SiC EMI compliance strategies for CISPR and conducted emissions

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC EMI Background and Objectives

Silicon Carbide (SiC) technology has emerged as a revolutionary force in power electronics, offering significant advantages over traditional silicon-based devices. The development of SiC power devices has been driven by the increasing demand for high-efficiency, high-power density, and high-temperature operation in various applications, including electric vehicles, renewable energy systems, and industrial motor drives.

The primary objective of SiC EMI compliance strategies for CISPR and conducted emissions is to address the electromagnetic interference (EMI) challenges associated with the rapid switching speeds and high-frequency operation of SiC devices. As SiC technology enables faster switching and higher operating frequencies, it inadvertently generates more electromagnetic noise, which can interfere with nearby electronic systems and violate electromagnetic compatibility (EMC) standards.

The evolution of SiC technology has been marked by continuous improvements in material quality, device design, and manufacturing processes. Early SiC devices faced challenges related to defect density and cost-effectiveness. However, advancements in crystal growth techniques and device fabrication have led to the commercial availability of high-quality SiC power devices, including MOSFETs and Schottky diodes.

The adoption of SiC technology has accelerated in recent years, driven by the need for more efficient power conversion systems and the push towards electrification in various industries. This trend has heightened the importance of addressing EMI issues to ensure compliance with international standards such as CISPR (Comité International Spécial des Perturbations Radioélectriques) and conducted emissions regulations.

The technical goals for SiC EMI compliance strategies are multifaceted. They include developing innovative circuit topologies and control techniques to mitigate EMI generation at the source, designing effective EMI filtering solutions tailored for SiC-based power converters, and implementing advanced packaging and shielding techniques to contain electromagnetic emissions.

Furthermore, there is a growing emphasis on developing comprehensive EMI modeling and prediction tools specific to SiC devices. These tools aim to enable designers to anticipate and address EMI issues early in the development process, reducing the time and cost associated with EMC compliance testing and certification.

As the SiC market continues to expand, the importance of EMI compliance strategies becomes increasingly critical. The industry is witnessing a shift towards system-level approaches to EMI mitigation, recognizing that addressing EMI challenges requires a holistic consideration of device characteristics, circuit design, and system integration.

The primary objective of SiC EMI compliance strategies for CISPR and conducted emissions is to address the electromagnetic interference (EMI) challenges associated with the rapid switching speeds and high-frequency operation of SiC devices. As SiC technology enables faster switching and higher operating frequencies, it inadvertently generates more electromagnetic noise, which can interfere with nearby electronic systems and violate electromagnetic compatibility (EMC) standards.

The evolution of SiC technology has been marked by continuous improvements in material quality, device design, and manufacturing processes. Early SiC devices faced challenges related to defect density and cost-effectiveness. However, advancements in crystal growth techniques and device fabrication have led to the commercial availability of high-quality SiC power devices, including MOSFETs and Schottky diodes.

The adoption of SiC technology has accelerated in recent years, driven by the need for more efficient power conversion systems and the push towards electrification in various industries. This trend has heightened the importance of addressing EMI issues to ensure compliance with international standards such as CISPR (Comité International Spécial des Perturbations Radioélectriques) and conducted emissions regulations.

The technical goals for SiC EMI compliance strategies are multifaceted. They include developing innovative circuit topologies and control techniques to mitigate EMI generation at the source, designing effective EMI filtering solutions tailored for SiC-based power converters, and implementing advanced packaging and shielding techniques to contain electromagnetic emissions.

Furthermore, there is a growing emphasis on developing comprehensive EMI modeling and prediction tools specific to SiC devices. These tools aim to enable designers to anticipate and address EMI issues early in the development process, reducing the time and cost associated with EMC compliance testing and certification.

As the SiC market continues to expand, the importance of EMI compliance strategies becomes increasingly critical. The industry is witnessing a shift towards system-level approaches to EMI mitigation, recognizing that addressing EMI challenges requires a holistic consideration of device characteristics, circuit design, and system integration.

Market Demand for SiC EMI Compliance

The market demand for SiC EMI compliance strategies is experiencing significant growth, driven by the rapid adoption of Silicon Carbide (SiC) technology in power electronics applications. As SiC devices gain popularity in electric vehicles, renewable energy systems, and industrial equipment, the need for effective electromagnetic interference (EMI) mitigation becomes increasingly critical.

The automotive sector, particularly electric vehicles, represents a major driver for SiC EMI compliance solutions. With the global electric vehicle market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, manufacturers are seeking robust EMI compliance strategies to ensure their SiC-based power systems meet stringent CISPR and conducted emissions standards.

Renewable energy applications, such as solar inverters and wind turbine converters, also contribute substantially to the demand for SiC EMI compliance. As countries worldwide push for greater adoption of clean energy technologies, the market for SiC-based power conversion systems is expanding, necessitating advanced EMI mitigation techniques to comply with grid connection requirements and electromagnetic compatibility (EMC) regulations.

The industrial sector, including motor drives, uninterruptible power supplies (UPS), and factory automation systems, presents another significant market for SiC EMI compliance solutions. As industries increasingly adopt SiC technology to improve energy efficiency and power density, the need for effective EMI management becomes paramount to ensure reliable operation in complex electromagnetic environments.

The growing emphasis on Industry 4.0 and smart manufacturing further amplifies the demand for SiC EMI compliance strategies. As industrial facilities incorporate more connected devices and sensitive electronic systems, maintaining electromagnetic compatibility becomes crucial for seamless operation and data integrity.

Telecommunications infrastructure, particularly 5G base stations and data centers, represents an emerging market for SiC EMI compliance solutions. The high-frequency operation and increased power requirements of these systems necessitate advanced EMI mitigation techniques to ensure compliance with regulatory standards and prevent interference with nearby electronic equipment.

The aerospace and defense sectors also contribute to the market demand for SiC EMI compliance strategies. As these industries adopt SiC technology for high-power, high-temperature applications, stringent EMI requirements must be met to ensure the reliability and safety of critical systems.

Overall, the market for SiC EMI compliance strategies is poised for substantial growth across multiple sectors. As SiC technology continues to penetrate various applications, the demand for innovative EMI mitigation solutions that address CISPR and conducted emissions standards will remain strong, driving research and development efforts in this field.

The automotive sector, particularly electric vehicles, represents a major driver for SiC EMI compliance solutions. With the global electric vehicle market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, manufacturers are seeking robust EMI compliance strategies to ensure their SiC-based power systems meet stringent CISPR and conducted emissions standards.

Renewable energy applications, such as solar inverters and wind turbine converters, also contribute substantially to the demand for SiC EMI compliance. As countries worldwide push for greater adoption of clean energy technologies, the market for SiC-based power conversion systems is expanding, necessitating advanced EMI mitigation techniques to comply with grid connection requirements and electromagnetic compatibility (EMC) regulations.

The industrial sector, including motor drives, uninterruptible power supplies (UPS), and factory automation systems, presents another significant market for SiC EMI compliance solutions. As industries increasingly adopt SiC technology to improve energy efficiency and power density, the need for effective EMI management becomes paramount to ensure reliable operation in complex electromagnetic environments.

The growing emphasis on Industry 4.0 and smart manufacturing further amplifies the demand for SiC EMI compliance strategies. As industrial facilities incorporate more connected devices and sensitive electronic systems, maintaining electromagnetic compatibility becomes crucial for seamless operation and data integrity.

Telecommunications infrastructure, particularly 5G base stations and data centers, represents an emerging market for SiC EMI compliance solutions. The high-frequency operation and increased power requirements of these systems necessitate advanced EMI mitigation techniques to ensure compliance with regulatory standards and prevent interference with nearby electronic equipment.

The aerospace and defense sectors also contribute to the market demand for SiC EMI compliance strategies. As these industries adopt SiC technology for high-power, high-temperature applications, stringent EMI requirements must be met to ensure the reliability and safety of critical systems.

Overall, the market for SiC EMI compliance strategies is poised for substantial growth across multiple sectors. As SiC technology continues to penetrate various applications, the demand for innovative EMI mitigation solutions that address CISPR and conducted emissions standards will remain strong, driving research and development efforts in this field.

SiC EMI Challenges and Limitations

Silicon Carbide (SiC) power devices have emerged as a promising technology for high-efficiency power conversion systems. However, their rapid switching speeds and high dv/dt and di/dt characteristics pose significant challenges in terms of electromagnetic interference (EMI) compliance. These challenges are particularly evident when attempting to meet the stringent requirements set by CISPR (Comité International Spécial des Perturbations Radioélectriques) standards and conducted emissions regulations.

One of the primary limitations of SiC devices in EMI compliance is their inherent high-frequency noise generation. The fast switching transitions of SiC MOSFETs and diodes result in broadband electromagnetic emissions that can extend well into the MHz range. This high-frequency noise is difficult to suppress using traditional EMI mitigation techniques, often requiring more sophisticated filtering and shielding solutions.

Another challenge lies in the parasitic elements of SiC device packages and circuit layouts. The high dv/dt and di/dt rates can excite parasitic capacitances and inductances, leading to resonances and oscillations that contribute to EMI. These parasitic effects are more pronounced in SiC-based systems compared to their silicon counterparts, necessitating careful consideration of package design and PCB layout to minimize their impact.

The increased switching frequency capabilities of SiC devices, while beneficial for power density and efficiency, also present EMI compliance hurdles. Higher switching frequencies push the EMI spectrum into ranges where traditional filtering components become less effective. This limitation often requires the use of advanced materials and novel filter topologies to achieve adequate EMI suppression across a wider frequency range.

Thermal management considerations in SiC-based systems can also indirectly affect EMI performance. The high power density of SiC devices may require more aggressive cooling solutions, which can introduce additional conductive paths for EMI propagation. Balancing thermal performance with EMI mitigation becomes a critical design challenge, often leading to trade-offs between system efficiency and electromagnetic compatibility.

Furthermore, the interaction between SiC devices and other system components, such as gate drivers and control circuits, can exacerbate EMI issues. The high-speed switching of SiC devices can induce noise in nearby sensitive circuits, potentially causing malfunctions or degrading overall system performance. This necessitates careful isolation and shielding strategies to ensure robust operation in the presence of electromagnetic disturbances.

Lastly, the current lack of standardized EMI compliance testing procedures specifically tailored for SiC-based power systems poses a challenge for manufacturers. Existing CISPR standards and conducted emissions tests may not fully capture the unique EMI characteristics of SiC devices, potentially leading to inconsistencies in compliance assessments across different testing facilities or regulatory bodies.

One of the primary limitations of SiC devices in EMI compliance is their inherent high-frequency noise generation. The fast switching transitions of SiC MOSFETs and diodes result in broadband electromagnetic emissions that can extend well into the MHz range. This high-frequency noise is difficult to suppress using traditional EMI mitigation techniques, often requiring more sophisticated filtering and shielding solutions.

Another challenge lies in the parasitic elements of SiC device packages and circuit layouts. The high dv/dt and di/dt rates can excite parasitic capacitances and inductances, leading to resonances and oscillations that contribute to EMI. These parasitic effects are more pronounced in SiC-based systems compared to their silicon counterparts, necessitating careful consideration of package design and PCB layout to minimize their impact.

The increased switching frequency capabilities of SiC devices, while beneficial for power density and efficiency, also present EMI compliance hurdles. Higher switching frequencies push the EMI spectrum into ranges where traditional filtering components become less effective. This limitation often requires the use of advanced materials and novel filter topologies to achieve adequate EMI suppression across a wider frequency range.

Thermal management considerations in SiC-based systems can also indirectly affect EMI performance. The high power density of SiC devices may require more aggressive cooling solutions, which can introduce additional conductive paths for EMI propagation. Balancing thermal performance with EMI mitigation becomes a critical design challenge, often leading to trade-offs between system efficiency and electromagnetic compatibility.

Furthermore, the interaction between SiC devices and other system components, such as gate drivers and control circuits, can exacerbate EMI issues. The high-speed switching of SiC devices can induce noise in nearby sensitive circuits, potentially causing malfunctions or degrading overall system performance. This necessitates careful isolation and shielding strategies to ensure robust operation in the presence of electromagnetic disturbances.

Lastly, the current lack of standardized EMI compliance testing procedures specifically tailored for SiC-based power systems poses a challenge for manufacturers. Existing CISPR standards and conducted emissions tests may not fully capture the unique EMI characteristics of SiC devices, potentially leading to inconsistencies in compliance assessments across different testing facilities or regulatory bodies.

Current SiC EMI Compliance Strategies

01 EMI shielding in SiC power devices

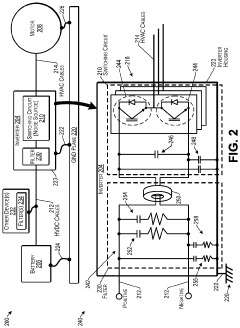

Silicon Carbide (SiC) power devices are prone to electromagnetic interference (EMI) due to their high-frequency switching capabilities. To mitigate this, various shielding techniques are employed, including the use of conductive enclosures, specialized packaging materials, and strategic layout designs. These methods help to contain electromagnetic emissions and protect surrounding components from interference.- EMI shielding in SiC power devices: Silicon Carbide (SiC) power devices often require effective EMI shielding to prevent electromagnetic interference. Various shielding techniques and materials are employed to minimize EMI emissions and improve device performance in high-frequency applications. These methods may include specialized packaging designs, conductive coatings, or integrated shielding structures.

- SiC device packaging for EMI reduction: Advanced packaging solutions for SiC devices are developed to address EMI concerns. These may include multi-layer structures, embedded passive components, or innovative substrate materials that help suppress electromagnetic emissions. The packaging design plays a crucial role in managing thermal issues while simultaneously providing EMI protection.

- EMI filtering techniques for SiC circuits: Various filtering techniques are implemented in SiC-based circuits to mitigate EMI. These may include the use of common-mode chokes, ferrite beads, or specialized filter designs tailored for high-frequency SiC applications. The goal is to attenuate unwanted electromagnetic emissions without compromising the device's performance.

- EMI-resistant SiC semiconductor structures: Novel semiconductor structures are developed to enhance the EMI resistance of SiC devices. These may involve modifications to the device architecture, such as incorporating buried layers, using specific doping profiles, or implementing unique junction designs. The aim is to improve the device's inherent immunity to electromagnetic interference.

- System-level EMI management for SiC applications: Comprehensive approaches to EMI management are developed for systems utilizing SiC devices. These strategies may include optimized PCB layouts, grounding schemes, and system-level shielding techniques. The focus is on creating a holistic EMI mitigation strategy that addresses interference at both the device and system levels.

02 EMI reduction through circuit design in SiC devices

Circuit design plays a crucial role in reducing EMI in SiC devices. Techniques such as optimized gate drive circuits, snubber networks, and careful PCB layout are implemented to minimize parasitic inductances and capacitances. These design strategies help to reduce voltage and current ringing, thereby lowering electromagnetic emissions from SiC-based power converters and modules.Expand Specific Solutions03 Thermal management and EMI reduction in SiC devices

Effective thermal management in SiC devices is essential not only for performance but also for EMI reduction. Advanced cooling solutions and thermally conductive materials are used to dissipate heat efficiently, which helps maintain stable device operation and reduces temperature-induced variations in electrical characteristics that can contribute to EMI. Proper thermal design also allows for more compact packaging, further aiding in EMI containment.Expand Specific Solutions04 EMI-resistant packaging for SiC devices

Specialized packaging techniques are developed for SiC devices to enhance their EMI resistance. These include the use of advanced molding compounds, metal-ceramic packages, and multi-layer substrates with embedded shielding layers. Such packaging solutions not only protect the SiC chips from external EMI but also contain the electromagnetic emissions generated by the high-frequency switching of the devices.Expand Specific Solutions05 System-level EMI mitigation for SiC-based power electronics

EMI mitigation in SiC-based power electronics extends beyond the device level to encompass system-wide solutions. This includes the design of EMI filters, common-mode chokes, and strategic grounding techniques. Additionally, software-based approaches such as spread spectrum modulation and advanced control algorithms are employed to distribute the EMI energy across a wider frequency range, reducing peak emissions and improving overall electromagnetic compatibility of SiC-based systems.Expand Specific Solutions

Key Players in SiC EMI Compliance Industry

The SiC EMI compliance strategies for CISPR and conducted emissions market is in a growth phase, driven by increasing adoption of SiC technology in power electronics. The market size is expanding as more industries implement SiC-based solutions. Technologically, the field is advancing rapidly, with companies like Fujitsu, Sony, and Texas Instruments leading innovation. These firms are developing sophisticated EMI mitigation techniques and compliance strategies. Other players like Continental Automotive and ABB Group are also contributing to the technological maturity of SiC EMI solutions. The competitive landscape is diverse, with both established electronics giants and specialized semiconductor firms vying for market share in this emerging field.

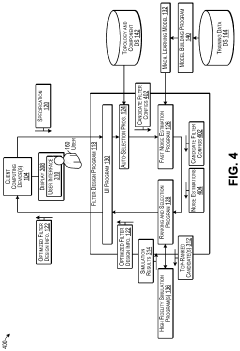

Toshiba Corp.

Technical Solution: Toshiba has developed advanced SiC EMI compliance strategies for CISPR and conducted emissions in their power electronics and semiconductor solutions. Their approach includes the implementation of novel gate drive technologies that optimize switching behavior to reduce EMI while maintaining high efficiency. Toshiba's SiC devices feature integrated EMI suppression circuits and utilize advanced packaging techniques to minimize parasitic inductances[10]. They have also developed sophisticated modeling and simulation tools for EMI prediction and optimization during the design phase. Toshiba's strategy emphasizes a balance between EMI compliance, efficiency, and reliability, incorporating advanced thermal management solutions that indirectly contribute to improved EMI performance by enabling more stable device operation[11].

Strengths: Strong integration of EMI compliance with overall device performance, advanced modeling and simulation capabilities. Weaknesses: Potential complexity in design process, may require specialized knowledge for optimal implementation.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced SiC EMI compliance strategies for CISPR and conducted emissions. Their approach includes implementing spread spectrum clocking techniques to reduce EMI peaks, utilizing advanced PCB layout techniques for optimal signal integrity, and integrating EMI filters directly into their SiC power modules. TI's SiC devices feature integrated gate drivers with adjustable slew rates to control dv/dt and di/dt, which helps minimize high-frequency emissions[1]. They have also introduced innovative packaging solutions that reduce parasitic inductances, further improving EMI performance[2]. TI's comprehensive EMI mitigation strategy involves a combination of hardware design, software control, and system-level optimization to ensure compliance with stringent CISPR standards[3].

Strengths: Integrated solutions, advanced packaging, and comprehensive system-level approach. Weaknesses: Potentially higher cost due to integrated features, may require specialized design knowledge.

Core Innovations in SiC EMI Reduction

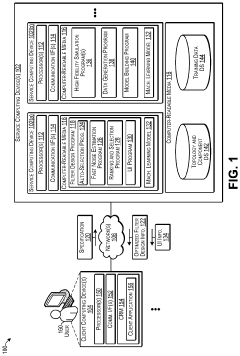

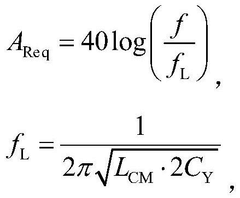

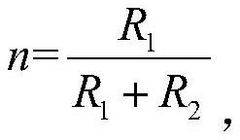

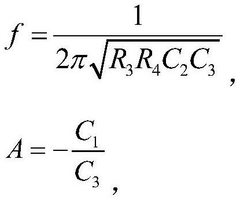

Automated electromagnetic interference filter design

PatentActiveUS20190362044A1

Innovation

- An automated filter design tool using machine learning models to determine optimal EMI filter configurations based on cost, size, and noise parameters, reducing the need for extensive simulations and manual redesign, and enabling rapid selection and verification of top-ranked candidates.

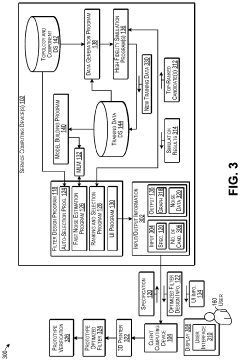

Broadband EMI filter for suppressing common-mode interference

PatentPendingCN118868598A

Innovation

- A broadband EMI filter including a passive filter circuit, a voltage detection circuit, a high-pass filter circuit and a current compensation circuit is designed. Through the capacitive isolation of the LC network of the passive filter circuit and the voltage detection circuit, high-frequency common mode interference is achieved. suppression, and injects low-frequency compensation current through the current compensation circuit to ensure effective suppression within a wide frequency range.

Regulatory Framework for EMI Standards

The regulatory framework for EMI standards is a complex and evolving landscape that governs electromagnetic interference (EMI) compliance for electronic devices, including those utilizing Silicon Carbide (SiC) technology. At the forefront of these regulations is the International Special Committee on Radio Interference (CISPR), which develops and maintains standards for EMI control.

CISPR standards are widely adopted globally and serve as the foundation for many national and regional EMI regulations. For SiC devices, particularly relevant are CISPR 11, which covers industrial, scientific, and medical equipment, and CISPR 22, focusing on information technology equipment. These standards set limits for both conducted and radiated emissions across various frequency ranges.

In the context of SiC EMI compliance, conducted emissions are of particular concern due to the high switching frequencies and fast switching speeds characteristic of SiC devices. The regulatory framework addresses this by specifying measurement methods and limits for conducted emissions in the frequency range of 150 kHz to 30 MHz.

Complementing CISPR standards are regional regulations such as the European Union's EMC Directive and the Federal Communications Commission (FCC) rules in the United States. These regulations often reference CISPR standards but may include additional requirements or modifications tailored to their specific jurisdictions.

The regulatory framework also encompasses product-specific standards that may apply to SiC-based systems. For instance, automotive applications must adhere to standards like CISPR 25, which defines more stringent limits due to the sensitive nature of vehicle electronics.

As SiC technology continues to advance, regulatory bodies are actively working to update standards to address the unique challenges posed by wide bandgap semiconductors. This includes ongoing discussions about extending frequency ranges for conducted emissions testing beyond the current 30 MHz limit to account for the higher harmonic content generated by SiC devices.

Compliance with these regulations requires manufacturers to implement robust EMI mitigation strategies throughout the design process. This often involves a combination of circuit design techniques, shielding, filtering, and careful PCB layout to ensure that SiC-based products meet the prescribed emission limits across all relevant frequency bands.

CISPR standards are widely adopted globally and serve as the foundation for many national and regional EMI regulations. For SiC devices, particularly relevant are CISPR 11, which covers industrial, scientific, and medical equipment, and CISPR 22, focusing on information technology equipment. These standards set limits for both conducted and radiated emissions across various frequency ranges.

In the context of SiC EMI compliance, conducted emissions are of particular concern due to the high switching frequencies and fast switching speeds characteristic of SiC devices. The regulatory framework addresses this by specifying measurement methods and limits for conducted emissions in the frequency range of 150 kHz to 30 MHz.

Complementing CISPR standards are regional regulations such as the European Union's EMC Directive and the Federal Communications Commission (FCC) rules in the United States. These regulations often reference CISPR standards but may include additional requirements or modifications tailored to their specific jurisdictions.

The regulatory framework also encompasses product-specific standards that may apply to SiC-based systems. For instance, automotive applications must adhere to standards like CISPR 25, which defines more stringent limits due to the sensitive nature of vehicle electronics.

As SiC technology continues to advance, regulatory bodies are actively working to update standards to address the unique challenges posed by wide bandgap semiconductors. This includes ongoing discussions about extending frequency ranges for conducted emissions testing beyond the current 30 MHz limit to account for the higher harmonic content generated by SiC devices.

Compliance with these regulations requires manufacturers to implement robust EMI mitigation strategies throughout the design process. This often involves a combination of circuit design techniques, shielding, filtering, and careful PCB layout to ensure that SiC-based products meet the prescribed emission limits across all relevant frequency bands.

Economic Impact of SiC EMI Compliance

The economic impact of SiC EMI compliance strategies for CISPR and conducted emissions is significant and multifaceted, affecting various aspects of the semiconductor industry and related sectors. Implementing effective EMI compliance measures for Silicon Carbide (SiC) devices is crucial for meeting regulatory standards and ensuring market access, but it also carries substantial financial implications.

Compliance with EMI standards, particularly CISPR requirements and conducted emissions regulations, often necessitates additional investment in research and development. Companies must allocate resources to design and implement sophisticated EMI mitigation techniques, which can increase product development costs. This investment, however, is essential for maintaining competitiveness in the global market and avoiding potential regulatory penalties.

The adoption of SiC technology, while offering numerous performance benefits, introduces new challenges in EMI compliance. The higher switching frequencies and faster switching speeds of SiC devices can exacerbate EMI issues, requiring more advanced and potentially costlier suppression methods. This may lead to increased component costs and more complex system designs, potentially impacting the overall cost structure of SiC-based products.

On the positive side, successful EMI compliance can open up new market opportunities and enhance product reliability. SiC devices that meet or exceed EMI standards are more likely to gain acceptance in sensitive applications such as automotive, aerospace, and industrial sectors. This expanded market access can lead to increased sales and revenue growth, offsetting the initial compliance costs.

Furthermore, effective EMI compliance strategies can reduce the risk of product recalls, warranty claims, and legal liabilities associated with non-compliant products. These risk mitigation benefits can translate into significant long-term cost savings and improved brand reputation, which are crucial for sustained economic success in the competitive semiconductor market.

The economic impact also extends to the supply chain. Suppliers of EMI suppression components and testing equipment may see increased demand, potentially leading to job creation and economic growth in these specialized sectors. Conversely, companies that fail to adapt to stringent EMI requirements may face market share losses and reduced profitability.

In conclusion, while SiC EMI compliance strategies for CISPR and conducted emissions present initial economic challenges, they also offer substantial long-term economic benefits. The investment in compliance can drive innovation, enhance product quality, and ultimately contribute to the growth and sustainability of businesses operating in the SiC semiconductor market.

Compliance with EMI standards, particularly CISPR requirements and conducted emissions regulations, often necessitates additional investment in research and development. Companies must allocate resources to design and implement sophisticated EMI mitigation techniques, which can increase product development costs. This investment, however, is essential for maintaining competitiveness in the global market and avoiding potential regulatory penalties.

The adoption of SiC technology, while offering numerous performance benefits, introduces new challenges in EMI compliance. The higher switching frequencies and faster switching speeds of SiC devices can exacerbate EMI issues, requiring more advanced and potentially costlier suppression methods. This may lead to increased component costs and more complex system designs, potentially impacting the overall cost structure of SiC-based products.

On the positive side, successful EMI compliance can open up new market opportunities and enhance product reliability. SiC devices that meet or exceed EMI standards are more likely to gain acceptance in sensitive applications such as automotive, aerospace, and industrial sectors. This expanded market access can lead to increased sales and revenue growth, offsetting the initial compliance costs.

Furthermore, effective EMI compliance strategies can reduce the risk of product recalls, warranty claims, and legal liabilities associated with non-compliant products. These risk mitigation benefits can translate into significant long-term cost savings and improved brand reputation, which are crucial for sustained economic success in the competitive semiconductor market.

The economic impact also extends to the supply chain. Suppliers of EMI suppression components and testing equipment may see increased demand, potentially leading to job creation and economic growth in these specialized sectors. Conversely, companies that fail to adapt to stringent EMI requirements may face market share losses and reduced profitability.

In conclusion, while SiC EMI compliance strategies for CISPR and conducted emissions present initial economic challenges, they also offer substantial long-term economic benefits. The investment in compliance can drive innovation, enhance product quality, and ultimately contribute to the growth and sustainability of businesses operating in the SiC semiconductor market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!