Solenoid Valves in Advanced Water Treatment Technologies

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Water Treatment

The evolution of solenoid valves in water treatment technologies has been marked by significant advancements over the past few decades. Initially, solenoid valves were primarily used for basic on/off control in water distribution systems. However, as water treatment processes became more sophisticated, the demand for more precise and reliable valve control increased.

In the 1980s and 1990s, the integration of electronic controls with solenoid valves led to improved accuracy in flow regulation. This development allowed for better management of chemical dosing and filtration processes in water treatment plants. The introduction of corrosion-resistant materials, such as stainless steel and engineered plastics, also enhanced the durability and lifespan of solenoid valves in harsh water treatment environments.

The early 2000s saw a shift towards energy efficiency and miniaturization. Manufacturers began developing low-power solenoid valves that could operate on battery power or solar energy, making them suitable for remote water treatment installations. Concurrently, the miniaturization of valve components allowed for the creation of compact, multi-valve assemblies that could handle complex water treatment sequences in smaller spaces.

As water quality standards became more stringent, solenoid valves evolved to meet these challenges. The introduction of high-precision flow control capabilities enabled more accurate management of chemical injection and backwash cycles in advanced filtration systems. Additionally, the development of self-cleaning valve designs helped reduce maintenance requirements and improve reliability in systems dealing with particulate-laden water.

In recent years, the integration of smart technologies has revolutionized solenoid valve applications in water treatment. IoT-enabled valves now offer real-time monitoring and remote control capabilities, allowing operators to optimize treatment processes and respond quickly to changing water conditions. Machine learning algorithms are being employed to predict valve failures and schedule preventive maintenance, further enhancing system reliability.

The latest generation of solenoid valves incorporates advanced materials and designs to address emerging contaminants. For instance, specialized valve coatings and seals have been developed to withstand aggressive chemicals used in advanced oxidation processes. Furthermore, high-speed solenoid valves are now being utilized in pulse-based treatment systems, enabling precise control of oxidant injection and improving the efficiency of contaminant removal.

Looking ahead, the evolution of solenoid valves in water treatment is likely to focus on sustainability and resource efficiency. Research is underway to develop valves that can operate with minimal pressure drop, reducing energy consumption in treatment plants. Additionally, there is growing interest in bio-based and recyclable materials for valve components, aligning with the broader trend towards environmentally friendly water treatment solutions.

In the 1980s and 1990s, the integration of electronic controls with solenoid valves led to improved accuracy in flow regulation. This development allowed for better management of chemical dosing and filtration processes in water treatment plants. The introduction of corrosion-resistant materials, such as stainless steel and engineered plastics, also enhanced the durability and lifespan of solenoid valves in harsh water treatment environments.

The early 2000s saw a shift towards energy efficiency and miniaturization. Manufacturers began developing low-power solenoid valves that could operate on battery power or solar energy, making them suitable for remote water treatment installations. Concurrently, the miniaturization of valve components allowed for the creation of compact, multi-valve assemblies that could handle complex water treatment sequences in smaller spaces.

As water quality standards became more stringent, solenoid valves evolved to meet these challenges. The introduction of high-precision flow control capabilities enabled more accurate management of chemical injection and backwash cycles in advanced filtration systems. Additionally, the development of self-cleaning valve designs helped reduce maintenance requirements and improve reliability in systems dealing with particulate-laden water.

In recent years, the integration of smart technologies has revolutionized solenoid valve applications in water treatment. IoT-enabled valves now offer real-time monitoring and remote control capabilities, allowing operators to optimize treatment processes and respond quickly to changing water conditions. Machine learning algorithms are being employed to predict valve failures and schedule preventive maintenance, further enhancing system reliability.

The latest generation of solenoid valves incorporates advanced materials and designs to address emerging contaminants. For instance, specialized valve coatings and seals have been developed to withstand aggressive chemicals used in advanced oxidation processes. Furthermore, high-speed solenoid valves are now being utilized in pulse-based treatment systems, enabling precise control of oxidant injection and improving the efficiency of contaminant removal.

Looking ahead, the evolution of solenoid valves in water treatment is likely to focus on sustainability and resource efficiency. Research is underway to develop valves that can operate with minimal pressure drop, reducing energy consumption in treatment plants. Additionally, there is growing interest in bio-based and recyclable materials for valve components, aligning with the broader trend towards environmentally friendly water treatment solutions.

Market Demand Analysis for Advanced Water Treatment

The global water treatment market is experiencing significant growth, driven by increasing water scarcity, stringent environmental regulations, and growing awareness of water quality issues. Advanced water treatment technologies, including those utilizing solenoid valves, are at the forefront of this market expansion. The demand for these technologies is particularly strong in regions facing severe water stress, such as the Middle East, North Africa, and parts of Asia.

Industrial sectors, including manufacturing, power generation, and oil & gas, are major contributors to the demand for advanced water treatment solutions. These industries require high-quality water for their processes and are under pressure to reduce water consumption and improve wastewater management. The adoption of sophisticated water treatment systems incorporating solenoid valves is seen as a key strategy to meet these challenges.

Municipal water treatment plants are another significant market segment driving demand. As urban populations grow and water sources become more polluted, there is an increasing need for advanced treatment technologies to ensure safe drinking water supply. Solenoid valves play a crucial role in automating and optimizing various stages of the water treatment process, from filtration to disinfection.

The pharmaceutical and food & beverage industries are also emerging as important markets for advanced water treatment technologies. These sectors require ultra-pure water for their production processes and are investing heavily in state-of-the-art treatment systems. Solenoid valves are essential components in these high-precision applications, ensuring accurate control of water flow and treatment processes.

Environmental concerns and regulatory pressures are further fueling market growth. Governments worldwide are implementing stricter regulations on water quality and wastewater discharge, compelling industries to invest in more effective treatment solutions. This regulatory landscape is creating opportunities for innovative technologies that can meet these stringent standards while also improving operational efficiency.

The market for advanced water treatment technologies is also being shaped by the trend towards smart water management systems. There is growing demand for solutions that integrate sensors, automation, and data analytics to optimize water treatment processes. Solenoid valves, with their ability to be precisely controlled and integrated into digital systems, are well-positioned to benefit from this trend.

In terms of geographical distribution, North America and Europe currently lead the market for advanced water treatment technologies. However, the fastest growth is expected in Asia-Pacific, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India. The Middle East, facing acute water scarcity, is another region showing strong demand for innovative water treatment solutions.

Industrial sectors, including manufacturing, power generation, and oil & gas, are major contributors to the demand for advanced water treatment solutions. These industries require high-quality water for their processes and are under pressure to reduce water consumption and improve wastewater management. The adoption of sophisticated water treatment systems incorporating solenoid valves is seen as a key strategy to meet these challenges.

Municipal water treatment plants are another significant market segment driving demand. As urban populations grow and water sources become more polluted, there is an increasing need for advanced treatment technologies to ensure safe drinking water supply. Solenoid valves play a crucial role in automating and optimizing various stages of the water treatment process, from filtration to disinfection.

The pharmaceutical and food & beverage industries are also emerging as important markets for advanced water treatment technologies. These sectors require ultra-pure water for their production processes and are investing heavily in state-of-the-art treatment systems. Solenoid valves are essential components in these high-precision applications, ensuring accurate control of water flow and treatment processes.

Environmental concerns and regulatory pressures are further fueling market growth. Governments worldwide are implementing stricter regulations on water quality and wastewater discharge, compelling industries to invest in more effective treatment solutions. This regulatory landscape is creating opportunities for innovative technologies that can meet these stringent standards while also improving operational efficiency.

The market for advanced water treatment technologies is also being shaped by the trend towards smart water management systems. There is growing demand for solutions that integrate sensors, automation, and data analytics to optimize water treatment processes. Solenoid valves, with their ability to be precisely controlled and integrated into digital systems, are well-positioned to benefit from this trend.

In terms of geographical distribution, North America and Europe currently lead the market for advanced water treatment technologies. However, the fastest growth is expected in Asia-Pacific, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India. The Middle East, facing acute water scarcity, is another region showing strong demand for innovative water treatment solutions.

Current Challenges in Solenoid Valve Technology

Solenoid valves play a crucial role in advanced water treatment technologies, but they face several significant challenges that hinder their optimal performance and reliability. One of the primary issues is the susceptibility to corrosion and scaling, particularly in harsh water environments. The constant exposure to various chemicals and contaminants in water treatment processes can lead to premature wear and degradation of valve components, reducing their lifespan and efficiency.

Another major challenge is the precision and speed of valve operation. In advanced water treatment systems, rapid and accurate control of fluid flow is essential. However, current solenoid valve technologies often struggle to maintain consistent response times and precise flow control, especially under varying pressure conditions. This can result in inefficiencies in the treatment process and potentially compromise water quality.

Energy consumption is also a significant concern in solenoid valve technology. Many existing valves require substantial power to operate, which can lead to increased operational costs and reduced sustainability in water treatment facilities. The development of more energy-efficient solenoid valves remains a key challenge for the industry.

Miniaturization presents another hurdle for solenoid valve manufacturers. As water treatment systems become more compact and modular, there is a growing demand for smaller, yet equally powerful valves. Balancing size reduction with performance maintenance is a complex engineering challenge that requires innovative design approaches and materials.

Reliability and maintenance issues continue to plague solenoid valve technology. Frequent valve failures or the need for regular maintenance can lead to system downtime and increased operational costs. Developing valves with improved durability and self-diagnostic capabilities is crucial for enhancing the overall efficiency of water treatment processes.

The integration of smart technologies into solenoid valves is another area facing challenges. While there is a clear trend towards IoT-enabled and automated water treatment systems, incorporating sensors, actuators, and communication capabilities into valve designs without compromising their core functionality or reliability remains a significant technical hurdle.

Lastly, the environmental impact of solenoid valve production and disposal is becoming increasingly important. Current manufacturing processes and materials used in valve construction may not align with sustainability goals. Developing eco-friendly alternatives and implementing circular economy principles in valve design and production is a pressing challenge for the industry.

Another major challenge is the precision and speed of valve operation. In advanced water treatment systems, rapid and accurate control of fluid flow is essential. However, current solenoid valve technologies often struggle to maintain consistent response times and precise flow control, especially under varying pressure conditions. This can result in inefficiencies in the treatment process and potentially compromise water quality.

Energy consumption is also a significant concern in solenoid valve technology. Many existing valves require substantial power to operate, which can lead to increased operational costs and reduced sustainability in water treatment facilities. The development of more energy-efficient solenoid valves remains a key challenge for the industry.

Miniaturization presents another hurdle for solenoid valve manufacturers. As water treatment systems become more compact and modular, there is a growing demand for smaller, yet equally powerful valves. Balancing size reduction with performance maintenance is a complex engineering challenge that requires innovative design approaches and materials.

Reliability and maintenance issues continue to plague solenoid valve technology. Frequent valve failures or the need for regular maintenance can lead to system downtime and increased operational costs. Developing valves with improved durability and self-diagnostic capabilities is crucial for enhancing the overall efficiency of water treatment processes.

The integration of smart technologies into solenoid valves is another area facing challenges. While there is a clear trend towards IoT-enabled and automated water treatment systems, incorporating sensors, actuators, and communication capabilities into valve designs without compromising their core functionality or reliability remains a significant technical hurdle.

Lastly, the environmental impact of solenoid valve production and disposal is becoming increasingly important. Current manufacturing processes and materials used in valve construction may not align with sustainability goals. Developing eco-friendly alternatives and implementing circular economy principles in valve design and production is a pressing challenge for the industry.

Existing Solenoid Valve Solutions

01 Solenoid valve design and structure

Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, efficiency, and reliability for different applications.- Solenoid valve design and structure: Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, efficiency, and reliability for different applications.

- Solenoid valve control systems: Control systems for solenoid valves involve electronic circuits and software that regulate valve operation. These systems can include pulse-width modulation (PWM) techniques, feedback mechanisms, and intelligent control algorithms to improve precision, response time, and energy efficiency. Advanced control systems may integrate with larger automation networks or IoT platforms.

- Solenoid valve applications in automotive systems: Solenoid valves play crucial roles in various automotive systems, including fuel injection, transmission control, and exhaust gas recirculation. They are designed to withstand harsh environments, operate at high speeds, and provide precise control. Automotive solenoid valves often require specialized materials and configurations to meet industry standards and performance requirements.

- Miniaturization and integration of solenoid valves: Advancements in solenoid valve technology focus on miniaturization and integration with other components. This trend enables the development of compact, multi-functional valve assemblies for space-constrained applications. Miniaturized solenoid valves often incorporate novel materials and manufacturing techniques to maintain performance while reducing size and weight.

- Energy-efficient solenoid valve designs: Energy efficiency is a key consideration in modern solenoid valve design. Innovations in this area include low-power coils, magnetic latching mechanisms, and optimized flow paths. These designs aim to reduce power consumption during operation and standby modes, making them suitable for battery-powered or energy-sensitive applications.

02 Control systems for solenoid valves

Advanced control systems are implemented to enhance the operation of solenoid valves. These systems may include electronic controllers, sensors, and feedback mechanisms to regulate valve timing, duration, and pressure. Such control systems improve precision, reduce energy consumption, and enable integration with larger automated systems.Expand Specific Solutions03 Solenoid valve applications in fluid systems

Solenoid valves find widespread use in various fluid systems, including hydraulic, pneumatic, and gas distribution networks. They are crucial components in automotive, industrial, and HVAC applications. Specific designs cater to different media, pressure ranges, and environmental conditions to ensure optimal performance across diverse scenarios.Expand Specific Solutions04 Energy-efficient solenoid valve technologies

Innovations in solenoid valve design focus on improving energy efficiency. This includes the development of low-power consumption coils, optimized magnetic circuits, and materials with enhanced electromagnetic properties. These advancements reduce heat generation, extend valve lifespan, and minimize operational costs in various applications.Expand Specific Solutions05 Miniaturization and integration of solenoid valves

Trends in solenoid valve development include miniaturization and integration with other components. Compact designs allow for space-saving installations in tight spaces, while integrated solutions combine multiple valves or incorporate them into larger assemblies. These advancements enable more efficient and streamlined fluid control systems across various industries.Expand Specific Solutions

Key Players in Water Treatment Valve Industry

The research on solenoid valves in advanced water treatment technologies is in a mature stage, with a growing market driven by increasing demand for efficient water management solutions. The global market size for solenoid valves in this sector is expected to expand significantly in the coming years. Key players like Eaton Corp., Robert Bosch GmbH, and Gree Electric Appliances are leading the technological advancements, focusing on improving valve efficiency and reliability. Smaller specialized companies such as RPE Srl and ODE SRL are also contributing to innovation in niche applications. The technology's maturity is evident in the diverse range of products offered by these companies, catering to various water treatment needs across industries.

Eaton Corp.

Technical Solution: Eaton Corp. has developed advanced solenoid valve technologies for water treatment applications. Their innovative designs incorporate smart control systems and energy-efficient actuators. Eaton's solenoid valves feature precision flow control and rapid response times, crucial for advanced water treatment processes[1]. The company has implemented corrosion-resistant materials and seal technologies to enhance valve durability in harsh water treatment environments[3]. Eaton's valves also integrate diagnostic capabilities, allowing for predictive maintenance and reduced downtime in water treatment facilities[5].

Strengths: Robust design for harsh environments, smart control integration, energy efficiency. Weaknesses: Potentially higher initial cost, may require specialized maintenance.

Ecolab USA, Inc.

Technical Solution: Ecolab USA has developed specialized solenoid valve solutions for advanced water treatment technologies. Their valves are designed to handle a wide range of chemicals used in water purification processes, including corrosive substances[2]. Ecolab's solenoid valves incorporate advanced materials such as PTFE and high-grade stainless steel to ensure longevity and reliability in challenging water treatment environments[4]. The company has also introduced smart valve systems that can be integrated with IoT platforms for real-time monitoring and control of water treatment processes[6]. Ecolab's valves feature precise dosing capabilities, critical for efficient chemical usage in water treatment applications.

Strengths: Chemical resistance, precision dosing, IoT integration. Weaknesses: May be more specialized, potentially limiting broader application range.

Innovative Solenoid Valve Designs

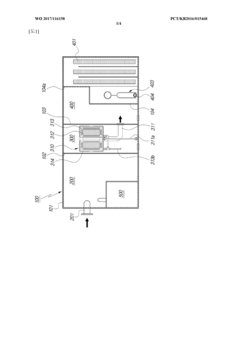

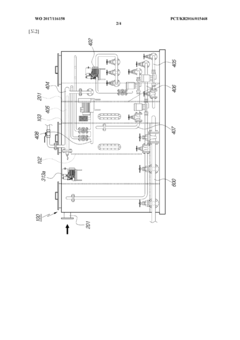

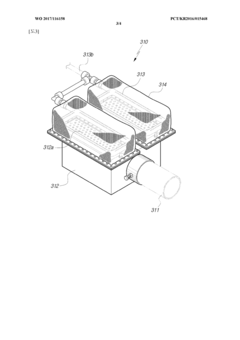

Advanced water treatment apparatus

PatentWO2017116158A1

Innovation

- An advanced water treatment device with an integrated chamber divided by partition walls, featuring a storage anaerobic tank, biological reactor, membrane separation tank, and filtration screen, which separates and treats sewage using anaerobic decomposition, membrane filtration, and aeration to remove organic matter, nitrogen, and phosphorus, and includes a UV lamp for disinfection.

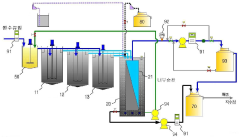

Advanced water treatment method of submerged membrane coupled with pac slurry blanket and equipment therefor

PatentInactiveKR1020090046397A

Innovation

- A method and apparatus utilizing a powdered activated carbon slurry blanket layer in a reactor for adsorption, followed by solid-liquid separation in a submerged membrane filtration tank, minimizing continuous carbon input and optimizing carbon use through microbial conversion to bioactive carbon.

Environmental Impact Assessment

The environmental impact assessment of solenoid valves in advanced water treatment technologies reveals both positive and negative effects on ecosystems and resource conservation. On the positive side, these valves contribute significantly to water conservation efforts by enabling precise control of water flow in treatment systems. Their ability to regulate water usage helps reduce overall water consumption, which is crucial in areas facing water scarcity. Additionally, the improved efficiency in water treatment processes facilitated by solenoid valves leads to a decrease in energy consumption, indirectly reducing the carbon footprint associated with water treatment facilities.

However, the production and disposal of solenoid valves present environmental challenges. The manufacturing process involves the use of various metals and synthetic materials, which can contribute to resource depletion and generate industrial waste. The disposal of these valves at the end of their lifecycle also raises concerns about electronic waste and potential soil and water contamination if not properly managed.

In terms of water quality, solenoid valves play a crucial role in maintaining high standards of treated water. By ensuring accurate dosing of chemicals and controlling the flow of water through different treatment stages, these valves help minimize the risk of contaminants entering the water supply. This not only protects human health but also reduces the potential for harmful substances to be released into natural water bodies, thereby safeguarding aquatic ecosystems.

The use of solenoid valves in advanced water treatment technologies also impacts land use and habitat conservation. By enhancing the efficiency of water treatment plants, these valves contribute to the optimization of facility size, potentially reducing the land footprint of treatment infrastructure. This can indirectly benefit habitat preservation by minimizing the expansion of industrial areas into natural environments.

Noise pollution is another aspect to consider in the environmental impact assessment. While solenoid valves themselves produce minimal noise, their role in automating water treatment processes can lead to a reduction in overall plant noise levels by minimizing the need for manual interventions and reducing the operation of larger, noisier equipment.

Lastly, the longevity and reliability of solenoid valves contribute to the sustainability of water treatment systems. Their durability reduces the frequency of replacements, which in turn minimizes the environmental impact associated with manufacturing and transportation of replacement parts. However, this benefit must be balanced against the need for regular maintenance, which may involve the use of lubricants and cleaning agents that could have environmental implications if not properly managed.

However, the production and disposal of solenoid valves present environmental challenges. The manufacturing process involves the use of various metals and synthetic materials, which can contribute to resource depletion and generate industrial waste. The disposal of these valves at the end of their lifecycle also raises concerns about electronic waste and potential soil and water contamination if not properly managed.

In terms of water quality, solenoid valves play a crucial role in maintaining high standards of treated water. By ensuring accurate dosing of chemicals and controlling the flow of water through different treatment stages, these valves help minimize the risk of contaminants entering the water supply. This not only protects human health but also reduces the potential for harmful substances to be released into natural water bodies, thereby safeguarding aquatic ecosystems.

The use of solenoid valves in advanced water treatment technologies also impacts land use and habitat conservation. By enhancing the efficiency of water treatment plants, these valves contribute to the optimization of facility size, potentially reducing the land footprint of treatment infrastructure. This can indirectly benefit habitat preservation by minimizing the expansion of industrial areas into natural environments.

Noise pollution is another aspect to consider in the environmental impact assessment. While solenoid valves themselves produce minimal noise, their role in automating water treatment processes can lead to a reduction in overall plant noise levels by minimizing the need for manual interventions and reducing the operation of larger, noisier equipment.

Lastly, the longevity and reliability of solenoid valves contribute to the sustainability of water treatment systems. Their durability reduces the frequency of replacements, which in turn minimizes the environmental impact associated with manufacturing and transportation of replacement parts. However, this benefit must be balanced against the need for regular maintenance, which may involve the use of lubricants and cleaning agents that could have environmental implications if not properly managed.

Regulatory Framework for Water Treatment Equipment

The regulatory framework for water treatment equipment plays a crucial role in ensuring the safety and efficacy of advanced water treatment technologies, including those utilizing solenoid valves. In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing water treatment standards and equipment. The Safe Drinking Water Act (SDWA) provides the foundation for these regulations, setting national standards for drinking water quality and treatment processes.

Under the SDWA, the EPA has established specific regulations for water treatment equipment, including the National Primary Drinking Water Regulations (NPDWRs) and the National Secondary Drinking Water Regulations (NSDWRs). These regulations set maximum contaminant levels (MCLs) for various pollutants and define treatment techniques for their removal. Solenoid valves, as critical components in advanced water treatment systems, must comply with these standards to ensure proper functionality and safety.

The NSF International, a non-governmental organization, works in collaboration with the EPA to develop and certify water treatment equipment standards. NSF/ANSI Standard 61 specifically addresses the health effects of drinking water system components, including solenoid valves. This standard ensures that materials used in these components do not leach harmful contaminants into the water supply.

In the European Union, the regulatory landscape for water treatment equipment is governed by the Drinking Water Directive (DWD). The DWD sets quality standards for drinking water and outlines requirements for water treatment processes and equipment. The European Committee for Standardization (CEN) develops harmonized standards for water treatment equipment, including solenoid valves, to ensure compliance with the DWD.

Globally, the World Health Organization (WHO) provides guidelines for drinking water quality, which many countries use as a basis for their national regulations. These guidelines influence the design and implementation of water treatment technologies, including the use of solenoid valves in advanced systems.

Regulatory compliance for solenoid valves in water treatment applications extends beyond water quality standards. Electrical safety regulations, such as those set by the International Electrotechnical Commission (IEC), apply to the electrical components of solenoid valves. Additionally, pressure equipment directives, like the Pressure Equipment Directive (PED) in the EU, may be relevant for high-pressure applications.

As water treatment technologies continue to advance, regulatory frameworks are evolving to address new challenges and emerging contaminants. This dynamic regulatory environment necessitates ongoing research and development in solenoid valve technology to ensure compliance with current and future standards, while also improving efficiency and performance in advanced water treatment processes.

Under the SDWA, the EPA has established specific regulations for water treatment equipment, including the National Primary Drinking Water Regulations (NPDWRs) and the National Secondary Drinking Water Regulations (NSDWRs). These regulations set maximum contaminant levels (MCLs) for various pollutants and define treatment techniques for their removal. Solenoid valves, as critical components in advanced water treatment systems, must comply with these standards to ensure proper functionality and safety.

The NSF International, a non-governmental organization, works in collaboration with the EPA to develop and certify water treatment equipment standards. NSF/ANSI Standard 61 specifically addresses the health effects of drinking water system components, including solenoid valves. This standard ensures that materials used in these components do not leach harmful contaminants into the water supply.

In the European Union, the regulatory landscape for water treatment equipment is governed by the Drinking Water Directive (DWD). The DWD sets quality standards for drinking water and outlines requirements for water treatment processes and equipment. The European Committee for Standardization (CEN) develops harmonized standards for water treatment equipment, including solenoid valves, to ensure compliance with the DWD.

Globally, the World Health Organization (WHO) provides guidelines for drinking water quality, which many countries use as a basis for their national regulations. These guidelines influence the design and implementation of water treatment technologies, including the use of solenoid valves in advanced systems.

Regulatory compliance for solenoid valves in water treatment applications extends beyond water quality standards. Electrical safety regulations, such as those set by the International Electrotechnical Commission (IEC), apply to the electrical components of solenoid valves. Additionally, pressure equipment directives, like the Pressure Equipment Directive (PED) in the EU, may be relevant for high-pressure applications.

As water treatment technologies continue to advance, regulatory frameworks are evolving to address new challenges and emerging contaminants. This dynamic regulatory environment necessitates ongoing research and development in solenoid valve technology to ensure compliance with current and future standards, while also improving efficiency and performance in advanced water treatment processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!