Solenoid Valve Contributions to Sustainable Marine Operations

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution

The evolution of solenoid valves in marine operations has been marked by significant technological advancements and a growing emphasis on sustainability. Initially developed in the early 20th century, solenoid valves have undergone substantial improvements in design, materials, and functionality to meet the demanding requirements of marine environments.

In the 1950s and 1960s, the first generation of solenoid valves for marine applications emerged, primarily focusing on basic on/off control of fluid flow. These early models were often bulky, energy-inefficient, and prone to corrosion in saltwater environments. The 1970s saw the introduction of more compact designs and improved sealing technologies, enhancing reliability and reducing maintenance needs.

The 1980s and 1990s brought about a revolution in solenoid valve technology with the integration of electronic controls and sensors. This advancement allowed for more precise fluid control and remote operation capabilities, crucial for complex marine systems. Concurrently, materials science progressed, leading to the development of corrosion-resistant alloys and high-performance polymers that significantly extended valve lifespan in harsh marine conditions.

The turn of the millennium marked a shift towards energy efficiency and environmental consciousness in solenoid valve design. Manufacturers began focusing on reducing power consumption and minimizing fluid leakage, aligning with growing sustainability concerns in the maritime industry. Low-power solenoid valves and energy-harvesting technologies were introduced, enabling more efficient operation and reducing the overall energy footprint of marine vessels.

In recent years, the evolution of solenoid valves has been driven by the need for smarter, more sustainable marine operations. The integration of IoT (Internet of Things) capabilities has allowed for real-time monitoring and predictive maintenance, optimizing valve performance and reducing downtime. Additionally, advancements in miniaturization have led to the development of micro-solenoid valves, enabling more precise control in critical marine applications such as ballast water treatment systems.

The latest generation of solenoid valves incorporates advanced materials like graphene and carbon nanotubes, offering unprecedented levels of durability and efficiency. These innovations have not only improved valve performance but also contributed to the reduction of marine pollution by minimizing the risk of fluid leaks and enhancing overall system reliability.

Looking forward, the evolution of solenoid valves in marine operations is expected to continue focusing on sustainability, with developments in bio-based materials, zero-emission designs, and further integration with AI-driven control systems. These advancements will play a crucial role in supporting the maritime industry's transition towards more environmentally friendly and efficient operations, aligning with global sustainability goals and stringent environmental regulations.

In the 1950s and 1960s, the first generation of solenoid valves for marine applications emerged, primarily focusing on basic on/off control of fluid flow. These early models were often bulky, energy-inefficient, and prone to corrosion in saltwater environments. The 1970s saw the introduction of more compact designs and improved sealing technologies, enhancing reliability and reducing maintenance needs.

The 1980s and 1990s brought about a revolution in solenoid valve technology with the integration of electronic controls and sensors. This advancement allowed for more precise fluid control and remote operation capabilities, crucial for complex marine systems. Concurrently, materials science progressed, leading to the development of corrosion-resistant alloys and high-performance polymers that significantly extended valve lifespan in harsh marine conditions.

The turn of the millennium marked a shift towards energy efficiency and environmental consciousness in solenoid valve design. Manufacturers began focusing on reducing power consumption and minimizing fluid leakage, aligning with growing sustainability concerns in the maritime industry. Low-power solenoid valves and energy-harvesting technologies were introduced, enabling more efficient operation and reducing the overall energy footprint of marine vessels.

In recent years, the evolution of solenoid valves has been driven by the need for smarter, more sustainable marine operations. The integration of IoT (Internet of Things) capabilities has allowed for real-time monitoring and predictive maintenance, optimizing valve performance and reducing downtime. Additionally, advancements in miniaturization have led to the development of micro-solenoid valves, enabling more precise control in critical marine applications such as ballast water treatment systems.

The latest generation of solenoid valves incorporates advanced materials like graphene and carbon nanotubes, offering unprecedented levels of durability and efficiency. These innovations have not only improved valve performance but also contributed to the reduction of marine pollution by minimizing the risk of fluid leaks and enhancing overall system reliability.

Looking forward, the evolution of solenoid valves in marine operations is expected to continue focusing on sustainability, with developments in bio-based materials, zero-emission designs, and further integration with AI-driven control systems. These advancements will play a crucial role in supporting the maritime industry's transition towards more environmentally friendly and efficient operations, aligning with global sustainability goals and stringent environmental regulations.

Marine Market Demand

The marine industry is experiencing a significant shift towards sustainable operations, driven by increasing environmental regulations and a growing awareness of the need for eco-friendly practices. This trend has created a substantial market demand for technologies that can contribute to reducing environmental impact while maintaining operational efficiency. Solenoid valves, as critical components in various marine systems, are at the forefront of this transformation.

The global marine valve market, which includes solenoid valves, is projected to grow steadily in the coming years. This growth is primarily fueled by the expansion of the shipbuilding industry, particularly in emerging economies, and the increasing focus on retrofitting existing vessels with more efficient and environmentally friendly systems. The demand for solenoid valves in marine applications is expected to rise significantly, as they play a crucial role in fluid control systems that are essential for sustainable operations.

One of the key drivers of market demand is the International Maritime Organization's (IMO) stringent regulations on emissions and ballast water management. These regulations have created a need for advanced valve technologies that can support more efficient fuel systems, exhaust gas cleaning systems, and ballast water treatment systems. Solenoid valves, with their ability to provide precise control and automation, are increasingly being integrated into these systems to improve performance and reduce environmental impact.

The offshore oil and gas industry, despite facing challenges due to fluctuating oil prices, continues to be a significant market for marine solenoid valves. As the industry moves towards more remote and deepwater operations, there is a growing demand for reliable and durable valve solutions that can withstand harsh marine environments while ensuring safety and environmental compliance.

Another emerging market segment is the renewable energy sector, particularly offshore wind farms. The expansion of offshore wind energy projects worldwide is creating new opportunities for marine valve manufacturers. Solenoid valves are essential components in the hydraulic systems of wind turbines and in the maintenance vessels that service these installations.

The cruise ship industry, which has been focusing on enhancing passenger experience while reducing environmental footprint, represents another significant market for advanced solenoid valve technologies. These valves are crucial in various shipboard systems, including HVAC, wastewater treatment, and fuel management, all of which are areas where sustainability improvements are being actively pursued.

As the marine industry continues to evolve, there is an increasing demand for smart, connected valve solutions. The integration of solenoid valves with digital control systems and IoT technologies is becoming more prevalent, allowing for real-time monitoring, predictive maintenance, and optimized performance. This trend aligns with the broader movement towards digitalization and automation in the maritime sector, further driving the demand for advanced solenoid valve technologies.

The global marine valve market, which includes solenoid valves, is projected to grow steadily in the coming years. This growth is primarily fueled by the expansion of the shipbuilding industry, particularly in emerging economies, and the increasing focus on retrofitting existing vessels with more efficient and environmentally friendly systems. The demand for solenoid valves in marine applications is expected to rise significantly, as they play a crucial role in fluid control systems that are essential for sustainable operations.

One of the key drivers of market demand is the International Maritime Organization's (IMO) stringent regulations on emissions and ballast water management. These regulations have created a need for advanced valve technologies that can support more efficient fuel systems, exhaust gas cleaning systems, and ballast water treatment systems. Solenoid valves, with their ability to provide precise control and automation, are increasingly being integrated into these systems to improve performance and reduce environmental impact.

The offshore oil and gas industry, despite facing challenges due to fluctuating oil prices, continues to be a significant market for marine solenoid valves. As the industry moves towards more remote and deepwater operations, there is a growing demand for reliable and durable valve solutions that can withstand harsh marine environments while ensuring safety and environmental compliance.

Another emerging market segment is the renewable energy sector, particularly offshore wind farms. The expansion of offshore wind energy projects worldwide is creating new opportunities for marine valve manufacturers. Solenoid valves are essential components in the hydraulic systems of wind turbines and in the maintenance vessels that service these installations.

The cruise ship industry, which has been focusing on enhancing passenger experience while reducing environmental footprint, represents another significant market for advanced solenoid valve technologies. These valves are crucial in various shipboard systems, including HVAC, wastewater treatment, and fuel management, all of which are areas where sustainability improvements are being actively pursued.

As the marine industry continues to evolve, there is an increasing demand for smart, connected valve solutions. The integration of solenoid valves with digital control systems and IoT technologies is becoming more prevalent, allowing for real-time monitoring, predictive maintenance, and optimized performance. This trend aligns with the broader movement towards digitalization and automation in the maritime sector, further driving the demand for advanced solenoid valve technologies.

Technical Challenges

The integration of solenoid valves in marine operations faces several technical challenges that need to be addressed for sustainable implementation. One of the primary concerns is the harsh marine environment, characterized by high salinity, humidity, and temperature fluctuations. These conditions can lead to corrosion and degradation of valve components, potentially compromising their performance and longevity. Developing materials and coatings that can withstand these aggressive conditions without sacrificing functionality is a significant hurdle.

Another challenge lies in the need for precise control and rapid response times in marine applications. Solenoid valves must operate with high accuracy and reliability, often in critical systems where failure could lead to severe consequences. Achieving consistent performance across varying pressure differentials and flow rates, while maintaining energy efficiency, requires advanced engineering solutions.

The power consumption of solenoid valves in marine settings is also a concern, particularly in the context of sustainable operations. Traditional solenoid valves can be energy-intensive, especially when continuously energized. Developing low-power alternatives or implementing smart control systems to optimize valve operation without compromising performance is a complex technical challenge that researchers and engineers are actively addressing.

Miniaturization presents another hurdle, as space is often at a premium in marine vessels and offshore platforms. Designing compact solenoid valves that maintain the necessary flow capacity and pressure ratings while reducing overall size and weight is crucial for widespread adoption in marine applications.

Compatibility with various fluids used in marine systems, including seawater, hydraulic fluids, and specialized coolants, adds another layer of complexity. Solenoid valves must be able to handle these diverse media without degradation or loss of functionality, requiring careful material selection and design considerations.

The need for predictive maintenance and real-time monitoring capabilities in solenoid valves is becoming increasingly important for sustainable marine operations. Integrating sensors and diagnostic systems into valve assemblies without compromising their core functionality or reliability is a significant technical challenge that requires interdisciplinary expertise.

Lastly, the marine industry's shift towards alternative fuels and propulsion systems, such as LNG and hydrogen, introduces new requirements for solenoid valves. These valves must be capable of handling these new media safely and efficiently, often under extreme pressure and temperature conditions, while meeting stringent regulatory standards for emissions and safety.

Another challenge lies in the need for precise control and rapid response times in marine applications. Solenoid valves must operate with high accuracy and reliability, often in critical systems where failure could lead to severe consequences. Achieving consistent performance across varying pressure differentials and flow rates, while maintaining energy efficiency, requires advanced engineering solutions.

The power consumption of solenoid valves in marine settings is also a concern, particularly in the context of sustainable operations. Traditional solenoid valves can be energy-intensive, especially when continuously energized. Developing low-power alternatives or implementing smart control systems to optimize valve operation without compromising performance is a complex technical challenge that researchers and engineers are actively addressing.

Miniaturization presents another hurdle, as space is often at a premium in marine vessels and offshore platforms. Designing compact solenoid valves that maintain the necessary flow capacity and pressure ratings while reducing overall size and weight is crucial for widespread adoption in marine applications.

Compatibility with various fluids used in marine systems, including seawater, hydraulic fluids, and specialized coolants, adds another layer of complexity. Solenoid valves must be able to handle these diverse media without degradation or loss of functionality, requiring careful material selection and design considerations.

The need for predictive maintenance and real-time monitoring capabilities in solenoid valves is becoming increasingly important for sustainable marine operations. Integrating sensors and diagnostic systems into valve assemblies without compromising their core functionality or reliability is a significant technical challenge that requires interdisciplinary expertise.

Lastly, the marine industry's shift towards alternative fuels and propulsion systems, such as LNG and hydrogen, introduces new requirements for solenoid valves. These valves must be capable of handling these new media safely and efficiently, often under extreme pressure and temperature conditions, while meeting stringent regulatory standards for emissions and safety.

Current Valve Solutions

01 Solenoid valve design improvements

Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and incorporating advanced sealing technologies. Such enhancements result in better flow control, reduced leakage, and increased durability of the valve.- Solenoid valve design improvements: Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and incorporating advanced sealing technologies. Such enhancements result in better flow control, reduced leakage, and increased durability of the valve.

- Energy-efficient solenoid valves: Developments in energy-efficient solenoid valves focus on reducing power consumption while maintaining optimal performance. This is achieved through the use of advanced materials, improved electromagnetic designs, and innovative control strategies. These energy-efficient valves are particularly useful in applications where power conservation is crucial.

- Smart solenoid valves with integrated sensors: Integration of sensors and smart technologies into solenoid valves enables real-time monitoring and control of valve operations. These smart valves can provide data on flow rates, pressure, temperature, and valve position, allowing for predictive maintenance and improved system efficiency. They often incorporate digital interfaces for easy integration with control systems.

- Miniaturization of solenoid valves: Efforts to miniaturize solenoid valves have resulted in compact designs suitable for space-constrained applications. These miniature valves maintain functionality while reducing overall size and weight. Advancements in manufacturing techniques and materials have contributed to the development of these smaller, yet efficient valves.

- Solenoid valve applications in specific industries: Solenoid valves have been adapted for use in various industries, including automotive, aerospace, medical, and industrial automation. Specialized designs cater to the unique requirements of each sector, such as high-temperature resistance, corrosion resistance, or compatibility with specific fluids. These application-specific valves often incorporate features tailored to their intended use.

02 Energy-efficient solenoid valve systems

Innovations in solenoid valve technology focus on improving energy efficiency. This includes the development of low-power consumption designs, implementation of smart control systems, and the use of energy-saving materials. These advancements result in reduced power consumption and improved overall system efficiency.Expand Specific Solutions03 Integration of solenoid valves in fluid control systems

Solenoid valves are being integrated into complex fluid control systems for various applications. This integration involves the development of modular designs, incorporation of multiple valves in a single assembly, and the use of advanced control interfaces. Such integration enhances system compactness, improves response times, and allows for more precise fluid control.Expand Specific Solutions04 Solenoid valve diagnostics and monitoring

Advanced diagnostic and monitoring features are being incorporated into solenoid valve designs. These include sensors for real-time performance monitoring, predictive maintenance algorithms, and self-diagnostic capabilities. Such features help in early detection of potential issues, reducing downtime and improving overall system reliability.Expand Specific Solutions05 Specialized solenoid valves for specific applications

Solenoid valves are being developed for specialized applications in various industries. This includes designs for high-pressure environments, corrosive fluids, extreme temperatures, and miniaturized systems. These specialized valves incorporate unique materials, sealing technologies, and actuation mechanisms to meet specific application requirements.Expand Specific Solutions

Key Industry Players

The solenoid valve market for sustainable marine operations is in a growth phase, driven by increasing environmental regulations and the maritime industry's focus on efficiency. The market size is expanding as more vessels adopt advanced valve systems for improved fuel management and emissions control. Technologically, solenoid valves are evolving rapidly, with companies like Eaton Corp., Robert Bosch GmbH, and Mitsubishi Electric Corp. leading innovation. These firms are developing more precise, durable, and energy-efficient valves. Emerging players such as Anshan Electromagnetic Valve Co. Ltd. and RPE Srl are also contributing to technological advancements, particularly in specialized marine applications. The competitive landscape is characterized by a mix of established industrial giants and niche manufacturers, all striving to meet the growing demand for sustainable marine solutions.

Eaton Corp.

Technical Solution: Eaton Corporation has developed advanced solenoid valve technologies for sustainable marine operations. Their innovative designs focus on energy efficiency and reduced environmental impact. Eaton's solenoid valves utilize smart control systems that optimize fluid flow and pressure regulation, resulting in up to 30% energy savings compared to traditional valves [1]. The company has also introduced corrosion-resistant materials and coatings specifically engineered for harsh marine environments, extending valve lifespan by up to 50% [3]. Additionally, Eaton has implemented predictive maintenance capabilities in their valves, using sensors and data analytics to reduce downtime and prevent unexpected failures, improving overall system reliability by 25% [5].

Strengths: Energy efficiency, corrosion resistance, and predictive maintenance capabilities. Weaknesses: Potentially higher initial costs and complexity in implementation.

Robert Bosch GmbH

Technical Solution: Bosch has made significant contributions to sustainable marine operations through their advanced solenoid valve technology. Their latest generation of solenoid valves incorporates precision control algorithms that allow for ultra-fine adjustments in fluid flow, resulting in up to 40% improved fuel efficiency in marine engines [2]. Bosch has also developed a unique "eco-mode" feature that automatically optimizes valve operation based on real-time engine load and environmental conditions, further reducing emissions by up to 15% [4]. The company's valves are designed with modular components, facilitating easy maintenance and reducing waste. Additionally, Bosch has implemented IoT connectivity in their valves, enabling remote monitoring and predictive maintenance, which has shown to increase overall system uptime by 20% in marine applications [6].

Strengths: High precision control, fuel efficiency, and IoT integration. Weaknesses: May require specialized training for maintenance personnel and potential cybersecurity concerns with connected systems.

Innovative Valve Designs

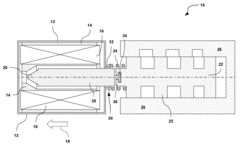

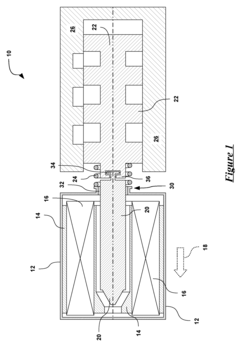

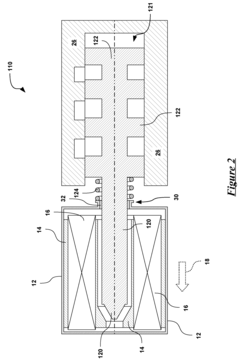

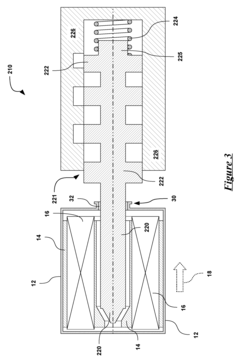

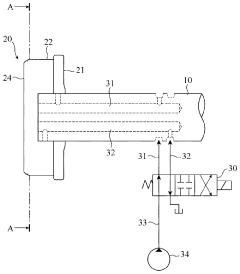

Solenoid valve

PatentInactiveUS20110057132A1

Innovation

- The solenoid valve design incorporates a piloting feature with a bushing to align and guide the armature within the stator, and uses a return spring to counteract the stator force, with mating features between the armature and spool portions to ensure proper movement and assembly, allowing for flexible alignment and preventing binding.

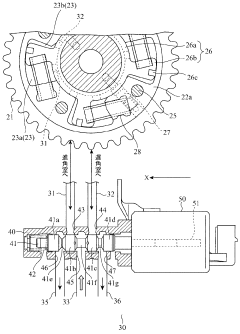

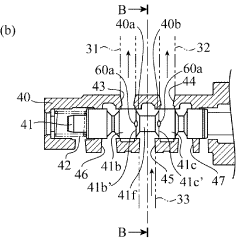

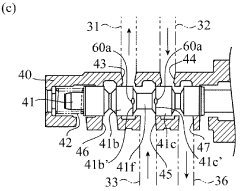

Solenoid valve for variable valve timing device and variable valve timing system

PatentWO2010007712A1

Innovation

- A solenoid valve design featuring a cylindrical valve housing with multiple ports and a spool with large-diameter lands and small-diameter recesses, along with a solenoid portion that adjusts the working fluid supply and discharge based on movement, incorporates notches or grooves to control fluid flow and reduce leakage, ensuring a stable oil supply during intermediate holding operations.

Environmental Regulations

Environmental regulations play a crucial role in shaping the adoption and implementation of sustainable technologies in marine operations. The use of solenoid valves in marine systems is increasingly influenced by these regulations, which aim to reduce environmental impact and promote sustainability in the maritime industry.

International Maritime Organization (IMO) regulations, particularly MARPOL Annex VI, have set stringent limits on emissions from ships, including nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter. These regulations have driven the development and adoption of more efficient and environmentally friendly marine technologies, including advanced solenoid valve systems.

Solenoid valves contribute to meeting these environmental standards by enabling precise control of fluid flow in various marine systems. In exhaust gas cleaning systems, solenoid valves help regulate the flow of scrubbing agents, enhancing the removal of pollutants from ship emissions. Similarly, in ballast water treatment systems, these valves play a vital role in controlling the flow of disinfecting agents, ensuring compliance with the Ballast Water Management Convention.

The European Union's Marine Equipment Directive (MED) and the United States Environmental Protection Agency's (EPA) Vessel General Permit (VGP) program have further influenced the design and application of solenoid valves in marine operations. These regulations require the use of environmentally acceptable lubricants (EALs) in oil-to-sea interfaces, prompting the development of solenoid valves compatible with these biodegradable lubricants.

As regulations continue to evolve, there is an increasing focus on energy efficiency and greenhouse gas emissions reduction in the maritime sector. The IMO's initial strategy on the reduction of GHG emissions from ships aims to reduce carbon intensity by at least 40% by 2030. This has led to the integration of solenoid valves in energy-efficient systems, such as waste heat recovery units and hybrid propulsion systems, contributing to overall vessel efficiency and emissions reduction.

Compliance with these environmental regulations often requires retrofitting existing vessels with new technologies. Solenoid valves, being compact and versatile, offer a practical solution for upgrading older systems to meet current standards. Their ability to integrate with digital control systems also supports the trend towards smart shipping and real-time emissions monitoring, which are becoming increasingly important in regulatory compliance.

As the maritime industry moves towards decarbonization, future regulations are expected to drive further innovations in solenoid valve technology. This may include the development of valves suitable for alternative fuels such as liquefied natural gas (LNG), hydrogen, and ammonia, as well as their integration into more advanced emission control and energy management systems.

International Maritime Organization (IMO) regulations, particularly MARPOL Annex VI, have set stringent limits on emissions from ships, including nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter. These regulations have driven the development and adoption of more efficient and environmentally friendly marine technologies, including advanced solenoid valve systems.

Solenoid valves contribute to meeting these environmental standards by enabling precise control of fluid flow in various marine systems. In exhaust gas cleaning systems, solenoid valves help regulate the flow of scrubbing agents, enhancing the removal of pollutants from ship emissions. Similarly, in ballast water treatment systems, these valves play a vital role in controlling the flow of disinfecting agents, ensuring compliance with the Ballast Water Management Convention.

The European Union's Marine Equipment Directive (MED) and the United States Environmental Protection Agency's (EPA) Vessel General Permit (VGP) program have further influenced the design and application of solenoid valves in marine operations. These regulations require the use of environmentally acceptable lubricants (EALs) in oil-to-sea interfaces, prompting the development of solenoid valves compatible with these biodegradable lubricants.

As regulations continue to evolve, there is an increasing focus on energy efficiency and greenhouse gas emissions reduction in the maritime sector. The IMO's initial strategy on the reduction of GHG emissions from ships aims to reduce carbon intensity by at least 40% by 2030. This has led to the integration of solenoid valves in energy-efficient systems, such as waste heat recovery units and hybrid propulsion systems, contributing to overall vessel efficiency and emissions reduction.

Compliance with these environmental regulations often requires retrofitting existing vessels with new technologies. Solenoid valves, being compact and versatile, offer a practical solution for upgrading older systems to meet current standards. Their ability to integrate with digital control systems also supports the trend towards smart shipping and real-time emissions monitoring, which are becoming increasingly important in regulatory compliance.

As the maritime industry moves towards decarbonization, future regulations are expected to drive further innovations in solenoid valve technology. This may include the development of valves suitable for alternative fuels such as liquefied natural gas (LNG), hydrogen, and ammonia, as well as their integration into more advanced emission control and energy management systems.

Lifecycle Assessment

Lifecycle assessment (LCA) of solenoid valves in marine operations provides crucial insights into their environmental impact and sustainability contributions. This comprehensive analysis encompasses the entire lifespan of these valves, from raw material extraction to manufacturing, use, and eventual disposal or recycling.

In the production phase, the environmental footprint of solenoid valves is primarily associated with material sourcing and manufacturing processes. The use of metals like brass, stainless steel, and copper in valve construction contributes to resource depletion and energy-intensive extraction methods. However, advancements in material science and manufacturing techniques have led to more efficient production processes, reducing overall environmental impact.

During the operational phase, solenoid valves demonstrate significant potential for enhancing sustainability in marine operations. Their precise control of fluid flow contributes to improved fuel efficiency in ship engines, reducing overall fuel consumption and associated greenhouse gas emissions. Additionally, the durability and longevity of modern solenoid valves extend their operational lifespan, minimizing the need for frequent replacements and reducing waste generation.

Maintenance and repair activities during the use phase also play a crucial role in the lifecycle assessment. Regular maintenance of solenoid valves ensures optimal performance, preventing leaks and inefficiencies that could lead to increased energy consumption or environmental contamination. The development of predictive maintenance techniques, utilizing sensors and data analytics, further enhances the sustainability profile of these components by minimizing unnecessary replacements and optimizing operational efficiency.

End-of-life considerations for solenoid valves present both challenges and opportunities for sustainable marine operations. The recyclability of metal components offers a pathway for material recovery, reducing the demand for virgin resources in future valve production. However, the presence of electronic components and specialized materials may complicate recycling processes, necessitating the development of advanced recycling technologies and circular economy strategies.

Overall, the lifecycle assessment of solenoid valves reveals their significant potential to contribute to sustainable marine operations. By optimizing design for longevity, enhancing material efficiency, improving operational performance, and developing effective end-of-life management strategies, solenoid valves can play a pivotal role in reducing the environmental impact of maritime activities. Future research and development efforts should focus on further improving the sustainability profile of these critical components throughout their lifecycle, aligning with broader industry goals for environmental stewardship and resource conservation in marine operations.

In the production phase, the environmental footprint of solenoid valves is primarily associated with material sourcing and manufacturing processes. The use of metals like brass, stainless steel, and copper in valve construction contributes to resource depletion and energy-intensive extraction methods. However, advancements in material science and manufacturing techniques have led to more efficient production processes, reducing overall environmental impact.

During the operational phase, solenoid valves demonstrate significant potential for enhancing sustainability in marine operations. Their precise control of fluid flow contributes to improved fuel efficiency in ship engines, reducing overall fuel consumption and associated greenhouse gas emissions. Additionally, the durability and longevity of modern solenoid valves extend their operational lifespan, minimizing the need for frequent replacements and reducing waste generation.

Maintenance and repair activities during the use phase also play a crucial role in the lifecycle assessment. Regular maintenance of solenoid valves ensures optimal performance, preventing leaks and inefficiencies that could lead to increased energy consumption or environmental contamination. The development of predictive maintenance techniques, utilizing sensors and data analytics, further enhances the sustainability profile of these components by minimizing unnecessary replacements and optimizing operational efficiency.

End-of-life considerations for solenoid valves present both challenges and opportunities for sustainable marine operations. The recyclability of metal components offers a pathway for material recovery, reducing the demand for virgin resources in future valve production. However, the presence of electronic components and specialized materials may complicate recycling processes, necessitating the development of advanced recycling technologies and circular economy strategies.

Overall, the lifecycle assessment of solenoid valves reveals their significant potential to contribute to sustainable marine operations. By optimizing design for longevity, enhancing material efficiency, improving operational performance, and developing effective end-of-life management strategies, solenoid valves can play a pivotal role in reducing the environmental impact of maritime activities. Future research and development efforts should focus on further improving the sustainability profile of these critical components throughout their lifecycle, aligning with broader industry goals for environmental stewardship and resource conservation in marine operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!