Solenoid Valve Design for Reduced Energy Footprint in Manufacturing

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution and Energy Efficiency Goals

Solenoid valves have undergone significant evolution since their inception in the early 20th century. Initially designed for basic on-off control in fluid systems, these electromagnetic devices have transformed into sophisticated components crucial for precise fluid control across various industries. The progression of solenoid valve technology has been driven by the increasing demands for improved performance, reliability, and energy efficiency in manufacturing processes.

In the 1950s and 1960s, solenoid valves saw substantial advancements in materials and design, leading to enhanced durability and operational life. The introduction of new alloys and synthetic materials allowed for better resistance to corrosion and wear, expanding their applicability in diverse industrial environments. The 1970s and 1980s marked a shift towards miniaturization and integration, as solenoid valves became essential components in automated systems and robotics.

The late 20th and early 21st centuries brought about a focus on energy efficiency and environmental considerations. This shift was prompted by growing awareness of energy consumption's impact on operational costs and carbon footprints. Manufacturers began to prioritize the development of low-power solenoid valves, utilizing advanced materials and optimized electromagnetic designs to reduce energy requirements without compromising performance.

Current technological goals for solenoid valve design center around further reducing energy consumption while maintaining or improving functionality. Key objectives include minimizing heat generation, optimizing magnetic circuit efficiency, and developing intelligent control systems for adaptive power management. Engineers are exploring novel approaches such as piezoelectric actuators, shape memory alloys, and nanotechnology-enhanced materials to achieve these goals.

The pursuit of energy efficiency in solenoid valve design aligns with broader manufacturing trends towards sustainability and cost reduction. As industries face increasing pressure to minimize their environmental impact and operational expenses, the demand for energy-efficient components has intensified. Solenoid valve manufacturers are responding by setting ambitious targets for power reduction, aiming to decrease energy consumption by up to 50% compared to traditional designs.

Achieving these energy efficiency goals requires a multifaceted approach, combining innovations in materials science, electromagnetic theory, and control systems. Research efforts are focused on developing new magnetic materials with higher permeability and lower hysteresis losses, as well as exploring advanced coil designs that maximize magnetic flux while minimizing resistive losses. Additionally, the integration of smart sensors and microcontrollers enables dynamic power adjustment based on real-time operational requirements, further optimizing energy usage.

In the 1950s and 1960s, solenoid valves saw substantial advancements in materials and design, leading to enhanced durability and operational life. The introduction of new alloys and synthetic materials allowed for better resistance to corrosion and wear, expanding their applicability in diverse industrial environments. The 1970s and 1980s marked a shift towards miniaturization and integration, as solenoid valves became essential components in automated systems and robotics.

The late 20th and early 21st centuries brought about a focus on energy efficiency and environmental considerations. This shift was prompted by growing awareness of energy consumption's impact on operational costs and carbon footprints. Manufacturers began to prioritize the development of low-power solenoid valves, utilizing advanced materials and optimized electromagnetic designs to reduce energy requirements without compromising performance.

Current technological goals for solenoid valve design center around further reducing energy consumption while maintaining or improving functionality. Key objectives include minimizing heat generation, optimizing magnetic circuit efficiency, and developing intelligent control systems for adaptive power management. Engineers are exploring novel approaches such as piezoelectric actuators, shape memory alloys, and nanotechnology-enhanced materials to achieve these goals.

The pursuit of energy efficiency in solenoid valve design aligns with broader manufacturing trends towards sustainability and cost reduction. As industries face increasing pressure to minimize their environmental impact and operational expenses, the demand for energy-efficient components has intensified. Solenoid valve manufacturers are responding by setting ambitious targets for power reduction, aiming to decrease energy consumption by up to 50% compared to traditional designs.

Achieving these energy efficiency goals requires a multifaceted approach, combining innovations in materials science, electromagnetic theory, and control systems. Research efforts are focused on developing new magnetic materials with higher permeability and lower hysteresis losses, as well as exploring advanced coil designs that maximize magnetic flux while minimizing resistive losses. Additionally, the integration of smart sensors and microcontrollers enables dynamic power adjustment based on real-time operational requirements, further optimizing energy usage.

Market Demand for Energy-Efficient Solenoid Valves

The market demand for energy-efficient solenoid valves has been steadily increasing in recent years, driven by several key factors. Manufacturing industries are facing growing pressure to reduce their energy consumption and carbon footprint, leading to a surge in demand for more efficient components and systems. Solenoid valves, being critical components in many industrial processes, have become a focal point for energy optimization efforts.

Energy costs represent a significant portion of operational expenses in manufacturing. As such, companies are actively seeking ways to minimize energy consumption without compromising performance. Energy-efficient solenoid valves offer a promising solution, as they can significantly reduce power consumption while maintaining or even improving operational efficiency.

The automotive industry, in particular, has shown a strong interest in energy-efficient solenoid valves. With the shift towards electric and hybrid vehicles, there is an increased focus on optimizing every component to extend battery life and improve overall vehicle efficiency. This trend has created a substantial market for solenoid valves that can operate with minimal energy input.

Process industries, including chemical, pharmaceutical, and food processing sectors, are also driving the demand for energy-efficient solenoid valves. These industries often require precise control of fluids and gases, and energy-efficient valves can provide the necessary accuracy while reducing energy costs.

Environmental regulations and sustainability initiatives are further propelling the market for energy-efficient solenoid valves. Many countries have implemented strict energy efficiency standards for industrial equipment, incentivizing manufacturers to adopt more efficient components. Companies are also increasingly setting their own sustainability targets, creating internal demand for energy-saving technologies.

The market is also seeing a shift towards smart manufacturing and Industry 4.0 concepts. Energy-efficient solenoid valves that can be integrated into smart systems and provide real-time data on energy consumption are gaining traction. This trend is expected to continue as more manufacturers embrace digital transformation and seek to optimize their energy usage through data-driven approaches.

While the initial cost of energy-efficient solenoid valves may be higher than traditional models, the long-term savings in energy costs are attracting buyers. Many companies are now considering the total cost of ownership, including energy expenses over the lifespan of the equipment, when making purchasing decisions. This shift in perspective is further boosting the demand for energy-efficient options.

As awareness of the benefits of energy-efficient solenoid valves grows, the market is expected to expand across various industries. Manufacturers of these valves are likely to see increased opportunities, particularly if they can demonstrate clear energy savings and return on investment for their products.

Energy costs represent a significant portion of operational expenses in manufacturing. As such, companies are actively seeking ways to minimize energy consumption without compromising performance. Energy-efficient solenoid valves offer a promising solution, as they can significantly reduce power consumption while maintaining or even improving operational efficiency.

The automotive industry, in particular, has shown a strong interest in energy-efficient solenoid valves. With the shift towards electric and hybrid vehicles, there is an increased focus on optimizing every component to extend battery life and improve overall vehicle efficiency. This trend has created a substantial market for solenoid valves that can operate with minimal energy input.

Process industries, including chemical, pharmaceutical, and food processing sectors, are also driving the demand for energy-efficient solenoid valves. These industries often require precise control of fluids and gases, and energy-efficient valves can provide the necessary accuracy while reducing energy costs.

Environmental regulations and sustainability initiatives are further propelling the market for energy-efficient solenoid valves. Many countries have implemented strict energy efficiency standards for industrial equipment, incentivizing manufacturers to adopt more efficient components. Companies are also increasingly setting their own sustainability targets, creating internal demand for energy-saving technologies.

The market is also seeing a shift towards smart manufacturing and Industry 4.0 concepts. Energy-efficient solenoid valves that can be integrated into smart systems and provide real-time data on energy consumption are gaining traction. This trend is expected to continue as more manufacturers embrace digital transformation and seek to optimize their energy usage through data-driven approaches.

While the initial cost of energy-efficient solenoid valves may be higher than traditional models, the long-term savings in energy costs are attracting buyers. Many companies are now considering the total cost of ownership, including energy expenses over the lifespan of the equipment, when making purchasing decisions. This shift in perspective is further boosting the demand for energy-efficient options.

As awareness of the benefits of energy-efficient solenoid valves grows, the market is expected to expand across various industries. Manufacturers of these valves are likely to see increased opportunities, particularly if they can demonstrate clear energy savings and return on investment for their products.

Current Challenges in Solenoid Valve Energy Consumption

Solenoid valves are critical components in many manufacturing processes, yet their energy consumption remains a significant challenge. The current design and operation of solenoid valves often result in excessive energy usage, contributing to increased production costs and environmental impact. One of the primary issues is the continuous power requirement for maintaining valve positions, particularly in applications where valves need to remain open or closed for extended periods.

The inefficiency of traditional solenoid valve designs is exacerbated by the use of outdated materials and manufacturing techniques. Many valves still rely on high-resistance coil windings, which generate substantial heat and waste energy during operation. This not only increases power consumption but also reduces the overall lifespan of the valve due to thermal stress.

Another challenge lies in the lack of intelligent control systems for solenoid valves. Most valves operate in a binary on/off mode, without the ability to modulate their power consumption based on actual demand. This results in unnecessary energy expenditure during periods of low activity or when full valve actuation is not required.

The integration of solenoid valves into broader manufacturing systems presents additional energy-related challenges. Poor synchronization between valve operations and production cycles can lead to valves being energized when not actively needed, further contributing to energy waste. Moreover, the absence of real-time monitoring and predictive maintenance capabilities means that energy-inefficient valves often continue to operate undetected, compounding losses over time.

Miniaturization trends in manufacturing have also introduced new challenges for solenoid valve energy efficiency. As production lines become more compact, there is a growing demand for smaller valves that can deliver the same performance. However, reducing valve size while maintaining energy efficiency has proven to be a complex engineering problem, often resulting in compromises that favor size over power consumption.

The environmental impact of high-energy consumption solenoid valves extends beyond electricity usage. The increased heat generation necessitates additional cooling systems in manufacturing facilities, further amplifying the overall energy footprint. This cascading effect underscores the importance of addressing valve efficiency as part of a holistic approach to sustainable manufacturing.

Lastly, the cost implications of energy-inefficient solenoid valves are becoming increasingly significant as energy prices rise and environmental regulations tighten. Manufacturers are facing growing pressure to reduce their carbon footprint and operational costs, making the optimization of valve energy consumption a critical priority. However, the initial investment required for upgrading to more efficient valve systems often presents a barrier to adoption, particularly for smaller manufacturing operations.

The inefficiency of traditional solenoid valve designs is exacerbated by the use of outdated materials and manufacturing techniques. Many valves still rely on high-resistance coil windings, which generate substantial heat and waste energy during operation. This not only increases power consumption but also reduces the overall lifespan of the valve due to thermal stress.

Another challenge lies in the lack of intelligent control systems for solenoid valves. Most valves operate in a binary on/off mode, without the ability to modulate their power consumption based on actual demand. This results in unnecessary energy expenditure during periods of low activity or when full valve actuation is not required.

The integration of solenoid valves into broader manufacturing systems presents additional energy-related challenges. Poor synchronization between valve operations and production cycles can lead to valves being energized when not actively needed, further contributing to energy waste. Moreover, the absence of real-time monitoring and predictive maintenance capabilities means that energy-inefficient valves often continue to operate undetected, compounding losses over time.

Miniaturization trends in manufacturing have also introduced new challenges for solenoid valve energy efficiency. As production lines become more compact, there is a growing demand for smaller valves that can deliver the same performance. However, reducing valve size while maintaining energy efficiency has proven to be a complex engineering problem, often resulting in compromises that favor size over power consumption.

The environmental impact of high-energy consumption solenoid valves extends beyond electricity usage. The increased heat generation necessitates additional cooling systems in manufacturing facilities, further amplifying the overall energy footprint. This cascading effect underscores the importance of addressing valve efficiency as part of a holistic approach to sustainable manufacturing.

Lastly, the cost implications of energy-inefficient solenoid valves are becoming increasingly significant as energy prices rise and environmental regulations tighten. Manufacturers are facing growing pressure to reduce their carbon footprint and operational costs, making the optimization of valve energy consumption a critical priority. However, the initial investment required for upgrading to more efficient valve systems often presents a barrier to adoption, particularly for smaller manufacturing operations.

Existing Energy Reduction Solutions for Solenoid Valves

01 Energy-efficient solenoid valve designs

Various designs aim to reduce the energy consumption of solenoid valves. These include optimized magnetic circuits, improved coil configurations, and advanced materials that enhance electromagnetic efficiency. Such designs minimize power losses and reduce the overall energy footprint of the valve during operation.- Energy-efficient solenoid valve designs: Various designs have been developed to improve the energy efficiency of solenoid valves. These include optimized magnetic circuits, low-power actuators, and innovative coil configurations. Such designs aim to reduce power consumption while maintaining valve performance, thereby decreasing the overall energy footprint of solenoid valve systems.

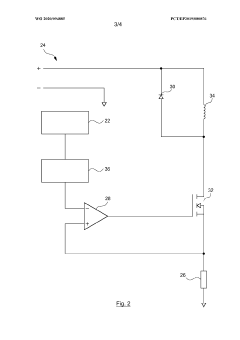

- Power management systems for solenoid valves: Advanced power management systems have been implemented to reduce the energy consumption of solenoid valves. These systems may include intelligent control algorithms, pulse-width modulation techniques, and adaptive power supply mechanisms. By optimizing power delivery to the valve, these systems can significantly decrease energy usage during operation.

- Energy recovery and regeneration in solenoid valve systems: Innovative approaches to energy recovery and regeneration have been developed for solenoid valve applications. These may involve capturing and reusing energy from valve actuation, implementing energy storage systems, or utilizing regenerative braking principles. Such techniques aim to reduce the net energy consumption of solenoid valve systems.

- Low-power solenoid valve materials and components: Research has focused on developing new materials and components for solenoid valves that require less energy to operate. This includes the use of advanced magnetic materials, lightweight alloys, and high-efficiency electrical components. These innovations contribute to reducing the overall energy footprint of solenoid valve systems.

- Smart control and monitoring systems for energy optimization: Intelligent control and monitoring systems have been developed to optimize the energy consumption of solenoid valves. These systems may incorporate sensors, predictive algorithms, and real-time feedback mechanisms to adjust valve operation based on demand and environmental conditions. By minimizing unnecessary actuation and optimizing performance, these systems can significantly reduce the energy footprint of solenoid valve installations.

02 Power management systems for solenoid valves

Implementing power management systems can significantly reduce the energy footprint of solenoid valves. These systems may include intelligent control algorithms, pulse-width modulation techniques, and adaptive power supply mechanisms. By optimizing power delivery based on operational requirements, these systems minimize unnecessary energy consumption.Expand Specific Solutions03 Low-power solenoid valve actuation methods

Novel actuation methods are developed to reduce the energy required for solenoid valve operation. These may include bistable mechanisms, latching designs, or energy harvesting techniques. Such methods allow the valve to maintain its state with minimal or no power input, significantly reducing its overall energy footprint.Expand Specific Solutions04 Energy-efficient control strategies for solenoid valves

Advanced control strategies are employed to optimize the energy consumption of solenoid valves. These may include predictive control algorithms, fuzzy logic systems, or machine learning approaches. By anticipating operational needs and adjusting valve behavior accordingly, these strategies minimize unnecessary energy expenditure.Expand Specific Solutions05 Integration of solenoid valves in energy-efficient systems

Solenoid valves are integrated into larger systems designed for overall energy efficiency. This may involve optimizing valve placement, sizing, and operation within the context of the entire system. By considering the valve's role in the broader energy landscape, significant reductions in the overall energy footprint can be achieved.Expand Specific Solutions

Key Players in Energy-Efficient Solenoid Valve Industry

The solenoid valve design for reduced energy footprint in manufacturing is in a mature stage of development, with a significant market size driven by increasing focus on energy efficiency. The technology is well-established, with major players like Robert Bosch GmbH, Festo SE & Co. KG, and Parker Hannifin France SAS offering advanced solutions. These companies, along with others such as Siemens Corp. and Continental Teves AG & Co. oHG, are continuously innovating to improve valve efficiency and reduce energy consumption. The competitive landscape is characterized by a mix of large multinational corporations and specialized manufacturers, all striving to meet the growing demand for energy-efficient industrial components in the global manufacturing sector.

Robert Bosch GmbH

Technical Solution: Bosch has developed an innovative solenoid valve design that significantly reduces energy consumption in manufacturing processes. Their approach incorporates advanced materials and optimized electromagnetic coil designs to minimize power losses. The valve utilizes a high-efficiency magnetic circuit with reduced air gaps and optimized flux paths, resulting in improved force-to-current ratios[1]. Additionally, Bosch has implemented smart control algorithms that adjust valve operation based on real-time process demands, further reducing energy waste[3]. The design also features a rapid response time, allowing for precise control of fluid flow in manufacturing applications[5].

Strengths: Significant energy savings, precise control, and adaptability to various manufacturing processes. Weaknesses: Potentially higher initial cost and complexity in implementation compared to traditional solenoid valves.

Zhejiang Sanhua Intelligent Controls Co., Ltd.

Technical Solution: Sanhua has developed a series of energy-efficient solenoid valves specifically tailored for manufacturing applications. Their design incorporates a unique plunger geometry that reduces magnetic hysteresis and improves overall efficiency[2]. The company has also implemented advanced coil winding techniques to minimize copper losses and optimize power consumption. Sanhua's valves feature a low-power holding mode, which significantly reduces energy consumption during steady-state operation[4]. Furthermore, they have integrated smart diagnostics and predictive maintenance capabilities, ensuring optimal performance and energy efficiency throughout the valve's lifecycle[6].

Strengths: High energy efficiency, smart features for optimized operation, and long-term reliability. Weaknesses: May require specialized training for maintenance personnel and potential compatibility issues with existing systems.

Core Innovations in Low-Power Solenoid Valve Design

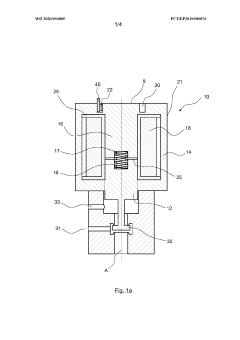

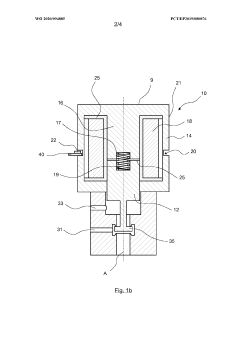

Solenoid valve, control electronics for a solenoid valve, and method for controlling a solenoid valve

PatentWO2020094885A1

Innovation

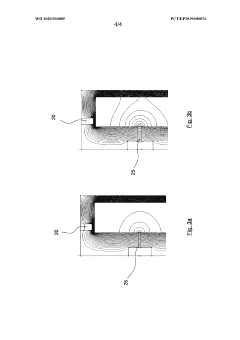

- A solenoid valve design with a magnetic field sensor placed in a profile recess on the magnetic yoke, allowing for reduced power consumption by distinguishing between armature positions using magnetic flux density measurements, and control electronics that adjust current levels to minimize power usage while maintaining valve operation.

Electromagnetic valve

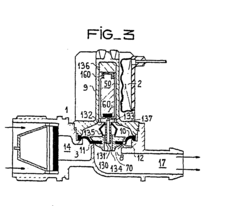

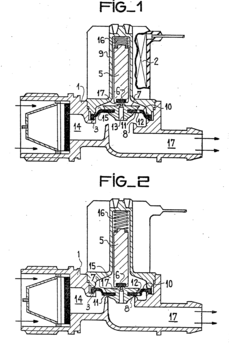

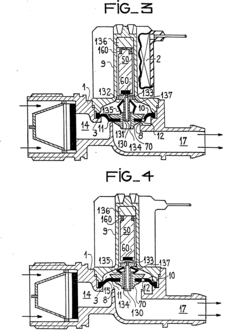

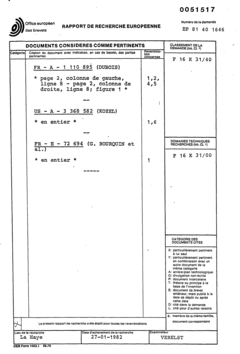

PatentInactiveEP0051517A1

Innovation

- A solenoid valve design featuring a flexible tubular sealing sleeve forming a bellows around the leakage channel, allowing the movable core to slide freely, reducing the energy required for opening and maintaining the valve with a calibrated leak orifice and a fixed core to minimize the air gap and energy consumption.

Environmental Impact of Solenoid Valve Energy Reduction

The environmental impact of reducing energy consumption in solenoid valves extends far beyond the manufacturing sector. As industrial processes become increasingly automated, the widespread use of solenoid valves in various applications has led to a significant cumulative energy demand. By focusing on energy-efficient solenoid valve designs, manufacturers can contribute substantially to global sustainability efforts.

Reducing the energy footprint of solenoid valves primarily affects electricity consumption. Traditional solenoid valves often require continuous power to maintain their state, resulting in constant energy draw. By implementing low-power holding mechanisms or bistable designs, the overall energy consumption can be drastically reduced. This decrease in electricity usage directly translates to lower greenhouse gas emissions from power generation, particularly in regions still heavily reliant on fossil fuels.

The materials used in solenoid valve production also play a crucial role in their environmental impact. Energy-efficient designs often incorporate advanced materials with improved magnetic properties, allowing for smaller and more efficient components. This reduction in material usage not only conserves resources but also minimizes the environmental footprint associated with raw material extraction and processing.

Furthermore, the longevity of energy-efficient solenoid valves contributes to waste reduction. By operating at lower power levels, these valves experience less wear and thermal stress, potentially extending their operational lifespan. This increased durability reduces the frequency of replacements, thereby decreasing the amount of electronic waste generated over time.

The adoption of energy-efficient solenoid valves can have cascading effects throughout industrial systems. Reduced power consumption in valves can lead to smaller power supply requirements, potentially downsizing entire electrical systems. This ripple effect can result in further energy savings and material reductions across manufacturing facilities.

In the context of global climate change mitigation efforts, the cumulative impact of widespread adoption of energy-efficient solenoid valves could be substantial. Industrial energy consumption is a significant contributor to global carbon emissions, and any reduction in this sector can play a vital role in meeting international climate targets. Moreover, as companies increasingly focus on their environmental, social, and governance (ESG) performance, the implementation of energy-efficient technologies like improved solenoid valves becomes a tangible demonstration of commitment to sustainability.

Reducing the energy footprint of solenoid valves primarily affects electricity consumption. Traditional solenoid valves often require continuous power to maintain their state, resulting in constant energy draw. By implementing low-power holding mechanisms or bistable designs, the overall energy consumption can be drastically reduced. This decrease in electricity usage directly translates to lower greenhouse gas emissions from power generation, particularly in regions still heavily reliant on fossil fuels.

The materials used in solenoid valve production also play a crucial role in their environmental impact. Energy-efficient designs often incorporate advanced materials with improved magnetic properties, allowing for smaller and more efficient components. This reduction in material usage not only conserves resources but also minimizes the environmental footprint associated with raw material extraction and processing.

Furthermore, the longevity of energy-efficient solenoid valves contributes to waste reduction. By operating at lower power levels, these valves experience less wear and thermal stress, potentially extending their operational lifespan. This increased durability reduces the frequency of replacements, thereby decreasing the amount of electronic waste generated over time.

The adoption of energy-efficient solenoid valves can have cascading effects throughout industrial systems. Reduced power consumption in valves can lead to smaller power supply requirements, potentially downsizing entire electrical systems. This ripple effect can result in further energy savings and material reductions across manufacturing facilities.

In the context of global climate change mitigation efforts, the cumulative impact of widespread adoption of energy-efficient solenoid valves could be substantial. Industrial energy consumption is a significant contributor to global carbon emissions, and any reduction in this sector can play a vital role in meeting international climate targets. Moreover, as companies increasingly focus on their environmental, social, and governance (ESG) performance, the implementation of energy-efficient technologies like improved solenoid valves becomes a tangible demonstration of commitment to sustainability.

Cost-Benefit Analysis of Energy-Efficient Solenoid Valves

The implementation of energy-efficient solenoid valves in manufacturing processes presents a compelling case for cost-benefit analysis. Initial investment in these advanced valves typically involves higher upfront costs compared to traditional models. However, the long-term financial benefits often outweigh this initial expenditure.

Energy consumption reduction is a primary advantage of efficient solenoid valves. Studies have shown that these valves can reduce energy usage by up to 30-50% compared to conventional designs. This translates to significant cost savings on electricity bills over the operational lifespan of the equipment. For large-scale manufacturing facilities, these savings can amount to thousands of dollars annually.

Maintenance costs also factor into the cost-benefit equation. Energy-efficient solenoid valves often incorporate advanced materials and designs that enhance durability and reduce wear. This results in extended service life and fewer replacements, leading to decreased maintenance expenses and reduced production downtime.

The environmental impact of energy-efficient valves contributes to indirect cost benefits. Many regions offer tax incentives or grants for implementing energy-saving technologies. Additionally, the reduced carbon footprint aligns with corporate sustainability goals, potentially enhancing brand value and customer perception, which can indirectly boost sales and market share.

Operational efficiency improvements represent another key benefit. Energy-efficient solenoid valves often provide more precise control and faster response times, leading to enhanced product quality and reduced waste. This optimization can result in increased production output and improved overall equipment effectiveness (OEE).

When considering the return on investment (ROI), it's crucial to calculate the payback period. Depending on the specific application and energy costs, the payback period for energy-efficient solenoid valves typically ranges from 6 to 18 months. After this period, the ongoing energy savings contribute directly to the bottom line.

It's important to note that the cost-benefit analysis should be tailored to each specific manufacturing environment. Factors such as production volume, operating hours, local energy costs, and existing infrastructure all influence the potential savings and ROI. A comprehensive analysis should include a detailed energy audit and simulation of potential savings under various scenarios.

Energy consumption reduction is a primary advantage of efficient solenoid valves. Studies have shown that these valves can reduce energy usage by up to 30-50% compared to conventional designs. This translates to significant cost savings on electricity bills over the operational lifespan of the equipment. For large-scale manufacturing facilities, these savings can amount to thousands of dollars annually.

Maintenance costs also factor into the cost-benefit equation. Energy-efficient solenoid valves often incorporate advanced materials and designs that enhance durability and reduce wear. This results in extended service life and fewer replacements, leading to decreased maintenance expenses and reduced production downtime.

The environmental impact of energy-efficient valves contributes to indirect cost benefits. Many regions offer tax incentives or grants for implementing energy-saving technologies. Additionally, the reduced carbon footprint aligns with corporate sustainability goals, potentially enhancing brand value and customer perception, which can indirectly boost sales and market share.

Operational efficiency improvements represent another key benefit. Energy-efficient solenoid valves often provide more precise control and faster response times, leading to enhanced product quality and reduced waste. This optimization can result in increased production output and improved overall equipment effectiveness (OEE).

When considering the return on investment (ROI), it's crucial to calculate the payback period. Depending on the specific application and energy costs, the payback period for energy-efficient solenoid valves typically ranges from 6 to 18 months. After this period, the ongoing energy savings contribute directly to the bottom line.

It's important to note that the cost-benefit analysis should be tailored to each specific manufacturing environment. Factors such as production volume, operating hours, local energy costs, and existing infrastructure all influence the potential savings and ROI. A comprehensive analysis should include a detailed energy audit and simulation of potential savings under various scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!