SiC freewheeling diode selection and co-design for hard-switching bridges

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Diode Evolution

Silicon carbide (SiC) diodes have undergone significant evolution since their introduction in the early 2000s. Initially, SiC Schottky barrier diodes (SBDs) were developed to address the limitations of silicon diodes in high-voltage, high-frequency applications. These first-generation SiC diodes offered superior switching performance and lower reverse recovery losses compared to their silicon counterparts.

As technology progressed, second-generation SiC diodes emerged, featuring improved performance characteristics. These diodes incorporated advanced designs such as merged PiN Schottky (MPS) structures, which combined the benefits of Schottky and PiN diodes. The MPS structure allowed for better surge current capability and reduced forward voltage drop, enhancing overall efficiency in power conversion systems.

The third generation of SiC diodes brought further refinements, focusing on reducing parasitic capacitances and improving thermal management. These advancements led to even faster switching speeds and lower losses, making SiC diodes increasingly attractive for hard-switching bridge applications in power electronics.

Recent developments have seen the introduction of fourth-generation SiC diodes, which feature optimized junction termination designs and enhanced carrier lifetime control. These improvements have resulted in diodes with higher voltage ratings, lower leakage currents, and improved reliability under extreme operating conditions.

In parallel with the evolution of discrete SiC diodes, there has been significant progress in the integration of SiC diodes with other power semiconductor devices. This integration has led to the development of hybrid modules and co-packaged solutions, where SiC freewheeling diodes are optimized to work in conjunction with SiC MOSFETs or IGBTs in bridge configurations.

The ongoing evolution of SiC diodes has been driven by the demand for higher efficiency, higher power density, and improved reliability in power electronic systems. Manufacturers have continuously pushed the boundaries of material quality, device design, and packaging technology to meet these requirements.

Looking ahead, the future evolution of SiC diodes is likely to focus on further increasing voltage and current ratings, reducing on-state resistance, and improving thermal performance. Additionally, there is a growing emphasis on developing SiC diodes that can operate reliably at higher junction temperatures, potentially enabling new applications in extreme environments.

As technology progressed, second-generation SiC diodes emerged, featuring improved performance characteristics. These diodes incorporated advanced designs such as merged PiN Schottky (MPS) structures, which combined the benefits of Schottky and PiN diodes. The MPS structure allowed for better surge current capability and reduced forward voltage drop, enhancing overall efficiency in power conversion systems.

The third generation of SiC diodes brought further refinements, focusing on reducing parasitic capacitances and improving thermal management. These advancements led to even faster switching speeds and lower losses, making SiC diodes increasingly attractive for hard-switching bridge applications in power electronics.

Recent developments have seen the introduction of fourth-generation SiC diodes, which feature optimized junction termination designs and enhanced carrier lifetime control. These improvements have resulted in diodes with higher voltage ratings, lower leakage currents, and improved reliability under extreme operating conditions.

In parallel with the evolution of discrete SiC diodes, there has been significant progress in the integration of SiC diodes with other power semiconductor devices. This integration has led to the development of hybrid modules and co-packaged solutions, where SiC freewheeling diodes are optimized to work in conjunction with SiC MOSFETs or IGBTs in bridge configurations.

The ongoing evolution of SiC diodes has been driven by the demand for higher efficiency, higher power density, and improved reliability in power electronic systems. Manufacturers have continuously pushed the boundaries of material quality, device design, and packaging technology to meet these requirements.

Looking ahead, the future evolution of SiC diodes is likely to focus on further increasing voltage and current ratings, reducing on-state resistance, and improving thermal performance. Additionally, there is a growing emphasis on developing SiC diodes that can operate reliably at higher junction temperatures, potentially enabling new applications in extreme environments.

Market Demand Analysis

The market demand for Silicon Carbide (SiC) freewheeling diodes in hard-switching bridge applications has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of SiC technology in power electronics, particularly in sectors such as electric vehicles, renewable energy systems, and industrial motor drives.

The automotive industry represents a major market for SiC freewheeling diodes, with electric and hybrid vehicles requiring high-efficiency power conversion systems. The ability of SiC diodes to operate at higher frequencies and temperatures compared to traditional silicon devices makes them ideal for these applications, leading to improved overall system efficiency and reduced cooling requirements.

In the renewable energy sector, SiC freewheeling diodes are gaining traction in solar inverters and wind power converters. The high-voltage capability and low switching losses of SiC diodes contribute to increased energy conversion efficiency, which is crucial for maximizing the output of renewable energy systems.

Industrial motor drives represent another significant market segment for SiC freewheeling diodes. The demand for more efficient and compact motor control systems in various industrial applications is driving the adoption of SiC technology. The ability to operate at higher switching frequencies allows for smaller passive components, resulting in more compact and cost-effective designs.

The power supply industry is also showing increased interest in SiC freewheeling diodes for use in server power supplies, telecom rectifiers, and other high-power density applications. The improved efficiency and thermal performance of SiC devices enable the design of more compact and reliable power supply units.

Market analysts project a compound annual growth rate (CAGR) for the SiC power device market, including freewheeling diodes, to be in the double digits over the next five years. This growth is expected to be fueled by the continued expansion of electric vehicle production, increasing investments in renewable energy infrastructure, and the ongoing push for energy efficiency in industrial applications.

However, challenges remain in the widespread adoption of SiC freewheeling diodes. The higher cost compared to traditional silicon devices is a significant barrier, particularly in price-sensitive markets. Additionally, the need for specialized packaging and gate driver designs to fully exploit the benefits of SiC technology presents challenges for system designers.

Despite these challenges, the market outlook for SiC freewheeling diodes remains positive. As manufacturing processes mature and economies of scale are achieved, the cost differential between SiC and silicon devices is expected to narrow, further accelerating market adoption. The ongoing research and development efforts in SiC technology are also likely to yield improvements in device performance and reliability, opening up new application areas and expanding the market potential for SiC freewheeling diodes in hard-switching bridge configurations.

The automotive industry represents a major market for SiC freewheeling diodes, with electric and hybrid vehicles requiring high-efficiency power conversion systems. The ability of SiC diodes to operate at higher frequencies and temperatures compared to traditional silicon devices makes them ideal for these applications, leading to improved overall system efficiency and reduced cooling requirements.

In the renewable energy sector, SiC freewheeling diodes are gaining traction in solar inverters and wind power converters. The high-voltage capability and low switching losses of SiC diodes contribute to increased energy conversion efficiency, which is crucial for maximizing the output of renewable energy systems.

Industrial motor drives represent another significant market segment for SiC freewheeling diodes. The demand for more efficient and compact motor control systems in various industrial applications is driving the adoption of SiC technology. The ability to operate at higher switching frequencies allows for smaller passive components, resulting in more compact and cost-effective designs.

The power supply industry is also showing increased interest in SiC freewheeling diodes for use in server power supplies, telecom rectifiers, and other high-power density applications. The improved efficiency and thermal performance of SiC devices enable the design of more compact and reliable power supply units.

Market analysts project a compound annual growth rate (CAGR) for the SiC power device market, including freewheeling diodes, to be in the double digits over the next five years. This growth is expected to be fueled by the continued expansion of electric vehicle production, increasing investments in renewable energy infrastructure, and the ongoing push for energy efficiency in industrial applications.

However, challenges remain in the widespread adoption of SiC freewheeling diodes. The higher cost compared to traditional silicon devices is a significant barrier, particularly in price-sensitive markets. Additionally, the need for specialized packaging and gate driver designs to fully exploit the benefits of SiC technology presents challenges for system designers.

Despite these challenges, the market outlook for SiC freewheeling diodes remains positive. As manufacturing processes mature and economies of scale are achieved, the cost differential between SiC and silicon devices is expected to narrow, further accelerating market adoption. The ongoing research and development efforts in SiC technology are also likely to yield improvements in device performance and reliability, opening up new application areas and expanding the market potential for SiC freewheeling diodes in hard-switching bridge configurations.

Technical Challenges

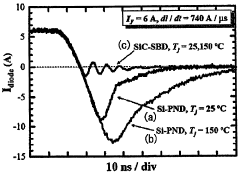

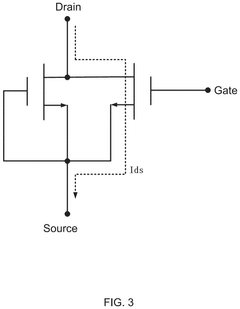

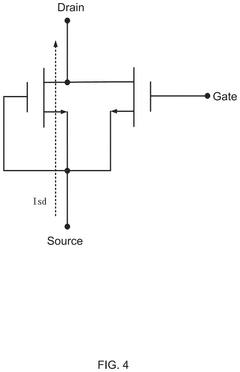

The selection and co-design of SiC freewheeling diodes for hard-switching bridges present several significant technical challenges. One of the primary issues is the high-frequency operation inherent in SiC-based power converters. As switching frequencies increase, the diode's reverse recovery characteristics become critical. SiC diodes must exhibit extremely fast reverse recovery times and low reverse recovery charges to minimize switching losses and electromagnetic interference (EMI).

Another challenge lies in the thermal management of SiC diodes. The high power density and fast switching speeds of SiC devices result in concentrated heat generation. Designing effective cooling solutions that can dissipate heat rapidly and maintain junction temperatures within safe operating limits is crucial for ensuring reliability and longevity of the diodes.

The voltage rating of SiC diodes poses an additional challenge. Hard-switching bridges often operate at high voltages, requiring diodes with sufficient blocking capability. However, as the voltage rating increases, so does the on-state resistance, leading to higher conduction losses. Balancing these conflicting requirements to optimize overall system efficiency is a complex task.

Parasitic inductances in the circuit layout present another significant hurdle. The fast switching transients of SiC devices can interact with these inductances, causing voltage overshoots and ringing. This not only increases EMI but also puts additional stress on the diodes, potentially leading to premature failure if not properly addressed.

The cost of SiC diodes remains a challenge for widespread adoption. While their performance benefits are clear, the higher price point compared to silicon alternatives can be a barrier in cost-sensitive applications. Designers must carefully weigh the performance gains against the increased component cost.

Reliability and long-term stability of SiC diodes under harsh operating conditions is another area of concern. The diodes must withstand repeated high-temperature and high-voltage stress cycles without degradation. Ensuring consistent performance over the expected lifetime of the power converter is crucial for industrial and automotive applications.

Lastly, the co-design process itself presents challenges in terms of optimization and trade-offs. Designers must consider the interplay between the SiC diodes and other components in the bridge circuit, such as the main switching devices and passive components. Achieving the optimal balance between switching speed, efficiency, EMI, thermal performance, and cost requires sophisticated modeling and simulation tools, as well as extensive experimental validation.

Another challenge lies in the thermal management of SiC diodes. The high power density and fast switching speeds of SiC devices result in concentrated heat generation. Designing effective cooling solutions that can dissipate heat rapidly and maintain junction temperatures within safe operating limits is crucial for ensuring reliability and longevity of the diodes.

The voltage rating of SiC diodes poses an additional challenge. Hard-switching bridges often operate at high voltages, requiring diodes with sufficient blocking capability. However, as the voltage rating increases, so does the on-state resistance, leading to higher conduction losses. Balancing these conflicting requirements to optimize overall system efficiency is a complex task.

Parasitic inductances in the circuit layout present another significant hurdle. The fast switching transients of SiC devices can interact with these inductances, causing voltage overshoots and ringing. This not only increases EMI but also puts additional stress on the diodes, potentially leading to premature failure if not properly addressed.

The cost of SiC diodes remains a challenge for widespread adoption. While their performance benefits are clear, the higher price point compared to silicon alternatives can be a barrier in cost-sensitive applications. Designers must carefully weigh the performance gains against the increased component cost.

Reliability and long-term stability of SiC diodes under harsh operating conditions is another area of concern. The diodes must withstand repeated high-temperature and high-voltage stress cycles without degradation. Ensuring consistent performance over the expected lifetime of the power converter is crucial for industrial and automotive applications.

Lastly, the co-design process itself presents challenges in terms of optimization and trade-offs. Designers must consider the interplay between the SiC diodes and other components in the bridge circuit, such as the main switching devices and passive components. Achieving the optimal balance between switching speed, efficiency, EMI, thermal performance, and cost requires sophisticated modeling and simulation tools, as well as extensive experimental validation.

Current Design Solutions

01 SiC freewheeling diode structure and fabrication

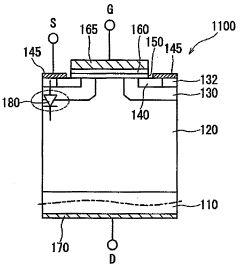

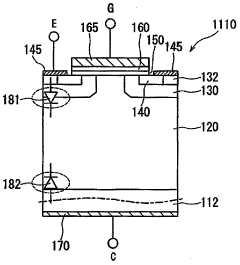

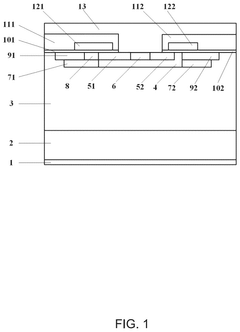

Silicon carbide (SiC) freewheeling diodes are designed with specific structures to enhance performance. This includes optimizing the doping profile, implementing junction termination techniques, and using advanced fabrication processes to improve voltage blocking capability and reduce on-resistance. The structure may incorporate features like buffer layers, field stop regions, or trench designs to balance electrical characteristics and thermal performance.- SiC freewheeling diode structure and fabrication: Silicon carbide (SiC) freewheeling diodes are designed with specific structures to enhance performance. This includes optimizing the doping profile, implementing junction termination techniques, and using advanced fabrication processes to reduce defects and improve reliability. The structure may incorporate features like buffer layers, field stop regions, or novel contact designs to enhance electrical characteristics and thermal management.

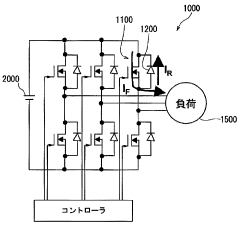

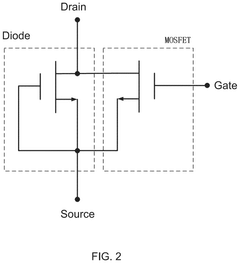

- Integration of SiC freewheeling diodes in power modules: SiC freewheeling diodes are often integrated into power modules alongside other components such as MOSFETs or IGBTs. This integration requires careful consideration of layout, thermal management, and electrical interconnections. Co-packaging SiC diodes with other power devices can lead to improved overall system performance, reduced parasitic inductances, and more compact designs.

- Selection criteria for SiC freewheeling diodes: Selecting the appropriate SiC freewheeling diode involves considering various parameters such as voltage rating, current handling capability, reverse recovery characteristics, and thermal performance. The choice depends on the specific application requirements, switching frequency, and operating conditions. Factors like forward voltage drop, leakage current, and surge current capability are also important in the selection process.

- Co-design of SiC freewheeling diodes with power converters: The co-design approach involves optimizing the SiC freewheeling diode characteristics in conjunction with the overall power converter design. This includes considering the interaction between the diode and other circuit components, optimizing gate drive circuits, and implementing advanced control strategies. The co-design process aims to maximize efficiency, reduce electromagnetic interference, and improve the overall system reliability.

- Reliability and performance enhancement techniques: Various techniques are employed to enhance the reliability and performance of SiC freewheeling diodes. These include implementing novel passivation layers, optimizing edge termination structures, and developing advanced packaging solutions. Techniques to mitigate issues like current crowding, thermal cycling stress, and cosmic ray-induced failures are also considered. Additionally, methods for improving surge current capability and reducing electromagnetic emissions are explored.

02 Integration of SiC freewheeling diodes in power modules

SiC freewheeling diodes are often co-designed and integrated into power modules alongside other semiconductor devices. This integration focuses on optimizing layout, minimizing parasitic inductances, and improving thermal management. Considerations include die attachment methods, interconnection techniques, and encapsulation strategies to enhance overall module performance and reliability in high-frequency switching applications.Expand Specific Solutions03 Selection criteria for SiC freewheeling diodes

Selecting the appropriate SiC freewheeling diode involves considering various parameters such as reverse recovery characteristics, forward voltage drop, surge current capability, and thermal performance. The selection process also takes into account the specific application requirements, including operating voltage, switching frequency, and environmental conditions. Matching the diode characteristics with the main switching device is crucial for optimal circuit performance.Expand Specific Solutions04 Thermal management and reliability considerations

Effective thermal management is critical in the design and selection of SiC freewheeling diodes. This involves implementing advanced cooling techniques, optimizing package designs for heat dissipation, and selecting materials with appropriate thermal properties. Reliability considerations include addressing issues such as cosmic ray resistance, surge current handling, and long-term stability under high-temperature operation.Expand Specific Solutions05 Circuit topology and control strategies

The selection and co-design of SiC freewheeling diodes are influenced by the overall circuit topology and control strategies. This includes considerations for soft-switching techniques, snubber circuit designs, and gate drive optimization to reduce switching losses and EMI. The interaction between the freewheeling diode and other circuit components is analyzed to achieve the best overall system performance in terms of efficiency, power density, and reliability.Expand Specific Solutions

Key Industry Players

The competition landscape for SiC freewheeling diode selection and co-design for hard-switching bridges is in a growth phase, with increasing market size and technological advancements. The market is driven by the rising demand for efficient power electronics in various applications. Key players like PI, Mitsubishi Electric, and Fuji Electric are leading the technological development, while emerging companies such as Rongsi Semiconductor and Xinta Electronics are also making significant contributions. Universities like Huazhong University of Science & Technology and Xi'an Jiaotong University are actively involved in research, indicating a strong focus on innovation and talent development in this field.

PI

Technical Solution: Power Integrations (PI) has developed a unique approach to SiC freewheeling diode selection and co-design for hard-switching bridges in their high-voltage power conversion solutions. Their strategy involves integrating SiC FWDs with advanced control ICs to create highly efficient and compact power conversion systems[10]. PI's SiC FWDs are optimized for high-frequency operation, featuring low reverse recovery charge and minimal forward voltage drop[11]. The company has also implemented innovative packaging techniques that improve thermal performance and reduce parasitic inductances, critical for hard-switching applications[12]. PI's co-design approach ensures seamless integration of SiC FWDs with their proprietary FluxLink™ technology, enabling isolated feedback and control in high-voltage converters without optocouplers.

Strengths: Highly integrated solutions, optimized for high-frequency operation, and excellent thermal management. Weaknesses: May be limited to specific power ranges and applications within PI's product portfolio.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced SiC freewheeling diodes (FWDs) optimized for hard-switching bridges. Their approach involves co-designing the SiC FWDs with the main switching devices to minimize switching losses and EMI. They utilize a unique trench structure in their SiC FWDs to reduce forward voltage drop while maintaining fast reverse recovery characteristics[1]. The company has also implemented advanced thermal management techniques to enhance the reliability of their SiC power modules in hard-switching applications[2]. Mitsubishi's SiC FWDs feature a positive temperature coefficient, which allows for easier parallel operation and improved current sharing in high-power applications[3].

Strengths: Advanced trench structure for low losses, excellent thermal management, and parallel operation capability. Weaknesses: Potentially higher cost compared to traditional Si diodes, and limited availability in some power ratings.

Core SiC Innovations

Semiconductor element, semiconductor device, and power converter

PatentWO2010125819A1

Innovation

- A semiconductor device design that allows the diode current to flow through the channel region instead of the body diode, reducing the rising voltage and conduction loss, and eliminating the need for a separate freewheeling diode by operating the MISFET as a diode at specific voltage conditions, thereby reducing the number of components and circuit cost.

Silicon carbide split-gate mosfets integrating high-speed freewheeling diodes and preparation methods thereof

PatentInactiveUS20240387722A1

Innovation

- A silicon carbide (SiC) split-gate MOSFET integrating a high-speed freewheeling diode is developed, featuring a split-gate structure with a P-type buried layer to shield edge electric fields, reducing Miller capacitance and incorporating a unipolar diode with no reverse recovery current, achieved through specific ion injection and doping concentration control.

Thermal Management

Thermal management is a critical aspect in the design and implementation of SiC freewheeling diodes for hard-switching bridges. The high switching frequencies and power densities associated with SiC devices necessitate effective heat dissipation strategies to ensure optimal performance and reliability.

One of the primary thermal challenges in SiC freewheeling diode applications is the management of junction temperature. SiC devices can operate at higher temperatures compared to their silicon counterparts, but maintaining junction temperatures within safe limits is crucial for long-term reliability. Advanced packaging techniques, such as direct bonded copper (DBC) substrates and advanced thermal interface materials, are employed to enhance heat transfer from the die to the heat sink.

The selection of appropriate heat sink designs plays a vital role in thermal management. Forced-air cooling systems are commonly used for lower power applications, while liquid cooling solutions may be necessary for high-power density scenarios. The thermal resistance of the entire system, from junction to ambient, must be carefully considered to ensure efficient heat dissipation.

Thermal simulation tools and computational fluid dynamics (CFD) analysis are increasingly utilized in the co-design process of SiC freewheeling diodes and their thermal management systems. These tools allow designers to predict hot spots, optimize heat spreader designs, and evaluate the effectiveness of various cooling strategies before physical prototyping.

The thermal behavior of SiC freewheeling diodes under different switching conditions must be thoroughly characterized. Transient thermal impedance measurements and thermal cycling tests are essential for understanding the device's thermal response and ensuring reliable operation over its lifetime. This information is crucial for developing accurate thermal models and designing appropriate thermal management solutions.

In hard-switching bridge applications, the interaction between the SiC freewheeling diode and other power components must be considered from a thermal perspective. The co-design approach should account for the mutual heating effects and potential thermal coupling between adjacent devices. This may involve optimizing component placement, implementing thermal barriers, or designing shared cooling systems to manage the overall thermal load of the power module.

Advanced thermal management techniques, such as phase-change materials and heat pipes, are being explored to enhance the cooling capabilities of SiC-based power systems. These innovative approaches aim to address the increasing thermal demands of high-frequency, high-power density applications while maintaining compact form factors.

One of the primary thermal challenges in SiC freewheeling diode applications is the management of junction temperature. SiC devices can operate at higher temperatures compared to their silicon counterparts, but maintaining junction temperatures within safe limits is crucial for long-term reliability. Advanced packaging techniques, such as direct bonded copper (DBC) substrates and advanced thermal interface materials, are employed to enhance heat transfer from the die to the heat sink.

The selection of appropriate heat sink designs plays a vital role in thermal management. Forced-air cooling systems are commonly used for lower power applications, while liquid cooling solutions may be necessary for high-power density scenarios. The thermal resistance of the entire system, from junction to ambient, must be carefully considered to ensure efficient heat dissipation.

Thermal simulation tools and computational fluid dynamics (CFD) analysis are increasingly utilized in the co-design process of SiC freewheeling diodes and their thermal management systems. These tools allow designers to predict hot spots, optimize heat spreader designs, and evaluate the effectiveness of various cooling strategies before physical prototyping.

The thermal behavior of SiC freewheeling diodes under different switching conditions must be thoroughly characterized. Transient thermal impedance measurements and thermal cycling tests are essential for understanding the device's thermal response and ensuring reliable operation over its lifetime. This information is crucial for developing accurate thermal models and designing appropriate thermal management solutions.

In hard-switching bridge applications, the interaction between the SiC freewheeling diode and other power components must be considered from a thermal perspective. The co-design approach should account for the mutual heating effects and potential thermal coupling between adjacent devices. This may involve optimizing component placement, implementing thermal barriers, or designing shared cooling systems to manage the overall thermal load of the power module.

Advanced thermal management techniques, such as phase-change materials and heat pipes, are being explored to enhance the cooling capabilities of SiC-based power systems. These innovative approaches aim to address the increasing thermal demands of high-frequency, high-power density applications while maintaining compact form factors.

Reliability Assessment

The reliability assessment of SiC freewheeling diodes in hard-switching bridges is crucial for ensuring the long-term performance and durability of power electronic systems. This evaluation encompasses various aspects, including thermal management, electrical stress, and environmental factors that can impact the diode's lifespan and operational stability.

One of the primary considerations in reliability assessment is the thermal performance of SiC freewheeling diodes. These devices are subjected to high-frequency switching and significant power dissipation, which can lead to thermal cycling and potential failure modes. Advanced thermal modeling techniques and experimental measurements are employed to analyze the temperature distribution across the diode structure and identify potential hotspots. This information is vital for optimizing heat dissipation strategies and selecting appropriate packaging materials to mitigate thermal-related degradation.

Electrical stress is another critical factor in the reliability assessment of SiC freewheeling diodes. The hard-switching environment exposes these devices to high dv/dt and di/dt conditions, which can lead to voltage overshoots and current spikes. Comprehensive testing protocols are implemented to evaluate the diode's ability to withstand these stresses over extended periods. This includes accelerated life testing, surge current testing, and reverse recovery characterization to assess the device's robustness under various operating conditions.

Environmental factors also play a significant role in the reliability of SiC freewheeling diodes. Humidity, temperature cycling, and mechanical vibrations can all contribute to device degradation over time. Reliability engineers conduct extensive environmental testing, including temperature-humidity bias (THB) tests and power cycling tests, to simulate real-world conditions and predict long-term performance. These tests help identify potential failure mechanisms and inform design improvements to enhance overall system reliability.

Statistical analysis techniques, such as Weibull distribution modeling and failure mode and effects analysis (FMEA), are employed to quantify the reliability of SiC freewheeling diodes. These methods provide valuable insights into the expected lifetime of the devices and help in establishing reliability metrics such as mean time between failures (MTBF) and failure in time (FIT) rates. This data is essential for system designers to make informed decisions regarding component selection and maintenance schedules.

Continuous monitoring and data collection during operation are increasingly being utilized to assess the real-time reliability of SiC freewheeling diodes in hard-switching bridges. Advanced diagnostic tools and prognostic algorithms can detect early signs of degradation and predict potential failures before they occur. This proactive approach to reliability assessment enables predictive maintenance strategies, minimizing downtime and improving overall system availability.

One of the primary considerations in reliability assessment is the thermal performance of SiC freewheeling diodes. These devices are subjected to high-frequency switching and significant power dissipation, which can lead to thermal cycling and potential failure modes. Advanced thermal modeling techniques and experimental measurements are employed to analyze the temperature distribution across the diode structure and identify potential hotspots. This information is vital for optimizing heat dissipation strategies and selecting appropriate packaging materials to mitigate thermal-related degradation.

Electrical stress is another critical factor in the reliability assessment of SiC freewheeling diodes. The hard-switching environment exposes these devices to high dv/dt and di/dt conditions, which can lead to voltage overshoots and current spikes. Comprehensive testing protocols are implemented to evaluate the diode's ability to withstand these stresses over extended periods. This includes accelerated life testing, surge current testing, and reverse recovery characterization to assess the device's robustness under various operating conditions.

Environmental factors also play a significant role in the reliability of SiC freewheeling diodes. Humidity, temperature cycling, and mechanical vibrations can all contribute to device degradation over time. Reliability engineers conduct extensive environmental testing, including temperature-humidity bias (THB) tests and power cycling tests, to simulate real-world conditions and predict long-term performance. These tests help identify potential failure mechanisms and inform design improvements to enhance overall system reliability.

Statistical analysis techniques, such as Weibull distribution modeling and failure mode and effects analysis (FMEA), are employed to quantify the reliability of SiC freewheeling diodes. These methods provide valuable insights into the expected lifetime of the devices and help in establishing reliability metrics such as mean time between failures (MTBF) and failure in time (FIT) rates. This data is essential for system designers to make informed decisions regarding component selection and maintenance schedules.

Continuous monitoring and data collection during operation are increasingly being utilized to assess the real-time reliability of SiC freewheeling diodes in hard-switching bridges. Advanced diagnostic tools and prognostic algorithms can detect early signs of degradation and predict potential failures before they occur. This proactive approach to reliability assessment enables predictive maintenance strategies, minimizing downtime and improving overall system availability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!