Role of Geometric Isomers in the Synthesis of Advanced Materials

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geometric Isomers in Advanced Materials: Background and Objectives

Geometric isomers have played a pivotal role in the evolution of advanced materials synthesis over the past decades. These molecular structures, characterized by the same chemical formula but different spatial arrangements of atoms, have opened up new avenues for material design and functionality. The field of advanced materials has seen a significant shift towards harnessing the unique properties of geometric isomers to create materials with enhanced performance and novel applications.

The historical development of geometric isomers in materials science can be traced back to the mid-20th century when researchers began to recognize the importance of molecular structure in determining material properties. As analytical techniques improved, scientists gained a deeper understanding of how subtle changes in molecular geometry could lead to dramatic differences in material behavior. This realization sparked a surge of interest in exploring the potential of geometric isomers for advanced materials synthesis.

In recent years, the field has witnessed exponential growth, driven by advancements in synthetic chemistry, computational modeling, and characterization techniques. Researchers have successfully leveraged geometric isomerism to fine-tune material properties such as optical activity, conductivity, and reactivity. This has led to breakthroughs in areas like organic electronics, photovoltaics, and drug delivery systems.

The primary objective of this technical research report is to provide a comprehensive overview of the current state of geometric isomers in advanced materials synthesis. We aim to explore the fundamental principles governing the behavior of geometric isomers, their impact on material properties, and the latest methodologies for their controlled synthesis and incorporation into advanced materials.

Furthermore, this report seeks to identify emerging trends and potential future directions in the field. By analyzing recent publications, patent filings, and industry developments, we will highlight promising areas for further research and development. This includes exploring novel applications of geometric isomers in fields such as nanotechnology, biomaterials, and energy storage.

Additionally, we will assess the challenges and limitations currently faced by researchers and industry professionals working with geometric isomers in advanced materials. This analysis will encompass technical hurdles, scalability issues, and regulatory considerations that may impact the widespread adoption of these materials in commercial applications.

By providing this comprehensive overview, we aim to equip our organization with the knowledge and insights necessary to make informed decisions regarding future research directions and potential investment opportunities in the field of geometric isomers for advanced materials synthesis.

The historical development of geometric isomers in materials science can be traced back to the mid-20th century when researchers began to recognize the importance of molecular structure in determining material properties. As analytical techniques improved, scientists gained a deeper understanding of how subtle changes in molecular geometry could lead to dramatic differences in material behavior. This realization sparked a surge of interest in exploring the potential of geometric isomers for advanced materials synthesis.

In recent years, the field has witnessed exponential growth, driven by advancements in synthetic chemistry, computational modeling, and characterization techniques. Researchers have successfully leveraged geometric isomerism to fine-tune material properties such as optical activity, conductivity, and reactivity. This has led to breakthroughs in areas like organic electronics, photovoltaics, and drug delivery systems.

The primary objective of this technical research report is to provide a comprehensive overview of the current state of geometric isomers in advanced materials synthesis. We aim to explore the fundamental principles governing the behavior of geometric isomers, their impact on material properties, and the latest methodologies for their controlled synthesis and incorporation into advanced materials.

Furthermore, this report seeks to identify emerging trends and potential future directions in the field. By analyzing recent publications, patent filings, and industry developments, we will highlight promising areas for further research and development. This includes exploring novel applications of geometric isomers in fields such as nanotechnology, biomaterials, and energy storage.

Additionally, we will assess the challenges and limitations currently faced by researchers and industry professionals working with geometric isomers in advanced materials. This analysis will encompass technical hurdles, scalability issues, and regulatory considerations that may impact the widespread adoption of these materials in commercial applications.

By providing this comprehensive overview, we aim to equip our organization with the knowledge and insights necessary to make informed decisions regarding future research directions and potential investment opportunities in the field of geometric isomers for advanced materials synthesis.

Market Analysis for Isomer-Based Advanced Materials

The market for advanced materials based on geometric isomers is experiencing significant growth and diversification across multiple industries. This trend is driven by the unique properties that geometric isomers impart to materials, enabling enhanced performance and novel functionalities. The automotive sector is a key market, with isomer-based materials finding applications in lightweight components, high-strength alloys, and advanced coatings. These materials contribute to improved fuel efficiency and vehicle safety, aligning with stringent regulatory requirements and consumer demands for eco-friendly transportation solutions.

In the electronics industry, isomer-based advanced materials are revolutionizing the development of next-generation devices. The market for flexible displays, wearable technology, and high-performance semiconductors is particularly robust, with geometric isomers playing a crucial role in creating materials with precise electronic and optical properties. This segment is expected to see substantial growth as consumer electronics continue to evolve towards more compact, efficient, and versatile designs.

The healthcare and pharmaceutical sectors represent another significant market for isomer-based materials. The ability to control molecular structure through geometric isomerism is invaluable in drug development, enabling the creation of more effective and targeted therapeutics. Additionally, biocompatible materials derived from specific isomeric configurations are finding increased use in medical devices and tissue engineering applications, driving market expansion in the biomedical field.

Aerospace and defense industries are also key consumers of isomer-based advanced materials. The demand for lightweight, high-strength materials capable of withstanding extreme conditions is fueling research and development in this area. Geometric isomers are instrumental in creating composites and alloys that meet the rigorous performance standards required for aerospace applications, from aircraft structures to satellite components.

The construction sector is emerging as a growing market for isomer-based materials, particularly in the development of smart building materials and energy-efficient solutions. Materials with specific isomeric structures are being utilized to create self-healing concrete, advanced insulation, and solar-responsive surfaces, contributing to sustainable and resilient infrastructure development.

As environmental concerns continue to shape market dynamics, there is an increasing focus on sustainable and bio-based materials. This trend is creating new opportunities for isomer-based materials derived from renewable sources, expanding the market into green chemistry and eco-friendly product development across various industries.

In the electronics industry, isomer-based advanced materials are revolutionizing the development of next-generation devices. The market for flexible displays, wearable technology, and high-performance semiconductors is particularly robust, with geometric isomers playing a crucial role in creating materials with precise electronic and optical properties. This segment is expected to see substantial growth as consumer electronics continue to evolve towards more compact, efficient, and versatile designs.

The healthcare and pharmaceutical sectors represent another significant market for isomer-based materials. The ability to control molecular structure through geometric isomerism is invaluable in drug development, enabling the creation of more effective and targeted therapeutics. Additionally, biocompatible materials derived from specific isomeric configurations are finding increased use in medical devices and tissue engineering applications, driving market expansion in the biomedical field.

Aerospace and defense industries are also key consumers of isomer-based advanced materials. The demand for lightweight, high-strength materials capable of withstanding extreme conditions is fueling research and development in this area. Geometric isomers are instrumental in creating composites and alloys that meet the rigorous performance standards required for aerospace applications, from aircraft structures to satellite components.

The construction sector is emerging as a growing market for isomer-based materials, particularly in the development of smart building materials and energy-efficient solutions. Materials with specific isomeric structures are being utilized to create self-healing concrete, advanced insulation, and solar-responsive surfaces, contributing to sustainable and resilient infrastructure development.

As environmental concerns continue to shape market dynamics, there is an increasing focus on sustainable and bio-based materials. This trend is creating new opportunities for isomer-based materials derived from renewable sources, expanding the market into green chemistry and eco-friendly product development across various industries.

Current Challenges in Geometric Isomer Synthesis

The synthesis of geometric isomers presents several significant challenges in the field of advanced materials. One of the primary obstacles is achieving precise control over the stereochemistry during the synthesis process. This is particularly crucial when dealing with complex molecular structures, as even slight variations in spatial arrangement can lead to drastically different properties in the final material.

Another major challenge lies in the scalability of geometric isomer synthesis. While laboratory-scale production may yield satisfactory results, translating these processes to industrial-scale manufacturing often proves problematic. Issues such as maintaining reaction conditions, ensuring consistent product quality, and managing cost-effectiveness become increasingly difficult as production volumes increase.

The purification and separation of geometric isomers pose additional hurdles. In many cases, the physical and chemical properties of different isomers are remarkably similar, making traditional separation techniques ineffective or economically unfeasible. This challenge is compounded when dealing with mixtures of multiple isomers, requiring the development of sophisticated separation methodologies.

Characterization of geometric isomers also presents significant difficulties. Advanced analytical techniques are often necessary to accurately determine the structure and purity of synthesized isomers. This requirement for specialized equipment and expertise can be a limiting factor in research and development efforts, particularly for smaller organizations or in resource-constrained environments.

The stability of geometric isomers under various conditions is another area of concern. Many isomers are susceptible to interconversion or degradation when exposed to heat, light, or certain chemical environments. This instability can lead to challenges in storage, handling, and application of the synthesized materials, necessitating the development of stabilization strategies or alternative formulations.

Furthermore, the environmental impact of geometric isomer synthesis is an increasingly important consideration. Many traditional synthetic routes involve the use of toxic reagents or generate significant waste streams. Developing greener, more sustainable synthesis methods that maintain the desired stereochemical control is a pressing challenge in the field.

Lastly, the regulatory landscape surrounding the synthesis and use of geometric isomers, particularly in sensitive applications such as pharmaceuticals or food additives, presents additional complexities. Ensuring compliance with evolving regulatory standards while maintaining efficient and cost-effective production processes is an ongoing challenge for researchers and manufacturers alike.

Another major challenge lies in the scalability of geometric isomer synthesis. While laboratory-scale production may yield satisfactory results, translating these processes to industrial-scale manufacturing often proves problematic. Issues such as maintaining reaction conditions, ensuring consistent product quality, and managing cost-effectiveness become increasingly difficult as production volumes increase.

The purification and separation of geometric isomers pose additional hurdles. In many cases, the physical and chemical properties of different isomers are remarkably similar, making traditional separation techniques ineffective or economically unfeasible. This challenge is compounded when dealing with mixtures of multiple isomers, requiring the development of sophisticated separation methodologies.

Characterization of geometric isomers also presents significant difficulties. Advanced analytical techniques are often necessary to accurately determine the structure and purity of synthesized isomers. This requirement for specialized equipment and expertise can be a limiting factor in research and development efforts, particularly for smaller organizations or in resource-constrained environments.

The stability of geometric isomers under various conditions is another area of concern. Many isomers are susceptible to interconversion or degradation when exposed to heat, light, or certain chemical environments. This instability can lead to challenges in storage, handling, and application of the synthesized materials, necessitating the development of stabilization strategies or alternative formulations.

Furthermore, the environmental impact of geometric isomer synthesis is an increasingly important consideration. Many traditional synthetic routes involve the use of toxic reagents or generate significant waste streams. Developing greener, more sustainable synthesis methods that maintain the desired stereochemical control is a pressing challenge in the field.

Lastly, the regulatory landscape surrounding the synthesis and use of geometric isomers, particularly in sensitive applications such as pharmaceuticals or food additives, presents additional complexities. Ensuring compliance with evolving regulatory standards while maintaining efficient and cost-effective production processes is an ongoing challenge for researchers and manufacturers alike.

Current Methodologies for Geometric Isomer Synthesis

01 Synthesis and separation of geometric isomers

Methods for synthesizing and separating geometric isomers, including techniques for controlling the formation of specific isomers during chemical reactions and purification processes to isolate desired isomers from mixtures.- Synthesis and separation of geometric isomers: Methods for synthesizing and separating geometric isomers are crucial in organic chemistry. These techniques involve various reaction conditions, catalysts, and purification processes to obtain specific isomers. Separation methods may include chromatography, crystallization, or selective complexation.

- Geometric isomers in pharmaceutical compounds: Geometric isomerism plays a significant role in pharmaceutical compounds, affecting their biological activity and efficacy. Research focuses on identifying and isolating specific isomers with desired therapeutic properties, as well as studying their metabolism and interactions within the body.

- Analytical methods for geometric isomers: Advanced analytical techniques are employed to identify, characterize, and quantify geometric isomers. These methods include spectroscopic techniques such as NMR and IR spectroscopy, as well as chromatographic methods like HPLC and GC. Computational modeling is also used to predict and analyze isomeric structures.

- Geometric isomers in materials science: The study of geometric isomers extends to materials science, where isomeric structures can influence the properties of polymers, liquid crystals, and other advanced materials. Research in this area focuses on controlling isomerization to achieve desired material characteristics and functionalities.

- Computational modeling of geometric isomers: Computational methods are increasingly used to study geometric isomers, predicting their structures, properties, and behavior. These techniques involve quantum mechanical calculations, molecular dynamics simulations, and machine learning approaches to understand isomeric systems and guide experimental research.

02 Characterization and analysis of geometric isomers

Techniques for identifying and analyzing geometric isomers, including spectroscopic methods, chromatography, and computational modeling to determine molecular structures and properties of different isomeric forms.Expand Specific Solutions03 Applications of geometric isomers in pharmaceuticals

Utilization of geometric isomers in drug development and pharmaceutical formulations, focusing on the different biological activities and therapeutic effects of various isomeric forms of active compounds.Expand Specific Solutions04 Geometric isomers in materials science and engineering

Exploration of geometric isomers in the development of advanced materials, including polymers, liquid crystals, and nanomaterials, with a focus on how isomeric structures influence material properties and performance.Expand Specific Solutions05 Computational methods for studying geometric isomers

Development and application of computational techniques for modeling, predicting, and visualizing geometric isomers, including molecular dynamics simulations and quantum chemical calculations to understand isomeric behavior and properties.Expand Specific Solutions

Key Players in Geometric Isomer Research and Application

The role of geometric isomers in advanced materials synthesis is an emerging field with significant potential for growth. The market is in its early stages, characterized by rapid technological advancements and increasing research investments. While the market size is still relatively small, it is expected to expand as applications in various industries, such as pharmaceuticals, electronics, and materials science, become more prevalent. The technology is progressing towards maturity, with companies like Schlumberger Technology BV, BASF Corp., and Mitsui Chemicals, Inc. leading the way in research and development. These firms are leveraging their expertise in chemical engineering and materials science to explore novel applications of geometric isomers in creating advanced materials with unique properties and functionalities.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced synthesis methods for geometric isomers in material science. They utilize stereoselective catalysis to control the formation of specific isomers, resulting in materials with enhanced properties[1]. Their approach involves the use of chiral ligands and metal complexes to direct the synthesis towards desired geometric configurations. This allows for the production of materials with improved thermal stability, optical properties, and mechanical strength[3]. BASF has also implemented computational modeling to predict and optimize isomer distributions in polymer synthesis, leading to more efficient production processes and tailored material characteristics[5].

Strengths: Extensive expertise in catalysis and polymer science, large-scale production capabilities. Weaknesses: High research and development costs, potential environmental concerns with some catalytic processes.

Stmicroelectronics Srl

Technical Solution: Stmicroelectronics has explored the role of geometric isomers in the development of advanced semiconductor materials and devices. They have focused on controlling the spatial arrangement of atoms and molecules in thin-film deposition processes to optimize electronic properties[11]. Their research includes the synthesis of isomeric organic semiconductors for flexible electronics and the development of novel epitaxial growth techniques for III-V compound semiconductors. Stmicroelectronics has also investigated the impact of geometric isomerism on the performance of high-electron-mobility transistors (HEMTs) and light-emitting diodes (LEDs)[12].

Strengths: Extensive semiconductor manufacturing expertise, strong presence in the electronics industry. Weaknesses: High capital requirements for research and production facilities, intense competition in the semiconductor market.

Breakthrough Innovations in Isomer-Specific Synthesis

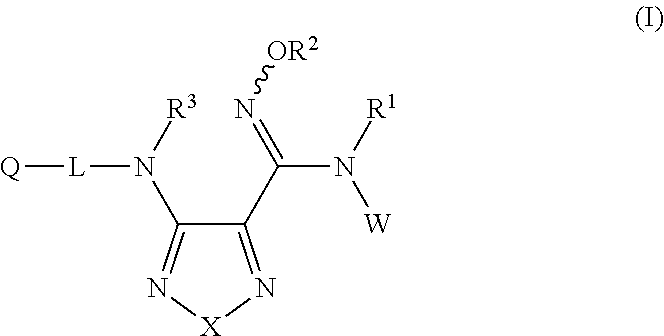

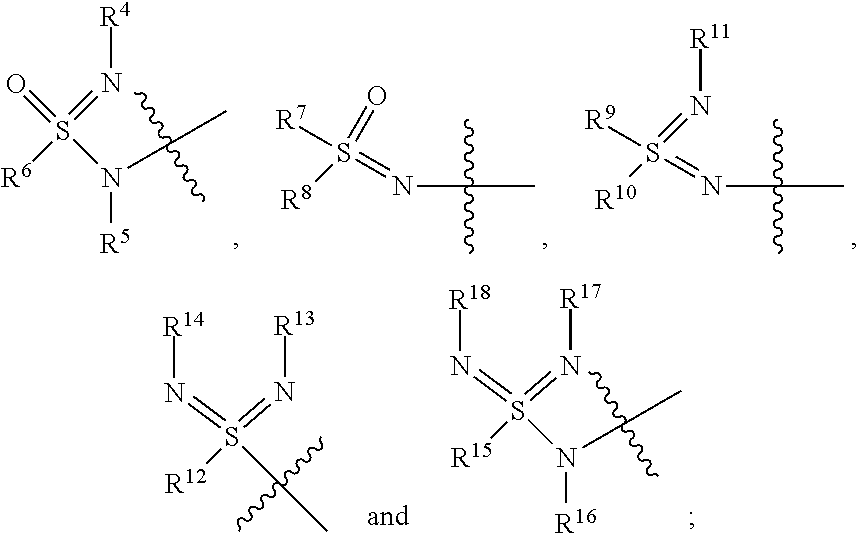

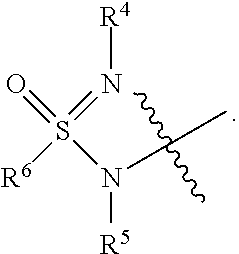

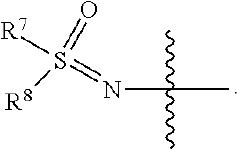

Sulfoximine, sulfonimidamide, sulfondiimine and diimidosulfonamide compounds as inhibitors of indoleamine 2,3-dioxygenase

PatentActiveUS20210070742A1

Innovation

- Development of novel sulfoximine, sulfonimidamide, and diimidosulfonamide compounds and their pharmaceutical compositions that inhibit indoleamine 2,3-dioxygenase (IDO) activity, offering enhanced properties over existing inhibitors.

Compounds and uses thereof

PatentPendingUS20230145003A1

Innovation

- Development of specific compounds that modulate the BAF complex by inhibiting BRG1 and/or BRM activity, which can be used alone or in combination with other pharmaceutically active agents to treat disorders like cancer.

Environmental Impact of Isomer Synthesis Processes

The synthesis of geometric isomers in advanced materials production has significant environmental implications that warrant careful consideration. Traditional isomer synthesis processes often involve the use of hazardous chemicals, high energy consumption, and the generation of substantial waste products. These factors contribute to environmental pollution, resource depletion, and potential health risks for workers and surrounding communities.

One of the primary environmental concerns is the use of toxic solvents and catalysts in isomer synthesis. Many conventional methods rely on organic solvents that are harmful to ecosystems and human health. The release of these substances into the environment can lead to soil and water contamination, affecting biodiversity and potentially entering the food chain. Additionally, the production and disposal of these chemicals contribute to air pollution and greenhouse gas emissions.

Energy-intensive processes are another critical environmental issue in isomer synthesis. High-temperature reactions and energy-demanding separation techniques often result in substantial carbon footprints. The reliance on fossil fuels for energy generation in these processes further exacerbates climate change concerns. As global efforts to reduce carbon emissions intensify, the environmental impact of isomer synthesis becomes increasingly scrutinized.

Waste management poses a significant challenge in isomer production. The generation of byproducts and unreacted materials necessitates complex purification steps, leading to increased waste streams. Improper disposal of these wastes can result in long-term environmental damage, including soil degradation and groundwater contamination. The accumulation of persistent organic pollutants from isomer synthesis waste is a growing concern for ecosystem health.

However, recent advancements in green chemistry and sustainable engineering are paving the way for more environmentally friendly isomer synthesis processes. The development of bio-based solvents, catalysts derived from renewable resources, and enzymatic synthesis routes offer promising alternatives with reduced environmental footprints. These innovations aim to minimize waste generation, lower energy requirements, and decrease the reliance on toxic substances.

Furthermore, the implementation of continuous flow chemistry in isomer synthesis has shown potential for improving process efficiency and reducing environmental impact. This approach allows for better control of reaction conditions, leading to higher yields and fewer side products. The reduced reactor volumes and improved heat transfer characteristics of continuous flow systems contribute to lower energy consumption and safer operating conditions.

As the demand for advanced materials continues to grow, addressing the environmental impact of isomer synthesis processes becomes increasingly crucial. Industry stakeholders and researchers must prioritize the development and adoption of sustainable practices to mitigate ecological harm while meeting the technological needs of various sectors. This shift towards environmentally conscious isomer synthesis aligns with global sustainability goals and regulatory trends, positioning it as a key focus area for future research and development in advanced materials production.

One of the primary environmental concerns is the use of toxic solvents and catalysts in isomer synthesis. Many conventional methods rely on organic solvents that are harmful to ecosystems and human health. The release of these substances into the environment can lead to soil and water contamination, affecting biodiversity and potentially entering the food chain. Additionally, the production and disposal of these chemicals contribute to air pollution and greenhouse gas emissions.

Energy-intensive processes are another critical environmental issue in isomer synthesis. High-temperature reactions and energy-demanding separation techniques often result in substantial carbon footprints. The reliance on fossil fuels for energy generation in these processes further exacerbates climate change concerns. As global efforts to reduce carbon emissions intensify, the environmental impact of isomer synthesis becomes increasingly scrutinized.

Waste management poses a significant challenge in isomer production. The generation of byproducts and unreacted materials necessitates complex purification steps, leading to increased waste streams. Improper disposal of these wastes can result in long-term environmental damage, including soil degradation and groundwater contamination. The accumulation of persistent organic pollutants from isomer synthesis waste is a growing concern for ecosystem health.

However, recent advancements in green chemistry and sustainable engineering are paving the way for more environmentally friendly isomer synthesis processes. The development of bio-based solvents, catalysts derived from renewable resources, and enzymatic synthesis routes offer promising alternatives with reduced environmental footprints. These innovations aim to minimize waste generation, lower energy requirements, and decrease the reliance on toxic substances.

Furthermore, the implementation of continuous flow chemistry in isomer synthesis has shown potential for improving process efficiency and reducing environmental impact. This approach allows for better control of reaction conditions, leading to higher yields and fewer side products. The reduced reactor volumes and improved heat transfer characteristics of continuous flow systems contribute to lower energy consumption and safer operating conditions.

As the demand for advanced materials continues to grow, addressing the environmental impact of isomer synthesis processes becomes increasingly crucial. Industry stakeholders and researchers must prioritize the development and adoption of sustainable practices to mitigate ecological harm while meeting the technological needs of various sectors. This shift towards environmentally conscious isomer synthesis aligns with global sustainability goals and regulatory trends, positioning it as a key focus area for future research and development in advanced materials production.

Intellectual Property Landscape in Geometric Isomer Technology

The intellectual property landscape in geometric isomer technology is characterized by a complex network of patents and proprietary innovations. Major players in the field have strategically positioned themselves through extensive patent portfolios, covering various aspects of geometric isomer synthesis, characterization, and application in advanced materials.

Key patent clusters focus on novel synthesis methods for specific geometric isomers, particularly those with potential in optoelectronic and pharmaceutical applications. These patents often detail innovative catalytic processes, stereoselective reactions, and purification techniques that enable precise control over isomer formation and isolation.

Another significant area of patent activity revolves around the incorporation of geometric isomers into advanced materials. This includes patents on polymer structures with controlled isomer ratios, self-assembling materials utilizing isomer-driven interactions, and responsive materials that leverage isomeric transformations for functional properties.

Analytical techniques for identifying and quantifying geometric isomers in complex mixtures have also seen substantial patent activity. These innovations range from advanced spectroscopic methods to high-throughput screening technologies, enabling rapid and accurate isomer profiling in various contexts.

The geographical distribution of patents reveals a concentration in countries with strong chemical and materials science industries, such as the United States, Japan, Germany, and increasingly, China. This reflects the global nature of research in this field and the strategic importance placed on geometric isomer technology by leading industrial nations.

Recent trends in patent filings indicate a growing interest in the application of geometric isomers in emerging fields such as nanotechnology, biomaterials, and energy storage. Patents in these areas often combine geometric isomer technology with other cutting-edge concepts, suggesting a trend towards interdisciplinary approaches in advanced materials development.

Notably, there has been an increase in patents related to computational methods for predicting and designing geometric isomer-based materials. These intellectual property assets cover algorithms, simulation techniques, and machine learning approaches that accelerate the discovery and optimization of new materials with tailored isomeric compositions.

The competitive landscape is marked by a mix of established chemical companies, specialized materials firms, and academic institutions. Cross-licensing agreements and collaborative patents are becoming more common, reflecting the complex nature of geometric isomer technology and the need for diverse expertise in developing commercial applications.

Key patent clusters focus on novel synthesis methods for specific geometric isomers, particularly those with potential in optoelectronic and pharmaceutical applications. These patents often detail innovative catalytic processes, stereoselective reactions, and purification techniques that enable precise control over isomer formation and isolation.

Another significant area of patent activity revolves around the incorporation of geometric isomers into advanced materials. This includes patents on polymer structures with controlled isomer ratios, self-assembling materials utilizing isomer-driven interactions, and responsive materials that leverage isomeric transformations for functional properties.

Analytical techniques for identifying and quantifying geometric isomers in complex mixtures have also seen substantial patent activity. These innovations range from advanced spectroscopic methods to high-throughput screening technologies, enabling rapid and accurate isomer profiling in various contexts.

The geographical distribution of patents reveals a concentration in countries with strong chemical and materials science industries, such as the United States, Japan, Germany, and increasingly, China. This reflects the global nature of research in this field and the strategic importance placed on geometric isomer technology by leading industrial nations.

Recent trends in patent filings indicate a growing interest in the application of geometric isomers in emerging fields such as nanotechnology, biomaterials, and energy storage. Patents in these areas often combine geometric isomer technology with other cutting-edge concepts, suggesting a trend towards interdisciplinary approaches in advanced materials development.

Notably, there has been an increase in patents related to computational methods for predicting and designing geometric isomer-based materials. These intellectual property assets cover algorithms, simulation techniques, and machine learning approaches that accelerate the discovery and optimization of new materials with tailored isomeric compositions.

The competitive landscape is marked by a mix of established chemical companies, specialized materials firms, and academic institutions. Cross-licensing agreements and collaborative patents are becoming more common, reflecting the complex nature of geometric isomer technology and the need for diverse expertise in developing commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!