Role of Solenoid Valves in Adapting to Renewable Energy Storage Systems

JUL 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valves in Renewable Energy: Background and Objectives

Solenoid valves have emerged as critical components in the rapidly evolving landscape of renewable energy storage systems. As the global push for sustainable energy solutions intensifies, these electromechanical devices play an increasingly vital role in managing and optimizing the flow of fluids and gases within various renewable energy applications. The integration of solenoid valves into these systems represents a significant technological advancement, bridging the gap between traditional fluid control mechanisms and the dynamic requirements of modern renewable energy storage.

The primary objective of incorporating solenoid valves into renewable energy storage systems is to enhance efficiency, reliability, and control precision. These valves offer rapid response times and accurate flow regulation, which are essential for managing the intermittent nature of renewable energy sources such as solar and wind power. By facilitating the seamless transition between energy generation, storage, and distribution phases, solenoid valves contribute to the overall stability and effectiveness of renewable energy systems.

The evolution of solenoid valve technology in the context of renewable energy storage can be traced back to the early 2000s when the renewable energy sector began to gain significant traction. Initially, these valves were adapted from existing industrial applications, but as the specific needs of renewable energy systems became apparent, specialized designs emerged. This technological progression has been driven by the increasing demand for more efficient and flexible energy storage solutions, particularly in grid-scale applications and decentralized energy systems.

Recent advancements in materials science and electronic control systems have further propelled the development of solenoid valves tailored for renewable energy storage. These innovations have resulted in valves with improved durability, reduced power consumption, and enhanced resistance to harsh environmental conditions often encountered in renewable energy installations. The integration of smart technologies and IoT capabilities has also enabled real-time monitoring and remote control of valve operations, contributing to more responsive and adaptive energy storage systems.

As we look towards the future, the role of solenoid valves in renewable energy storage is expected to expand significantly. The ongoing transition to a low-carbon economy and the increasing adoption of renewable energy sources worldwide are driving the need for more sophisticated and efficient storage solutions. Solenoid valves are poised to play a crucial part in addressing these challenges, facilitating the development of next-generation energy storage technologies such as advanced compressed air energy storage (CAES) systems, flow batteries, and hydrogen-based storage solutions.

The primary objective of incorporating solenoid valves into renewable energy storage systems is to enhance efficiency, reliability, and control precision. These valves offer rapid response times and accurate flow regulation, which are essential for managing the intermittent nature of renewable energy sources such as solar and wind power. By facilitating the seamless transition between energy generation, storage, and distribution phases, solenoid valves contribute to the overall stability and effectiveness of renewable energy systems.

The evolution of solenoid valve technology in the context of renewable energy storage can be traced back to the early 2000s when the renewable energy sector began to gain significant traction. Initially, these valves were adapted from existing industrial applications, but as the specific needs of renewable energy systems became apparent, specialized designs emerged. This technological progression has been driven by the increasing demand for more efficient and flexible energy storage solutions, particularly in grid-scale applications and decentralized energy systems.

Recent advancements in materials science and electronic control systems have further propelled the development of solenoid valves tailored for renewable energy storage. These innovations have resulted in valves with improved durability, reduced power consumption, and enhanced resistance to harsh environmental conditions often encountered in renewable energy installations. The integration of smart technologies and IoT capabilities has also enabled real-time monitoring and remote control of valve operations, contributing to more responsive and adaptive energy storage systems.

As we look towards the future, the role of solenoid valves in renewable energy storage is expected to expand significantly. The ongoing transition to a low-carbon economy and the increasing adoption of renewable energy sources worldwide are driving the need for more sophisticated and efficient storage solutions. Solenoid valves are poised to play a crucial part in addressing these challenges, facilitating the development of next-generation energy storage technologies such as advanced compressed air energy storage (CAES) systems, flow batteries, and hydrogen-based storage solutions.

Market Analysis for Solenoid Valves in Energy Storage

The market for solenoid valves in energy storage systems is experiencing significant growth, driven by the increasing adoption of renewable energy sources and the need for efficient energy management solutions. As renewable energy generation becomes more prevalent, the demand for advanced energy storage systems has surged, creating a robust market for solenoid valves that play a crucial role in these systems.

The global energy storage market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2030. This growth is primarily fueled by the integration of intermittent renewable energy sources like solar and wind into power grids, necessitating reliable storage solutions to balance supply and demand. Solenoid valves, as essential components in various energy storage technologies, are poised to benefit from this market expansion.

In the context of energy storage, solenoid valves find applications across multiple technologies, including compressed air energy storage (CAES), pumped hydro storage, and hydrogen storage systems. The versatility of solenoid valves in controlling fluid and gas flow makes them indispensable in these applications, contributing to their growing market demand.

The market for solenoid valves in energy storage is characterized by a diverse range of end-users, including utility companies, industrial facilities, and commercial buildings. Utility-scale energy storage projects, in particular, represent a significant market segment, as grid operators seek to enhance grid stability and integrate higher percentages of renewable energy.

Geographically, the market for solenoid valves in energy storage is witnessing strong growth in regions with ambitious renewable energy targets and supportive policies. North America and Europe are currently leading markets, with Asia-Pacific expected to show the fastest growth rate in the coming years, driven by rapid renewable energy adoption in countries like China and India.

The competitive landscape of the solenoid valve market for energy storage is characterized by a mix of established industrial valve manufacturers and specialized energy storage component suppliers. Key players are focusing on developing high-performance, durable valves capable of withstanding the demanding operational conditions of energy storage systems.

Market trends indicate a growing preference for smart solenoid valves equipped with sensors and connectivity features, enabling remote monitoring and predictive maintenance. This trend aligns with the broader Industry 4.0 movement and the increasing digitalization of energy infrastructure.

As the energy storage market continues to evolve, solenoid valve manufacturers are likely to face both opportunities and challenges. The need for customized solutions to meet specific energy storage technology requirements presents a significant opportunity for innovation and market differentiation. However, manufacturers must also contend with pricing pressures and the need for continuous technological advancements to remain competitive in this rapidly growing market.

The global energy storage market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2030. This growth is primarily fueled by the integration of intermittent renewable energy sources like solar and wind into power grids, necessitating reliable storage solutions to balance supply and demand. Solenoid valves, as essential components in various energy storage technologies, are poised to benefit from this market expansion.

In the context of energy storage, solenoid valves find applications across multiple technologies, including compressed air energy storage (CAES), pumped hydro storage, and hydrogen storage systems. The versatility of solenoid valves in controlling fluid and gas flow makes them indispensable in these applications, contributing to their growing market demand.

The market for solenoid valves in energy storage is characterized by a diverse range of end-users, including utility companies, industrial facilities, and commercial buildings. Utility-scale energy storage projects, in particular, represent a significant market segment, as grid operators seek to enhance grid stability and integrate higher percentages of renewable energy.

Geographically, the market for solenoid valves in energy storage is witnessing strong growth in regions with ambitious renewable energy targets and supportive policies. North America and Europe are currently leading markets, with Asia-Pacific expected to show the fastest growth rate in the coming years, driven by rapid renewable energy adoption in countries like China and India.

The competitive landscape of the solenoid valve market for energy storage is characterized by a mix of established industrial valve manufacturers and specialized energy storage component suppliers. Key players are focusing on developing high-performance, durable valves capable of withstanding the demanding operational conditions of energy storage systems.

Market trends indicate a growing preference for smart solenoid valves equipped with sensors and connectivity features, enabling remote monitoring and predictive maintenance. This trend aligns with the broader Industry 4.0 movement and the increasing digitalization of energy infrastructure.

As the energy storage market continues to evolve, solenoid valve manufacturers are likely to face both opportunities and challenges. The need for customized solutions to meet specific energy storage technology requirements presents a significant opportunity for innovation and market differentiation. However, manufacturers must also contend with pricing pressures and the need for continuous technological advancements to remain competitive in this rapidly growing market.

Technical Challenges in Solenoid Valve Adaptation

The adaptation of solenoid valves to renewable energy storage systems presents several significant technical challenges. One of the primary issues is the need for enhanced durability and reliability under fluctuating operational conditions. Renewable energy sources, such as solar and wind, are inherently intermittent, leading to frequent cycling and variable load demands on storage systems. This variability puts increased stress on solenoid valves, requiring them to withstand rapid and frequent actuations without compromising performance or lifespan.

Another critical challenge lies in the development of materials that can withstand the diverse and often corrosive environments found in renewable energy storage applications. For instance, in hydrogen storage systems, solenoid valves must be resistant to hydrogen embrittlement, while in certain battery technologies, they may need to withstand highly acidic or alkaline conditions. The selection and engineering of appropriate materials that maintain their integrity and functionality under these demanding conditions remain a significant hurdle.

Energy efficiency is a paramount concern in renewable energy systems, and this extends to the solenoid valves used within them. Traditional solenoid valves can be energy-intensive, particularly when held in an open or closed position for extended periods. Developing low-power consumption valves that can maintain their state with minimal energy input is crucial for maximizing the overall efficiency of storage systems.

The need for precise control and rapid response times poses another technical challenge. In many renewable energy storage applications, such as flow batteries or compressed air energy storage, the ability to quickly and accurately regulate fluid or gas flow is essential for system performance and safety. This requires advancements in solenoid valve design to achieve faster actuation speeds and more precise flow control capabilities.

Miniaturization and integration present additional hurdles. As energy storage systems become more compact and modular, there is a growing demand for smaller, lighter solenoid valves that can be seamlessly integrated into these systems without compromising functionality. This miniaturization must be achieved while maintaining or improving performance characteristics, a task that often requires innovative design approaches and advanced manufacturing techniques.

Lastly, the challenge of scalability cannot be overlooked. As renewable energy storage systems grow in size and complexity, solenoid valves must be capable of handling larger flow rates and higher pressures while maintaining reliability and efficiency. Developing valves that can be easily scaled up for industrial-scale applications, without a proportional increase in cost or complexity, remains a significant technical challenge in the field.

Another critical challenge lies in the development of materials that can withstand the diverse and often corrosive environments found in renewable energy storage applications. For instance, in hydrogen storage systems, solenoid valves must be resistant to hydrogen embrittlement, while in certain battery technologies, they may need to withstand highly acidic or alkaline conditions. The selection and engineering of appropriate materials that maintain their integrity and functionality under these demanding conditions remain a significant hurdle.

Energy efficiency is a paramount concern in renewable energy systems, and this extends to the solenoid valves used within them. Traditional solenoid valves can be energy-intensive, particularly when held in an open or closed position for extended periods. Developing low-power consumption valves that can maintain their state with minimal energy input is crucial for maximizing the overall efficiency of storage systems.

The need for precise control and rapid response times poses another technical challenge. In many renewable energy storage applications, such as flow batteries or compressed air energy storage, the ability to quickly and accurately regulate fluid or gas flow is essential for system performance and safety. This requires advancements in solenoid valve design to achieve faster actuation speeds and more precise flow control capabilities.

Miniaturization and integration present additional hurdles. As energy storage systems become more compact and modular, there is a growing demand for smaller, lighter solenoid valves that can be seamlessly integrated into these systems without compromising functionality. This miniaturization must be achieved while maintaining or improving performance characteristics, a task that often requires innovative design approaches and advanced manufacturing techniques.

Lastly, the challenge of scalability cannot be overlooked. As renewable energy storage systems grow in size and complexity, solenoid valves must be capable of handling larger flow rates and higher pressures while maintaining reliability and efficiency. Developing valves that can be easily scaled up for industrial-scale applications, without a proportional increase in cost or complexity, remains a significant technical challenge in the field.

Current Solenoid Valve Solutions for Energy Storage

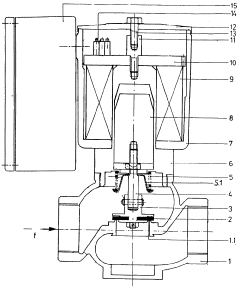

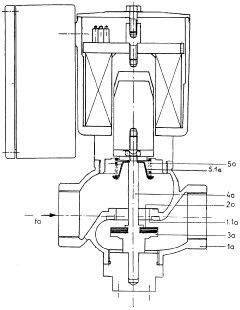

01 Design and structure of solenoid valves

Solenoid valves are designed with specific structures to control fluid flow. They typically consist of a coil, plunger, and valve body. The design may include features for improved performance, such as noise reduction, faster response times, or enhanced sealing capabilities. Various configurations are used to suit different applications and operating conditions.- Solenoid valve design and structure: Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, efficiency, and reliability for different applications.

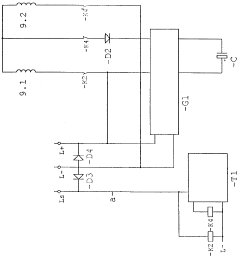

- Solenoid valve control systems: Control systems for solenoid valves include electronic circuits and microcontrollers that regulate valve operation. These systems can incorporate sensors, feedback mechanisms, and advanced algorithms to ensure precise timing, pressure control, and flow regulation. Some designs feature adaptive control to optimize performance under varying conditions.

- Solenoid valve applications in automotive systems: Solenoid valves play crucial roles in various automotive systems, including fuel injection, transmission control, and emission control systems. They are used to regulate fluid flow, control pressure, and manage the timing of different processes within the engine and other vehicle subsystems.

- Miniaturization and integration of solenoid valves: Advancements in solenoid valve technology focus on miniaturization and integration with other components. This trend allows for more compact and efficient systems, particularly in applications where space is limited. Integrated designs can combine multiple valves or incorporate additional functionalities within a single unit.

- Energy-efficient solenoid valve designs: Innovative solenoid valve designs aim to improve energy efficiency by reducing power consumption and heat generation. These designs may incorporate advanced materials, optimized magnetic circuits, or novel actuation mechanisms. Some approaches include latching solenoids or pulse-width modulation control to minimize energy use during steady-state operation.

02 Control systems for solenoid valves

Control systems are crucial for the efficient operation of solenoid valves. These systems may include electronic controllers, sensors, and feedback mechanisms to regulate valve opening and closing. Advanced control systems can provide precise timing, variable flow control, and integration with larger automated systems for improved overall performance.Expand Specific Solutions03 Applications of solenoid valves

Solenoid valves find applications in various industries and systems. They are used in automotive systems, industrial processes, irrigation systems, and household appliances. Specific applications include fuel injection systems, pneumatic control systems, and water management systems. The versatility of solenoid valves makes them suitable for a wide range of fluid control applications.Expand Specific Solutions04 Energy efficiency and power management in solenoid valves

Improving energy efficiency is a key focus in solenoid valve design. This includes developing low-power consumption valves, implementing power-saving modes, and optimizing the electromagnetic circuit. Some designs incorporate energy recovery systems or use alternative power sources to reduce overall energy consumption while maintaining performance.Expand Specific Solutions05 Materials and manufacturing techniques for solenoid valves

The choice of materials and manufacturing techniques plays a crucial role in solenoid valve performance and durability. Advanced materials may be used for specific components to enhance corrosion resistance, reduce wear, or improve magnetic properties. Manufacturing techniques such as precision machining, 3D printing, or advanced molding processes can be employed to produce complex valve geometries and improve overall quality.Expand Specific Solutions

Key Players in Solenoid Valve Industry

The role of solenoid valves in adapting to renewable energy storage systems is an emerging field within the broader renewable energy sector. The market is in its early growth stage, with increasing demand driven by the global shift towards sustainable energy solutions. Key players like Robert Bosch GmbH, Festo SE & Co. KG, and Mitsubishi Electric Corp. are leveraging their expertise in industrial automation and control systems to develop advanced solenoid valve technologies. The market size is expected to grow significantly as renewable energy storage systems become more prevalent. While the technology is still evolving, established companies are investing in R&D to improve efficiency, reliability, and integration capabilities of solenoid valves for these applications.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has made significant strides in adapting solenoid valves for renewable energy storage systems. Their approach focuses on developing highly efficient and precise solenoid valves that can handle the variable loads and intermittent nature of renewable energy sources[4]. Bosch's solenoid valves incorporate advanced materials and designs to minimize energy losses and improve overall system efficiency. The company has also developed smart valve systems that can communicate with other components in the energy storage setup, allowing for real-time adjustments and optimizations[5]. Bosch's valves are particularly well-suited for hydrogen storage systems, where precise control of gas flow is crucial for safety and efficiency[6].

Strengths: High precision and efficiency, smart communication capabilities, and suitability for hydrogen storage systems. Weaknesses: May have higher complexity, potentially leading to increased maintenance requirements.

Festo SE & Co. KG

Technical Solution: Festo SE & Co. KG has developed innovative solenoid valve solutions for renewable energy storage systems, with a particular focus on pneumatic and hydraulic applications. Their valves are designed to handle the high-pressure requirements of compressed air energy storage (CAES) systems, offering precise control and fast switching times[7]. Festo's solenoid valves incorporate energy-efficient designs, including low-power holding circuits and optimized magnetic circuits, to reduce overall energy consumption[8]. The company has also introduced modular valve systems that can be easily scaled and adapted to different renewable energy storage applications, providing flexibility for system designers[9].

Strengths: Expertise in pneumatic and hydraulic applications, energy-efficient designs, and modular scalability. Weaknesses: May have limitations in certain types of renewable energy storage systems that do not rely on pneumatic or hydraulic principles.

Innovative Solenoid Valve Designs for Renewables

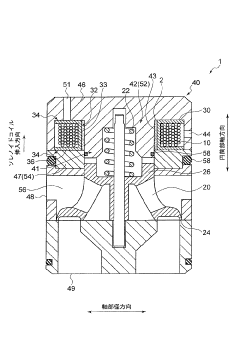

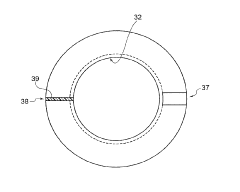

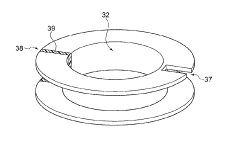

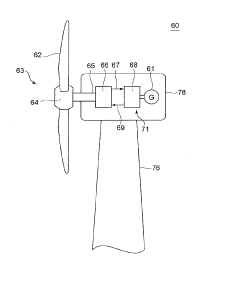

Solenoid valve, fluid machine, hydraulic machine and renewable energy type power generation device, and manufacturing method of solenoid valve

PatentInactiveJP2015222087A

Innovation

- Incorporating a filler with higher thermal conductivity than air in the gap between the inner peripheral surface of the coil bobbin and the outer peripheral surface of the valve casing to enhance heat transfer, along with a magnetic material configuration to concentrate magnetic flux and improve electromagnetic force.

Magnetic valve

PatentWO2001025659A1

Innovation

- A solenoid valve design that utilizes a capacitor and resistor circuit to reduce electrical control power by using high pull-in current only during opening or closing, with a small holding current, and automatic capacitor charging and recharging to minimize power consumption, employing relay switches and a DC/DC converter to manage power efficiently.

Environmental Impact Assessment

The integration of solenoid valves in renewable energy storage systems has significant environmental implications that warrant careful consideration. These valves play a crucial role in managing fluid flow and pressure within various storage technologies, such as compressed air energy storage (CAES) and pumped hydro storage. Their implementation can lead to both positive and negative environmental impacts.

On the positive side, solenoid valves contribute to the overall efficiency of renewable energy storage systems, thereby reducing the reliance on fossil fuels and decreasing greenhouse gas emissions. By enabling precise control of energy storage and release processes, these valves help maximize the utilization of renewable energy sources, which are inherently cleaner than conventional power generation methods. This improved efficiency translates to a reduced carbon footprint and less environmental degradation associated with energy production.

However, the manufacturing and disposal of solenoid valves also present environmental challenges. The production process involves the use of various materials, including metals and plastics, which require energy-intensive extraction and processing. Additionally, the electronic components in solenoid valves often contain rare earth elements and other materials that can be environmentally harmful if not properly managed at the end of their lifecycle.

The operation of solenoid valves in renewable energy storage systems may also have localized environmental impacts. For instance, in CAES systems, the repeated compression and expansion of air can lead to temperature fluctuations and potential noise pollution in the surrounding area. Similarly, in pumped hydro storage, the controlled release of water through solenoid valves may affect local aquatic ecosystems if not carefully managed.

Maintenance and replacement of solenoid valves over the lifespan of renewable energy storage systems also contribute to the overall environmental footprint. Regular servicing may require the use of lubricants and cleaning agents, which must be handled and disposed of responsibly to prevent soil and water contamination. Furthermore, the replacement of faulty valves generates electronic waste that requires proper recycling and disposal procedures to minimize environmental harm.

To mitigate these environmental concerns, manufacturers and operators of renewable energy storage systems are increasingly focusing on sustainable design and lifecycle management of solenoid valves. This includes developing valves with longer operational lifespans, using more environmentally friendly materials, and implementing efficient recycling programs. Additionally, advancements in valve technology are leading to more energy-efficient designs that further reduce the overall environmental impact of renewable energy storage systems.

In conclusion, while solenoid valves play a vital role in enhancing the efficiency and effectiveness of renewable energy storage systems, their environmental impact must be carefully managed. Balancing the positive contributions to clean energy storage with the potential negative effects of production and disposal is crucial for ensuring the overall sustainability of these systems.

On the positive side, solenoid valves contribute to the overall efficiency of renewable energy storage systems, thereby reducing the reliance on fossil fuels and decreasing greenhouse gas emissions. By enabling precise control of energy storage and release processes, these valves help maximize the utilization of renewable energy sources, which are inherently cleaner than conventional power generation methods. This improved efficiency translates to a reduced carbon footprint and less environmental degradation associated with energy production.

However, the manufacturing and disposal of solenoid valves also present environmental challenges. The production process involves the use of various materials, including metals and plastics, which require energy-intensive extraction and processing. Additionally, the electronic components in solenoid valves often contain rare earth elements and other materials that can be environmentally harmful if not properly managed at the end of their lifecycle.

The operation of solenoid valves in renewable energy storage systems may also have localized environmental impacts. For instance, in CAES systems, the repeated compression and expansion of air can lead to temperature fluctuations and potential noise pollution in the surrounding area. Similarly, in pumped hydro storage, the controlled release of water through solenoid valves may affect local aquatic ecosystems if not carefully managed.

Maintenance and replacement of solenoid valves over the lifespan of renewable energy storage systems also contribute to the overall environmental footprint. Regular servicing may require the use of lubricants and cleaning agents, which must be handled and disposed of responsibly to prevent soil and water contamination. Furthermore, the replacement of faulty valves generates electronic waste that requires proper recycling and disposal procedures to minimize environmental harm.

To mitigate these environmental concerns, manufacturers and operators of renewable energy storage systems are increasingly focusing on sustainable design and lifecycle management of solenoid valves. This includes developing valves with longer operational lifespans, using more environmentally friendly materials, and implementing efficient recycling programs. Additionally, advancements in valve technology are leading to more energy-efficient designs that further reduce the overall environmental impact of renewable energy storage systems.

In conclusion, while solenoid valves play a vital role in enhancing the efficiency and effectiveness of renewable energy storage systems, their environmental impact must be carefully managed. Balancing the positive contributions to clean energy storage with the potential negative effects of production and disposal is crucial for ensuring the overall sustainability of these systems.

Regulatory Framework for Energy Storage Components

The regulatory framework for energy storage components, particularly solenoid valves in renewable energy storage systems, is a complex and evolving landscape. As these systems become increasingly integral to the global energy transition, governments and regulatory bodies are developing comprehensive guidelines to ensure safety, reliability, and environmental compliance.

At the international level, organizations such as the International Electrotechnical Commission (IEC) have established standards for energy storage systems, including components like solenoid valves. The IEC 62933 series, for instance, provides guidelines for electrical energy storage systems integrated with grid-connected power plants. These standards address safety considerations, testing methods, and environmental impact assessments.

In the United States, the Federal Energy Regulatory Commission (FERC) has taken significant steps to integrate energy storage into the regulatory framework. Order No. 841, issued in 2018, requires grid operators to establish market rules that recognize the physical and operational characteristics of electric storage resources. This order has implications for the design and operation of storage systems, including the use of solenoid valves for flow control and pressure regulation.

The European Union has also been proactive in developing regulations for energy storage. The Clean Energy Package, adopted in 2019, includes provisions for energy storage and aims to create a more flexible and efficient energy system. This package has led to the development of specific regulations for energy storage components, including safety standards for valves and other control devices.

At the national level, countries are implementing their own regulatory frameworks. For example, Germany's Energy Industry Act (EnWG) includes provisions for energy storage systems, while the UK's Electricity Storage Standard License Conditions set out specific requirements for storage facilities. These regulations often include specifications for components like solenoid valves, addressing issues such as material compatibility, pressure ratings, and fail-safe mechanisms.

Safety standards play a crucial role in the regulatory framework. Organizations like Underwriters Laboratories (UL) in the United States and the European Committee for Standardization (CEN) in Europe have developed specific standards for energy storage systems and their components. These standards often include requirements for solenoid valves, such as UL 1973 for batteries and energy storage systems, which addresses valve safety in battery management systems.

Environmental regulations also impact the design and use of solenoid valves in energy storage systems. For instance, the EU's Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electrical and electronic equipment, affecting the manufacturing of solenoid valves and other components.

As the renewable energy sector continues to grow, regulatory frameworks are likely to evolve further. This may include more specific guidelines for solenoid valves in energy storage applications, addressing issues such as durability, efficiency, and compatibility with various storage mediums. Manufacturers and system integrators must stay informed of these regulatory developments to ensure compliance and optimize their products for the changing energy landscape.

At the international level, organizations such as the International Electrotechnical Commission (IEC) have established standards for energy storage systems, including components like solenoid valves. The IEC 62933 series, for instance, provides guidelines for electrical energy storage systems integrated with grid-connected power plants. These standards address safety considerations, testing methods, and environmental impact assessments.

In the United States, the Federal Energy Regulatory Commission (FERC) has taken significant steps to integrate energy storage into the regulatory framework. Order No. 841, issued in 2018, requires grid operators to establish market rules that recognize the physical and operational characteristics of electric storage resources. This order has implications for the design and operation of storage systems, including the use of solenoid valves for flow control and pressure regulation.

The European Union has also been proactive in developing regulations for energy storage. The Clean Energy Package, adopted in 2019, includes provisions for energy storage and aims to create a more flexible and efficient energy system. This package has led to the development of specific regulations for energy storage components, including safety standards for valves and other control devices.

At the national level, countries are implementing their own regulatory frameworks. For example, Germany's Energy Industry Act (EnWG) includes provisions for energy storage systems, while the UK's Electricity Storage Standard License Conditions set out specific requirements for storage facilities. These regulations often include specifications for components like solenoid valves, addressing issues such as material compatibility, pressure ratings, and fail-safe mechanisms.

Safety standards play a crucial role in the regulatory framework. Organizations like Underwriters Laboratories (UL) in the United States and the European Committee for Standardization (CEN) in Europe have developed specific standards for energy storage systems and their components. These standards often include requirements for solenoid valves, such as UL 1973 for batteries and energy storage systems, which addresses valve safety in battery management systems.

Environmental regulations also impact the design and use of solenoid valves in energy storage systems. For instance, the EU's Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electrical and electronic equipment, affecting the manufacturing of solenoid valves and other components.

As the renewable energy sector continues to grow, regulatory frameworks are likely to evolve further. This may include more specific guidelines for solenoid valves in energy storage applications, addressing issues such as durability, efficiency, and compatibility with various storage mediums. Manufacturers and system integrators must stay informed of these regulatory developments to ensure compliance and optimize their products for the changing energy landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!