Solenoid Valves and their Role in Adaptive Optics Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Adaptive Optics

The evolution of solenoid valves in adaptive optics systems represents a significant technological advancement in the field of precision optics. Initially developed for industrial applications, solenoid valves have found a crucial role in the dynamic correction of optical aberrations. The journey began in the late 1970s when adaptive optics systems were first conceptualized for astronomical observations.

In the early stages, solenoid valves were primarily used in hydraulic and pneumatic systems, with limited precision and response times. However, as the demands of adaptive optics increased, engineers recognized the potential of solenoid valves for rapid and precise actuation. The 1980s saw the first integration of solenoid valves into adaptive optics systems, albeit with modest performance characteristics.

A significant breakthrough came in the 1990s with the development of fast-switching solenoid valves. These valves could operate at frequencies up to 1 kHz, allowing for real-time correction of atmospheric turbulence effects on optical systems. This advancement greatly improved the image quality in ground-based telescopes and laid the foundation for more sophisticated adaptive optics applications.

The turn of the millennium marked a new era for solenoid valves in adaptive optics. Miniaturization techniques enabled the creation of compact, high-performance valves suitable for integration into increasingly complex optical systems. These miniature solenoid valves offered improved response times, reduced power consumption, and enhanced precision, making them ideal for use in deformable mirrors and wavefront correctors.

In recent years, the evolution of solenoid valves has focused on materials science and advanced manufacturing techniques. The introduction of novel alloys and composite materials has resulted in valves with superior magnetic properties and reduced hysteresis, further improving their performance in adaptive optics systems. Additionally, 3D printing and microfabrication technologies have allowed for the creation of custom-designed valve geometries optimized for specific optical applications.

The latest generation of solenoid valves for adaptive optics incorporates smart features such as integrated sensors and feedback mechanisms. These innovations enable real-time monitoring and adjustment of valve performance, ensuring optimal operation under varying conditions. Furthermore, the development of energy-efficient designs has made it possible to deploy large arrays of solenoid valves in complex adaptive optics systems without excessive power requirements.

Looking ahead, the evolution of solenoid valves in adaptive optics is expected to continue, with a focus on enhancing speed, precision, and reliability. Emerging technologies such as piezoelectric actuators and MEMS-based valves are being explored as potential alternatives or complements to traditional solenoid designs, promising even greater performance in future adaptive optics systems.

In the early stages, solenoid valves were primarily used in hydraulic and pneumatic systems, with limited precision and response times. However, as the demands of adaptive optics increased, engineers recognized the potential of solenoid valves for rapid and precise actuation. The 1980s saw the first integration of solenoid valves into adaptive optics systems, albeit with modest performance characteristics.

A significant breakthrough came in the 1990s with the development of fast-switching solenoid valves. These valves could operate at frequencies up to 1 kHz, allowing for real-time correction of atmospheric turbulence effects on optical systems. This advancement greatly improved the image quality in ground-based telescopes and laid the foundation for more sophisticated adaptive optics applications.

The turn of the millennium marked a new era for solenoid valves in adaptive optics. Miniaturization techniques enabled the creation of compact, high-performance valves suitable for integration into increasingly complex optical systems. These miniature solenoid valves offered improved response times, reduced power consumption, and enhanced precision, making them ideal for use in deformable mirrors and wavefront correctors.

In recent years, the evolution of solenoid valves has focused on materials science and advanced manufacturing techniques. The introduction of novel alloys and composite materials has resulted in valves with superior magnetic properties and reduced hysteresis, further improving their performance in adaptive optics systems. Additionally, 3D printing and microfabrication technologies have allowed for the creation of custom-designed valve geometries optimized for specific optical applications.

The latest generation of solenoid valves for adaptive optics incorporates smart features such as integrated sensors and feedback mechanisms. These innovations enable real-time monitoring and adjustment of valve performance, ensuring optimal operation under varying conditions. Furthermore, the development of energy-efficient designs has made it possible to deploy large arrays of solenoid valves in complex adaptive optics systems without excessive power requirements.

Looking ahead, the evolution of solenoid valves in adaptive optics is expected to continue, with a focus on enhancing speed, precision, and reliability. Emerging technologies such as piezoelectric actuators and MEMS-based valves are being explored as potential alternatives or complements to traditional solenoid designs, promising even greater performance in future adaptive optics systems.

Market Demand for Precision Optical Control

The market demand for precision optical control in adaptive optics systems has been steadily increasing, driven by advancements in various fields such as astronomy, laser communication, and medical imaging. Adaptive optics technology, which relies heavily on solenoid valves for precise control, has become crucial in correcting atmospheric distortions and improving image quality in these applications.

In the astronomy sector, the need for high-resolution imaging of celestial objects has fueled the demand for adaptive optics systems. Large ground-based telescopes equipped with adaptive optics can achieve near diffraction-limited performance, rivaling space-based telescopes. This has led to a growing market for precision optical control components, including solenoid valves, in observatory upgrades and new telescope projects worldwide.

The laser communication industry has also emerged as a significant driver for precision optical control. As the demand for high-bandwidth, long-distance communication increases, adaptive optics systems are being employed to mitigate atmospheric turbulence effects on laser beams. This application requires extremely fast and accurate control of optical elements, creating a substantial market for advanced solenoid valves and related components.

In the medical field, adaptive optics is gaining traction in ophthalmology and microscopy applications. The ability to correct for optical aberrations in the human eye has opened new possibilities in retinal imaging and early disease detection. This has created a niche market for precision optical control systems in medical devices, with solenoid valves playing a critical role in their operation.

The defense and aerospace sectors have also contributed to the growing demand for precision optical control. Applications such as directed energy weapons, missile defense systems, and satellite-based imaging all require adaptive optics for optimal performance. These high-stakes applications drive the need for increasingly sophisticated and reliable solenoid valve technologies.

As the Internet of Things (IoT) and autonomous systems continue to evolve, there is an emerging market for compact, energy-efficient adaptive optics solutions. This trend is creating opportunities for miniaturized solenoid valves and integrated control systems, expanding the potential applications of precision optical control beyond traditional domains.

The global market for adaptive optics components, including solenoid valves, is expected to grow significantly in the coming years. This growth is supported by ongoing research and development efforts to improve the speed, accuracy, and reliability of optical control systems. As new applications emerge and existing technologies mature, the demand for precision optical control is likely to continue its upward trajectory, presenting substantial opportunities for innovation and market expansion in the field of solenoid valves and related technologies.

In the astronomy sector, the need for high-resolution imaging of celestial objects has fueled the demand for adaptive optics systems. Large ground-based telescopes equipped with adaptive optics can achieve near diffraction-limited performance, rivaling space-based telescopes. This has led to a growing market for precision optical control components, including solenoid valves, in observatory upgrades and new telescope projects worldwide.

The laser communication industry has also emerged as a significant driver for precision optical control. As the demand for high-bandwidth, long-distance communication increases, adaptive optics systems are being employed to mitigate atmospheric turbulence effects on laser beams. This application requires extremely fast and accurate control of optical elements, creating a substantial market for advanced solenoid valves and related components.

In the medical field, adaptive optics is gaining traction in ophthalmology and microscopy applications. The ability to correct for optical aberrations in the human eye has opened new possibilities in retinal imaging and early disease detection. This has created a niche market for precision optical control systems in medical devices, with solenoid valves playing a critical role in their operation.

The defense and aerospace sectors have also contributed to the growing demand for precision optical control. Applications such as directed energy weapons, missile defense systems, and satellite-based imaging all require adaptive optics for optimal performance. These high-stakes applications drive the need for increasingly sophisticated and reliable solenoid valve technologies.

As the Internet of Things (IoT) and autonomous systems continue to evolve, there is an emerging market for compact, energy-efficient adaptive optics solutions. This trend is creating opportunities for miniaturized solenoid valves and integrated control systems, expanding the potential applications of precision optical control beyond traditional domains.

The global market for adaptive optics components, including solenoid valves, is expected to grow significantly in the coming years. This growth is supported by ongoing research and development efforts to improve the speed, accuracy, and reliability of optical control systems. As new applications emerge and existing technologies mature, the demand for precision optical control is likely to continue its upward trajectory, presenting substantial opportunities for innovation and market expansion in the field of solenoid valves and related technologies.

Current Challenges in Solenoid Valve Technology

Despite the widespread use of solenoid valves in adaptive optics systems, several challenges persist in their technology, hindering optimal performance and reliability. One of the primary issues is the response time of solenoid valves, which can limit the overall speed and accuracy of adaptive optics systems. The electromagnetic actuation mechanism, while efficient, still faces limitations in achieving ultra-fast response times required for high-frequency corrections in advanced optical systems.

Another significant challenge lies in the precision and repeatability of valve operations. Adaptive optics systems demand extremely precise control over fluid flow or pressure, and even minor inconsistencies in valve performance can lead to substantial errors in wavefront correction. Factors such as wear, temperature fluctuations, and manufacturing tolerances can contribute to variations in valve behavior over time, affecting system reliability.

Power consumption and heat generation present additional hurdles, particularly in compact or portable adaptive optics systems. The electromagnetic coils in solenoid valves can consume considerable power and generate heat, potentially affecting the thermal stability of the optical system and limiting operational duration in battery-powered applications.

Miniaturization of solenoid valves while maintaining performance characteristics poses a significant engineering challenge. As adaptive optics systems become more compact and integrated, there is a growing need for smaller valves that can deliver the same level of precision and speed as their larger counterparts. This miniaturization effort is complicated by the need to balance magnetic field strength, coil size, and overall valve dimensions.

Durability and lifespan of solenoid valves in high-cycle applications remain areas of concern. Adaptive optics systems often require continuous, rapid actuation of valves, leading to mechanical stress and potential fatigue. Improving the longevity of valve components, particularly moving parts and seals, is crucial for ensuring sustained performance in demanding operational environments.

The integration of advanced materials and manufacturing techniques presents both opportunities and challenges. While novel materials can potentially enhance valve performance, their integration into existing designs and manufacturing processes can be complex. Ensuring compatibility with various working fluids, especially in specialized applications, adds another layer of complexity to material selection and valve design.

Lastly, the development of more sophisticated control algorithms and driver electronics for solenoid valves is an ongoing challenge. Achieving precise, adaptive control over valve operation, including features like soft-landing to reduce wear and noise, requires advanced control strategies and high-performance electronics. Balancing these requirements with cost considerations and system complexity remains a significant hurdle in advancing solenoid valve technology for adaptive optics applications.

Another significant challenge lies in the precision and repeatability of valve operations. Adaptive optics systems demand extremely precise control over fluid flow or pressure, and even minor inconsistencies in valve performance can lead to substantial errors in wavefront correction. Factors such as wear, temperature fluctuations, and manufacturing tolerances can contribute to variations in valve behavior over time, affecting system reliability.

Power consumption and heat generation present additional hurdles, particularly in compact or portable adaptive optics systems. The electromagnetic coils in solenoid valves can consume considerable power and generate heat, potentially affecting the thermal stability of the optical system and limiting operational duration in battery-powered applications.

Miniaturization of solenoid valves while maintaining performance characteristics poses a significant engineering challenge. As adaptive optics systems become more compact and integrated, there is a growing need for smaller valves that can deliver the same level of precision and speed as their larger counterparts. This miniaturization effort is complicated by the need to balance magnetic field strength, coil size, and overall valve dimensions.

Durability and lifespan of solenoid valves in high-cycle applications remain areas of concern. Adaptive optics systems often require continuous, rapid actuation of valves, leading to mechanical stress and potential fatigue. Improving the longevity of valve components, particularly moving parts and seals, is crucial for ensuring sustained performance in demanding operational environments.

The integration of advanced materials and manufacturing techniques presents both opportunities and challenges. While novel materials can potentially enhance valve performance, their integration into existing designs and manufacturing processes can be complex. Ensuring compatibility with various working fluids, especially in specialized applications, adds another layer of complexity to material selection and valve design.

Lastly, the development of more sophisticated control algorithms and driver electronics for solenoid valves is an ongoing challenge. Achieving precise, adaptive control over valve operation, including features like soft-landing to reduce wear and noise, requires advanced control strategies and high-performance electronics. Balancing these requirements with cost considerations and system complexity remains a significant hurdle in advancing solenoid valve technology for adaptive optics applications.

Solenoid Valve Integration in Adaptive Optics

01 Solenoid valve design and structure

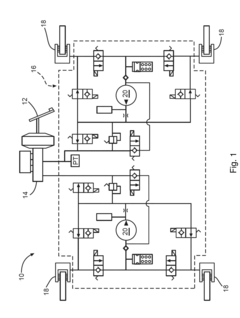

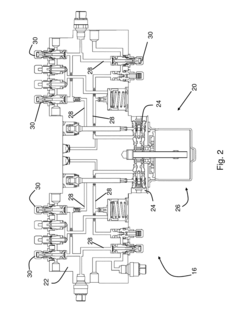

Solenoid valves are electromechanical devices that control the flow of fluids. Their design typically includes a coil, plunger, and valve body. When the coil is energized, it creates a magnetic field that moves the plunger, which in turn opens or closes the valve. Various structural improvements focus on enhancing efficiency, reducing size, and improving reliability.- Solenoid valve design and structure: Solenoid valves are electromechanical devices that control the flow of fluids. Their design typically includes a coil, plunger, and valve body. When the coil is energized, it creates a magnetic field that moves the plunger, which in turn opens or closes the valve. Various structural improvements focus on enhancing efficiency, reliability, and response time.

- Application in fuel injection systems: Solenoid valves play a crucial role in fuel injection systems for internal combustion engines. They control the precise timing and amount of fuel delivered to the engine, improving fuel efficiency and reducing emissions. Advancements in this area focus on faster response times, durability under high-pressure conditions, and compatibility with various fuel types.

- Miniaturization and integration: There is a trend towards miniaturizing solenoid valves and integrating them into compact systems. This involves developing smaller components, optimizing magnetic circuits, and using advanced materials. Miniaturized solenoid valves find applications in medical devices, automotive systems, and portable equipment where space is at a premium.

- Energy efficiency and power management: Improving the energy efficiency of solenoid valves is a key focus area. This includes developing low-power consumption designs, implementing smart control systems that optimize power usage, and utilizing energy recovery mechanisms. These advancements aim to reduce overall system power consumption and extend battery life in portable applications.

- Specialized solenoid valves for extreme conditions: Solenoid valves designed for extreme conditions, such as high temperatures, corrosive environments, or high-pressure applications, are being developed. These specialized valves incorporate advanced materials, sealing technologies, and robust designs to ensure reliable operation under challenging conditions. Applications include chemical processing, oil and gas industries, and aerospace.

02 Application in fuel injection systems

Solenoid valves play a crucial role in fuel injection systems for internal combustion engines. They control the precise timing and amount of fuel delivered to the engine, improving fuel efficiency and reducing emissions. Advancements in this area focus on faster response times, higher pressure capabilities, and integration with electronic control units.Expand Specific Solutions03 Miniaturization and integration

There is a trend towards miniaturization and integration of solenoid valves in various applications. This includes developing compact designs for space-constrained environments and integrating multiple valves into a single unit. Such advancements allow for more efficient use of space and improved overall system performance in industries like automotive, aerospace, and medical devices.Expand Specific Solutions04 Energy efficiency and power management

Improving the energy efficiency of solenoid valves is a key focus area. This includes developing low-power consumption designs, implementing smart power management systems, and utilizing advanced materials to reduce energy losses. These improvements lead to longer battery life in portable applications and reduced operating costs in industrial settings.Expand Specific Solutions05 Specialized solenoid valves for extreme conditions

Development of solenoid valves for extreme operating conditions, such as high-temperature environments, corrosive fluids, or high-pressure systems. These specialized valves incorporate advanced materials, sealing technologies, and design features to ensure reliable operation under challenging conditions. Applications include oil and gas industry, chemical processing, and aerospace.Expand Specific Solutions

Key Players in Solenoid Valve Manufacturing

The research on solenoid valves in adaptive optics systems is in a growth phase, with increasing market size due to expanding applications in astronomy, ophthalmology, and laser communication. The technology's maturity varies across sectors, with aerospace and defense leading. Key players like Eaton Corp., Robert Bosch GmbH, and Parker-Hannifin Corp. are driving innovation, while companies such as BorgWarner, Inc. and Continental Teves AG & Co. oHG are expanding their presence. Academic institutions like Hefei University of Technology and Shandong University contribute to fundamental research, fostering a competitive landscape that blends established industrial giants with emerging specialized firms.

National Technology & Engineering Solutions of Sandia LLC

Technical Solution: Sandia National Laboratories has developed a state-of-the-art adaptive optics system utilizing advanced solenoid valve technology for high-energy laser applications. Their approach employs a dense array of micro-solenoid valves to control the shape of a deformable mirror with sub-nanometer precision. The system uses sophisticated control algorithms and high-speed electronics to achieve closed-loop correction rates exceeding 1 kHz, enabling real-time compensation for atmospheric turbulence and thermal blooming effects in directed energy weapons[9]. Sandia's implementation also features a novel cooling system to manage the thermal load from high-power laser operation, ensuring consistent performance under extreme conditions[10].

Strengths: Extremely high precision, fast correction rates, and ability to handle high-power applications. Weaknesses: High development and production costs, and limited commercial availability due to sensitive nature of the technology.

Rafael Advanced Defense Systems Ltd.

Technical Solution: Rafael has developed a cutting-edge adaptive optics system utilizing solenoid valves for military and aerospace applications. Their technology employs an array of high-speed, low-latency solenoid valves to control the shape of a deformable mirror with nanometer-scale precision. The system uses advanced algorithms to process wavefront sensor data and actuate the valves in real-time, effectively compensating for atmospheric turbulence and optical system aberrations[3]. Rafael's implementation also features a robust, ruggedized design to withstand harsh environmental conditions, making it suitable for deployment in various defense and space-based platforms[4].

Strengths: High durability, extreme precision, and suitability for demanding environments. Weaknesses: High cost and potential export restrictions due to military applications.

Innovative Solenoid Valve Designs for Optics

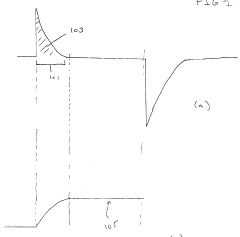

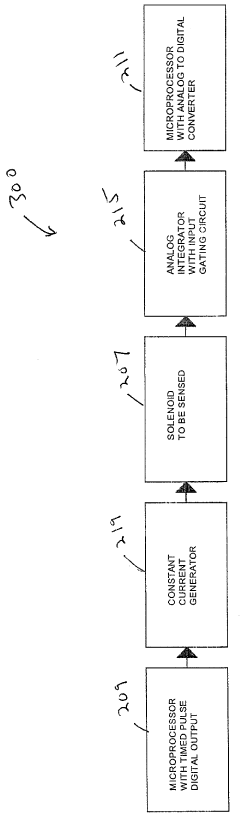

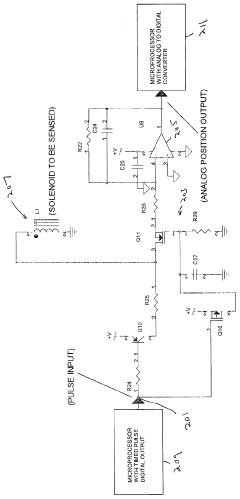

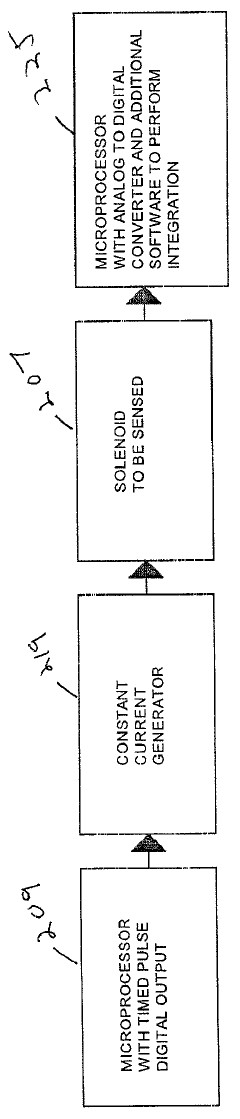

Systems and methods for determining the position of an electrical solenoid

PatentWO2008144661A1

Innovation

- The method integrates the back-emf waveform generated by a small current pulse applied to the solenoid coil to determine the position of the armature, using the solenoid itself for both motion and sensing, without the need for additional sensing hardware, by measuring the change in self-inductance and integrating the back-emf waveform to amplify small changes in inductance.

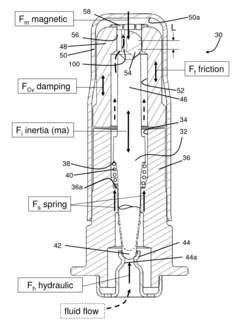

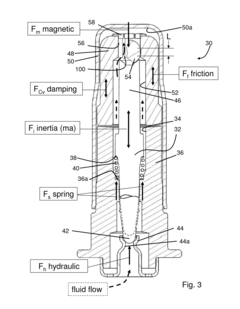

Solenoid Valve Having Hydraulic Damping Mechanism

PatentInactiveUS20150130265A1

Innovation

- A solenoid valve design featuring a damping port with a specific flow groove depth, flow diameter, and effective length ratio, creating turbulent fluid flow characteristics to attenuate vibrations, and an actuating ball that connects the armature to the tappet, enhancing damping and reducing NVH disturbances.

Environmental Impact of Solenoid Production

The production of solenoid valves for adaptive optics systems has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of various materials, including metals, plastics, and electronic components, each with its own environmental footprint. The extraction and processing of raw materials, particularly metals like copper and iron, contribute to resource depletion and energy consumption. Mining activities associated with these materials can lead to habitat destruction, soil erosion, and water pollution if not properly managed.

During the manufacturing phase, energy-intensive processes such as metal casting, machining, and assembly contribute to greenhouse gas emissions. The use of chemicals for cleaning and coating components may result in the release of volatile organic compounds (VOCs) and other pollutants if not adequately controlled. Additionally, the production of electronic components for solenoid control systems often involves the use of rare earth elements and hazardous substances, which can have severe environmental impacts if not properly handled and disposed of.

Water usage is another critical environmental factor in solenoid valve production. Cooling processes, cleaning operations, and material treatments all require substantial amounts of water, potentially straining local water resources. Proper water management and recycling systems are essential to mitigate this impact.

The disposal and end-of-life management of solenoid valves also present environmental challenges. While many components can be recycled, the complex nature of these devices, which often combine different materials, can make separation and recycling difficult. Improper disposal can lead to electronic waste accumulation, potentially releasing harmful substances into the environment.

However, it is important to note that the environmental impact of solenoid valve production must be balanced against their role in adaptive optics systems. These systems significantly improve the efficiency and performance of optical instruments, potentially leading to reduced energy consumption and improved resource utilization in various applications, from astronomy to medical imaging.

To address these environmental concerns, manufacturers are increasingly adopting sustainable practices. These include implementing energy-efficient production processes, using recycled materials where possible, and designing products for easier disassembly and recycling. Some companies are also exploring alternative materials and manufacturing techniques to reduce the overall environmental footprint of solenoid valve production.

During the manufacturing phase, energy-intensive processes such as metal casting, machining, and assembly contribute to greenhouse gas emissions. The use of chemicals for cleaning and coating components may result in the release of volatile organic compounds (VOCs) and other pollutants if not adequately controlled. Additionally, the production of electronic components for solenoid control systems often involves the use of rare earth elements and hazardous substances, which can have severe environmental impacts if not properly handled and disposed of.

Water usage is another critical environmental factor in solenoid valve production. Cooling processes, cleaning operations, and material treatments all require substantial amounts of water, potentially straining local water resources. Proper water management and recycling systems are essential to mitigate this impact.

The disposal and end-of-life management of solenoid valves also present environmental challenges. While many components can be recycled, the complex nature of these devices, which often combine different materials, can make separation and recycling difficult. Improper disposal can lead to electronic waste accumulation, potentially releasing harmful substances into the environment.

However, it is important to note that the environmental impact of solenoid valve production must be balanced against their role in adaptive optics systems. These systems significantly improve the efficiency and performance of optical instruments, potentially leading to reduced energy consumption and improved resource utilization in various applications, from astronomy to medical imaging.

To address these environmental concerns, manufacturers are increasingly adopting sustainable practices. These include implementing energy-efficient production processes, using recycled materials where possible, and designing products for easier disassembly and recycling. Some companies are also exploring alternative materials and manufacturing techniques to reduce the overall environmental footprint of solenoid valve production.

Reliability and Longevity of Optical Valves

The reliability and longevity of optical valves are critical factors in the performance and sustainability of adaptive optics systems. These components play a crucial role in controlling the flow of light and adjusting optical elements to compensate for atmospheric distortions. As such, their durability and consistent operation over extended periods are essential for maintaining the effectiveness of adaptive optics systems in various applications, including astronomy, laser communication, and medical imaging.

Optical valves, including solenoid valves used in adaptive optics, are subject to various stressors that can impact their reliability and lifespan. These stressors include thermal cycling, mechanical wear, electrical fatigue, and environmental factors such as humidity and contamination. To ensure long-term performance, manufacturers employ advanced materials and design techniques to mitigate these challenges.

One key aspect of improving the reliability of optical valves is the use of high-quality materials that can withstand repeated actuation cycles. For instance, valve seats and seals are often made from durable polymers or ceramics that resist wear and maintain their sealing properties over time. Additionally, the use of corrosion-resistant alloys for valve bodies and actuators helps prevent degradation due to environmental factors.

Thermal management is another critical consideration in enhancing the longevity of optical valves. Excessive heat generation during operation can lead to premature failure of components and affect the valve's precision. Advanced cooling systems and thermally efficient designs are implemented to dissipate heat effectively and maintain optimal operating temperatures.

To further improve reliability, manufacturers incorporate redundancy and fault-tolerance features into their valve designs. This may include dual-coil solenoids or backup actuation mechanisms that can take over in case of primary system failure. Such redundancies ensure continuous operation of the adaptive optics system even if individual components experience issues.

Regular maintenance and condition monitoring are essential for maximizing the lifespan of optical valves. Advanced diagnostic tools and sensors can be integrated into valve assemblies to provide real-time data on performance metrics, allowing for predictive maintenance and early detection of potential failures. This proactive approach helps prevent unexpected downtime and extends the overall operational life of the system.

In conclusion, the reliability and longevity of optical valves are paramount in ensuring the sustained performance of adaptive optics systems. Through careful material selection, innovative design approaches, and proactive maintenance strategies, manufacturers and operators can significantly enhance the durability and consistency of these critical components, ultimately improving the long-term effectiveness of adaptive optics technologies across various applications.

Optical valves, including solenoid valves used in adaptive optics, are subject to various stressors that can impact their reliability and lifespan. These stressors include thermal cycling, mechanical wear, electrical fatigue, and environmental factors such as humidity and contamination. To ensure long-term performance, manufacturers employ advanced materials and design techniques to mitigate these challenges.

One key aspect of improving the reliability of optical valves is the use of high-quality materials that can withstand repeated actuation cycles. For instance, valve seats and seals are often made from durable polymers or ceramics that resist wear and maintain their sealing properties over time. Additionally, the use of corrosion-resistant alloys for valve bodies and actuators helps prevent degradation due to environmental factors.

Thermal management is another critical consideration in enhancing the longevity of optical valves. Excessive heat generation during operation can lead to premature failure of components and affect the valve's precision. Advanced cooling systems and thermally efficient designs are implemented to dissipate heat effectively and maintain optimal operating temperatures.

To further improve reliability, manufacturers incorporate redundancy and fault-tolerance features into their valve designs. This may include dual-coil solenoids or backup actuation mechanisms that can take over in case of primary system failure. Such redundancies ensure continuous operation of the adaptive optics system even if individual components experience issues.

Regular maintenance and condition monitoring are essential for maximizing the lifespan of optical valves. Advanced diagnostic tools and sensors can be integrated into valve assemblies to provide real-time data on performance metrics, allowing for predictive maintenance and early detection of potential failures. This proactive approach helps prevent unexpected downtime and extends the overall operational life of the system.

In conclusion, the reliability and longevity of optical valves are paramount in ensuring the sustained performance of adaptive optics systems. Through careful material selection, innovative design approaches, and proactive maintenance strategies, manufacturers and operators can significantly enhance the durability and consistency of these critical components, ultimately improving the long-term effectiveness of adaptive optics technologies across various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!