Solenoid Valve Diagnostics in Smart Hospital Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Diagnostics Background and Objectives

Solenoid valve diagnostics in smart hospital systems have emerged as a critical area of research and development in recent years. These valves play a vital role in various medical equipment and systems, including ventilators, infusion pumps, and sterilization equipment. The evolution of solenoid valve technology in healthcare settings has been driven by the increasing demand for precision, reliability, and real-time monitoring capabilities in medical devices.

The primary objective of this research is to enhance the diagnostic capabilities of solenoid valves within smart hospital environments. This involves developing advanced sensing technologies, data analytics algorithms, and predictive maintenance strategies to ensure optimal performance and minimize downtime of critical medical equipment. By improving solenoid valve diagnostics, healthcare providers can significantly reduce the risk of equipment failure, enhance patient safety, and optimize resource allocation.

The technological progression in this field has been marked by several key milestones. Initially, basic mechanical diagnostics were employed to detect valve failures. This evolved into more sophisticated electronic monitoring systems that could detect changes in valve performance. The current trend is moving towards intelligent diagnostic systems that integrate machine learning and Internet of Things (IoT) technologies to provide predictive maintenance capabilities.

One of the main drivers for this research is the growing adoption of smart hospital systems worldwide. These systems rely heavily on interconnected medical devices and equipment, making the reliability and performance of components like solenoid valves crucial. The global smart hospital market is projected to grow significantly in the coming years, further emphasizing the importance of advanced diagnostic technologies for critical components.

The research aims to address several technical challenges, including the development of non-invasive sensing methods, real-time data processing algorithms, and integration with existing hospital management systems. Additionally, there is a focus on creating standardized protocols for solenoid valve diagnostics to ensure interoperability across different medical devices and manufacturers.

Another key objective is to improve the energy efficiency of solenoid valves through advanced diagnostics. By accurately predicting maintenance needs and optimizing valve operation, hospitals can reduce energy consumption and operational costs. This aligns with the broader goals of sustainability and cost-effectiveness in healthcare facilities.

The research also seeks to explore the potential of artificial intelligence and machine learning in enhancing diagnostic accuracy and predictive capabilities. These technologies could enable more precise fault detection, reduce false alarms, and provide valuable insights into long-term valve performance trends.

The primary objective of this research is to enhance the diagnostic capabilities of solenoid valves within smart hospital environments. This involves developing advanced sensing technologies, data analytics algorithms, and predictive maintenance strategies to ensure optimal performance and minimize downtime of critical medical equipment. By improving solenoid valve diagnostics, healthcare providers can significantly reduce the risk of equipment failure, enhance patient safety, and optimize resource allocation.

The technological progression in this field has been marked by several key milestones. Initially, basic mechanical diagnostics were employed to detect valve failures. This evolved into more sophisticated electronic monitoring systems that could detect changes in valve performance. The current trend is moving towards intelligent diagnostic systems that integrate machine learning and Internet of Things (IoT) technologies to provide predictive maintenance capabilities.

One of the main drivers for this research is the growing adoption of smart hospital systems worldwide. These systems rely heavily on interconnected medical devices and equipment, making the reliability and performance of components like solenoid valves crucial. The global smart hospital market is projected to grow significantly in the coming years, further emphasizing the importance of advanced diagnostic technologies for critical components.

The research aims to address several technical challenges, including the development of non-invasive sensing methods, real-time data processing algorithms, and integration with existing hospital management systems. Additionally, there is a focus on creating standardized protocols for solenoid valve diagnostics to ensure interoperability across different medical devices and manufacturers.

Another key objective is to improve the energy efficiency of solenoid valves through advanced diagnostics. By accurately predicting maintenance needs and optimizing valve operation, hospitals can reduce energy consumption and operational costs. This aligns with the broader goals of sustainability and cost-effectiveness in healthcare facilities.

The research also seeks to explore the potential of artificial intelligence and machine learning in enhancing diagnostic accuracy and predictive capabilities. These technologies could enable more precise fault detection, reduce false alarms, and provide valuable insights into long-term valve performance trends.

Smart Hospital Systems Market Analysis

The smart hospital systems market is experiencing significant growth, driven by the increasing demand for efficient healthcare delivery and the integration of advanced technologies in medical facilities. This market segment encompasses a wide range of solutions, including solenoid valve diagnostics, which play a crucial role in maintaining the functionality and safety of various hospital equipment and systems.

The global smart hospital market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% from 2021 to 2026. This growth is attributed to factors such as the rising adoption of Internet of Things (IoT) devices, artificial intelligence, and cloud computing in healthcare settings. The market for smart hospital systems is expected to reach a substantial value by 2026, reflecting the increasing investments in healthcare infrastructure and technology.

Within this broader market, the demand for solenoid valve diagnostics is also on the rise. Solenoid valves are essential components in many hospital systems, including medical gas distribution, HVAC systems, and sterilization equipment. The ability to diagnose and predict failures in these valves is becoming increasingly important for ensuring uninterrupted hospital operations and patient safety.

The market for solenoid valve diagnostics in smart hospitals is driven by several factors. First, there is a growing emphasis on preventive maintenance and predictive analytics in healthcare facilities to minimize downtime and reduce operational costs. Second, regulatory requirements for patient safety and equipment reliability are becoming more stringent, necessitating advanced diagnostic capabilities. Third, the integration of IoT and AI technologies is enabling real-time monitoring and analysis of valve performance, creating new opportunities for innovative diagnostic solutions.

Geographically, North America and Europe are currently leading the smart hospital systems market, including solenoid valve diagnostics. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid healthcare infrastructure development and increasing healthcare expenditure in countries like China and India.

Key market players in the smart hospital systems sector are investing heavily in research and development to enhance their diagnostic capabilities, including those for solenoid valves. This trend is likely to continue as hospitals increasingly prioritize operational efficiency and equipment reliability. The market is also seeing a rise in partnerships between technology companies and healthcare providers to develop and implement advanced diagnostic solutions.

The global smart hospital market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% from 2021 to 2026. This growth is attributed to factors such as the rising adoption of Internet of Things (IoT) devices, artificial intelligence, and cloud computing in healthcare settings. The market for smart hospital systems is expected to reach a substantial value by 2026, reflecting the increasing investments in healthcare infrastructure and technology.

Within this broader market, the demand for solenoid valve diagnostics is also on the rise. Solenoid valves are essential components in many hospital systems, including medical gas distribution, HVAC systems, and sterilization equipment. The ability to diagnose and predict failures in these valves is becoming increasingly important for ensuring uninterrupted hospital operations and patient safety.

The market for solenoid valve diagnostics in smart hospitals is driven by several factors. First, there is a growing emphasis on preventive maintenance and predictive analytics in healthcare facilities to minimize downtime and reduce operational costs. Second, regulatory requirements for patient safety and equipment reliability are becoming more stringent, necessitating advanced diagnostic capabilities. Third, the integration of IoT and AI technologies is enabling real-time monitoring and analysis of valve performance, creating new opportunities for innovative diagnostic solutions.

Geographically, North America and Europe are currently leading the smart hospital systems market, including solenoid valve diagnostics. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid healthcare infrastructure development and increasing healthcare expenditure in countries like China and India.

Key market players in the smart hospital systems sector are investing heavily in research and development to enhance their diagnostic capabilities, including those for solenoid valves. This trend is likely to continue as hospitals increasingly prioritize operational efficiency and equipment reliability. The market is also seeing a rise in partnerships between technology companies and healthcare providers to develop and implement advanced diagnostic solutions.

Current Challenges in Solenoid Valve Diagnostics

The current challenges in solenoid valve diagnostics within smart hospital systems are multifaceted and complex. One of the primary issues is the lack of real-time monitoring capabilities for these critical components. Solenoid valves play a crucial role in various medical equipment and systems, yet traditional diagnostic methods often rely on periodic maintenance checks, which may not detect sudden failures or gradual performance degradation.

Another significant challenge is the difficulty in accurately predicting valve failures before they occur. While predictive maintenance has made strides in many areas of hospital operations, solenoid valves present unique challenges due to their rapid cycling nature and the diverse range of fluids and gases they control. This unpredictability can lead to unexpected downtime of critical medical equipment, potentially compromising patient care.

The integration of solenoid valve diagnostics into existing smart hospital infrastructures also poses a considerable challenge. Many hospitals have legacy systems that may not be compatible with advanced diagnostic tools, creating a need for retrofitting solutions or complete system overhauls. This integration challenge is further complicated by the need for seamless data communication between various hospital systems and the diagnostic tools.

Data interpretation and analysis present another hurdle in solenoid valve diagnostics. The vast amount of data generated by continuous monitoring systems can be overwhelming, and extracting meaningful insights requires sophisticated algorithms and machine learning techniques. Developing these analytical tools to accurately interpret valve performance data and distinguish between normal wear and impending failure is an ongoing challenge.

Furthermore, the diverse applications of solenoid valves in hospital settings, from medication dispensing systems to HVAC controls, necessitate a flexible diagnostic approach. A one-size-fits-all solution is not feasible, as different valve types and applications require tailored diagnostic parameters and thresholds. This diversity complicates the development of standardized diagnostic protocols and increases the complexity of implementation across various hospital departments.

Lastly, there are significant regulatory and compliance challenges associated with implementing new diagnostic technologies in healthcare settings. Any new system must adhere to strict medical device regulations and data privacy laws, which can slow down the adoption of innovative diagnostic solutions. Balancing the need for comprehensive diagnostics with patient safety and data security requirements remains a persistent challenge in the field.

Another significant challenge is the difficulty in accurately predicting valve failures before they occur. While predictive maintenance has made strides in many areas of hospital operations, solenoid valves present unique challenges due to their rapid cycling nature and the diverse range of fluids and gases they control. This unpredictability can lead to unexpected downtime of critical medical equipment, potentially compromising patient care.

The integration of solenoid valve diagnostics into existing smart hospital infrastructures also poses a considerable challenge. Many hospitals have legacy systems that may not be compatible with advanced diagnostic tools, creating a need for retrofitting solutions or complete system overhauls. This integration challenge is further complicated by the need for seamless data communication between various hospital systems and the diagnostic tools.

Data interpretation and analysis present another hurdle in solenoid valve diagnostics. The vast amount of data generated by continuous monitoring systems can be overwhelming, and extracting meaningful insights requires sophisticated algorithms and machine learning techniques. Developing these analytical tools to accurately interpret valve performance data and distinguish between normal wear and impending failure is an ongoing challenge.

Furthermore, the diverse applications of solenoid valves in hospital settings, from medication dispensing systems to HVAC controls, necessitate a flexible diagnostic approach. A one-size-fits-all solution is not feasible, as different valve types and applications require tailored diagnostic parameters and thresholds. This diversity complicates the development of standardized diagnostic protocols and increases the complexity of implementation across various hospital departments.

Lastly, there are significant regulatory and compliance challenges associated with implementing new diagnostic technologies in healthcare settings. Any new system must adhere to strict medical device regulations and data privacy laws, which can slow down the adoption of innovative diagnostic solutions. Balancing the need for comprehensive diagnostics with patient safety and data security requirements remains a persistent challenge in the field.

Existing Solenoid Valve Diagnostic Solutions

01 Electrical signal analysis for solenoid valve diagnostics

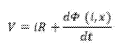

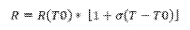

Diagnostic methods for solenoid valves involve analyzing electrical signals, such as current and voltage, to detect abnormalities. This approach can identify issues like coil degradation, mechanical wear, or blockages by examining signal patterns and deviations from expected behavior.- Electrical signal analysis for solenoid valve diagnostics: This method involves analyzing electrical signals, such as current and voltage, to diagnose solenoid valve performance. By monitoring changes in these signals during valve operation, issues like wear, sticking, or electrical faults can be detected. Advanced signal processing techniques may be employed to extract meaningful diagnostic information from the electrical data.

- Pressure-based diagnostics for solenoid valves: Pressure measurements are used to assess solenoid valve functionality. This approach involves monitoring pressure changes upstream and downstream of the valve during operation. Abnormal pressure patterns can indicate valve malfunctions such as leakage, blockage, or improper sealing. Pressure sensors and data analysis algorithms are typically employed in this diagnostic method.

- Acoustic and vibration analysis for valve diagnostics: This diagnostic technique utilizes acoustic and vibration sensors to detect abnormalities in solenoid valve operation. By analyzing sound and vibration patterns during valve actuation, issues such as mechanical wear, loose components, or improper seating can be identified. Advanced signal processing and machine learning algorithms may be used to interpret the acoustic and vibration data.

- Temperature-based solenoid valve diagnostics: Temperature monitoring is employed to diagnose solenoid valve conditions. This method involves measuring temperature changes in the valve body, coil, or surrounding fluid during operation. Abnormal temperature patterns can indicate issues such as coil overheating, friction-induced heating, or fluid leakage. Thermal sensors and data analysis techniques are typically used in this diagnostic approach.

- Integrated multi-parameter diagnostics for solenoid valves: This comprehensive approach combines multiple diagnostic parameters to provide a holistic assessment of solenoid valve health. It may incorporate electrical, pressure, acoustic, vibration, and temperature measurements, along with advanced data fusion and analysis techniques. By correlating data from various sensors, this method can provide more accurate and reliable diagnostics, enabling predictive maintenance and early fault detection.

02 Pressure-based diagnostics for solenoid valves

Pressure measurements are used to diagnose solenoid valve performance. By monitoring pressure changes during valve operation, issues such as leaks, stuck valves, or improper sealing can be detected. This method often involves comparing actual pressure readings to expected values for various operating conditions.Expand Specific Solutions03 Flow rate analysis for solenoid valve diagnostics

Diagnostic techniques based on flow rate analysis can identify solenoid valve problems. By measuring and comparing flow rates under different operating conditions, issues such as partial blockages, wear, or improper valve opening/closing can be detected. This method often involves using flow sensors and comparing results to baseline measurements.Expand Specific Solutions04 Temperature monitoring for solenoid valve diagnostics

Temperature monitoring is used to diagnose solenoid valve issues. Abnormal temperature patterns can indicate problems such as coil overheating, excessive friction, or fluid leaks. This method often involves using temperature sensors and analyzing thermal profiles during valve operation.Expand Specific Solutions05 Integrated multi-parameter diagnostics for solenoid valves

Advanced diagnostic systems for solenoid valves integrate multiple parameters such as electrical signals, pressure, flow rate, and temperature. By combining and correlating data from various sensors, these systems can provide more comprehensive and accurate fault detection and diagnosis, enabling predictive maintenance and reducing downtime.Expand Specific Solutions

Key Players in Smart Hospital Systems

The research on solenoid valve diagnostics in smart hospital systems is in an emerging stage, with the market showing significant growth potential. The global smart hospital market is expanding rapidly, driven by increasing healthcare digitization and demand for efficient patient care. While the technology for solenoid valve diagnostics is advancing, it is not yet fully mature. Companies like Baxter International, ZF Friedrichshafen, and Danfoss are leading in developing innovative solutions, leveraging their expertise in medical devices and industrial automation. However, the field remains competitive, with opportunities for both established players and new entrants to make significant contributions to this niche but growing segment of smart hospital technology.

Baxter International, Inc.

Technical Solution: Baxter International has developed an advanced solenoid valve diagnostic system for smart hospital applications. Their solution integrates real-time monitoring and predictive maintenance capabilities. The system employs machine learning algorithms to analyze valve performance data, detecting subtle changes in pressure, flow rates, and response times[1]. This allows for early identification of potential valve failures, reducing downtime and improving patient safety. Baxter's diagnostic system also incorporates IoT connectivity, enabling remote monitoring and data analysis across multiple hospital locations[3]. The company has implemented this technology in their infusion pumps and other medical devices, enhancing the reliability of critical care equipment.

Strengths: Extensive experience in medical devices, strong focus on patient safety, and integration with existing hospital systems. Weaknesses: May face challenges in adapting to rapidly evolving IoT and AI technologies in healthcare.

Camozzi Automation SpA

Technical Solution: Camozzi Automation has developed a comprehensive solenoid valve diagnostic system for smart hospital environments. Their approach combines advanced sensor technology with edge computing capabilities. The system utilizes high-precision pressure and flow sensors to continuously monitor valve performance[2]. Real-time data is processed locally using embedded microcontrollers, enabling rapid response to anomalies. Camozzi's solution also incorporates a cloud-based analytics platform for long-term trend analysis and predictive maintenance scheduling. The company has implemented this technology in their pneumatic systems used in various medical applications, such as ventilators and anesthesia machines[4].

Strengths: Expertise in pneumatic systems, robust edge computing capabilities, and scalable cloud integration. Weaknesses: May have limited experience in specific hospital environments compared to dedicated medical device manufacturers.

Innovative Diagnostic Techniques for Solenoid Valves

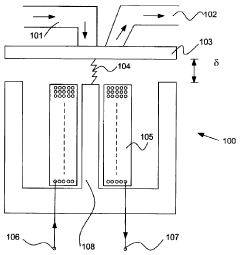

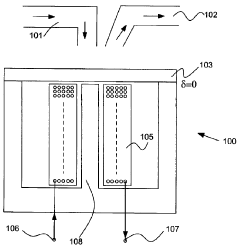

Method and system for diagnose of a solenoid valve

PatentInactiveKR1020160095148A

Innovation

- A method for diagnosing solenoid valves by determining the first and second derivatives of the current at specific points in time during the movement of the movable valve element, comparing these derivatives to ensure the valve functions correctly.

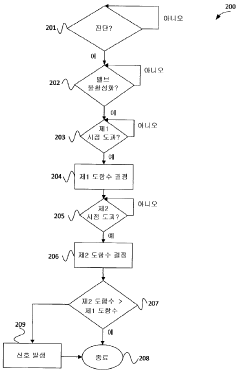

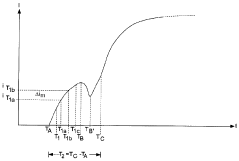

Diagnostic device and method for solenoid valves

PatentWO2019043573A1

Innovation

- A diagnostic device and method that involves detecting the rate of variation of the solenoid supply voltage and current waveform characteristics, comparing them to predetermined values, and generating alarm signals for deviations, using a microcontroller-based electronic diagnostic circuit integrated into the solenoid valve's power supply and control circuit board, which can communicate with external control units and provide visual status indications.

Regulatory Framework for Medical Device Diagnostics

The regulatory framework for medical device diagnostics plays a crucial role in ensuring the safety, efficacy, and quality of solenoid valve diagnostics in smart hospital systems. In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing medical devices, including diagnostic equipment. The FDA classifies medical devices into three categories based on their risk level and intended use, with Class I being the lowest risk and Class III being the highest.

Solenoid valve diagnostic systems in smart hospitals would likely fall under Class II, requiring a 510(k) premarket notification submission to demonstrate substantial equivalence to a legally marketed predicate device. This process involves providing detailed information about the device's design, performance, and safety features. Additionally, manufacturers must comply with Quality System Regulations (QSR) to ensure consistent production and quality control.

In the European Union, the Medical Device Regulation (MDR) governs the approval and marketing of medical devices. The MDR requires manufacturers to obtain CE marking for their devices, which involves a conformity assessment procedure and the implementation of a quality management system. For solenoid valve diagnostics, this would likely involve demonstrating compliance with essential requirements related to safety and performance.

International standards, such as ISO 13485 for quality management systems in medical devices, provide a framework for manufacturers to ensure their products meet regulatory requirements across different markets. Compliance with these standards is often necessary for obtaining regulatory approvals and maintaining market access.

Specific to smart hospital systems, regulations around data privacy and cybersecurity are increasingly important. In the United States, the Health Insurance Portability and Accountability Act (HIPAA) sets standards for protecting patient data. In the EU, the General Data Protection Regulation (GDPR) imposes strict requirements on the handling of personal health information.

As solenoid valve diagnostics in smart hospitals involve the collection and analysis of data, manufacturers must ensure their systems comply with these data protection regulations. This includes implementing robust security measures to protect against unauthorized access and ensuring patient data is handled in accordance with privacy laws.

Regulatory bodies are also increasingly focusing on the validation of artificial intelligence and machine learning algorithms used in medical diagnostics. Manufacturers developing advanced diagnostic systems for solenoid valves may need to provide evidence of the algorithm's performance, reliability, and safety through clinical studies and rigorous testing protocols.

Solenoid valve diagnostic systems in smart hospitals would likely fall under Class II, requiring a 510(k) premarket notification submission to demonstrate substantial equivalence to a legally marketed predicate device. This process involves providing detailed information about the device's design, performance, and safety features. Additionally, manufacturers must comply with Quality System Regulations (QSR) to ensure consistent production and quality control.

In the European Union, the Medical Device Regulation (MDR) governs the approval and marketing of medical devices. The MDR requires manufacturers to obtain CE marking for their devices, which involves a conformity assessment procedure and the implementation of a quality management system. For solenoid valve diagnostics, this would likely involve demonstrating compliance with essential requirements related to safety and performance.

International standards, such as ISO 13485 for quality management systems in medical devices, provide a framework for manufacturers to ensure their products meet regulatory requirements across different markets. Compliance with these standards is often necessary for obtaining regulatory approvals and maintaining market access.

Specific to smart hospital systems, regulations around data privacy and cybersecurity are increasingly important. In the United States, the Health Insurance Portability and Accountability Act (HIPAA) sets standards for protecting patient data. In the EU, the General Data Protection Regulation (GDPR) imposes strict requirements on the handling of personal health information.

As solenoid valve diagnostics in smart hospitals involve the collection and analysis of data, manufacturers must ensure their systems comply with these data protection regulations. This includes implementing robust security measures to protect against unauthorized access and ensuring patient data is handled in accordance with privacy laws.

Regulatory bodies are also increasingly focusing on the validation of artificial intelligence and machine learning algorithms used in medical diagnostics. Manufacturers developing advanced diagnostic systems for solenoid valves may need to provide evidence of the algorithm's performance, reliability, and safety through clinical studies and rigorous testing protocols.

Cost-Benefit Analysis of Diagnostic Implementation

Implementing solenoid valve diagnostics in smart hospital systems requires careful consideration of the associated costs and benefits. The initial investment in diagnostic equipment and software can be substantial, including expenses for sensors, data acquisition systems, and integration with existing hospital infrastructure. However, these upfront costs must be weighed against the long-term benefits of improved system reliability and reduced maintenance expenses.

One of the primary advantages of implementing solenoid valve diagnostics is the potential for predictive maintenance. By continuously monitoring valve performance and detecting early signs of degradation, hospitals can schedule maintenance activities proactively, minimizing unexpected failures and associated downtime. This approach can significantly reduce the costs of emergency repairs and replacement parts, as well as the potential risks to patient care caused by system failures.

The implementation of diagnostic systems can also lead to improved energy efficiency. Solenoid valves that are not functioning optimally may consume more energy or allow for inefficiencies in connected systems. By identifying and addressing these issues promptly, hospitals can reduce their overall energy consumption, leading to lower utility costs and a smaller carbon footprint.

Another benefit to consider is the potential for extended equipment lifespan. Through early detection of wear and tear, hospitals can take corrective actions that prevent premature failure of solenoid valves and related components. This can result in a longer operational life for these systems, delaying the need for costly replacements and maximizing the return on investment for existing infrastructure.

The implementation of diagnostic systems can also contribute to improved patient outcomes and safety. In critical hospital systems, such as those controlling medical gas delivery or sterilization processes, the reliable operation of solenoid valves is paramount. Enhanced diagnostics can help ensure these systems function as intended, reducing the risk of adverse events and potentially improving overall quality of care.

From a labor perspective, the introduction of automated diagnostics can lead to more efficient use of maintenance personnel. Instead of relying on time-based maintenance schedules or responding to failures, staff can focus their efforts on addressing specific issues identified by the diagnostic system. This targeted approach can result in more effective use of human resources and potentially reduce overall labor costs associated with system maintenance.

However, it is important to consider the ongoing costs of operating and maintaining the diagnostic system itself. This includes expenses for software updates, sensor calibration, and potential upgrades as technology advances. Additionally, staff training may be required to effectively interpret diagnostic data and implement appropriate maintenance strategies based on the system's outputs.

One of the primary advantages of implementing solenoid valve diagnostics is the potential for predictive maintenance. By continuously monitoring valve performance and detecting early signs of degradation, hospitals can schedule maintenance activities proactively, minimizing unexpected failures and associated downtime. This approach can significantly reduce the costs of emergency repairs and replacement parts, as well as the potential risks to patient care caused by system failures.

The implementation of diagnostic systems can also lead to improved energy efficiency. Solenoid valves that are not functioning optimally may consume more energy or allow for inefficiencies in connected systems. By identifying and addressing these issues promptly, hospitals can reduce their overall energy consumption, leading to lower utility costs and a smaller carbon footprint.

Another benefit to consider is the potential for extended equipment lifespan. Through early detection of wear and tear, hospitals can take corrective actions that prevent premature failure of solenoid valves and related components. This can result in a longer operational life for these systems, delaying the need for costly replacements and maximizing the return on investment for existing infrastructure.

The implementation of diagnostic systems can also contribute to improved patient outcomes and safety. In critical hospital systems, such as those controlling medical gas delivery or sterilization processes, the reliable operation of solenoid valves is paramount. Enhanced diagnostics can help ensure these systems function as intended, reducing the risk of adverse events and potentially improving overall quality of care.

From a labor perspective, the introduction of automated diagnostics can lead to more efficient use of maintenance personnel. Instead of relying on time-based maintenance schedules or responding to failures, staff can focus their efforts on addressing specific issues identified by the diagnostic system. This targeted approach can result in more effective use of human resources and potentially reduce overall labor costs associated with system maintenance.

However, it is important to consider the ongoing costs of operating and maintaining the diagnostic system itself. This includes expenses for software updates, sensor calibration, and potential upgrades as technology advances. Additionally, staff training may be required to effectively interpret diagnostic data and implement appropriate maintenance strategies based on the system's outputs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!