Role of Geometric Isomers in Quantum Dot Technology

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Isomers: Background and Objectives

Quantum dot technology has emerged as a revolutionary field in materials science and nanotechnology, with applications spanning from advanced displays to quantum computing. At the heart of this technology lies the intricate world of geometric isomers, which play a crucial role in determining the properties and performance of quantum dots.

The concept of quantum dots dates back to the early 1980s when researchers first observed the quantum confinement effect in semiconductor nanocrystals. Since then, the field has experienced rapid growth, driven by advancements in synthesis techniques and characterization methods. The ability to precisely control the size, shape, and composition of quantum dots has opened up new possibilities for tailoring their optical and electronic properties.

Geometric isomers in quantum dots refer to different spatial arrangements of atoms within the nanocrystal structure. These isomers can significantly influence the quantum dot's behavior, including its emission wavelength, quantum yield, and stability. Understanding and controlling these isomeric forms has become a key focus in quantum dot research, as it offers a pathway to fine-tune the performance of quantum dot-based devices.

The evolution of quantum dot technology has been marked by several key milestones. Initially, the focus was on developing synthesis methods to produce high-quality, monodisperse quantum dots. This was followed by efforts to enhance their stability and reduce toxicity, particularly for biological applications. More recently, attention has shifted towards exploring novel compositions and heterostructures to expand the range of accessible properties.

The current technological landscape is characterized by a growing interest in leveraging geometric isomers to push the boundaries of quantum dot performance. Researchers are exploring ways to selectively synthesize specific isomeric forms, as well as developing techniques to interconvert between different isomers post-synthesis. This approach holds promise for creating quantum dots with unprecedented levels of control over their electronic and optical characteristics.

Looking ahead, the field of quantum dot isomers is poised for significant advancements. The primary objectives include developing a deeper understanding of the relationship between isomeric structure and quantum dot properties, improving methods for isomer-selective synthesis, and exploring novel applications that exploit the unique features of different geometric isomers. These efforts are expected to drive innovation in areas such as next-generation displays, solar cells, and quantum information processing.

The concept of quantum dots dates back to the early 1980s when researchers first observed the quantum confinement effect in semiconductor nanocrystals. Since then, the field has experienced rapid growth, driven by advancements in synthesis techniques and characterization methods. The ability to precisely control the size, shape, and composition of quantum dots has opened up new possibilities for tailoring their optical and electronic properties.

Geometric isomers in quantum dots refer to different spatial arrangements of atoms within the nanocrystal structure. These isomers can significantly influence the quantum dot's behavior, including its emission wavelength, quantum yield, and stability. Understanding and controlling these isomeric forms has become a key focus in quantum dot research, as it offers a pathway to fine-tune the performance of quantum dot-based devices.

The evolution of quantum dot technology has been marked by several key milestones. Initially, the focus was on developing synthesis methods to produce high-quality, monodisperse quantum dots. This was followed by efforts to enhance their stability and reduce toxicity, particularly for biological applications. More recently, attention has shifted towards exploring novel compositions and heterostructures to expand the range of accessible properties.

The current technological landscape is characterized by a growing interest in leveraging geometric isomers to push the boundaries of quantum dot performance. Researchers are exploring ways to selectively synthesize specific isomeric forms, as well as developing techniques to interconvert between different isomers post-synthesis. This approach holds promise for creating quantum dots with unprecedented levels of control over their electronic and optical characteristics.

Looking ahead, the field of quantum dot isomers is poised for significant advancements. The primary objectives include developing a deeper understanding of the relationship between isomeric structure and quantum dot properties, improving methods for isomer-selective synthesis, and exploring novel applications that exploit the unique features of different geometric isomers. These efforts are expected to drive innovation in areas such as next-generation displays, solar cells, and quantum information processing.

Market Analysis for Quantum Dot Applications

The quantum dot market has experienced significant growth in recent years, driven by the increasing demand for high-performance display technologies and advanced lighting solutions. The global quantum dot market size was valued at approximately $4.5 billion in 2020 and is projected to reach $10.6 billion by 2025, with a compound annual growth rate (CAGR) of 18.7% during the forecast period.

The display segment dominates the quantum dot market, accounting for over 60% of the total market share. This is primarily due to the widespread adoption of quantum dot technology in televisions, monitors, and smartphones. Major players in the consumer electronics industry, such as Samsung, LG, and Sony, have incorporated quantum dot technology into their premium display products, enhancing color accuracy and brightness.

The lighting and optoelectronics segment is expected to witness the highest growth rate in the coming years. Quantum dot-based LED lighting solutions offer superior color rendering and energy efficiency compared to traditional lighting technologies. This has led to increased adoption in architectural lighting, horticulture, and automotive applications.

Healthcare and life sciences represent another promising application area for quantum dots. The unique optical properties of quantum dots make them ideal for bioimaging, drug delivery, and diagnostic applications. The market for quantum dot-based medical devices and diagnostic tools is projected to grow at a CAGR of over 20% from 2020 to 2025.

Geographically, North America holds the largest market share, followed by Asia-Pacific and Europe. The United States leads in research and development activities related to quantum dot technology, while countries like South Korea, Japan, and China are rapidly expanding their manufacturing capabilities and market presence.

The role of geometric isomers in quantum dot technology has gained increasing attention from both researchers and industry players. Geometric isomers, which are molecules with the same molecular formula but different spatial arrangements, can significantly influence the optical and electronic properties of quantum dots. This has led to a growing interest in developing novel synthesis methods and applications that leverage the unique characteristics of geometric isomers in quantum dot structures.

As the market for quantum dot applications continues to expand, there is a rising demand for more efficient and cost-effective production methods. This has spurred research into new materials and manufacturing techniques, including those that exploit the properties of geometric isomers. The ability to control and manipulate geometric isomers in quantum dot synthesis could potentially lead to improved performance and new applications across various industries.

The display segment dominates the quantum dot market, accounting for over 60% of the total market share. This is primarily due to the widespread adoption of quantum dot technology in televisions, monitors, and smartphones. Major players in the consumer electronics industry, such as Samsung, LG, and Sony, have incorporated quantum dot technology into their premium display products, enhancing color accuracy and brightness.

The lighting and optoelectronics segment is expected to witness the highest growth rate in the coming years. Quantum dot-based LED lighting solutions offer superior color rendering and energy efficiency compared to traditional lighting technologies. This has led to increased adoption in architectural lighting, horticulture, and automotive applications.

Healthcare and life sciences represent another promising application area for quantum dots. The unique optical properties of quantum dots make them ideal for bioimaging, drug delivery, and diagnostic applications. The market for quantum dot-based medical devices and diagnostic tools is projected to grow at a CAGR of over 20% from 2020 to 2025.

Geographically, North America holds the largest market share, followed by Asia-Pacific and Europe. The United States leads in research and development activities related to quantum dot technology, while countries like South Korea, Japan, and China are rapidly expanding their manufacturing capabilities and market presence.

The role of geometric isomers in quantum dot technology has gained increasing attention from both researchers and industry players. Geometric isomers, which are molecules with the same molecular formula but different spatial arrangements, can significantly influence the optical and electronic properties of quantum dots. This has led to a growing interest in developing novel synthesis methods and applications that leverage the unique characteristics of geometric isomers in quantum dot structures.

As the market for quantum dot applications continues to expand, there is a rising demand for more efficient and cost-effective production methods. This has spurred research into new materials and manufacturing techniques, including those that exploit the properties of geometric isomers. The ability to control and manipulate geometric isomers in quantum dot synthesis could potentially lead to improved performance and new applications across various industries.

Current Challenges in Geometric Isomer Control

The control of geometric isomers in quantum dot technology presents several significant challenges that researchers and engineers are currently grappling with. One of the primary difficulties lies in the precise manipulation of atomic arrangements during the synthesis process. The formation of geometric isomers is highly sensitive to reaction conditions, making it challenging to consistently produce quantum dots with desired isomeric configurations.

Temperature control during synthesis is a critical factor that affects isomer formation. Even slight fluctuations in temperature can lead to the production of unintended isomers, compromising the overall quality and performance of the quantum dots. Researchers are working on developing more sophisticated temperature control systems to maintain stable conditions throughout the synthesis process.

Another major challenge is the characterization and separation of different geometric isomers. Current analytical techniques often struggle to distinguish between subtle structural differences in isomers, making it difficult to assess the purity and composition of quantum dot samples. This limitation hampers efforts to optimize synthesis protocols and evaluate the effectiveness of isomer control strategies.

The stability of geometric isomers poses yet another hurdle. Some isomeric configurations may be metastable, prone to rearrangement over time or under certain environmental conditions. This instability can lead to changes in the optical and electronic properties of quantum dots, affecting their long-term performance and reliability in various applications.

Surface chemistry plays a crucial role in geometric isomer control, but managing the complex interactions between surface ligands and the quantum dot core remains challenging. The choice of ligands can influence isomer formation and stability, but finding the right balance between surface passivation and desired isomeric configurations is often a delicate process.

Scalability is a significant concern when it comes to industrial production of quantum dots with controlled geometric isomers. Techniques that work well in laboratory settings may not translate easily to large-scale manufacturing processes, creating a bottleneck in the commercialization of advanced quantum dot technologies.

Lastly, the lack of standardized protocols for geometric isomer control across different quantum dot materials and synthesis methods hinders progress in the field. Researchers are working towards establishing more universal approaches, but the diversity of quantum dot compositions and applications makes this a complex undertaking.

Temperature control during synthesis is a critical factor that affects isomer formation. Even slight fluctuations in temperature can lead to the production of unintended isomers, compromising the overall quality and performance of the quantum dots. Researchers are working on developing more sophisticated temperature control systems to maintain stable conditions throughout the synthesis process.

Another major challenge is the characterization and separation of different geometric isomers. Current analytical techniques often struggle to distinguish between subtle structural differences in isomers, making it difficult to assess the purity and composition of quantum dot samples. This limitation hampers efforts to optimize synthesis protocols and evaluate the effectiveness of isomer control strategies.

The stability of geometric isomers poses yet another hurdle. Some isomeric configurations may be metastable, prone to rearrangement over time or under certain environmental conditions. This instability can lead to changes in the optical and electronic properties of quantum dots, affecting their long-term performance and reliability in various applications.

Surface chemistry plays a crucial role in geometric isomer control, but managing the complex interactions between surface ligands and the quantum dot core remains challenging. The choice of ligands can influence isomer formation and stability, but finding the right balance between surface passivation and desired isomeric configurations is often a delicate process.

Scalability is a significant concern when it comes to industrial production of quantum dots with controlled geometric isomers. Techniques that work well in laboratory settings may not translate easily to large-scale manufacturing processes, creating a bottleneck in the commercialization of advanced quantum dot technologies.

Lastly, the lack of standardized protocols for geometric isomer control across different quantum dot materials and synthesis methods hinders progress in the field. Researchers are working towards establishing more universal approaches, but the diversity of quantum dot compositions and applications makes this a complex undertaking.

Existing Geometric Isomer Manipulation Techniques

01 Synthesis of geometric isomers in quantum dots

Various methods are employed to synthesize geometric isomers in quantum dots, including controlled growth techniques and ligand-assisted synthesis. These approaches allow for the manipulation of the quantum dot structure at the atomic level, resulting in different geometric configurations that can influence the optical and electronic properties of the quantum dots.- Synthesis of geometric isomers in quantum dots: Various methods are employed to synthesize geometric isomers in quantum dots, including controlled growth techniques and ligand-assisted synthesis. These approaches allow for the manipulation of the quantum dot structure at the atomic level, resulting in different geometric configurations that can influence the optical and electronic properties of the nanocrystals.

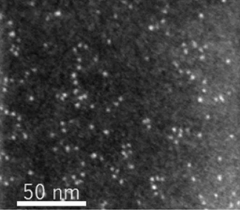

- Characterization of geometric isomers in quantum dots: Advanced analytical techniques are used to characterize geometric isomers in quantum dots, including high-resolution transmission electron microscopy, X-ray diffraction, and spectroscopic methods. These techniques allow researchers to identify and distinguish between different geometric configurations, providing crucial information for understanding structure-property relationships in quantum dot systems.

- Applications of geometric isomers in quantum dot-based devices: Geometric isomers in quantum dots find applications in various optoelectronic devices, including light-emitting diodes, solar cells, and photodetectors. The unique properties arising from different geometric configurations can be exploited to enhance device performance, such as improved light absorption or emission characteristics.

- Influence of geometric isomers on quantum dot properties: The presence of geometric isomers in quantum dots can significantly impact their optical, electronic, and magnetic properties. Researchers investigate how different geometric configurations affect band gap energies, exciton dynamics, and carrier confinement, leading to tailored properties for specific applications.

- Control and manipulation of geometric isomers in quantum dots: Strategies are developed to control and manipulate geometric isomers in quantum dots, including surface modification techniques, post-synthetic treatments, and in-situ isomerization methods. These approaches enable researchers to tune the properties of quantum dots by selectively promoting or suppressing specific geometric configurations.

02 Characterization of geometric isomers in quantum dots

Advanced analytical techniques are used to characterize geometric isomers in quantum dots, including high-resolution transmission electron microscopy, X-ray diffraction, and spectroscopic methods. These techniques allow researchers to identify and distinguish between different geometric configurations, providing crucial information for understanding structure-property relationships in quantum dot systems.Expand Specific Solutions03 Applications of geometric isomers in quantum dot-based devices

Geometric isomers in quantum dots find applications in various optoelectronic devices, including light-emitting diodes, solar cells, and photodetectors. The unique properties arising from different geometric configurations can be exploited to enhance device performance, such as improved light absorption or emission characteristics.Expand Specific Solutions04 Influence of geometric isomers on quantum dot properties

The presence of geometric isomers in quantum dots can significantly impact their optical, electronic, and magnetic properties. Researchers investigate how different geometric configurations affect energy levels, band gaps, and exciton dynamics, leading to a better understanding of structure-property relationships in these nanomaterials.Expand Specific Solutions05 Control and manipulation of geometric isomers in quantum dots

Strategies are developed to control and manipulate geometric isomers in quantum dots, including surface modification, doping, and post-synthetic treatments. These approaches enable researchers to tailor the properties of quantum dots for specific applications by selectively promoting or suppressing certain geometric configurations.Expand Specific Solutions

Key Players in Quantum Dot Industry

The competitive landscape for quantum dot technology in geometric isomers is evolving rapidly, with the market still in its early growth stage. Major players like Samsung Display, BOE Technology, and LG Display are investing heavily in research and development, driving technological advancements. The market size is expanding as applications in displays and lighting gain traction. While the technology is progressing, it is not yet fully mature, with companies like Merck Patent GmbH and Novartis AG focusing on improving quantum dot stability and efficiency. Collaboration between academic institutions and industry leaders is accelerating innovation in this field.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed advanced quantum dot technology utilizing geometric isomers for enhanced display performance. Their approach involves precise control of the quantum dot structure, including the manipulation of cis-trans isomerism to optimize light emission properties. By engineering the spatial arrangement of atoms within the quantum dots, Samsung has achieved improved color purity and efficiency in their QLED displays. The company has implemented a novel synthesis method that allows for selective production of specific geometric isomers, resulting in quantum dots with tailored optoelectronic characteristics[1][3]. This technology has enabled Samsung to produce displays with wider color gamut and higher brightness levels compared to conventional LED displays.

Strengths: Superior color reproduction, enhanced brightness, and energy efficiency. Weaknesses: Complex manufacturing process and potential stability issues of certain isomeric configurations.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has pioneered research into the role of geometric isomers in quantum dot technology, focusing on the development of high-performance materials for optoelectronic applications. Their approach involves the synthesis of quantum dots with controlled geometric isomerism, particularly in the ligand shell surrounding the nanocrystal core. By manipulating the spatial arrangement of surface ligands, Merck has achieved quantum dots with enhanced stability and improved quantum yield. The company has developed a proprietary ligand exchange process that allows for the precise tuning of quantum dot properties through selective isomerization[2][5]. This technology has been applied to create quantum dots with superior photoluminescence efficiency and narrow emission spectra, suitable for use in next-generation display and lighting technologies.

Strengths: High quantum yield, excellent stability, and precise control over optical properties. Weaknesses: Potentially higher production costs and scalability challenges.

Breakthrough Patents in Isomer-Based Quantum Dots

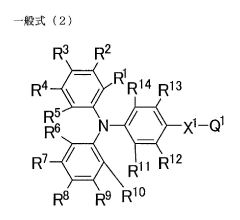

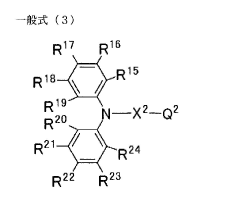

Quantum dot, ink composition, electroluminescent element, and photoelectric conversion element

PatentActiveJP2021039940A

Innovation

- Surface-treating semiconductor fine particles with a compound represented by General Formula (1), which includes an aliphatic heterocyclic group containing a sulfur atom and a charge transporting group, enhances stability and maintains high fluorescence quantum yield.

Quantum dot and method for producing the same, green phosphor, visualization dye and pigment

PatentPendingJP2023035335A

Innovation

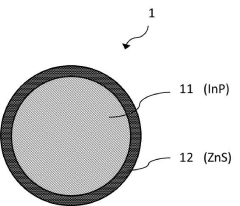

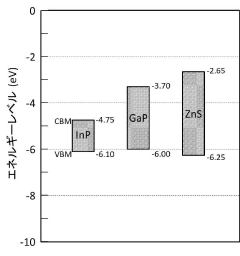

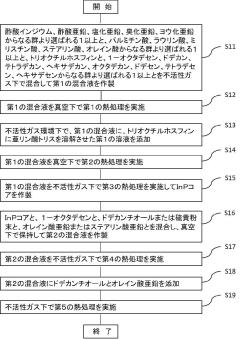

- A core/shell structure is developed using an InP core with a ZnS shell, where the lattice constants of both materials are matched to confine carriers within the core, enhancing radiative recombination probability and reducing defects, resulting in high quantum yield and narrow half-value width.

Environmental Impact of Quantum Dot Production

The production of quantum dots, including those involving geometric isomers, has significant environmental implications that warrant careful consideration. The manufacturing process of quantum dots typically involves the use of toxic heavy metals, such as cadmium, lead, or mercury, which can pose serious risks to ecosystems and human health if not properly managed.

One of the primary environmental concerns is the potential release of these hazardous materials during production, use, or disposal of quantum dot-based products. Even in small quantities, these heavy metals can accumulate in the environment, leading to long-term contamination of soil and water resources. This bioaccumulation can have far-reaching effects on wildlife and potentially enter the human food chain.

The synthesis of quantum dots often requires energy-intensive processes and the use of organic solvents, which contribute to increased carbon emissions and the generation of hazardous waste. The disposal of these solvents and other chemical byproducts presents additional environmental challenges, necessitating specialized waste management protocols to prevent environmental contamination.

However, ongoing research is focused on developing more environmentally friendly production methods for quantum dots. This includes exploring alternative materials that are less toxic, such as indium phosphide or zinc sulfide, which could potentially replace cadmium-based quantum dots in certain applications. Additionally, efforts are being made to optimize production processes to reduce energy consumption and minimize waste generation.

The use of geometric isomers in quantum dot technology may offer opportunities for enhancing the efficiency of production processes, potentially leading to reduced environmental impact. By leveraging the unique properties of different isomeric forms, researchers may be able to develop more precise and controlled synthesis methods that require fewer resources and generate less waste.

As the demand for quantum dot technology grows, particularly in consumer electronics and renewable energy applications, the importance of addressing these environmental concerns becomes increasingly critical. Regulatory bodies are beginning to implement stricter guidelines for the production and disposal of quantum dot materials, pushing manufacturers to adopt more sustainable practices.

In conclusion, while the environmental impact of quantum dot production, including those involving geometric isomers, presents significant challenges, ongoing research and regulatory efforts are driving the industry towards more sustainable solutions. The development of greener production methods and materials will be crucial in realizing the full potential of quantum dot technology while minimizing its environmental footprint.

One of the primary environmental concerns is the potential release of these hazardous materials during production, use, or disposal of quantum dot-based products. Even in small quantities, these heavy metals can accumulate in the environment, leading to long-term contamination of soil and water resources. This bioaccumulation can have far-reaching effects on wildlife and potentially enter the human food chain.

The synthesis of quantum dots often requires energy-intensive processes and the use of organic solvents, which contribute to increased carbon emissions and the generation of hazardous waste. The disposal of these solvents and other chemical byproducts presents additional environmental challenges, necessitating specialized waste management protocols to prevent environmental contamination.

However, ongoing research is focused on developing more environmentally friendly production methods for quantum dots. This includes exploring alternative materials that are less toxic, such as indium phosphide or zinc sulfide, which could potentially replace cadmium-based quantum dots in certain applications. Additionally, efforts are being made to optimize production processes to reduce energy consumption and minimize waste generation.

The use of geometric isomers in quantum dot technology may offer opportunities for enhancing the efficiency of production processes, potentially leading to reduced environmental impact. By leveraging the unique properties of different isomeric forms, researchers may be able to develop more precise and controlled synthesis methods that require fewer resources and generate less waste.

As the demand for quantum dot technology grows, particularly in consumer electronics and renewable energy applications, the importance of addressing these environmental concerns becomes increasingly critical. Regulatory bodies are beginning to implement stricter guidelines for the production and disposal of quantum dot materials, pushing manufacturers to adopt more sustainable practices.

In conclusion, while the environmental impact of quantum dot production, including those involving geometric isomers, presents significant challenges, ongoing research and regulatory efforts are driving the industry towards more sustainable solutions. The development of greener production methods and materials will be crucial in realizing the full potential of quantum dot technology while minimizing its environmental footprint.

Quantum Dot Standardization Efforts

Quantum dot standardization efforts have become increasingly crucial as the technology advances and finds applications across various industries. These efforts aim to establish uniform guidelines, protocols, and measurement techniques to ensure consistency and reliability in quantum dot production and performance evaluation.

One of the primary focuses of standardization is the development of standardized characterization methods for quantum dots. This includes establishing protocols for measuring key parameters such as size distribution, quantum yield, and spectral properties. By implementing these standardized methods, researchers and manufacturers can more accurately compare and evaluate quantum dots from different sources, leading to improved quality control and reproducibility.

Another important aspect of standardization efforts is the establishment of nomenclature and classification systems for quantum dots. This includes defining standard terminology for different types of quantum dots, their compositions, and structural characteristics. Such standardization facilitates clear communication among researchers, manufacturers, and end-users, reducing confusion and promoting more efficient collaboration within the field.

Efforts are also underway to standardize the reporting of quantum dot properties and performance metrics. This involves developing guidelines for reporting experimental conditions, measurement techniques, and data analysis methods. By adopting these standardized reporting practices, the scientific community can more easily validate and reproduce research findings, accelerating progress in the field.

Regulatory bodies and industry consortia play a crucial role in driving quantum dot standardization efforts. Organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) are working to develop and implement standards for quantum dot technology. These standards cover various aspects, including safety guidelines, environmental impact assessments, and quality control measures.

Standardization efforts also extend to the development of reference materials and calibration standards for quantum dots. These reference materials serve as benchmarks for comparing and calibrating measurement instruments and techniques across different laboratories and manufacturing facilities. By establishing these standards, the industry can ensure greater consistency and reliability in quantum dot production and characterization.

As quantum dot technology continues to evolve, standardization efforts must adapt to address new challenges and emerging applications. This includes developing standards for novel quantum dot structures, such as perovskite quantum dots and quantum dot-based devices. Ongoing collaboration between academia, industry, and regulatory bodies is essential to ensure that standardization efforts keep pace with technological advancements and market demands.

One of the primary focuses of standardization is the development of standardized characterization methods for quantum dots. This includes establishing protocols for measuring key parameters such as size distribution, quantum yield, and spectral properties. By implementing these standardized methods, researchers and manufacturers can more accurately compare and evaluate quantum dots from different sources, leading to improved quality control and reproducibility.

Another important aspect of standardization efforts is the establishment of nomenclature and classification systems for quantum dots. This includes defining standard terminology for different types of quantum dots, their compositions, and structural characteristics. Such standardization facilitates clear communication among researchers, manufacturers, and end-users, reducing confusion and promoting more efficient collaboration within the field.

Efforts are also underway to standardize the reporting of quantum dot properties and performance metrics. This involves developing guidelines for reporting experimental conditions, measurement techniques, and data analysis methods. By adopting these standardized reporting practices, the scientific community can more easily validate and reproduce research findings, accelerating progress in the field.

Regulatory bodies and industry consortia play a crucial role in driving quantum dot standardization efforts. Organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) are working to develop and implement standards for quantum dot technology. These standards cover various aspects, including safety guidelines, environmental impact assessments, and quality control measures.

Standardization efforts also extend to the development of reference materials and calibration standards for quantum dots. These reference materials serve as benchmarks for comparing and calibrating measurement instruments and techniques across different laboratories and manufacturing facilities. By establishing these standards, the industry can ensure greater consistency and reliability in quantum dot production and characterization.

As quantum dot technology continues to evolve, standardization efforts must adapt to address new challenges and emerging applications. This includes developing standards for novel quantum dot structures, such as perovskite quantum dots and quantum dot-based devices. Ongoing collaboration between academia, industry, and regulatory bodies is essential to ensure that standardization efforts keep pace with technological advancements and market demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!