Solenoid Valves in High-Performance Automotive Transmission Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Automotive Transmissions

Solenoid valves have played a pivotal role in the evolution of automotive transmission systems, revolutionizing the way vehicles shift gears and manage fluid control. The journey of these electromechanical devices in transmissions began in the late 1980s, coinciding with the advent of electronic control units (ECUs) in vehicles. Initially, solenoid valves were primarily used for basic on/off control of hydraulic circuits in automatic transmissions.

As automotive technology progressed through the 1990s, solenoid valves became more sophisticated, enabling finer control over transmission fluid pressure and flow. This advancement led to the development of continuously variable transmissions (CVTs) and more efficient automatic transmissions with a higher number of gear ratios. The integration of solenoid valves allowed for smoother gear changes and improved fuel efficiency.

The early 2000s saw a significant leap in solenoid valve technology with the introduction of variable force solenoids (VFS). These devices could precisely modulate hydraulic pressure, enabling more complex transmission control strategies. This innovation paved the way for dual-clutch transmissions (DCTs) and advanced multi-speed automatic transmissions, offering both performance and efficiency benefits.

In the following decade, solenoid valve design focused on miniaturization and increased precision. Manufacturers developed compact solenoid packages that could fit into increasingly crowded transmission housings while maintaining or improving performance. This trend aligned with the automotive industry's push towards lighter, more fuel-efficient vehicles.

Recent years have witnessed the emergence of smart solenoid valves equipped with integrated sensors and advanced control algorithms. These valves can adapt to changing operating conditions in real-time, further optimizing transmission performance. The integration of solenoid valves with transmission control modules has enabled more sophisticated shift strategies, including predictive shifting based on driving conditions and driver behavior.

Looking towards the future, solenoid valve evolution in automotive transmissions is likely to focus on enhanced durability, reduced power consumption, and improved compatibility with electrified powertrains. As hybrid and electric vehicles become more prevalent, solenoid valves will need to adapt to new transmission architectures and cooling requirements. Additionally, the ongoing development of autonomous vehicles may lead to new demands for solenoid valve technology, potentially requiring even greater precision and reliability in transmission control.

As automotive technology progressed through the 1990s, solenoid valves became more sophisticated, enabling finer control over transmission fluid pressure and flow. This advancement led to the development of continuously variable transmissions (CVTs) and more efficient automatic transmissions with a higher number of gear ratios. The integration of solenoid valves allowed for smoother gear changes and improved fuel efficiency.

The early 2000s saw a significant leap in solenoid valve technology with the introduction of variable force solenoids (VFS). These devices could precisely modulate hydraulic pressure, enabling more complex transmission control strategies. This innovation paved the way for dual-clutch transmissions (DCTs) and advanced multi-speed automatic transmissions, offering both performance and efficiency benefits.

In the following decade, solenoid valve design focused on miniaturization and increased precision. Manufacturers developed compact solenoid packages that could fit into increasingly crowded transmission housings while maintaining or improving performance. This trend aligned with the automotive industry's push towards lighter, more fuel-efficient vehicles.

Recent years have witnessed the emergence of smart solenoid valves equipped with integrated sensors and advanced control algorithms. These valves can adapt to changing operating conditions in real-time, further optimizing transmission performance. The integration of solenoid valves with transmission control modules has enabled more sophisticated shift strategies, including predictive shifting based on driving conditions and driver behavior.

Looking towards the future, solenoid valve evolution in automotive transmissions is likely to focus on enhanced durability, reduced power consumption, and improved compatibility with electrified powertrains. As hybrid and electric vehicles become more prevalent, solenoid valves will need to adapt to new transmission architectures and cooling requirements. Additionally, the ongoing development of autonomous vehicles may lead to new demands for solenoid valve technology, potentially requiring even greater precision and reliability in transmission control.

Market Demand for High-Performance Transmission Systems

The demand for high-performance transmission systems in the automotive industry has been steadily increasing, driven by several key factors. Consumers are increasingly seeking vehicles that offer improved fuel efficiency, enhanced driving experience, and better overall performance. This trend has led to a growing market for advanced transmission technologies, including those incorporating sophisticated solenoid valve systems.

In recent years, the global automotive transmission market has experienced significant growth, with a particular emphasis on high-performance systems. These systems are crucial for optimizing engine power delivery, improving fuel economy, and reducing emissions. The integration of solenoid valves in these transmission systems plays a vital role in achieving precise control over gear shifts, fluid pressure, and overall transmission efficiency.

The market demand is further fueled by stringent government regulations aimed at reducing vehicle emissions and improving fuel efficiency. As automakers strive to meet these standards, they are increasingly turning to advanced transmission technologies that can help achieve these goals. High-performance transmission systems with advanced solenoid valves offer a solution by enabling more efficient power transfer and reducing energy losses.

Another driving factor is the growing consumer preference for vehicles with smoother and more responsive driving experiences. High-performance transmission systems equipped with advanced solenoid valves can provide quicker and more precise gear shifts, resulting in improved acceleration and overall vehicle performance. This aspect is particularly important in the luxury and sports car segments, where driving dynamics are a key selling point.

The rise of electric and hybrid vehicles has also contributed to the demand for high-performance transmission systems. While electric vehicles typically use single-speed transmissions, hybrid vehicles often require more complex transmission systems to manage the interaction between the internal combustion engine and electric motor. Solenoid valves play a crucial role in these hybrid transmissions, controlling the flow of hydraulic fluid and enabling seamless transitions between power sources.

In the commercial vehicle sector, there is a growing demand for high-performance transmission systems that can improve fuel efficiency and reduce operating costs. Fleet operators are increasingly recognizing the long-term benefits of investing in advanced transmission technologies, including those with sophisticated solenoid valve systems, to optimize their vehicles' performance and reduce maintenance requirements.

As the automotive industry continues to evolve, the market for high-performance transmission systems is expected to expand further. The integration of advanced technologies such as artificial intelligence and machine learning in transmission control systems is likely to drive additional demand for more sophisticated solenoid valve solutions. This trend is expected to create new opportunities for innovation and market growth in the coming years.

In recent years, the global automotive transmission market has experienced significant growth, with a particular emphasis on high-performance systems. These systems are crucial for optimizing engine power delivery, improving fuel economy, and reducing emissions. The integration of solenoid valves in these transmission systems plays a vital role in achieving precise control over gear shifts, fluid pressure, and overall transmission efficiency.

The market demand is further fueled by stringent government regulations aimed at reducing vehicle emissions and improving fuel efficiency. As automakers strive to meet these standards, they are increasingly turning to advanced transmission technologies that can help achieve these goals. High-performance transmission systems with advanced solenoid valves offer a solution by enabling more efficient power transfer and reducing energy losses.

Another driving factor is the growing consumer preference for vehicles with smoother and more responsive driving experiences. High-performance transmission systems equipped with advanced solenoid valves can provide quicker and more precise gear shifts, resulting in improved acceleration and overall vehicle performance. This aspect is particularly important in the luxury and sports car segments, where driving dynamics are a key selling point.

The rise of electric and hybrid vehicles has also contributed to the demand for high-performance transmission systems. While electric vehicles typically use single-speed transmissions, hybrid vehicles often require more complex transmission systems to manage the interaction between the internal combustion engine and electric motor. Solenoid valves play a crucial role in these hybrid transmissions, controlling the flow of hydraulic fluid and enabling seamless transitions between power sources.

In the commercial vehicle sector, there is a growing demand for high-performance transmission systems that can improve fuel efficiency and reduce operating costs. Fleet operators are increasingly recognizing the long-term benefits of investing in advanced transmission technologies, including those with sophisticated solenoid valve systems, to optimize their vehicles' performance and reduce maintenance requirements.

As the automotive industry continues to evolve, the market for high-performance transmission systems is expected to expand further. The integration of advanced technologies such as artificial intelligence and machine learning in transmission control systems is likely to drive additional demand for more sophisticated solenoid valve solutions. This trend is expected to create new opportunities for innovation and market growth in the coming years.

Current Challenges in Solenoid Valve Technology

Solenoid valves in high-performance automotive transmission systems face several significant challenges that hinder their optimal performance and reliability. One of the primary issues is the demand for increasingly precise control of fluid flow and pressure within the transmission system. As modern vehicles require more sophisticated transmission operations, the accuracy and responsiveness of solenoid valves become critical factors.

The miniaturization trend in automotive design presents another challenge. Engineers must develop compact solenoid valves that maintain high performance while occupying minimal space within the transmission housing. This size reduction often leads to compromises in valve durability and heat dissipation capabilities, potentially affecting long-term reliability.

Thermal management is a persistent challenge for solenoid valves in high-performance transmissions. The high operating temperatures within these systems can lead to degradation of valve components, affecting their longevity and performance consistency. Developing materials and designs that can withstand extreme temperature fluctuations without compromising functionality remains a significant hurdle.

The need for faster response times poses another technical challenge. High-performance transmissions require near-instantaneous valve actuation to facilitate smooth gear shifts and optimal power delivery. Achieving rapid response while maintaining precision and avoiding overshooting or undershooting the desired valve position is a complex engineering task.

Durability under high-pressure conditions is an ongoing concern. Solenoid valves in these systems must withstand substantial fluid pressures while maintaining consistent performance over extended periods. The development of robust sealing solutions and wear-resistant materials is crucial to address this challenge.

Electromagnetic interference (EMI) is becoming an increasingly significant issue as vehicles incorporate more electronic systems. Solenoid valves must be designed to operate reliably in environments with high levels of electromagnetic noise, requiring advanced shielding and signal processing techniques.

The integration of smart features and diagnostics into solenoid valves presents both opportunities and challenges. While these features can enhance performance and facilitate predictive maintenance, they also introduce additional complexity and potential failure points that must be carefully managed.

Lastly, the automotive industry's push towards electrification and alternative powertrains is reshaping the requirements for transmission systems. Solenoid valve technology must evolve to meet the unique demands of hybrid and electric vehicle transmissions, which may involve different operating conditions and control strategies compared to traditional internal combustion engine vehicles.

The miniaturization trend in automotive design presents another challenge. Engineers must develop compact solenoid valves that maintain high performance while occupying minimal space within the transmission housing. This size reduction often leads to compromises in valve durability and heat dissipation capabilities, potentially affecting long-term reliability.

Thermal management is a persistent challenge for solenoid valves in high-performance transmissions. The high operating temperatures within these systems can lead to degradation of valve components, affecting their longevity and performance consistency. Developing materials and designs that can withstand extreme temperature fluctuations without compromising functionality remains a significant hurdle.

The need for faster response times poses another technical challenge. High-performance transmissions require near-instantaneous valve actuation to facilitate smooth gear shifts and optimal power delivery. Achieving rapid response while maintaining precision and avoiding overshooting or undershooting the desired valve position is a complex engineering task.

Durability under high-pressure conditions is an ongoing concern. Solenoid valves in these systems must withstand substantial fluid pressures while maintaining consistent performance over extended periods. The development of robust sealing solutions and wear-resistant materials is crucial to address this challenge.

Electromagnetic interference (EMI) is becoming an increasingly significant issue as vehicles incorporate more electronic systems. Solenoid valves must be designed to operate reliably in environments with high levels of electromagnetic noise, requiring advanced shielding and signal processing techniques.

The integration of smart features and diagnostics into solenoid valves presents both opportunities and challenges. While these features can enhance performance and facilitate predictive maintenance, they also introduce additional complexity and potential failure points that must be carefully managed.

Lastly, the automotive industry's push towards electrification and alternative powertrains is reshaping the requirements for transmission systems. Solenoid valve technology must evolve to meet the unique demands of hybrid and electric vehicle transmissions, which may involve different operating conditions and control strategies compared to traditional internal combustion engine vehicles.

Existing Solenoid Valve Solutions for Transmissions

01 Solenoid valve design and structure

Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, efficiency, and reliability for different applications.- Solenoid valve design and structure: Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, including improvements in sealing, response time, and durability.

- Application in fuel injection systems: Solenoid valves play a crucial role in fuel injection systems for internal combustion engines. They precisely control the timing and amount of fuel delivered to the engine, improving efficiency and reducing emissions. Advanced designs incorporate features like multiple injection events per cycle and high-speed operation to meet stringent performance and environmental requirements.

- Integration with electronic control systems: Modern solenoid valves are often integrated with electronic control systems for enhanced functionality. This integration allows for precise control of valve operation, real-time monitoring, and adaptive responses to changing conditions. Advanced control algorithms and sensors can be used to optimize valve performance and diagnose potential issues.

- Energy-efficient solenoid valve designs: Innovations in solenoid valve design focus on improving energy efficiency. This includes the development of low-power consumption valves, the use of advanced materials to reduce magnetic losses, and the implementation of energy-saving control strategies. Some designs incorporate latching mechanisms or bistable configurations to maintain valve position without continuous power input.

- Miniaturization and specialized applications: There is a trend towards miniaturization of solenoid valves for use in compact systems and specialized applications. These miniature valves maintain high performance while occupying minimal space. They find use in medical devices, analytical instruments, and other fields requiring precise fluid control in confined spaces. Additionally, specialized solenoid valves are being developed for extreme environments or unique fluid handling requirements.

02 Solenoid valve control systems

Control systems for solenoid valves include electronic circuits and microcontrollers that manage valve operation. These systems can incorporate sensors, feedback mechanisms, and advanced algorithms to precisely regulate fluid flow, pressure, and timing. They may also feature diagnostic capabilities and remote control options for improved performance and maintenance.Expand Specific Solutions03 Solenoid valve applications in automotive systems

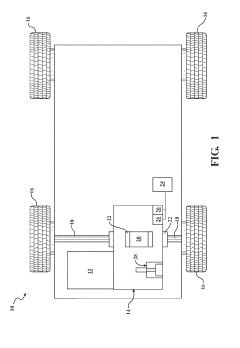

Solenoid valves are widely used in automotive systems for various functions, including fuel injection, transmission control, and engine management. They play a crucial role in optimizing engine performance, fuel efficiency, and emissions control. Specialized designs cater to the specific requirements of different automotive applications.Expand Specific Solutions04 Solenoid valve materials and manufacturing

The choice of materials for solenoid valve components is critical for durability, chemical resistance, and performance. Common materials include stainless steel, brass, and engineered plastics. Advanced manufacturing techniques, such as precision machining and 3D printing, are employed to produce complex valve geometries and improve production efficiency.Expand Specific Solutions05 Energy-efficient solenoid valve designs

Innovations in solenoid valve design focus on improving energy efficiency and reducing power consumption. This includes the development of low-power coils, latching mechanisms, and pulse-width modulation control techniques. These advancements help extend battery life in portable applications and reduce overall energy costs in industrial settings.Expand Specific Solutions

Key Players in Automotive Solenoid Valve Industry

The research on solenoid valves in high-performance automotive transmission systems is in a mature stage, with a competitive landscape dominated by established players. The market size is substantial, driven by the growing demand for advanced transmission technologies in the automotive sector. Key players like BorgWarner, Continental AG, and ZF Friedrichshafen AG have developed sophisticated solenoid valve solutions, leveraging their extensive experience in automotive systems. The technology's maturity is evident in the widespread adoption across various vehicle types, from passenger cars to commercial vehicles. However, emerging companies like Solero Technologies are introducing innovative approaches, potentially disrupting the market with new, more efficient designs.

BorgWarner, Inc.

Technical Solution: BorgWarner has made significant advancements in solenoid valve technology for high-performance automotive transmissions. Their latest innovation is the "Smart Valve" system, which integrates microprocessors directly into the valve assembly for enhanced control and diagnostics[17]. BorgWarner's solenoid valves utilize a proprietary magnetic circuit design that optimizes force output while minimizing power consumption[18]. The company has also developed a unique fluid flow path geometry that reduces pressure drops and improves overall hydraulic efficiency[19]. BorgWarner's valves incorporate advanced materials such as ceramic coatings to enhance wear resistance and extend service life[20]. Additionally, they have implemented a modular design approach that allows for easy customization and rapid integration into various transmission architectures[21].

Strengths: Advanced control capabilities, energy efficiency, improved hydraulic performance, and modular design. Weaknesses: Potential increased complexity due to integrated electronics and higher initial costs.

Eaton Corp.

Technical Solution: Eaton has focused on developing solenoid valves for high-performance transmissions that offer improved durability and reliability. Their latest valve designs incorporate a patented "Dual Coil" technology that provides redundancy and fail-safe operation[9]. Eaton's solenoid valves feature a unique sealing system that reduces internal leakage, improving overall transmission efficiency[10]. The company has also implemented advanced manufacturing techniques, such as precision laser welding, to enhance valve consistency and longevity[11]. Eaton's valves are designed with a modular architecture, allowing for easy customization and integration into various transmission designs[12].

Strengths: High reliability, improved efficiency, and modular design for easy integration. Weaknesses: Potentially higher manufacturing costs and complexity due to advanced manufacturing techniques.

Core Innovations in Solenoid Valve Design

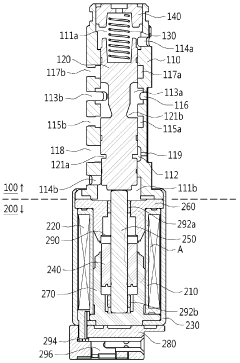

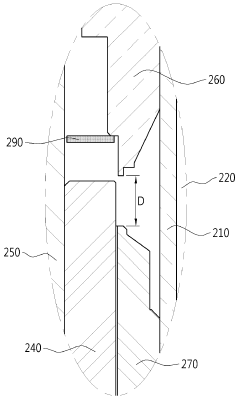

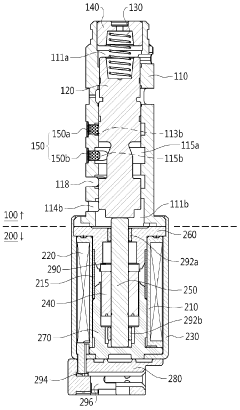

Solenoid valve for transmission

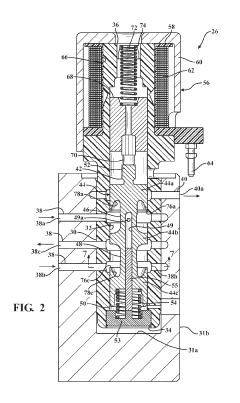

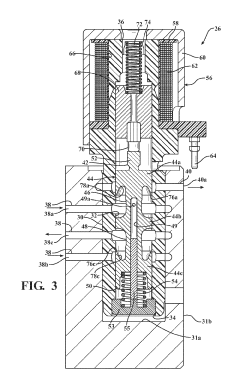

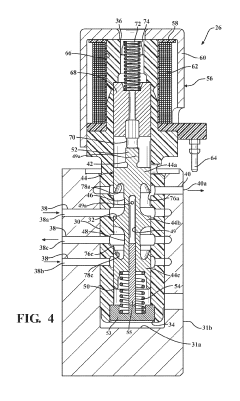

PatentWO2011090256A1

Innovation

- A solenoid valve design featuring a solenoid section with a core and yoke separated by a predetermined gap, a plunger for reciprocation, and a valve section with chambers and ports, including a feedback flow channel and filter, to ensure sufficient magnetic force for high pressure and flow rate control while simplifying the hydraulic circuit.

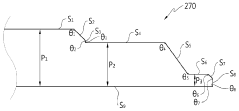

High flow high pressure hydraulic solenoid valve for automatic transmission

PatentInactiveUS20190203846A1

Innovation

- A high flow high pressure hydraulic solenoid valve design featuring a proportional solenoid, valve body with undercut fluid ports, and a spool valve with metering faces and a control module port configuration to balance pressure and minimize hydraulic forces during high-flow conditions.

Environmental Impact of Solenoid Valve Technologies

The environmental impact of solenoid valve technologies in high-performance automotive transmission systems is a critical consideration in the automotive industry's pursuit of sustainability. These valves play a crucial role in controlling fluid flow and pressure within transmission systems, directly influencing vehicle performance and efficiency. However, their production, operation, and disposal have significant environmental implications.

Manufacturing solenoid valves involves the use of various materials, including metals, plastics, and rare earth elements for the electromagnetic components. The extraction and processing of these materials contribute to resource depletion and energy consumption. Additionally, the production process generates waste and emissions, potentially impacting air and water quality if not properly managed.

During operation, solenoid valves in high-performance transmissions contribute to the overall energy efficiency of vehicles. Advanced valve designs can improve fuel economy by enabling more precise control of transmission fluid, resulting in reduced fuel consumption and lower greenhouse gas emissions. However, the increased complexity of these systems may lead to higher maintenance requirements and potential reliability issues, which could offset some environmental benefits if not addressed effectively.

The lifespan of solenoid valves is an important factor in their environmental impact. While high-quality valves can last for many years, eventual wear and failure necessitate replacement. This creates a waste stream that requires proper handling and recycling to minimize environmental harm. The automotive industry is increasingly focusing on designing for disassembly and recyclability to address end-of-life concerns.

Electromagnetic fields generated by solenoid valves during operation may have localized environmental effects, although these are generally considered minimal in the context of overall vehicle emissions. However, the cumulative impact of millions of vehicles equipped with these systems warrants ongoing research and monitoring.

As the automotive industry transitions towards electrification, the role of solenoid valves in transmission systems may evolve. While electric vehicles typically have simpler transmission systems, advanced solenoid valve technologies may still find applications in thermal management and other vehicle systems, potentially altering their environmental footprint.

Efforts to mitigate the environmental impact of solenoid valve technologies include the development of more efficient designs, the use of sustainable materials, and improved manufacturing processes. Research into alternative actuation methods, such as piezoelectric systems, may offer environmentally friendlier options in the future. Additionally, advancements in control algorithms and integration with vehicle management systems can further optimize valve operation for reduced environmental impact.

Manufacturing solenoid valves involves the use of various materials, including metals, plastics, and rare earth elements for the electromagnetic components. The extraction and processing of these materials contribute to resource depletion and energy consumption. Additionally, the production process generates waste and emissions, potentially impacting air and water quality if not properly managed.

During operation, solenoid valves in high-performance transmissions contribute to the overall energy efficiency of vehicles. Advanced valve designs can improve fuel economy by enabling more precise control of transmission fluid, resulting in reduced fuel consumption and lower greenhouse gas emissions. However, the increased complexity of these systems may lead to higher maintenance requirements and potential reliability issues, which could offset some environmental benefits if not addressed effectively.

The lifespan of solenoid valves is an important factor in their environmental impact. While high-quality valves can last for many years, eventual wear and failure necessitate replacement. This creates a waste stream that requires proper handling and recycling to minimize environmental harm. The automotive industry is increasingly focusing on designing for disassembly and recyclability to address end-of-life concerns.

Electromagnetic fields generated by solenoid valves during operation may have localized environmental effects, although these are generally considered minimal in the context of overall vehicle emissions. However, the cumulative impact of millions of vehicles equipped with these systems warrants ongoing research and monitoring.

As the automotive industry transitions towards electrification, the role of solenoid valves in transmission systems may evolve. While electric vehicles typically have simpler transmission systems, advanced solenoid valve technologies may still find applications in thermal management and other vehicle systems, potentially altering their environmental footprint.

Efforts to mitigate the environmental impact of solenoid valve technologies include the development of more efficient designs, the use of sustainable materials, and improved manufacturing processes. Research into alternative actuation methods, such as piezoelectric systems, may offer environmentally friendlier options in the future. Additionally, advancements in control algorithms and integration with vehicle management systems can further optimize valve operation for reduced environmental impact.

Regulatory Standards for Automotive Solenoid Valves

Regulatory standards for automotive solenoid valves play a crucial role in ensuring the safety, reliability, and performance of high-performance transmission systems. These standards are established and enforced by various regulatory bodies worldwide, including the National Highway Traffic Safety Administration (NHTSA) in the United States, the European Union's Vehicle Certification Agency (VCA), and the United Nations Economic Commission for Europe (UNECE).

One of the primary regulatory standards for automotive solenoid valves is the Federal Motor Vehicle Safety Standards (FMVSS) in the United States. Specifically, FMVSS No. 106 addresses brake hoses, including those used in conjunction with solenoid valves in transmission systems. This standard sets requirements for the construction, labeling, and performance of brake hoses to ensure their durability and effectiveness under various operating conditions.

In the European Union, the ECE Regulation No. 13 governs braking systems for vehicles, including components such as solenoid valves. This regulation outlines specific requirements for the design, installation, and performance of braking system components, ensuring they meet stringent safety and reliability standards.

The International Organization for Standardization (ISO) has also developed relevant standards for automotive solenoid valves. ISO 15500-2:2016 specifies test methods and general requirements for components used in compressed natural gas (CNG) fuel systems, including solenoid valves. While this standard is not specific to transmission systems, it provides valuable guidelines for the testing and performance evaluation of solenoid valves in automotive applications.

Electromagnetic compatibility (EMC) regulations are another critical aspect of solenoid valve standards. The European Union's EMC Directive 2014/30/EU and the corresponding UN Regulation No. 10 set limits for electromagnetic emissions and immunity of automotive components, including solenoid valves. These regulations ensure that solenoid valves do not interfere with other electronic systems in the vehicle and can function reliably in the presence of electromagnetic disturbances.

Environmental considerations are also addressed in regulatory standards for automotive solenoid valves. The European Union's End-of-Life Vehicles (ELV) Directive 2000/53/EC restricts the use of certain hazardous substances in vehicle components, including solenoid valves. This directive promotes the recyclability and recoverability of vehicle parts, encouraging manufacturers to use environmentally friendly materials in their solenoid valve designs.

Compliance with these regulatory standards is essential for manufacturers of high-performance automotive transmission systems. It ensures that solenoid valves meet the necessary safety, performance, and environmental requirements, allowing for their use in vehicles sold in various global markets. As technology advances and environmental concerns grow, these standards are continually updated to reflect the latest industry developments and societal expectations.

One of the primary regulatory standards for automotive solenoid valves is the Federal Motor Vehicle Safety Standards (FMVSS) in the United States. Specifically, FMVSS No. 106 addresses brake hoses, including those used in conjunction with solenoid valves in transmission systems. This standard sets requirements for the construction, labeling, and performance of brake hoses to ensure their durability and effectiveness under various operating conditions.

In the European Union, the ECE Regulation No. 13 governs braking systems for vehicles, including components such as solenoid valves. This regulation outlines specific requirements for the design, installation, and performance of braking system components, ensuring they meet stringent safety and reliability standards.

The International Organization for Standardization (ISO) has also developed relevant standards for automotive solenoid valves. ISO 15500-2:2016 specifies test methods and general requirements for components used in compressed natural gas (CNG) fuel systems, including solenoid valves. While this standard is not specific to transmission systems, it provides valuable guidelines for the testing and performance evaluation of solenoid valves in automotive applications.

Electromagnetic compatibility (EMC) regulations are another critical aspect of solenoid valve standards. The European Union's EMC Directive 2014/30/EU and the corresponding UN Regulation No. 10 set limits for electromagnetic emissions and immunity of automotive components, including solenoid valves. These regulations ensure that solenoid valves do not interfere with other electronic systems in the vehicle and can function reliably in the presence of electromagnetic disturbances.

Environmental considerations are also addressed in regulatory standards for automotive solenoid valves. The European Union's End-of-Life Vehicles (ELV) Directive 2000/53/EC restricts the use of certain hazardous substances in vehicle components, including solenoid valves. This directive promotes the recyclability and recoverability of vehicle parts, encouraging manufacturers to use environmentally friendly materials in their solenoid valve designs.

Compliance with these regulatory standards is essential for manufacturers of high-performance automotive transmission systems. It ensures that solenoid valves meet the necessary safety, performance, and environmental requirements, allowing for their use in vehicles sold in various global markets. As technology advances and environmental concerns grow, these standards are continually updated to reflect the latest industry developments and societal expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!