Solenoid Valve Applications in Reverse Osmosis Systems for Water Purification

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RO Solenoid Valve Tech Evolution

The evolution of solenoid valve technology in reverse osmosis (RO) systems for water purification has been marked by significant advancements over the past few decades. Initially, solenoid valves in RO systems were primarily used for basic on/off control of water flow. These early valves were often large, energy-intensive, and prone to mechanical failures due to their simple designs and materials.

As water purification technologies progressed, the demand for more efficient and reliable solenoid valves grew. The 1980s and 1990s saw the introduction of more compact and durable valve designs, incorporating improved materials such as corrosion-resistant alloys and high-performance plastics. These advancements allowed for better resistance to the harsh chemical environments often present in water treatment processes.

The turn of the millennium brought about a shift towards energy efficiency and precision control. Manufacturers began developing low-power solenoid valves that could operate effectively with minimal energy consumption, aligning with the growing focus on sustainability in water treatment. Concurrently, the integration of electronic controls allowed for more precise regulation of water flow and pressure, enhancing the overall efficiency of RO systems.

In the 2010s, the advent of smart technology revolutionized solenoid valve applications in RO systems. Internet of Things (IoT) capabilities were integrated into valve designs, enabling remote monitoring and control. This innovation allowed for real-time adjustments to system parameters, predictive maintenance, and improved overall system performance.

Recent years have seen a focus on miniaturization and modularization of solenoid valves. Compact, modular designs have facilitated easier installation and maintenance, while also allowing for more flexible system configurations. Additionally, advancements in materials science have led to the development of valves with enhanced chemical resistance and longer operational lifespans.

The latest trend in solenoid valve technology for RO systems is the incorporation of artificial intelligence and machine learning algorithms. These cutting-edge technologies enable self-optimizing systems that can adapt to changing water conditions and usage patterns, further improving efficiency and reducing waste.

Looking ahead, the future of solenoid valve technology in RO systems is likely to focus on even greater precision, energy efficiency, and integration with smart water management systems. Emerging areas of research include the development of self-cleaning valve mechanisms to reduce maintenance requirements and the exploration of novel materials that can withstand increasingly challenging water treatment conditions.

As water purification technologies progressed, the demand for more efficient and reliable solenoid valves grew. The 1980s and 1990s saw the introduction of more compact and durable valve designs, incorporating improved materials such as corrosion-resistant alloys and high-performance plastics. These advancements allowed for better resistance to the harsh chemical environments often present in water treatment processes.

The turn of the millennium brought about a shift towards energy efficiency and precision control. Manufacturers began developing low-power solenoid valves that could operate effectively with minimal energy consumption, aligning with the growing focus on sustainability in water treatment. Concurrently, the integration of electronic controls allowed for more precise regulation of water flow and pressure, enhancing the overall efficiency of RO systems.

In the 2010s, the advent of smart technology revolutionized solenoid valve applications in RO systems. Internet of Things (IoT) capabilities were integrated into valve designs, enabling remote monitoring and control. This innovation allowed for real-time adjustments to system parameters, predictive maintenance, and improved overall system performance.

Recent years have seen a focus on miniaturization and modularization of solenoid valves. Compact, modular designs have facilitated easier installation and maintenance, while also allowing for more flexible system configurations. Additionally, advancements in materials science have led to the development of valves with enhanced chemical resistance and longer operational lifespans.

The latest trend in solenoid valve technology for RO systems is the incorporation of artificial intelligence and machine learning algorithms. These cutting-edge technologies enable self-optimizing systems that can adapt to changing water conditions and usage patterns, further improving efficiency and reducing waste.

Looking ahead, the future of solenoid valve technology in RO systems is likely to focus on even greater precision, energy efficiency, and integration with smart water management systems. Emerging areas of research include the development of self-cleaning valve mechanisms to reduce maintenance requirements and the exploration of novel materials that can withstand increasingly challenging water treatment conditions.

Water Purification Market Analysis

The global water purification market has been experiencing significant growth in recent years, driven by increasing concerns over water quality and scarcity. The market encompasses various technologies and solutions, with reverse osmosis (RO) systems emerging as a dominant player due to their efficiency and effectiveness in removing contaminants. Within this context, solenoid valves play a crucial role in the operation of RO systems, contributing to the overall market dynamics.

The water purification market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is fueled by several factors, including rapid urbanization, industrialization, and growing awareness of health and environmental issues related to water quality. Developing countries, particularly in Asia-Pacific and Africa, are witnessing a surge in demand for water purification solutions, presenting substantial opportunities for market expansion.

In the residential sector, there is an increasing adoption of point-of-use (POU) and point-of-entry (POE) water purification systems, with RO systems gaining popularity due to their ability to remove a wide range of contaminants. The commercial and industrial sectors are also significant contributors to market growth, as businesses and industries seek to comply with stringent water quality regulations and reduce their environmental footprint.

The market for solenoid valves within RO systems is closely tied to the overall water purification market trends. As the demand for RO systems grows, so does the need for high-quality, reliable solenoid valves. These components are essential for controlling water flow and pressure within RO systems, ensuring optimal performance and efficiency. Manufacturers of solenoid valves are focusing on developing innovative products that offer improved durability, energy efficiency, and compatibility with smart water management systems.

Geographically, North America and Europe currently hold significant market shares in the water purification industry, including RO systems and associated components like solenoid valves. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, population growth, and increasing water pollution concerns in countries like China and India.

The competitive landscape of the water purification market is characterized by the presence of both large multinational corporations and smaller, specialized companies. Key players in the RO system market are increasingly integrating advanced technologies, such as IoT and AI, to enhance system performance and provide value-added services. This trend is likely to impact the demand for more sophisticated solenoid valves capable of interfacing with smart control systems.

In conclusion, the water purification market, particularly the segment related to RO systems and solenoid valves, presents a promising outlook. The growing emphasis on water quality, coupled with technological advancements and regulatory pressures, is expected to drive continued market expansion and innovation in the coming years.

The water purification market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is fueled by several factors, including rapid urbanization, industrialization, and growing awareness of health and environmental issues related to water quality. Developing countries, particularly in Asia-Pacific and Africa, are witnessing a surge in demand for water purification solutions, presenting substantial opportunities for market expansion.

In the residential sector, there is an increasing adoption of point-of-use (POU) and point-of-entry (POE) water purification systems, with RO systems gaining popularity due to their ability to remove a wide range of contaminants. The commercial and industrial sectors are also significant contributors to market growth, as businesses and industries seek to comply with stringent water quality regulations and reduce their environmental footprint.

The market for solenoid valves within RO systems is closely tied to the overall water purification market trends. As the demand for RO systems grows, so does the need for high-quality, reliable solenoid valves. These components are essential for controlling water flow and pressure within RO systems, ensuring optimal performance and efficiency. Manufacturers of solenoid valves are focusing on developing innovative products that offer improved durability, energy efficiency, and compatibility with smart water management systems.

Geographically, North America and Europe currently hold significant market shares in the water purification industry, including RO systems and associated components like solenoid valves. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, population growth, and increasing water pollution concerns in countries like China and India.

The competitive landscape of the water purification market is characterized by the presence of both large multinational corporations and smaller, specialized companies. Key players in the RO system market are increasingly integrating advanced technologies, such as IoT and AI, to enhance system performance and provide value-added services. This trend is likely to impact the demand for more sophisticated solenoid valves capable of interfacing with smart control systems.

In conclusion, the water purification market, particularly the segment related to RO systems and solenoid valves, presents a promising outlook. The growing emphasis on water quality, coupled with technological advancements and regulatory pressures, is expected to drive continued market expansion and innovation in the coming years.

Solenoid Valve Challenges in RO

Solenoid valves play a crucial role in reverse osmosis (RO) systems for water purification, but they face several significant challenges that impact their performance and reliability. One of the primary issues is the harsh operating environment within RO systems. These valves are constantly exposed to high-pressure water, often containing various contaminants and minerals, which can lead to corrosion, scaling, and premature wear of valve components.

The precision control required in RO systems presents another major challenge. Solenoid valves must maintain accurate flow rates and pressure levels to ensure optimal membrane performance and system efficiency. However, the accumulation of mineral deposits and debris can interfere with valve operation, leading to inconsistent flow control and reduced system effectiveness over time.

Durability and longevity are critical concerns in RO applications. The frequent cycling of solenoid valves in these systems puts significant stress on their mechanical components. This constant operation can result in fatigue failure of springs, seals, and other vital parts, necessitating more frequent maintenance or replacement. The challenge lies in designing valves that can withstand this rigorous duty cycle while maintaining consistent performance.

Energy efficiency is another area where solenoid valves face challenges in RO systems. Traditional solenoid valves can consume significant amounts of power, especially in larger industrial RO installations. This not only increases operational costs but also contributes to the overall energy footprint of water purification processes. Developing more energy-efficient valve designs without compromising performance is a key challenge for manufacturers.

The need for miniaturization in modern RO systems, particularly in residential and small commercial applications, poses additional challenges for solenoid valve design. Engineers must balance the requirements for compact size with the need for robust construction and reliable operation. This often involves trade-offs between valve size, flow capacity, and durability.

Compatibility with different water qualities and treatment chemicals is another significant challenge. Solenoid valves in RO systems must be able to handle a wide range of water conditions, from highly chlorinated municipal water to brackish or seawater in desalination plants. The materials used in valve construction must resist chemical degradation while maintaining their functional properties over extended periods.

Lastly, the increasing demand for smart and automated RO systems introduces new challenges in solenoid valve technology. Integration with digital control systems, real-time monitoring capabilities, and remote operation features require more sophisticated valve designs. This evolution necessitates the development of valves with enhanced electronic interfaces and sensor capabilities, adding complexity to their design and potential points of failure.

The precision control required in RO systems presents another major challenge. Solenoid valves must maintain accurate flow rates and pressure levels to ensure optimal membrane performance and system efficiency. However, the accumulation of mineral deposits and debris can interfere with valve operation, leading to inconsistent flow control and reduced system effectiveness over time.

Durability and longevity are critical concerns in RO applications. The frequent cycling of solenoid valves in these systems puts significant stress on their mechanical components. This constant operation can result in fatigue failure of springs, seals, and other vital parts, necessitating more frequent maintenance or replacement. The challenge lies in designing valves that can withstand this rigorous duty cycle while maintaining consistent performance.

Energy efficiency is another area where solenoid valves face challenges in RO systems. Traditional solenoid valves can consume significant amounts of power, especially in larger industrial RO installations. This not only increases operational costs but also contributes to the overall energy footprint of water purification processes. Developing more energy-efficient valve designs without compromising performance is a key challenge for manufacturers.

The need for miniaturization in modern RO systems, particularly in residential and small commercial applications, poses additional challenges for solenoid valve design. Engineers must balance the requirements for compact size with the need for robust construction and reliable operation. This often involves trade-offs between valve size, flow capacity, and durability.

Compatibility with different water qualities and treatment chemicals is another significant challenge. Solenoid valves in RO systems must be able to handle a wide range of water conditions, from highly chlorinated municipal water to brackish or seawater in desalination plants. The materials used in valve construction must resist chemical degradation while maintaining their functional properties over extended periods.

Lastly, the increasing demand for smart and automated RO systems introduces new challenges in solenoid valve technology. Integration with digital control systems, real-time monitoring capabilities, and remote operation features require more sophisticated valve designs. This evolution necessitates the development of valves with enhanced electronic interfaces and sensor capabilities, adding complexity to their design and potential points of failure.

Current Solenoid Valve Solutions

01 Solenoid valve design improvements

Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and incorporating advanced sealing technologies. Such enhancements result in better flow control, reduced leakage, and increased durability of the valve.- Solenoid valve design improvements: Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and refining the electromagnetic coil design. Such enhancements can lead to better flow control, reduced power consumption, and increased durability of the valve.

- Control systems for solenoid valves: Advanced control systems have been developed for solenoid valves to improve their precision and responsiveness. These systems may incorporate electronic controllers, sensors, and feedback mechanisms to regulate valve operation. Such control systems can enable more accurate flow control, faster response times, and adaptive behavior based on operating conditions.

- Energy-efficient solenoid valve designs: Efforts have been made to create more energy-efficient solenoid valve designs. These may include the use of low-power actuators, improved magnetic circuit designs, and energy recovery mechanisms. Such designs aim to reduce power consumption while maintaining or improving valve performance, making them suitable for applications where energy efficiency is crucial.

- Miniaturization of solenoid valves: There has been a trend towards miniaturization of solenoid valves for use in compact systems and portable devices. This involves developing smaller valve components, integrating multiple functions into a single valve assembly, and using advanced manufacturing techniques. Miniaturized solenoid valves can offer space savings and improved response times in various applications.

- Solenoid valve materials and manufacturing: Advancements have been made in the materials and manufacturing processes used for solenoid valves. This includes the use of corrosion-resistant alloys, composite materials, and advanced coatings to improve valve durability and performance. Additionally, new manufacturing techniques such as 3D printing and precision machining have been employed to produce more complex and efficient valve designs.

02 Energy-efficient solenoid valves

Developments in energy-efficient solenoid valves focus on reducing power consumption while maintaining optimal performance. This is achieved through the use of advanced materials, improved electromagnetic designs, and innovative control mechanisms. These energy-efficient valves are particularly useful in applications where power conservation is crucial.Expand Specific Solutions03 Smart solenoid valves with integrated sensors

Integration of sensors and smart technologies into solenoid valves enables real-time monitoring and control of valve operations. These smart valves can provide data on flow rates, pressure, temperature, and valve position, allowing for predictive maintenance and improved system efficiency. They often incorporate digital interfaces for easy integration with control systems.Expand Specific Solutions04 Miniaturization of solenoid valves

Efforts to miniaturize solenoid valves have resulted in compact designs suitable for space-constrained applications. These miniature valves maintain functionality while reducing overall size and weight. Advancements in manufacturing techniques and materials have contributed to the development of these smaller, yet efficient valves.Expand Specific Solutions05 Solenoid valve applications in specific industries

Solenoid valves have been adapted for use in various specialized industries, including automotive, medical, and aerospace. These industry-specific valves are designed to meet unique requirements such as high-temperature resistance, chemical compatibility, or extreme precision. Customizations may include special materials, specific flow characteristics, or compliance with industry standards.Expand Specific Solutions

Key RO System Manufacturers

The solenoid valve applications in reverse osmosis systems for water purification market is in a growth phase, driven by increasing demand for clean water solutions. The global market size is projected to expand significantly in the coming years, with a compound annual growth rate expected to be in the double digits. Technologically, the field is moderately mature, with ongoing innovations focused on improving efficiency and reliability. Key players like Midea Group, Gree Electric Appliances, and LG Electronics are investing heavily in R&D to enhance their product offerings. Emerging companies such as KX Technologies and Zhejiang Qinyuan Water Treatment Technology are also making strides in developing advanced solenoid valve technologies for reverse osmosis systems, intensifying competition in this sector.

KX Technologies LLC

Technical Solution: KX Technologies has focused on developing high-efficiency solenoid valves specifically tailored for point-of-use RO systems. Their valves utilize a proprietary magnetic field optimization technique that reduces power consumption while maintaining rapid response times[10]. KX Technologies has also introduced a series of multi-port solenoid valves that can control multiple water flow paths simultaneously, simplifying the overall RO system design and reducing the total number of components required[11]. Additionally, the company has developed solenoid valves with integrated flow sensors, allowing for precise monitoring and control of water production rates in RO systems[12].

Strengths: Energy efficiency, simplified system design, and precise flow control. Weaknesses: May have limited scalability for larger industrial applications and potentially higher unit costs.

A. O. Smith India Water Products Pvt Ltd.

Technical Solution: A. O. Smith has developed robust solenoid valve solutions for RO systems, with a focus on durability and adaptability to varying water conditions. Their valves feature a reinforced diaphragm design that can withstand high mineral content and particulate matter often found in challenging water sources[13]. The company has also introduced a series of "smart" solenoid valves that can adjust their operation based on incoming water quality, optimizing the RO process for different source water conditions[14]. A. O. Smith's valves incorporate a fail-safe mechanism that automatically shuts off water flow in case of power failure or system malfunction, preventing water waste and potential flooding[15].

Strengths: Durability in challenging conditions, adaptive operation, and safety features. Weaknesses: May have higher power requirements and potentially more complex maintenance procedures.

Innovative Valve Technologies

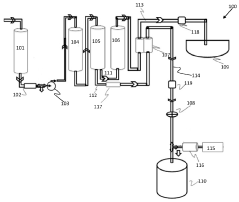

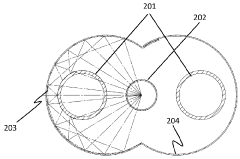

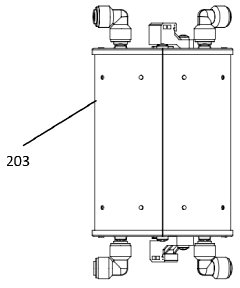

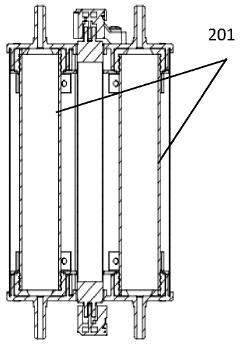

A reverse osmosis based water purification system with zero water wastage

PatentActiveIN202011033588A

Innovation

- A Reverse Osmosis based water purification system with zero water wastage, incorporating a UV column for microbiological disinfection of both purified and reject water streams, and a recirculation mechanism to reuse treated reject water, along with a value addition cartridge to enhance water quality for household and recreational use.

Water storage tank structure and operating method for the reverse osmosis water purifying system

PatentInactiveUS20170073942A1

Innovation

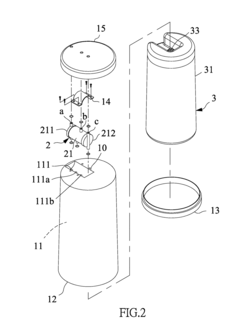

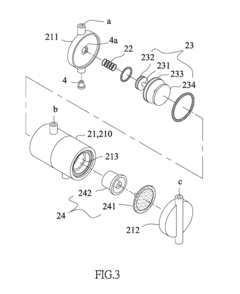

- A water storage tank with multiple passages and a mechanical lever positioner for water flow control, using drainage water to squeeze purified water out of a soft bladder without air or electrical power, and incorporating a check valve for pressure safety, allowing operation with low, medium, or high pressure RO membranes and enhancing water and energy efficiency.

Environmental Impact Assessment

The application of solenoid valves in reverse osmosis (RO) systems for water purification has significant environmental implications. These valves play a crucial role in controlling water flow and pressure within RO systems, thereby influencing the overall efficiency and environmental impact of the water purification process.

One of the primary environmental benefits of using solenoid valves in RO systems is the reduction of water waste. By precisely controlling the flow of water through the system, these valves help minimize the amount of water rejected during the purification process. This is particularly important in regions facing water scarcity, as it allows for more efficient use of available water resources.

Furthermore, the accurate control provided by solenoid valves contributes to energy conservation in RO systems. By optimizing the pressure and flow rates, these valves help reduce the energy required to operate the high-pressure pumps used in reverse osmosis. This leads to lower electricity consumption and, consequently, a reduction in the carbon footprint associated with water purification processes.

The use of solenoid valves also enhances the longevity of RO membranes, which are critical components in the purification process. By preventing sudden pressure changes and ensuring consistent flow, these valves help protect the membranes from damage. This results in less frequent membrane replacements, reducing the environmental impact associated with membrane production and disposal.

In terms of chemical usage, solenoid valves contribute to more precise dosing of cleaning and anti-scaling agents in RO systems. This optimization leads to a reduction in the overall chemical consumption, minimizing the environmental impact of these substances and decreasing the potential for chemical contamination in water bodies.

However, it is important to consider the environmental impact of the solenoid valves themselves. The production of these valves involves the use of various materials, including metals and plastics, which have their own environmental footprints. Additionally, the electronic components in solenoid valves may contain hazardous materials that require proper disposal at the end of their lifecycle.

To mitigate these concerns, efforts are being made to develop more environmentally friendly solenoid valves. This includes the use of recyclable materials, the reduction of hazardous components, and the improvement of energy efficiency in valve operation. Some manufacturers are also exploring the use of biodegradable materials for certain valve components, further reducing the environmental impact.

In conclusion, while solenoid valves in RO systems for water purification offer significant environmental benefits through improved efficiency and resource conservation, it is crucial to consider their full lifecycle impact. Continued research and development in this field should focus on further enhancing the environmental performance of these valves, ensuring that their positive contributions to water purification outweigh any negative impacts associated with their production and disposal.

One of the primary environmental benefits of using solenoid valves in RO systems is the reduction of water waste. By precisely controlling the flow of water through the system, these valves help minimize the amount of water rejected during the purification process. This is particularly important in regions facing water scarcity, as it allows for more efficient use of available water resources.

Furthermore, the accurate control provided by solenoid valves contributes to energy conservation in RO systems. By optimizing the pressure and flow rates, these valves help reduce the energy required to operate the high-pressure pumps used in reverse osmosis. This leads to lower electricity consumption and, consequently, a reduction in the carbon footprint associated with water purification processes.

The use of solenoid valves also enhances the longevity of RO membranes, which are critical components in the purification process. By preventing sudden pressure changes and ensuring consistent flow, these valves help protect the membranes from damage. This results in less frequent membrane replacements, reducing the environmental impact associated with membrane production and disposal.

In terms of chemical usage, solenoid valves contribute to more precise dosing of cleaning and anti-scaling agents in RO systems. This optimization leads to a reduction in the overall chemical consumption, minimizing the environmental impact of these substances and decreasing the potential for chemical contamination in water bodies.

However, it is important to consider the environmental impact of the solenoid valves themselves. The production of these valves involves the use of various materials, including metals and plastics, which have their own environmental footprints. Additionally, the electronic components in solenoid valves may contain hazardous materials that require proper disposal at the end of their lifecycle.

To mitigate these concerns, efforts are being made to develop more environmentally friendly solenoid valves. This includes the use of recyclable materials, the reduction of hazardous components, and the improvement of energy efficiency in valve operation. Some manufacturers are also exploring the use of biodegradable materials for certain valve components, further reducing the environmental impact.

In conclusion, while solenoid valves in RO systems for water purification offer significant environmental benefits through improved efficiency and resource conservation, it is crucial to consider their full lifecycle impact. Continued research and development in this field should focus on further enhancing the environmental performance of these valves, ensuring that their positive contributions to water purification outweigh any negative impacts associated with their production and disposal.

RO System Energy Efficiency

Energy efficiency is a critical aspect of reverse osmosis (RO) systems for water purification, and solenoid valves play a significant role in optimizing energy consumption. RO systems are known for their high energy requirements, primarily due to the need for maintaining high pressure to overcome osmotic pressure and force water through semi-permeable membranes. Improving energy efficiency in these systems is crucial for reducing operational costs and environmental impact.

Solenoid valves contribute to energy efficiency in RO systems through precise control of fluid flow and pressure. By rapidly and accurately regulating the flow of water and brine, these valves help minimize energy waste and optimize the overall system performance. Advanced solenoid valve designs incorporate features such as low-power actuation and rapid response times, which directly impact energy consumption.

One key area where solenoid valves enhance energy efficiency is in the management of feed water and concentrate streams. By precisely controlling the flow rates and pressures in these streams, solenoid valves help maintain optimal operating conditions, reducing the energy required for pumping and pressurization. This fine-tuned control also helps prevent over-pressurization and unnecessary energy expenditure.

Energy recovery devices (ERDs) are another critical component in improving RO system efficiency, and solenoid valves play a crucial role in their operation. ERDs recover energy from the high-pressure concentrate stream, transferring it to the incoming feed water. Solenoid valves facilitate the precise timing and flow control required for effective energy recovery, significantly reducing the overall energy consumption of the system.

In modern RO systems, smart solenoid valves integrated with advanced control systems contribute to dynamic energy management. These valves can adjust their operation based on real-time system parameters, such as feed water quality, membrane condition, and desired output. This adaptive control helps maintain optimal energy efficiency across varying operating conditions.

The development of low-power solenoid valves has further contributed to energy savings in RO systems. These valves require minimal electrical energy for actuation, reducing the auxiliary power consumption of the system. When multiplied across numerous valves in large-scale RO plants, this reduction in power consumption can lead to significant energy savings.

Maintenance and longevity of RO systems also impact their long-term energy efficiency. Solenoid valves with enhanced durability and reliability help maintain system integrity, preventing energy losses due to leaks or malfunctions. Regular maintenance and timely replacement of these valves ensure that the system continues to operate at peak efficiency throughout its lifecycle.

Solenoid valves contribute to energy efficiency in RO systems through precise control of fluid flow and pressure. By rapidly and accurately regulating the flow of water and brine, these valves help minimize energy waste and optimize the overall system performance. Advanced solenoid valve designs incorporate features such as low-power actuation and rapid response times, which directly impact energy consumption.

One key area where solenoid valves enhance energy efficiency is in the management of feed water and concentrate streams. By precisely controlling the flow rates and pressures in these streams, solenoid valves help maintain optimal operating conditions, reducing the energy required for pumping and pressurization. This fine-tuned control also helps prevent over-pressurization and unnecessary energy expenditure.

Energy recovery devices (ERDs) are another critical component in improving RO system efficiency, and solenoid valves play a crucial role in their operation. ERDs recover energy from the high-pressure concentrate stream, transferring it to the incoming feed water. Solenoid valves facilitate the precise timing and flow control required for effective energy recovery, significantly reducing the overall energy consumption of the system.

In modern RO systems, smart solenoid valves integrated with advanced control systems contribute to dynamic energy management. These valves can adjust their operation based on real-time system parameters, such as feed water quality, membrane condition, and desired output. This adaptive control helps maintain optimal energy efficiency across varying operating conditions.

The development of low-power solenoid valves has further contributed to energy savings in RO systems. These valves require minimal electrical energy for actuation, reducing the auxiliary power consumption of the system. When multiplied across numerous valves in large-scale RO plants, this reduction in power consumption can lead to significant energy savings.

Maintenance and longevity of RO systems also impact their long-term energy efficiency. Solenoid valves with enhanced durability and reliability help maintain system integrity, preventing energy losses due to leaks or malfunctions. Regular maintenance and timely replacement of these valves ensure that the system continues to operate at peak efficiency throughout its lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!