Solenoid Valve Application in Autonomous Vehicle Fluid Control Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution

The evolution of solenoid valves in autonomous vehicle fluid control systems represents a significant technological advancement in the automotive industry. Initially developed for basic on-off control in traditional vehicles, solenoid valves have undergone substantial improvements to meet the complex demands of autonomous driving systems.

In the early stages of autonomous vehicle development, solenoid valves were primarily used for simple fluid control tasks, such as activating brake lines or controlling transmission fluid flow. These early applications relied on basic electromagnetic principles, with limited precision and response times.

As autonomous vehicle technology progressed, the need for more sophisticated fluid control systems became apparent. This led to the development of proportional solenoid valves, which offered variable flow control and improved precision. These valves allowed for finer adjustments in fluid pressure and flow rates, essential for the smooth operation of advanced braking and steering systems in autonomous vehicles.

The next significant evolution came with the integration of electronic controls and sensors. Smart solenoid valves emerged, incorporating microprocessors and advanced algorithms to optimize valve performance. These intelligent valves could adapt to changing conditions in real-time, enhancing the overall responsiveness and efficiency of fluid control systems.

Miniaturization has been another key trend in solenoid valve evolution. As autonomous vehicles require an increasing number of fluid control points, compact and lightweight valve designs have become crucial. This has led to the development of micro-solenoid valves, capable of precise control in tight spaces without compromising performance.

Recent advancements have focused on improving the energy efficiency and durability of solenoid valves. New materials and manufacturing techniques have resulted in valves with reduced power consumption and extended operational lifespans, critical for the continuous operation of autonomous vehicles.

The latest generation of solenoid valves for autonomous vehicles incorporates advanced features such as self-diagnosis and predictive maintenance capabilities. These valves can monitor their own performance, detect potential issues before they become critical, and communicate with the vehicle's central control system to ensure optimal operation and safety.

Looking ahead, the evolution of solenoid valves in autonomous vehicle fluid control systems is likely to continue, with a focus on further integration with AI and machine learning technologies. This will enable even more precise and adaptive fluid control, contributing to the overall safety, efficiency, and performance of autonomous vehicles.

In the early stages of autonomous vehicle development, solenoid valves were primarily used for simple fluid control tasks, such as activating brake lines or controlling transmission fluid flow. These early applications relied on basic electromagnetic principles, with limited precision and response times.

As autonomous vehicle technology progressed, the need for more sophisticated fluid control systems became apparent. This led to the development of proportional solenoid valves, which offered variable flow control and improved precision. These valves allowed for finer adjustments in fluid pressure and flow rates, essential for the smooth operation of advanced braking and steering systems in autonomous vehicles.

The next significant evolution came with the integration of electronic controls and sensors. Smart solenoid valves emerged, incorporating microprocessors and advanced algorithms to optimize valve performance. These intelligent valves could adapt to changing conditions in real-time, enhancing the overall responsiveness and efficiency of fluid control systems.

Miniaturization has been another key trend in solenoid valve evolution. As autonomous vehicles require an increasing number of fluid control points, compact and lightweight valve designs have become crucial. This has led to the development of micro-solenoid valves, capable of precise control in tight spaces without compromising performance.

Recent advancements have focused on improving the energy efficiency and durability of solenoid valves. New materials and manufacturing techniques have resulted in valves with reduced power consumption and extended operational lifespans, critical for the continuous operation of autonomous vehicles.

The latest generation of solenoid valves for autonomous vehicles incorporates advanced features such as self-diagnosis and predictive maintenance capabilities. These valves can monitor their own performance, detect potential issues before they become critical, and communicate with the vehicle's central control system to ensure optimal operation and safety.

Looking ahead, the evolution of solenoid valves in autonomous vehicle fluid control systems is likely to continue, with a focus on further integration with AI and machine learning technologies. This will enable even more precise and adaptive fluid control, contributing to the overall safety, efficiency, and performance of autonomous vehicles.

AV Fluid Control Demand

The autonomous vehicle (AV) industry is experiencing a surge in demand for advanced fluid control systems, driven by the need for precise and reliable management of various fluids within these complex vehicles. As AVs become more sophisticated, the requirements for fluid control systems have evolved to meet the challenges of safety, efficiency, and performance.

One of the primary drivers of this demand is the increasing complexity of AV powertrains. With the rise of electric and hybrid vehicles, there is a growing need for sophisticated cooling systems to manage battery temperatures and ensure optimal performance. These systems require precise control of coolant flow, which can be achieved through the use of advanced solenoid valves.

Additionally, the development of more advanced braking systems in AVs has led to a higher demand for fluid control components. Regenerative braking systems, which are common in electric and hybrid vehicles, require precise control of hydraulic fluids to maximize energy recovery and ensure smooth operation. Solenoid valves play a crucial role in managing these fluid flows, contributing to improved vehicle efficiency and performance.

The push for greater fuel efficiency in traditional internal combustion engine vehicles has also impacted fluid control demand. Advanced engine management systems require precise control of fuel and oil flow, which can be achieved through the use of high-performance solenoid valves. These valves enable more accurate fuel injection timing and variable valve timing, leading to improved engine efficiency and reduced emissions.

Furthermore, the integration of advanced driver assistance systems (ADAS) and autonomous driving features has created new requirements for fluid control in areas such as windshield washer systems and headlight cleaning systems. These systems must operate reliably and precisely to ensure clear visibility for both sensors and human occupants, especially in adverse weather conditions.

The demand for fluid control systems in AVs is also influenced by the need for increased reliability and durability. As vehicles become more autonomous, the expectations for system uptime and longevity increase. This has led to a focus on developing fluid control components that can withstand harsh operating conditions and maintain consistent performance over extended periods.

Lastly, the trend towards vehicle electrification has created new opportunities for fluid control applications in areas such as battery thermal management and power electronics cooling. These systems require precise control of coolant flow to maintain optimal operating temperatures and prevent damage to sensitive electronic components.

One of the primary drivers of this demand is the increasing complexity of AV powertrains. With the rise of electric and hybrid vehicles, there is a growing need for sophisticated cooling systems to manage battery temperatures and ensure optimal performance. These systems require precise control of coolant flow, which can be achieved through the use of advanced solenoid valves.

Additionally, the development of more advanced braking systems in AVs has led to a higher demand for fluid control components. Regenerative braking systems, which are common in electric and hybrid vehicles, require precise control of hydraulic fluids to maximize energy recovery and ensure smooth operation. Solenoid valves play a crucial role in managing these fluid flows, contributing to improved vehicle efficiency and performance.

The push for greater fuel efficiency in traditional internal combustion engine vehicles has also impacted fluid control demand. Advanced engine management systems require precise control of fuel and oil flow, which can be achieved through the use of high-performance solenoid valves. These valves enable more accurate fuel injection timing and variable valve timing, leading to improved engine efficiency and reduced emissions.

Furthermore, the integration of advanced driver assistance systems (ADAS) and autonomous driving features has created new requirements for fluid control in areas such as windshield washer systems and headlight cleaning systems. These systems must operate reliably and precisely to ensure clear visibility for both sensors and human occupants, especially in adverse weather conditions.

The demand for fluid control systems in AVs is also influenced by the need for increased reliability and durability. As vehicles become more autonomous, the expectations for system uptime and longevity increase. This has led to a focus on developing fluid control components that can withstand harsh operating conditions and maintain consistent performance over extended periods.

Lastly, the trend towards vehicle electrification has created new opportunities for fluid control applications in areas such as battery thermal management and power electronics cooling. These systems require precise control of coolant flow to maintain optimal operating temperatures and prevent damage to sensitive electronic components.

Solenoid Tech Challenges

The application of solenoid valves in autonomous vehicle fluid control systems presents several significant technical challenges that require innovative solutions. One of the primary issues is the need for precise and rapid control of fluid flow in various vehicle subsystems, such as braking, cooling, and fuel injection. Solenoid valves must operate with millisecond-level response times to ensure optimal performance and safety in autonomous driving scenarios.

Miniaturization is another critical challenge, as space constraints within autonomous vehicles demand compact valve designs without compromising functionality. Engineers must develop solenoid valves that are smaller and lighter while maintaining or improving their performance characteristics. This requires advancements in materials science and manufacturing techniques to create more efficient electromagnetic components and reduce overall valve size.

Durability and reliability pose significant hurdles in the harsh automotive environment. Solenoid valves must withstand extreme temperatures, vibrations, and contaminants while maintaining consistent operation over extended periods. The development of robust sealing technologies and wear-resistant materials is crucial to ensure long-term reliability and minimize maintenance requirements.

Energy efficiency is a paramount concern, particularly in electric and hybrid autonomous vehicles where power consumption directly impacts range and overall vehicle efficiency. Designing solenoid valves with lower power consumption and improved electromagnetic efficiency is essential to optimize energy usage without sacrificing performance.

Integration with advanced control systems and sensors presents another challenge. Solenoid valves must seamlessly interface with the vehicle's central control unit, receiving and executing commands with high precision and minimal latency. This requires the development of sophisticated control algorithms and communication protocols to ensure real-time responsiveness and adaptability to changing driving conditions.

Electromagnetic interference (EMI) is a significant issue in autonomous vehicles, where numerous electronic systems operate in close proximity. Solenoid valves must be designed to minimize EMI generation and maintain proper functionality in the presence of external electromagnetic fields. This necessitates careful shielding and filtering techniques to ensure reliable operation of both the valves and surrounding electronic components.

Lastly, the challenge of cost-effectiveness cannot be overlooked. As autonomous vehicles move towards mass production, solenoid valve manufacturers must find ways to reduce production costs while maintaining high quality and performance standards. This may involve exploring new manufacturing processes, materials, or design optimizations to achieve economies of scale without compromising on technological advancements.

Miniaturization is another critical challenge, as space constraints within autonomous vehicles demand compact valve designs without compromising functionality. Engineers must develop solenoid valves that are smaller and lighter while maintaining or improving their performance characteristics. This requires advancements in materials science and manufacturing techniques to create more efficient electromagnetic components and reduce overall valve size.

Durability and reliability pose significant hurdles in the harsh automotive environment. Solenoid valves must withstand extreme temperatures, vibrations, and contaminants while maintaining consistent operation over extended periods. The development of robust sealing technologies and wear-resistant materials is crucial to ensure long-term reliability and minimize maintenance requirements.

Energy efficiency is a paramount concern, particularly in electric and hybrid autonomous vehicles where power consumption directly impacts range and overall vehicle efficiency. Designing solenoid valves with lower power consumption and improved electromagnetic efficiency is essential to optimize energy usage without sacrificing performance.

Integration with advanced control systems and sensors presents another challenge. Solenoid valves must seamlessly interface with the vehicle's central control unit, receiving and executing commands with high precision and minimal latency. This requires the development of sophisticated control algorithms and communication protocols to ensure real-time responsiveness and adaptability to changing driving conditions.

Electromagnetic interference (EMI) is a significant issue in autonomous vehicles, where numerous electronic systems operate in close proximity. Solenoid valves must be designed to minimize EMI generation and maintain proper functionality in the presence of external electromagnetic fields. This necessitates careful shielding and filtering techniques to ensure reliable operation of both the valves and surrounding electronic components.

Lastly, the challenge of cost-effectiveness cannot be overlooked. As autonomous vehicles move towards mass production, solenoid valve manufacturers must find ways to reduce production costs while maintaining high quality and performance standards. This may involve exploring new manufacturing processes, materials, or design optimizations to achieve economies of scale without compromising on technological advancements.

Current Solenoid Solutions

01 Solenoid valve design improvements

Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and incorporating advanced sealing technologies. Such enhancements result in better flow control, reduced leakage, and increased durability of the valve.- Solenoid valve design improvements: Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and refining the electromagnetic coil design. Such enhancements can lead to better flow control, reduced power consumption, and increased durability of the valve.

- Control systems for solenoid valves: Advanced control systems have been developed for solenoid valves to improve their precision and responsiveness. These systems may incorporate electronic controllers, sensors, and feedback mechanisms to regulate valve operation. Such control systems can enable more accurate flow control, faster response times, and better integration with other automated systems.

- Energy-efficient solenoid valve designs: Efforts have been made to develop energy-efficient solenoid valve designs that reduce power consumption without compromising performance. These designs may include improvements in coil winding techniques, use of low-power materials, and implementation of energy-saving control strategies. Such innovations can lead to reduced operating costs and improved environmental sustainability.

- Miniaturization of solenoid valves: Advancements in solenoid valve technology have led to the development of miniaturized designs suitable for compact applications. These miniature valves maintain functionality while reducing size and weight, making them ideal for use in portable devices, medical equipment, and other space-constrained environments.

- Specialized solenoid valves for specific applications: Solenoid valves have been developed for specialized applications, such as high-pressure systems, corrosive environments, or extreme temperatures. These valves incorporate materials and designs tailored to withstand specific operating conditions, ensuring reliable performance in challenging environments across various industries.

02 Energy-efficient solenoid valves

Developments in energy-efficient solenoid valves focus on reducing power consumption while maintaining optimal performance. This is achieved through the use of advanced materials, improved electromagnetic designs, and innovative control mechanisms. These energy-efficient valves are particularly useful in applications where power conservation is crucial.Expand Specific Solutions03 Smart solenoid valves with integrated sensors

Integration of sensors and smart technologies into solenoid valves enables real-time monitoring and control of valve operations. These smart valves can provide feedback on flow rates, pressure, and valve position, allowing for more precise control and predictive maintenance. They often incorporate digital interfaces for easy integration with modern control systems.Expand Specific Solutions04 Miniaturization of solenoid valves

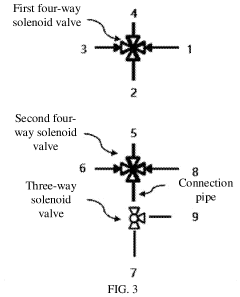

Efforts to miniaturize solenoid valves have resulted in compact designs suitable for space-constrained applications. These miniature valves maintain functionality while significantly reducing size and weight. Advanced manufacturing techniques and materials are employed to achieve this miniaturization without compromising performance.Expand Specific Solutions05 Multi-way solenoid valves

Development of multi-way solenoid valves allows for more complex flow control in a single valve assembly. These valves can direct flow between multiple ports, offering versatility in fluid control applications. Innovations in this area focus on improving the valve's ability to handle multiple flow paths efficiently and reliably.Expand Specific Solutions

Key AV Fluid Control Firms

The autonomous vehicle fluid control systems market, including solenoid valve applications, is in a growth phase with increasing market size due to the rising demand for advanced automotive technologies. The market is characterized by a mix of established automotive suppliers and emerging tech companies, reflecting the industry's transition towards electrification and autonomous driving. Companies like Eaton Corp., Robert Bosch GmbH, and BorgWarner are leveraging their extensive experience in traditional automotive systems to develop innovative fluid control solutions. Meanwhile, newer entrants such as Zhejiang Geely Holding Group and Bethel Automotive Safety Systems are focusing on integrating these technologies into their autonomous vehicle platforms. The technology's maturity is advancing rapidly, with major players investing heavily in R&D to improve efficiency, reliability, and integration with other vehicle systems.

Eaton Corp.

Technical Solution: Eaton has developed a range of solenoid valves specifically designed for autonomous vehicle fluid control systems. Their technology focuses on compact, lightweight designs that minimize space requirements while maintaining high performance. Eaton's solenoid valves feature multi-function capabilities, combining flow control, pressure regulation, and system protection in a single unit[4]. The company has implemented advanced sealing technologies to ensure long-term reliability and reduce the risk of fluid leakage. Eaton's valves also incorporate smart diagnostics and prognostics capabilities, allowing for predictive maintenance and real-time system health monitoring[5]. Furthermore, they have developed energy-efficient solenoid designs that reduce power consumption by up to 30% compared to conventional valves, contributing to extended battery life in electric autonomous vehicles[6].

Strengths: Compact and lightweight design, multi-function capabilities, and energy efficiency. Weaknesses: May have limitations in extreme operating conditions, potential for higher initial costs due to advanced features.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid valve systems for autonomous vehicle fluid control. Their technology incorporates high-precision electromagnetic actuators with integrated sensors for real-time feedback. The valves feature rapid response times of less than 5 milliseconds and can operate at pressures up to 300 bar[1]. Bosch's solenoid valves utilize a modular design, allowing for easy integration into various vehicle systems such as braking, steering, and suspension. The company has also implemented advanced materials like high-performance polymers to reduce weight and improve durability[2]. Additionally, Bosch has developed smart valve control algorithms that adapt to changing environmental conditions, enhancing overall system efficiency and reliability in autonomous vehicles[3].

Strengths: Industry-leading response times, high operating pressures, and modular design for easy integration. Weaknesses: Potentially higher cost due to advanced materials and integrated sensors, may require specialized maintenance.

Core Solenoid Innovations

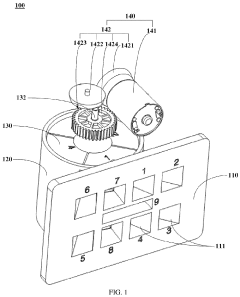

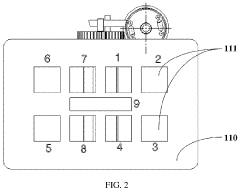

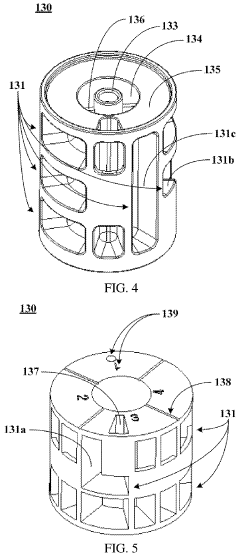

Integrated multi-way solenoid valve and vehicle thermal management system

PatentPendingUS20230332699A1

Innovation

- An integrated multi-way solenoid valve with a cylindrical mounting panel, valve seat, and valve cartridge, featuring a specific arrangement of channel interfaces and communication grooves, allows for compact and lightweight design by enabling multiple passageways through a single valve assembly, reducing the need for multiple solenoid valves and simplifying pipeline arrangements.

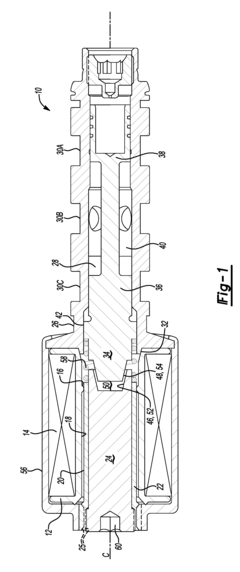

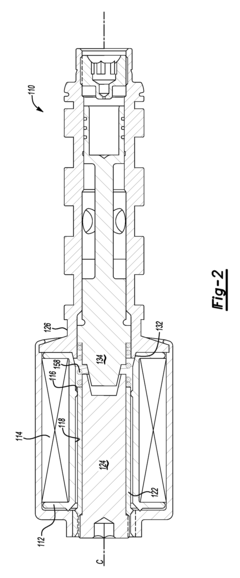

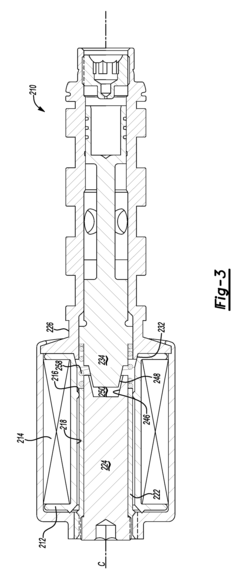

Solenoid valve assembly

PatentInactiveUS8082953B2

Innovation

- A solenoid valve assembly with a bobbin, adjustment member, pole piece, and spool, where the components are aligned using protrusions and seats to achieve substantial concentricity, minimizing radial movement and friction, and a resilient member for force adjustment.

AV Safety Regulations

The integration of autonomous vehicles (AVs) into existing transportation systems has necessitated the development of comprehensive safety regulations. These regulations aim to ensure the safe operation of AVs while addressing the unique challenges posed by their advanced technologies, including solenoid valve applications in fluid control systems.

Regulatory bodies worldwide have been working to establish frameworks that govern the development, testing, and deployment of AVs. In the United States, the National Highway Traffic Safety Administration (NHTSA) has issued guidelines for AV safety, emphasizing the importance of robust systems and fail-safe mechanisms. These guidelines specifically address the critical role of fluid control systems, including those utilizing solenoid valves, in maintaining vehicle stability and performance.

The European Union has also taken significant steps in regulating AV safety through the implementation of the General Safety Regulation (GSR). This regulation mandates the inclusion of advanced safety features in all new vehicles, with specific provisions for autonomous systems. The GSR emphasizes the need for redundancy in critical components, including fluid control systems, to ensure continued safe operation in the event of component failure.

In Asia, countries like Japan and Singapore have introduced their own AV safety regulations, focusing on the reliability and durability of key systems. These regulations often require extensive testing and validation of components such as solenoid valves in fluid control applications, ensuring their ability to withstand various environmental conditions and operational stresses.

A common thread among global AV safety regulations is the emphasis on system integrity and fault tolerance. Solenoid valves, as crucial components in fluid control systems, are subject to stringent performance and reliability standards. Regulations typically require manufacturers to demonstrate the valves' ability to maintain proper function under a wide range of operating conditions and to fail in a safe manner if compromised.

Furthermore, AV safety regulations often mandate the implementation of advanced diagnostic systems capable of detecting and reporting any malfunctions in critical components, including solenoid valves. This requirement ensures that potential issues can be identified and addressed promptly, minimizing the risk of system failures during operation.

As AV technology continues to evolve, safety regulations are expected to become increasingly sophisticated. Future iterations may incorporate more specific guidelines for the design and implementation of fluid control systems, potentially including standardized testing protocols for solenoid valves and other critical components. This ongoing regulatory development aims to keep pace with technological advancements while maintaining the highest standards of safety for autonomous vehicles.

Regulatory bodies worldwide have been working to establish frameworks that govern the development, testing, and deployment of AVs. In the United States, the National Highway Traffic Safety Administration (NHTSA) has issued guidelines for AV safety, emphasizing the importance of robust systems and fail-safe mechanisms. These guidelines specifically address the critical role of fluid control systems, including those utilizing solenoid valves, in maintaining vehicle stability and performance.

The European Union has also taken significant steps in regulating AV safety through the implementation of the General Safety Regulation (GSR). This regulation mandates the inclusion of advanced safety features in all new vehicles, with specific provisions for autonomous systems. The GSR emphasizes the need for redundancy in critical components, including fluid control systems, to ensure continued safe operation in the event of component failure.

In Asia, countries like Japan and Singapore have introduced their own AV safety regulations, focusing on the reliability and durability of key systems. These regulations often require extensive testing and validation of components such as solenoid valves in fluid control applications, ensuring their ability to withstand various environmental conditions and operational stresses.

A common thread among global AV safety regulations is the emphasis on system integrity and fault tolerance. Solenoid valves, as crucial components in fluid control systems, are subject to stringent performance and reliability standards. Regulations typically require manufacturers to demonstrate the valves' ability to maintain proper function under a wide range of operating conditions and to fail in a safe manner if compromised.

Furthermore, AV safety regulations often mandate the implementation of advanced diagnostic systems capable of detecting and reporting any malfunctions in critical components, including solenoid valves. This requirement ensures that potential issues can be identified and addressed promptly, minimizing the risk of system failures during operation.

As AV technology continues to evolve, safety regulations are expected to become increasingly sophisticated. Future iterations may incorporate more specific guidelines for the design and implementation of fluid control systems, potentially including standardized testing protocols for solenoid valves and other critical components. This ongoing regulatory development aims to keep pace with technological advancements while maintaining the highest standards of safety for autonomous vehicles.

Environmental Impact

The application of solenoid valves in autonomous vehicle fluid control systems has significant environmental implications that warrant careful consideration. These valves play a crucial role in managing various fluid systems within vehicles, including fuel injection, transmission, and cooling systems. As autonomous vehicles gain prominence, the environmental impact of their components becomes increasingly important.

Solenoid valves in autonomous vehicles contribute to improved fuel efficiency and reduced emissions. By precisely controlling fluid flow, these valves optimize engine performance and minimize fuel waste. This leads to lower carbon dioxide emissions and reduced overall environmental footprint. Additionally, the accurate control provided by solenoid valves helps maintain optimal operating conditions for catalytic converters, further reducing harmful emissions.

The durability and longevity of solenoid valves also have environmental implications. High-quality valves with extended lifespans reduce the need for frequent replacements, thereby minimizing waste generation and resource consumption associated with manufacturing and disposing of these components. This aligns with the principles of sustainable design and circular economy practices in the automotive industry.

However, the production of solenoid valves involves the use of various materials, including metals and plastics, which have their own environmental impacts. The mining and processing of raw materials, as well as the manufacturing processes, contribute to energy consumption and potential pollution. As the demand for autonomous vehicles grows, it is crucial to develop more sustainable production methods and explore eco-friendly materials for valve construction.

The end-of-life management of solenoid valves is another environmental consideration. Proper recycling and disposal procedures must be established to prevent these components from contributing to electronic waste. Developing efficient recycling processes for the materials used in solenoid valves can help recover valuable resources and reduce the environmental burden of waste management.

In the context of autonomous vehicles, the reliability of solenoid valves is paramount for safety and environmental protection. Malfunctioning valves could lead to fluid leaks or system failures, potentially resulting in environmental contamination. Therefore, robust quality control measures and predictive maintenance strategies are essential to prevent such incidents and minimize environmental risks associated with autonomous vehicle operation.

As the automotive industry transitions towards more sustainable practices, the role of solenoid valves in supporting alternative fuel systems becomes increasingly important. These valves are crucial in managing hydrogen fuel cells and electric vehicle cooling systems, contributing to the broader shift towards cleaner transportation technologies. The adaptability of solenoid valves to various fluid types positions them as key components in the evolution of environmentally friendly vehicle designs.

Solenoid valves in autonomous vehicles contribute to improved fuel efficiency and reduced emissions. By precisely controlling fluid flow, these valves optimize engine performance and minimize fuel waste. This leads to lower carbon dioxide emissions and reduced overall environmental footprint. Additionally, the accurate control provided by solenoid valves helps maintain optimal operating conditions for catalytic converters, further reducing harmful emissions.

The durability and longevity of solenoid valves also have environmental implications. High-quality valves with extended lifespans reduce the need for frequent replacements, thereby minimizing waste generation and resource consumption associated with manufacturing and disposing of these components. This aligns with the principles of sustainable design and circular economy practices in the automotive industry.

However, the production of solenoid valves involves the use of various materials, including metals and plastics, which have their own environmental impacts. The mining and processing of raw materials, as well as the manufacturing processes, contribute to energy consumption and potential pollution. As the demand for autonomous vehicles grows, it is crucial to develop more sustainable production methods and explore eco-friendly materials for valve construction.

The end-of-life management of solenoid valves is another environmental consideration. Proper recycling and disposal procedures must be established to prevent these components from contributing to electronic waste. Developing efficient recycling processes for the materials used in solenoid valves can help recover valuable resources and reduce the environmental burden of waste management.

In the context of autonomous vehicles, the reliability of solenoid valves is paramount for safety and environmental protection. Malfunctioning valves could lead to fluid leaks or system failures, potentially resulting in environmental contamination. Therefore, robust quality control measures and predictive maintenance strategies are essential to prevent such incidents and minimize environmental risks associated with autonomous vehicle operation.

As the automotive industry transitions towards more sustainable practices, the role of solenoid valves in supporting alternative fuel systems becomes increasingly important. These valves are crucial in managing hydrogen fuel cells and electric vehicle cooling systems, contributing to the broader shift towards cleaner transportation technologies. The adaptability of solenoid valves to various fluid types positions them as key components in the evolution of environmentally friendly vehicle designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!