Solenoid Actuated Injection Valves in Advanced Engine Technology

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Tech Evolution and Objectives

Solenoid actuated injection valves have played a pivotal role in the evolution of advanced engine technology. The development of these valves can be traced back to the early 1980s when electronic fuel injection systems began to replace carburetors in automotive engines. Initially, these valves were relatively simple in design and operation, primarily focused on controlling fuel delivery timing and quantity.

As engine technology progressed, so did the demands placed on injection valves. The 1990s saw a significant leap in solenoid valve technology, with the introduction of high-pressure direct injection systems. This advancement required valves capable of withstanding much higher fuel pressures and operating at faster speeds. The evolution of materials science and manufacturing techniques enabled the production of more robust and precise valve components.

The turn of the millennium brought about a new era of engine efficiency and emissions reduction. Solenoid actuated injection valves became increasingly sophisticated, incorporating features such as multiple injection events per combustion cycle and variable spray patterns. These advancements allowed for finer control over the combustion process, resulting in improved fuel economy and reduced emissions.

In recent years, the focus has shifted towards even greater precision and flexibility in fuel delivery. Modern solenoid actuated injection valves are capable of ultra-fast response times, often measured in microseconds, and can deliver multiple precisely metered injections during a single engine cycle. This level of control has become crucial in meeting stringent emissions regulations while maintaining or improving engine performance.

The current technological objectives for solenoid actuated injection valves are multifaceted. One primary goal is to further reduce response times and increase the precision of fuel metering. This involves refining the electromagnetic design of the solenoid and optimizing the mechanical components for faster, more accurate movement. Another objective is to enhance the durability and reliability of these valves, ensuring they can withstand the harsh operating conditions of modern high-efficiency engines over extended periods.

Researchers are also exploring ways to make solenoid actuated injection valves more versatile, capable of handling a wider range of fuel types and operating conditions. This is particularly important as the automotive industry moves towards alternative fuels and hybrid powertrains. Additionally, there is a push to integrate advanced sensing and diagnostic capabilities into the valves themselves, allowing for real-time monitoring and adjustment of fuel delivery parameters.

Looking ahead, the development of solenoid actuated injection valves is likely to focus on further miniaturization, increased operating pressures, and enhanced integration with engine management systems. The ultimate goal is to create injection systems that can adapt in real-time to changing engine conditions and driver demands, optimizing performance and efficiency on a cycle-by-cycle basis.

As engine technology progressed, so did the demands placed on injection valves. The 1990s saw a significant leap in solenoid valve technology, with the introduction of high-pressure direct injection systems. This advancement required valves capable of withstanding much higher fuel pressures and operating at faster speeds. The evolution of materials science and manufacturing techniques enabled the production of more robust and precise valve components.

The turn of the millennium brought about a new era of engine efficiency and emissions reduction. Solenoid actuated injection valves became increasingly sophisticated, incorporating features such as multiple injection events per combustion cycle and variable spray patterns. These advancements allowed for finer control over the combustion process, resulting in improved fuel economy and reduced emissions.

In recent years, the focus has shifted towards even greater precision and flexibility in fuel delivery. Modern solenoid actuated injection valves are capable of ultra-fast response times, often measured in microseconds, and can deliver multiple precisely metered injections during a single engine cycle. This level of control has become crucial in meeting stringent emissions regulations while maintaining or improving engine performance.

The current technological objectives for solenoid actuated injection valves are multifaceted. One primary goal is to further reduce response times and increase the precision of fuel metering. This involves refining the electromagnetic design of the solenoid and optimizing the mechanical components for faster, more accurate movement. Another objective is to enhance the durability and reliability of these valves, ensuring they can withstand the harsh operating conditions of modern high-efficiency engines over extended periods.

Researchers are also exploring ways to make solenoid actuated injection valves more versatile, capable of handling a wider range of fuel types and operating conditions. This is particularly important as the automotive industry moves towards alternative fuels and hybrid powertrains. Additionally, there is a push to integrate advanced sensing and diagnostic capabilities into the valves themselves, allowing for real-time monitoring and adjustment of fuel delivery parameters.

Looking ahead, the development of solenoid actuated injection valves is likely to focus on further miniaturization, increased operating pressures, and enhanced integration with engine management systems. The ultimate goal is to create injection systems that can adapt in real-time to changing engine conditions and driver demands, optimizing performance and efficiency on a cycle-by-cycle basis.

Market Demand for Advanced Injection Systems

The market demand for advanced injection systems, particularly solenoid actuated injection valves, has been steadily increasing in recent years. This growth is primarily driven by the automotive industry's push towards more efficient and environmentally friendly engines. As emission regulations become increasingly stringent worldwide, manufacturers are seeking innovative solutions to improve fuel economy and reduce harmful emissions.

Solenoid actuated injection valves offer precise control over fuel delivery, allowing for optimized combustion processes. This technology enables engines to meet strict emission standards while maintaining or even improving performance. The demand for these advanced injection systems extends beyond passenger vehicles to commercial trucks, off-road equipment, and marine applications.

In the passenger vehicle segment, the market for solenoid actuated injection valves is experiencing significant growth. This is due to the rising adoption of gasoline direct injection (GDI) and diesel common rail systems, both of which rely heavily on advanced injection technology. The trend towards downsized, turbocharged engines further amplifies the need for precise fuel control, driving demand for sophisticated injection systems.

The commercial vehicle sector is another key driver of market demand. With increasing pressure to reduce fleet emissions and improve fuel efficiency, truck manufacturers are incorporating advanced injection systems into their powertrains. This trend is particularly pronounced in developed markets where regulatory requirements are more stringent.

Emerging markets are also contributing to the growing demand for advanced injection systems. As countries like China and India implement stricter emission norms, there is a surge in demand for technologies that can help meet these standards. This presents a significant opportunity for manufacturers of solenoid actuated injection valves.

The off-road equipment sector, including construction and agricultural machinery, is another area where demand for advanced injection systems is rising. These applications often require robust and reliable injection systems that can withstand harsh operating conditions while delivering improved fuel efficiency and reduced emissions.

In the marine sector, the implementation of new emission regulations is driving the adoption of advanced injection systems. Vessels operating in emission control areas (ECAs) are required to meet stringent emission limits, creating a market for sophisticated engine technologies, including advanced injection systems.

The aftermarket segment also presents opportunities for growth in the advanced injection systems market. As vehicles equipped with these technologies age, there will be an increasing need for replacement parts and servicing, creating a sustained demand for solenoid actuated injection valves and related components.

Solenoid actuated injection valves offer precise control over fuel delivery, allowing for optimized combustion processes. This technology enables engines to meet strict emission standards while maintaining or even improving performance. The demand for these advanced injection systems extends beyond passenger vehicles to commercial trucks, off-road equipment, and marine applications.

In the passenger vehicle segment, the market for solenoid actuated injection valves is experiencing significant growth. This is due to the rising adoption of gasoline direct injection (GDI) and diesel common rail systems, both of which rely heavily on advanced injection technology. The trend towards downsized, turbocharged engines further amplifies the need for precise fuel control, driving demand for sophisticated injection systems.

The commercial vehicle sector is another key driver of market demand. With increasing pressure to reduce fleet emissions and improve fuel efficiency, truck manufacturers are incorporating advanced injection systems into their powertrains. This trend is particularly pronounced in developed markets where regulatory requirements are more stringent.

Emerging markets are also contributing to the growing demand for advanced injection systems. As countries like China and India implement stricter emission norms, there is a surge in demand for technologies that can help meet these standards. This presents a significant opportunity for manufacturers of solenoid actuated injection valves.

The off-road equipment sector, including construction and agricultural machinery, is another area where demand for advanced injection systems is rising. These applications often require robust and reliable injection systems that can withstand harsh operating conditions while delivering improved fuel efficiency and reduced emissions.

In the marine sector, the implementation of new emission regulations is driving the adoption of advanced injection systems. Vessels operating in emission control areas (ECAs) are required to meet stringent emission limits, creating a market for sophisticated engine technologies, including advanced injection systems.

The aftermarket segment also presents opportunities for growth in the advanced injection systems market. As vehicles equipped with these technologies age, there will be an increasing need for replacement parts and servicing, creating a sustained demand for solenoid actuated injection valves and related components.

Current Challenges in Solenoid Valve Technology

Despite significant advancements in solenoid actuated injection valve technology for advanced engines, several challenges persist that hinder optimal performance and widespread adoption. One of the primary issues is the response time of solenoid valves, which directly impacts fuel injection precision and engine efficiency. Current solenoid designs struggle to achieve ultra-fast actuation speeds necessary for high-performance engines, particularly in multi-pulse injection scenarios.

Another critical challenge lies in the durability and reliability of solenoid valves under extreme operating conditions. Modern engines demand components that can withstand high temperatures, pressures, and vibrations while maintaining consistent performance over extended periods. The intricate balance between robust construction and rapid actuation remains a significant hurdle for engineers.

Electromagnetic interference (EMI) poses a growing concern as vehicle electronics become increasingly sophisticated. Solenoid valves, being electromagnetic devices, can both generate and be affected by EMI, potentially compromising the overall system integrity and performance. Shielding and isolation techniques have shown limited success in mitigating this issue without compromising valve responsiveness.

Energy efficiency is another area where current solenoid valve technology faces challenges. The power consumption of these valves, especially in systems requiring frequent actuation, can be substantial. This not only affects the vehicle's overall energy efficiency but also places additional demands on the electrical system, potentially necessitating more robust power management solutions.

Miniaturization remains a persistent challenge, particularly as engine designs evolve towards more compact and lightweight configurations. Reducing the size of solenoid valves while maintaining or improving their performance characteristics is crucial for next-generation engine designs. However, this often conflicts with the need for increased durability and heat dissipation capabilities.

Lastly, the complexity of manufacturing high-precision solenoid valves at scale presents significant challenges. Achieving consistent quality and performance across large production volumes, while keeping costs competitive, requires advanced manufacturing techniques and stringent quality control measures. The intricate nature of these components, combined with the tight tolerances required for optimal operation, makes mass production a formidable challenge for the industry.

Another critical challenge lies in the durability and reliability of solenoid valves under extreme operating conditions. Modern engines demand components that can withstand high temperatures, pressures, and vibrations while maintaining consistent performance over extended periods. The intricate balance between robust construction and rapid actuation remains a significant hurdle for engineers.

Electromagnetic interference (EMI) poses a growing concern as vehicle electronics become increasingly sophisticated. Solenoid valves, being electromagnetic devices, can both generate and be affected by EMI, potentially compromising the overall system integrity and performance. Shielding and isolation techniques have shown limited success in mitigating this issue without compromising valve responsiveness.

Energy efficiency is another area where current solenoid valve technology faces challenges. The power consumption of these valves, especially in systems requiring frequent actuation, can be substantial. This not only affects the vehicle's overall energy efficiency but also places additional demands on the electrical system, potentially necessitating more robust power management solutions.

Miniaturization remains a persistent challenge, particularly as engine designs evolve towards more compact and lightweight configurations. Reducing the size of solenoid valves while maintaining or improving their performance characteristics is crucial for next-generation engine designs. However, this often conflicts with the need for increased durability and heat dissipation capabilities.

Lastly, the complexity of manufacturing high-precision solenoid valves at scale presents significant challenges. Achieving consistent quality and performance across large production volumes, while keeping costs competitive, requires advanced manufacturing techniques and stringent quality control measures. The intricate nature of these components, combined with the tight tolerances required for optimal operation, makes mass production a formidable challenge for the industry.

Existing Solenoid Valve Design Solutions

01 Solenoid actuation mechanism for injection valves

Solenoid actuated injection valves utilize electromagnetic force to control the opening and closing of the valve. The solenoid coil, when energized, creates a magnetic field that moves a plunger or armature, which in turn operates the valve. This mechanism allows for precise and rapid control of fuel or fluid injection in various applications.- Solenoid-actuated valve design for fuel injection systems: Solenoid-actuated valves are widely used in fuel injection systems for internal combustion engines. These valves utilize electromagnetic force to control the flow of fuel, allowing for precise timing and metering of fuel delivery. The design typically includes a solenoid coil, armature, and valve needle, which work together to open and close the fuel passage.

- Improvements in solenoid valve response time and efficiency: Advancements in solenoid valve technology focus on improving response time and efficiency. This includes optimizing the magnetic circuit, reducing moving mass, and enhancing the valve's overall design. These improvements lead to faster valve opening and closing times, more precise fuel metering, and better overall engine performance.

- Integration of solenoid valves in common rail injection systems: Solenoid-actuated injection valves play a crucial role in common rail injection systems. These systems maintain high fuel pressure in a common rail, with solenoid valves controlling the injection timing and duration for each cylinder. This setup allows for multiple injections per cycle and precise control over fuel delivery, resulting in improved engine efficiency and reduced emissions.

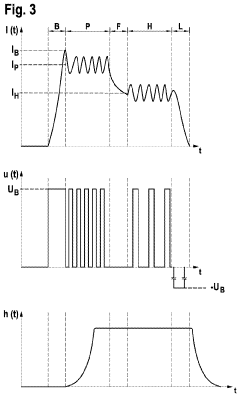

- Solenoid valve control strategies and electronic management: Advanced control strategies and electronic management systems are employed to optimize solenoid valve operation. These include pulse width modulation techniques, adaptive control algorithms, and integration with engine management systems. Such strategies allow for real-time adjustment of injection parameters based on engine operating conditions, enhancing performance and fuel efficiency.

- Durability and reliability enhancements for solenoid injection valves: Improving the durability and reliability of solenoid-actuated injection valves is crucial for long-term engine performance. This involves using wear-resistant materials, optimizing component designs to reduce stress and fatigue, and implementing advanced sealing technologies. These enhancements ensure consistent valve operation over extended periods and under various operating conditions.

02 Fuel injection systems with solenoid valves

Solenoid actuated injection valves are widely used in fuel injection systems for internal combustion engines. These valves provide accurate control of fuel delivery, improving engine performance and efficiency. The solenoid valves can be electronically controlled to adjust injection timing and duration based on engine operating conditions.Expand Specific Solutions03 Design improvements for solenoid injection valves

Various design improvements have been developed for solenoid actuated injection valves to enhance their performance and reliability. These include optimized magnetic circuit designs, improved sealing mechanisms, and advanced materials for valve components. Such improvements aim to reduce response time, increase durability, and enhance overall valve efficiency.Expand Specific Solutions04 Control systems for solenoid injection valves

Advanced control systems have been developed to optimize the operation of solenoid actuated injection valves. These systems may include electronic control units, sensors, and feedback mechanisms to precisely regulate valve timing and flow rates. Such control systems enable adaptive injection strategies and improved overall system performance.Expand Specific Solutions05 Applications of solenoid actuated injection valves

Solenoid actuated injection valves find applications in various fields beyond automotive fuel injection. They are used in industrial processes, agricultural equipment, and fluid control systems. These valves offer advantages such as fast response times, precise control, and compatibility with electronic control systems in diverse applications.Expand Specific Solutions

Key Players in Solenoid Valve Manufacturing

The research on solenoid actuated injection valves in advanced engine technology is in a mature stage, with significant market potential due to increasing demand for fuel-efficient and low-emission engines. The global market for these components is expected to grow steadily, driven by stringent emission regulations and the automotive industry's focus on engine optimization. Key players in this field include established automotive suppliers like DENSO Corp., Robert Bosch GmbH, Continental Automotive GmbH, and BorgWarner, Inc., who have extensive experience and advanced R&D capabilities. Academic institutions such as Harbin Engineering University and Beijing Jiaotong University are also contributing to technological advancements, fostering industry-academia collaborations and driving innovation in this sector.

DENSO Corp.

Technical Solution: DENSO Corp. has innovated in solenoid actuated injection valve technology for advanced engines. Their latest systems employ a compact, high-response solenoid actuator capable of multiple injections per cycle. DENSO's injectors can achieve injection pressures up to 2,500 bar, with the ability to perform up to nine separate injection events per combustion cycle[4]. The company has developed a unique ball-seat design that improves sealing and reduces deposit formation. DENSO's technology also incorporates advanced electronic control units that can adjust injection parameters in real-time based on engine operating conditions[5].

Strengths: High-precision multiple injection capability and advanced electronic control. Weaknesses: Potential for increased maintenance requirements due to complex design.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced solenoid actuated injection valves for modern engine technology. Their system utilizes a high-pressure fuel pump and common rail to deliver precise fuel quantities at pressures up to 2,500 bar[1]. The injectors feature piezoelectric or solenoid actuators for rapid, accurate valve opening and closing. Bosch's technology enables multiple injections per combustion cycle, with injection durations as short as 0.1 milliseconds[2]. This allows for pre-injection, main injection, and post-injection events to optimize combustion. The company has also implemented digital rate shaping to control the injection rate profile, improving emissions and fuel economy[3].

Strengths: Industry-leading injection pressures and precision timing for optimized combustion. Weaknesses: High system complexity and cost compared to simpler injection systems.

Core Innovations in Valve Actuation Technology

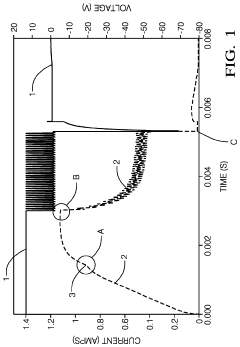

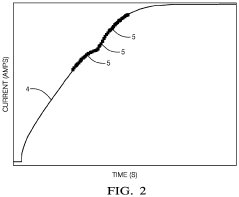

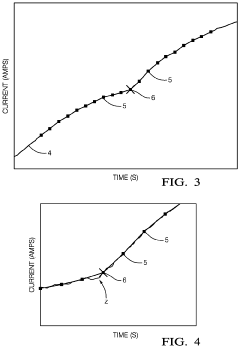

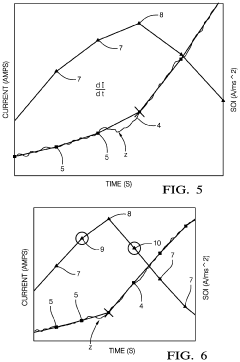

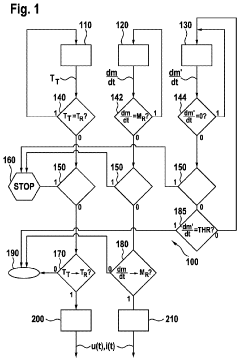

Method of adaptively sampling data to determine the start of injection in a solenoid actuated valve

PatentActiveUS11242941B2

Innovation

- Adaptive sampling method where the sampling points are adjusted based on the values of the first derivative of current (dI/dt) at preceding and following sampling points to optimize synchronization, shifting sampling times earlier if dI/dt(z−1) is greater than dI/dt(z+1) and later if it is smaller, to better capture the start of injection.

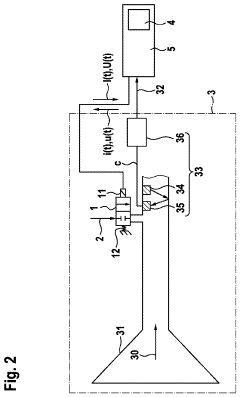

Monitoring the function of solenoid valves for fuel injection systems

PatentActiveUS20200018249A1

Innovation

- A method to monitor and control the solenoid valve's operation by detecting temporal profiles of current and voltage, mass flow, and leakage, allowing for real-time compensation and correction to maintain valve performance, using existing sensors and a calibration database to assess wear and predict remaining lifetime.

Environmental Impact of Injection Technologies

The environmental impact of injection technologies in advanced engine systems, particularly those utilizing solenoid actuated injection valves, is a critical consideration in the automotive industry's pursuit of sustainability. These technologies have significantly influenced emissions reduction and fuel efficiency improvements, playing a crucial role in meeting increasingly stringent environmental regulations.

Solenoid actuated injection valves have enabled more precise control over fuel delivery, resulting in optimized combustion processes. This precision has led to substantial reductions in harmful emissions, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). By allowing for multiple injection events per combustion cycle, these systems have improved fuel atomization and mixing, further enhancing combustion efficiency and reducing unburned hydrocarbons.

The adoption of advanced injection technologies has also contributed to the development of more fuel-efficient engines. By precisely metering fuel delivery, these systems have helped reduce overall fuel consumption, directly impacting the carbon footprint of vehicles. This improvement in fuel economy translates to lower CO2 emissions, aligning with global efforts to combat climate change.

Furthermore, solenoid actuated injection valves have facilitated the implementation of start-stop systems in modern vehicles. These systems automatically shut off the engine when the vehicle is stationary, reducing unnecessary idling and associated emissions. The rapid response time of solenoid actuators ensures quick and smooth engine restarts, making this technology viable for widespread adoption.

However, the environmental benefits of these injection technologies must be balanced against the potential impacts of their production and disposal. The manufacturing of solenoid actuated injection valves involves the use of rare earth metals and other materials that may have significant environmental footprints in terms of extraction and processing. Additionally, the complex nature of these components can present challenges for recycling at the end of their lifecycle.

As the automotive industry continues to evolve, the role of injection technologies in environmental protection is likely to expand. Future developments may focus on further improving the efficiency and durability of these systems, as well as exploring more sustainable materials and manufacturing processes. The integration of injection technologies with alternative fuels and hybrid powertrains also presents opportunities for additional environmental benefits, potentially leading to even cleaner and more efficient transportation solutions.

Solenoid actuated injection valves have enabled more precise control over fuel delivery, resulting in optimized combustion processes. This precision has led to substantial reductions in harmful emissions, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). By allowing for multiple injection events per combustion cycle, these systems have improved fuel atomization and mixing, further enhancing combustion efficiency and reducing unburned hydrocarbons.

The adoption of advanced injection technologies has also contributed to the development of more fuel-efficient engines. By precisely metering fuel delivery, these systems have helped reduce overall fuel consumption, directly impacting the carbon footprint of vehicles. This improvement in fuel economy translates to lower CO2 emissions, aligning with global efforts to combat climate change.

Furthermore, solenoid actuated injection valves have facilitated the implementation of start-stop systems in modern vehicles. These systems automatically shut off the engine when the vehicle is stationary, reducing unnecessary idling and associated emissions. The rapid response time of solenoid actuators ensures quick and smooth engine restarts, making this technology viable for widespread adoption.

However, the environmental benefits of these injection technologies must be balanced against the potential impacts of their production and disposal. The manufacturing of solenoid actuated injection valves involves the use of rare earth metals and other materials that may have significant environmental footprints in terms of extraction and processing. Additionally, the complex nature of these components can present challenges for recycling at the end of their lifecycle.

As the automotive industry continues to evolve, the role of injection technologies in environmental protection is likely to expand. Future developments may focus on further improving the efficiency and durability of these systems, as well as exploring more sustainable materials and manufacturing processes. The integration of injection technologies with alternative fuels and hybrid powertrains also presents opportunities for additional environmental benefits, potentially leading to even cleaner and more efficient transportation solutions.

Standardization and Testing Protocols

Standardization and testing protocols play a crucial role in ensuring the reliability, performance, and safety of solenoid actuated injection valves in advanced engine technology. These protocols provide a framework for consistent evaluation and comparison of different valve designs and manufacturers, ultimately contributing to the overall advancement of engine technology.

One of the primary aspects of standardization in this field is the establishment of uniform testing conditions. This includes specifying parameters such as fuel pressure, temperature ranges, and actuation frequencies. By adhering to these standardized conditions, researchers and manufacturers can produce comparable results across different testing facilities, enhancing the validity and reproducibility of their findings.

Performance metrics are another key area of standardization. Common metrics include response time, flow rate consistency, and durability under various operating conditions. These metrics allow for objective evaluation of valve performance and facilitate the identification of areas for improvement. Additionally, standardized metrics enable easier comparison between different valve designs and technologies, driving innovation and competition in the industry.

Safety protocols are an integral part of standardization efforts. These protocols outline procedures for handling high-pressure fuel systems, electrical components, and potential failure modes. They also specify safety features that must be incorporated into valve designs, such as fail-safe mechanisms and leak detection systems. Adherence to these safety standards is critical for ensuring the reliability and safety of engine systems in real-world applications.

Environmental testing is another crucial aspect of standardization protocols. This includes subjecting injection valves to extreme temperatures, vibration, and corrosive environments to simulate real-world operating conditions. Standardized environmental testing procedures help ensure that valves can maintain performance and reliability across a wide range of automotive applications and geographic locations.

Durability testing protocols are designed to assess the long-term reliability of solenoid actuated injection valves. These tests typically involve cyclic operation over extended periods, simulating the lifespan of an engine. Standardized durability tests help manufacturers predict the expected service life of their valves and identify potential failure modes before they occur in real-world applications.

Electromagnetic compatibility (EMC) testing is becoming increasingly important as automotive systems become more electronically sophisticated. Standardized EMC protocols ensure that solenoid actuated injection valves can operate reliably in the presence of electromagnetic interference from other vehicle components and external sources.

As the technology continues to evolve, standardization and testing protocols must adapt to address new challenges and opportunities. This includes developing new test methods for emerging technologies such as piezoelectric actuators or direct-acting solenoid valves. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions is essential for maintaining up-to-date and relevant standardization practices in this rapidly advancing field.

One of the primary aspects of standardization in this field is the establishment of uniform testing conditions. This includes specifying parameters such as fuel pressure, temperature ranges, and actuation frequencies. By adhering to these standardized conditions, researchers and manufacturers can produce comparable results across different testing facilities, enhancing the validity and reproducibility of their findings.

Performance metrics are another key area of standardization. Common metrics include response time, flow rate consistency, and durability under various operating conditions. These metrics allow for objective evaluation of valve performance and facilitate the identification of areas for improvement. Additionally, standardized metrics enable easier comparison between different valve designs and technologies, driving innovation and competition in the industry.

Safety protocols are an integral part of standardization efforts. These protocols outline procedures for handling high-pressure fuel systems, electrical components, and potential failure modes. They also specify safety features that must be incorporated into valve designs, such as fail-safe mechanisms and leak detection systems. Adherence to these safety standards is critical for ensuring the reliability and safety of engine systems in real-world applications.

Environmental testing is another crucial aspect of standardization protocols. This includes subjecting injection valves to extreme temperatures, vibration, and corrosive environments to simulate real-world operating conditions. Standardized environmental testing procedures help ensure that valves can maintain performance and reliability across a wide range of automotive applications and geographic locations.

Durability testing protocols are designed to assess the long-term reliability of solenoid actuated injection valves. These tests typically involve cyclic operation over extended periods, simulating the lifespan of an engine. Standardized durability tests help manufacturers predict the expected service life of their valves and identify potential failure modes before they occur in real-world applications.

Electromagnetic compatibility (EMC) testing is becoming increasingly important as automotive systems become more electronically sophisticated. Standardized EMC protocols ensure that solenoid actuated injection valves can operate reliably in the presence of electromagnetic interference from other vehicle components and external sources.

As the technology continues to evolve, standardization and testing protocols must adapt to address new challenges and opportunities. This includes developing new test methods for emerging technologies such as piezoelectric actuators or direct-acting solenoid valves. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions is essential for maintaining up-to-date and relevant standardization practices in this rapidly advancing field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!