevertheless, the long-term benefits in terms of improved efficiency, reduced cooling requirements, and potential for system size reduction often justify the higher upfront investment.

The efficiency advantage of SiC synchronous rectification also contributes to improved battery charging times in electric vehicles. The higher efficiency allows for faster power transfer to the battery without excessive heat generation, potentially reducing charging times and improving the overall user experience.

In conclusion, while both SiC synchronous rectification and diode rectification have their place in onboard charger designs, SiC technology offers clear efficiency advantages. As SiC device costs continue to decrease and manufacturing processes improve, the adoption of SiC synchronous rectification in onboard chargers is expected to increase, driving further improvements in electric vehicle charging efficiency and performance.

Thermal Management in SiC Rectification Systems

Thermal management is a critical aspect of SiC rectification systems in onboard chargers, particularly when comparing synchronous rectification to diode rectification. The high switching frequencies and power densities associated with SiC devices generate significant heat, which must be effectively dissipated to maintain optimal performance and reliability.

In synchronous rectification systems, the primary heat sources are the SiC MOSFETs used as switches. These devices generate heat during both conduction and switching phases. The conduction losses are generally lower than those in diode rectification, but the switching losses can be substantial, especially at high frequencies. Effective thermal management strategies for synchronous rectification often involve advanced packaging techniques, such as direct bonded copper (DBC) substrates or integrated cooling solutions.

Diode rectification systems, on the other hand, primarily deal with heat generated by the forward voltage drop across the diodes. While SiC Schottky diodes offer lower forward voltage drops compared to traditional silicon diodes, they still produce significant heat, particularly in high-power applications. The thermal management approach for diode rectification typically focuses on efficient heat spreading and removal from the diode junction.

Both systems benefit from advanced cooling techniques such as liquid cooling, phase-change materials, or forced-air convection. However, the specific implementation may differ based on the rectification method. Synchronous rectification systems often require more sophisticated thermal designs due to the distributed nature of heat generation across multiple switching devices.

The choice between synchronous and diode rectification also impacts the overall thermal profile of the onboard charger. Synchronous rectification generally offers higher efficiency, potentially reducing the total heat generated in the system. This can lead to smaller heatsinks and cooling systems, contributing to the overall compactness of the charger. However, the complexity of the thermal design may increase due to the need to manage multiple heat sources.

Thermal simulation and modeling play crucial roles in optimizing the thermal management of both rectification systems. Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) tools are employed to predict heat distribution and identify potential hotspots. These simulations guide the design of thermal interfaces, heatsink geometries, and cooling system layouts to ensure optimal heat dissipation.

In synchronous rectification systems, the primary heat sources are the SiC MOSFETs used as switches. These devices generate heat during both conduction and switching phases. The conduction losses are generally lower than those in diode rectification, but the switching losses can be substantial, especially at high frequencies. Effective thermal management strategies for synchronous rectification often involve advanced packaging techniques, such as direct bonded copper (DBC) substrates or integrated cooling solutions.

Diode rectification systems, on the other hand, primarily deal with heat generated by the forward voltage drop across the diodes. While SiC Schottky diodes offer lower forward voltage drops compared to traditional silicon diodes, they still produce significant heat, particularly in high-power applications. The thermal management approach for diode rectification typically focuses on efficient heat spreading and removal from the diode junction.

Both systems benefit from advanced cooling techniques such as liquid cooling, phase-change materials, or forced-air convection. However, the specific implementation may differ based on the rectification method. Synchronous rectification systems often require more sophisticated thermal designs due to the distributed nature of heat generation across multiple switching devices.

The choice between synchronous and diode rectification also impacts the overall thermal profile of the onboard charger. Synchronous rectification generally offers higher efficiency, potentially reducing the total heat generated in the system. This can lead to smaller heatsinks and cooling systems, contributing to the overall compactness of the charger. However, the complexity of the thermal design may increase due to the need to manage multiple heat sources.

Thermal simulation and modeling play crucial roles in optimizing the thermal management of both rectification systems. Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) tools are employed to predict heat distribution and identify potential hotspots. These simulations guide the design of thermal interfaces, heatsink geometries, and cooling system layouts to ensure optimal heat dissipation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!