Solenoid Valve Innovations for Enhanced Fire Protection Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution

The evolution of solenoid valves in fire protection systems has been marked by significant technological advancements and innovations over the years. Initially, solenoid valves were simple on-off devices with limited functionality. However, as the demands for more sophisticated fire protection systems grew, so did the capabilities of these crucial components.

In the early stages, solenoid valves were primarily used for basic water flow control in sprinkler systems. These valves operated on a binary principle, either fully open or fully closed, with limited intermediate control. The first generation of solenoid valves in fire protection systems faced challenges such as slow response times and reliability issues under extreme conditions.

As technology progressed, manufacturers began incorporating materials that could withstand higher pressures and temperatures, improving the overall durability and performance of solenoid valves. This led to the development of valves capable of operating in a wider range of environmental conditions, crucial for diverse fire protection applications.

The integration of electronic controls marked a significant milestone in solenoid valve evolution. This advancement allowed for more precise control over valve operation, enabling features such as variable flow rates and programmable activation sequences. The introduction of microprocessors and smart sensors further enhanced the capabilities of solenoid valves, allowing for real-time monitoring and adjustment of system parameters.

Another key development was the miniaturization of solenoid valve components. This trend resulted in more compact and efficient designs, allowing for easier installation in confined spaces and reducing the overall footprint of fire protection systems. Simultaneously, efforts to improve energy efficiency led to the creation of low-power solenoid valves, which could operate effectively while consuming less electricity.

Recent innovations have focused on enhancing the reliability and fail-safe mechanisms of solenoid valves. Advanced materials and manufacturing techniques have been employed to create valves with improved sealing properties, reducing the risk of leaks and ensuring consistent performance over extended periods. Additionally, the development of redundant systems and self-diagnostic capabilities has significantly increased the overall safety and dependability of fire protection systems.

The latest generation of solenoid valves incorporates smart technologies, enabling seamless integration with building management systems and IoT platforms. This connectivity allows for remote monitoring, predictive maintenance, and automated system adjustments, further improving the effectiveness of fire protection systems.

As the field continues to evolve, ongoing research is exploring the potential of new materials, such as shape memory alloys and advanced polymers, to create even more responsive and efficient solenoid valves. These developments promise to further enhance the capabilities of fire protection systems, ensuring faster response times and more targeted suppression efforts in the face of evolving fire safety challenges.

In the early stages, solenoid valves were primarily used for basic water flow control in sprinkler systems. These valves operated on a binary principle, either fully open or fully closed, with limited intermediate control. The first generation of solenoid valves in fire protection systems faced challenges such as slow response times and reliability issues under extreme conditions.

As technology progressed, manufacturers began incorporating materials that could withstand higher pressures and temperatures, improving the overall durability and performance of solenoid valves. This led to the development of valves capable of operating in a wider range of environmental conditions, crucial for diverse fire protection applications.

The integration of electronic controls marked a significant milestone in solenoid valve evolution. This advancement allowed for more precise control over valve operation, enabling features such as variable flow rates and programmable activation sequences. The introduction of microprocessors and smart sensors further enhanced the capabilities of solenoid valves, allowing for real-time monitoring and adjustment of system parameters.

Another key development was the miniaturization of solenoid valve components. This trend resulted in more compact and efficient designs, allowing for easier installation in confined spaces and reducing the overall footprint of fire protection systems. Simultaneously, efforts to improve energy efficiency led to the creation of low-power solenoid valves, which could operate effectively while consuming less electricity.

Recent innovations have focused on enhancing the reliability and fail-safe mechanisms of solenoid valves. Advanced materials and manufacturing techniques have been employed to create valves with improved sealing properties, reducing the risk of leaks and ensuring consistent performance over extended periods. Additionally, the development of redundant systems and self-diagnostic capabilities has significantly increased the overall safety and dependability of fire protection systems.

The latest generation of solenoid valves incorporates smart technologies, enabling seamless integration with building management systems and IoT platforms. This connectivity allows for remote monitoring, predictive maintenance, and automated system adjustments, further improving the effectiveness of fire protection systems.

As the field continues to evolve, ongoing research is exploring the potential of new materials, such as shape memory alloys and advanced polymers, to create even more responsive and efficient solenoid valves. These developments promise to further enhance the capabilities of fire protection systems, ensuring faster response times and more targeted suppression efforts in the face of evolving fire safety challenges.

Fire Protection Market

The fire protection market has experienced significant growth in recent years, driven by increasing awareness of safety measures and stringent regulations across various industries. This market encompasses a wide range of products and services, including fire detection systems, suppression systems, and emergency response equipment. The global fire protection market was valued at approximately $52 billion in 2020 and is projected to reach $78 billion by 2025, growing at a CAGR of 8.5% during the forecast period.

One of the key factors driving market growth is the rising demand for advanced fire protection systems in commercial and residential buildings. Urbanization and the construction of high-rise structures have led to a greater need for sophisticated fire safety solutions. Additionally, the implementation of strict building codes and safety regulations by governments worldwide has further propelled market expansion.

The industrial sector, particularly oil and gas, manufacturing, and chemical industries, represents a significant portion of the fire protection market. These industries require specialized fire protection systems due to the high-risk nature of their operations. The increasing focus on workplace safety and the potential for catastrophic losses in case of fire incidents have led to substantial investments in fire protection technologies.

Technological advancements have played a crucial role in shaping the fire protection market. The integration of IoT, artificial intelligence, and cloud-based solutions has revolutionized fire detection and suppression systems. Smart fire protection systems that offer real-time monitoring, predictive maintenance, and remote control capabilities are gaining traction among end-users.

Geographically, North America and Europe dominate the fire protection market, owing to stringent safety regulations and high adoption rates of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing investments in infrastructure development.

The market is characterized by the presence of both established players and innovative startups. Key market players are focusing on product innovations, strategic partnerships, and mergers and acquisitions to strengthen their market position. The competitive landscape is expected to intensify as companies strive to develop more efficient and cost-effective fire protection solutions.

In the context of solenoid valve innovations for enhanced fire protection systems, there is a growing demand for more reliable, efficient, and intelligent valve solutions. Manufacturers are developing solenoid valves with improved response times, higher flow rates, and enhanced durability to meet the evolving requirements of modern fire protection systems. The integration of smart technologies in solenoid valves, such as self-diagnostic capabilities and remote monitoring features, is expected to drive their adoption in advanced fire protection applications.

One of the key factors driving market growth is the rising demand for advanced fire protection systems in commercial and residential buildings. Urbanization and the construction of high-rise structures have led to a greater need for sophisticated fire safety solutions. Additionally, the implementation of strict building codes and safety regulations by governments worldwide has further propelled market expansion.

The industrial sector, particularly oil and gas, manufacturing, and chemical industries, represents a significant portion of the fire protection market. These industries require specialized fire protection systems due to the high-risk nature of their operations. The increasing focus on workplace safety and the potential for catastrophic losses in case of fire incidents have led to substantial investments in fire protection technologies.

Technological advancements have played a crucial role in shaping the fire protection market. The integration of IoT, artificial intelligence, and cloud-based solutions has revolutionized fire detection and suppression systems. Smart fire protection systems that offer real-time monitoring, predictive maintenance, and remote control capabilities are gaining traction among end-users.

Geographically, North America and Europe dominate the fire protection market, owing to stringent safety regulations and high adoption rates of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing investments in infrastructure development.

The market is characterized by the presence of both established players and innovative startups. Key market players are focusing on product innovations, strategic partnerships, and mergers and acquisitions to strengthen their market position. The competitive landscape is expected to intensify as companies strive to develop more efficient and cost-effective fire protection solutions.

In the context of solenoid valve innovations for enhanced fire protection systems, there is a growing demand for more reliable, efficient, and intelligent valve solutions. Manufacturers are developing solenoid valves with improved response times, higher flow rates, and enhanced durability to meet the evolving requirements of modern fire protection systems. The integration of smart technologies in solenoid valves, such as self-diagnostic capabilities and remote monitoring features, is expected to drive their adoption in advanced fire protection applications.

Valve Tech Challenges

Solenoid valves in fire protection systems face several significant challenges that hinder their optimal performance and reliability. One of the primary issues is the potential for valve clogging or sticking due to the accumulation of debris, mineral deposits, or corrosion over time. This can lead to valve malfunction during critical moments, compromising the entire fire protection system's effectiveness.

Another major challenge is the need for rapid response times in emergency situations. Traditional solenoid valves may experience delays in activation or deactivation, which can be detrimental in fire scenarios where every second counts. Improving the speed and precision of valve operation remains a key area for innovation.

The harsh environmental conditions in which these valves operate pose additional challenges. Extreme temperatures, high pressures, and exposure to corrosive substances can degrade valve components, leading to reduced lifespan and increased maintenance requirements. Developing materials and designs that can withstand these conditions without compromising performance is crucial.

Power consumption is another significant concern, particularly in large-scale fire protection systems. Conventional solenoid valves often require substantial electrical power to operate, which can strain backup power systems during emergencies. Reducing energy consumption while maintaining or improving valve performance is a critical challenge that needs to be addressed.

Reliability and fail-safe operation are paramount in fire protection systems. Current solenoid valve designs may be susceptible to failure modes that could leave the system inoperable or cause unintended activation. Enhancing the overall reliability and implementing robust fail-safe mechanisms are ongoing challenges in valve technology.

Size and weight constraints present additional hurdles, especially in retrofit applications or space-limited installations. Miniaturization of valve components without sacrificing performance or durability is a complex engineering challenge that requires innovative solutions.

Lastly, the integration of smart technologies and IoT capabilities into solenoid valves for fire protection systems introduces new challenges. While these advancements offer improved monitoring and control, they also bring concerns about cybersecurity, data management, and system complexity. Balancing the benefits of smart technologies with the need for simplicity and reliability in critical safety systems remains a significant challenge for valve manufacturers and system designers.

Another major challenge is the need for rapid response times in emergency situations. Traditional solenoid valves may experience delays in activation or deactivation, which can be detrimental in fire scenarios where every second counts. Improving the speed and precision of valve operation remains a key area for innovation.

The harsh environmental conditions in which these valves operate pose additional challenges. Extreme temperatures, high pressures, and exposure to corrosive substances can degrade valve components, leading to reduced lifespan and increased maintenance requirements. Developing materials and designs that can withstand these conditions without compromising performance is crucial.

Power consumption is another significant concern, particularly in large-scale fire protection systems. Conventional solenoid valves often require substantial electrical power to operate, which can strain backup power systems during emergencies. Reducing energy consumption while maintaining or improving valve performance is a critical challenge that needs to be addressed.

Reliability and fail-safe operation are paramount in fire protection systems. Current solenoid valve designs may be susceptible to failure modes that could leave the system inoperable or cause unintended activation. Enhancing the overall reliability and implementing robust fail-safe mechanisms are ongoing challenges in valve technology.

Size and weight constraints present additional hurdles, especially in retrofit applications or space-limited installations. Miniaturization of valve components without sacrificing performance or durability is a complex engineering challenge that requires innovative solutions.

Lastly, the integration of smart technologies and IoT capabilities into solenoid valves for fire protection systems introduces new challenges. While these advancements offer improved monitoring and control, they also bring concerns about cybersecurity, data management, and system complexity. Balancing the benefits of smart technologies with the need for simplicity and reliability in critical safety systems remains a significant challenge for valve manufacturers and system designers.

Current Valve Solutions

01 Improved valve design for enhanced performance

Solenoid valve performance can be improved through innovative design features. These may include optimized flow paths, reduced friction, and enhanced sealing mechanisms. Such designs can lead to better response times, increased efficiency, and improved overall valve performance.- Improved valve design for enhanced performance: Advanced solenoid valve designs focus on optimizing flow characteristics, reducing pressure drop, and improving response times. These improvements may include redesigned valve seats, optimized plunger shapes, and enhanced magnetic circuits to increase efficiency and reliability.

- Electronic control systems for precise operation: Integration of sophisticated electronic control systems allows for more precise and responsive solenoid valve operation. These systems can include microprocessors, sensors, and adaptive algorithms to optimize valve performance based on real-time conditions and requirements.

- Materials selection for durability and efficiency: Careful selection of materials for valve components, such as corrosion-resistant alloys, high-performance polymers, and advanced magnetic materials, can significantly improve valve durability, reduce wear, and enhance overall performance in various operating conditions.

- Miniaturization and compact design: Development of compact and miniaturized solenoid valve designs allows for improved performance in space-constrained applications. These designs often incorporate advanced manufacturing techniques and innovative component layouts to maintain or enhance performance while reducing size and weight.

- Energy efficiency and power management: Implementing energy-efficient designs and power management strategies can improve solenoid valve performance while reducing power consumption. This may include the use of low-power coils, energy recovery circuits, and intelligent power control algorithms to optimize valve operation and extend battery life in portable applications.

02 Advanced materials for solenoid valve components

The use of advanced materials in solenoid valve construction can significantly impact performance. Materials with improved magnetic properties, wear resistance, and thermal stability can enhance valve longevity, reduce power consumption, and improve operational reliability across various conditions.Expand Specific Solutions03 Electronic control and monitoring systems

Integration of sophisticated electronic control and monitoring systems can optimize solenoid valve performance. These systems can provide precise actuation timing, real-time performance feedback, and adaptive control algorithms, resulting in improved efficiency and reliability.Expand Specific Solutions04 Energy-efficient solenoid valve designs

Developing energy-efficient solenoid valve designs is crucial for improving overall performance. This includes optimizing coil designs, implementing power-saving modes, and utilizing energy recovery mechanisms. Such innovations can lead to reduced power consumption and heat generation, enhancing valve longevity and operational efficiency.Expand Specific Solutions05 Performance testing and quality control methods

Implementing advanced performance testing and quality control methods can ensure consistent and reliable solenoid valve performance. This may involve automated testing systems, precision measurement techniques, and comprehensive performance analysis tools to identify and address potential issues before valve deployment.Expand Specific Solutions

Fire System Competitors

The solenoid valve market for fire protection systems is in a growth phase, driven by increasing safety regulations and technological advancements. The global market size is expanding, with a projected CAGR of 3-5% over the next five years. Technologically, the field is moderately mature but evolving, with companies like Eaton Corp., Mitsubishi Materials Corp., and DENSO Corp. leading innovations. These firms are focusing on enhancing valve reliability, efficiency, and integration with smart systems. Emerging players such as Dalian Shian Science & Technology Co., Ltd. and Shanghai Juliang Solenoid Valve Manufacturing Co., Ltd are introducing niche solutions, particularly in the Asian market. The competitive landscape is characterized by a mix of established industrial conglomerates and specialized valve manufacturers, with increasing emphasis on IoT-enabled and energy-efficient solutions.

Eaton Corp.

Technical Solution: Eaton Corp. has developed advanced solenoid valve technologies for enhanced fire protection systems. Their innovative approach includes the use of smart solenoid valves with integrated sensors and microprocessors[1]. These valves can continuously monitor system pressure, flow rates, and valve position, providing real-time data for improved system performance and maintenance[2]. Eaton's solenoid valves also feature a fail-safe design, ensuring that the valve defaults to a safe position in case of power loss or system failure[3]. Additionally, they have implemented a unique coil design that reduces power consumption by up to 75% compared to traditional solenoid valves, contributing to energy efficiency in fire protection systems[4].

Strengths: Advanced monitoring capabilities, fail-safe design, and energy efficiency. Weaknesses: Potentially higher initial cost and complexity in installation and maintenance.

Continental Automotive Systems, Inc.

Technical Solution: Continental Automotive Systems, Inc. has innovated in solenoid valve technology for fire protection systems by focusing on reliability and durability in extreme conditions. They have developed valves with enhanced corrosion resistance and temperature tolerance, suitable for harsh industrial environments[1]. Continental's solenoid valves feature a unique sealing technology that ensures leak-free operation even under high pressure and temperature variations[2]. They have also implemented advanced electromagnetic shielding techniques to protect the valves from electromagnetic interference, ensuring consistent performance in various industrial settings[3]. Furthermore, Continental has developed a range of low-power solenoid valves specifically designed for battery-operated or solar-powered fire protection systems in remote locations[4].

Strengths: High durability in extreme conditions, advanced sealing technology, and low power consumption options. Weaknesses: Potentially limited flexibility in certain applications due to specialized designs.

Key Solenoid Patents

Release valve for fire protection systems, fire protection system and relative activation method

PatentPendingUS20230356016A1

Innovation

- A pressure-activated release valve with a tubular body featuring a coupling means, a rupture disc that opens at a higher pressure, a non-return device, and a safety disc, designed to minimize head loss and allow larger diameters, while ensuring efficient gas release and safety through a non-fragmentable rupture disc and calibrated safety mechanisms.

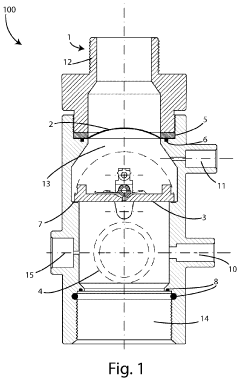

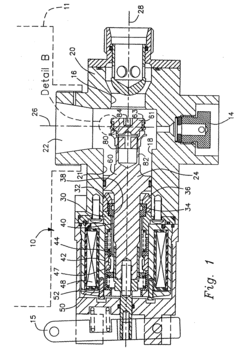

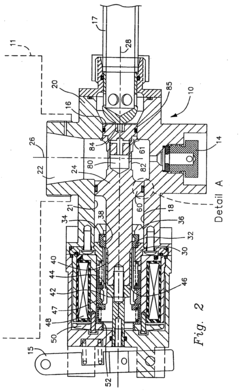

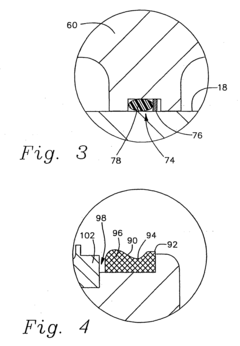

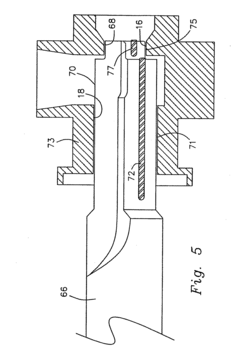

Valve for fire suppression device

PatentInactiveEP1098680B1

Innovation

- A fire suppression valve with a low profile design featuring a transversely mounted two-stage piston and precisely finished internal seals using a gun reamer, allowing for minimal vertical space usage and improved sealing, including a piston gasket with a scraping member for dry powder applications, enabling easy cleaning and reduced leakage.

Safety Standards

Safety standards play a crucial role in the development and implementation of solenoid valve innovations for enhanced fire protection systems. These standards ensure that the valves meet specific requirements for reliability, durability, and performance under various conditions. The National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) are two primary organizations that establish and maintain safety standards for fire protection equipment, including solenoid valves.

NFPA 13, the Standard for the Installation of Sprinkler Systems, provides guidelines for the design and installation of fire sprinkler systems, including the use of solenoid valves. This standard outlines the requirements for valve construction, materials, and performance testing. Additionally, NFPA 25, the Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, sets forth the minimum requirements for maintaining solenoid valves in fire protection systems.

UL 260, the Standard for Dry Pipe and Deluge Valves for Fire-Protection Service, specifically addresses the safety requirements for solenoid valves used in dry pipe and deluge systems. This standard covers aspects such as valve construction, materials, performance testing, and marking requirements. Compliance with UL 260 ensures that solenoid valves meet the necessary safety and performance criteria for use in fire protection applications.

The International Organization for Standardization (ISO) also contributes to safety standards for solenoid valves in fire protection systems. ISO 6182-1, Fire protection - Automatic sprinkler systems - Part 1: Requirements and test methods for sprinklers, provides guidelines for the design and testing of sprinkler components, including solenoid valves.

Safety standards for solenoid valves in fire protection systems often focus on key performance criteria such as response time, flow capacity, and pressure ratings. These standards typically require valves to undergo rigorous testing to ensure they can withstand extreme temperatures, pressures, and corrosive environments commonly encountered in fire protection applications.

Manufacturers of solenoid valves for fire protection systems must adhere to these safety standards throughout the design, production, and testing processes. Compliance with these standards is often verified through third-party certification programs, which provide assurance to end-users that the valves meet the necessary safety and performance requirements.

As technology advances and new innovations emerge in solenoid valve design, safety standards continue to evolve to address new challenges and opportunities. This ongoing development of standards ensures that fire protection systems remain effective and reliable, incorporating the latest advancements in solenoid valve technology while maintaining the highest levels of safety.

NFPA 13, the Standard for the Installation of Sprinkler Systems, provides guidelines for the design and installation of fire sprinkler systems, including the use of solenoid valves. This standard outlines the requirements for valve construction, materials, and performance testing. Additionally, NFPA 25, the Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, sets forth the minimum requirements for maintaining solenoid valves in fire protection systems.

UL 260, the Standard for Dry Pipe and Deluge Valves for Fire-Protection Service, specifically addresses the safety requirements for solenoid valves used in dry pipe and deluge systems. This standard covers aspects such as valve construction, materials, performance testing, and marking requirements. Compliance with UL 260 ensures that solenoid valves meet the necessary safety and performance criteria for use in fire protection applications.

The International Organization for Standardization (ISO) also contributes to safety standards for solenoid valves in fire protection systems. ISO 6182-1, Fire protection - Automatic sprinkler systems - Part 1: Requirements and test methods for sprinklers, provides guidelines for the design and testing of sprinkler components, including solenoid valves.

Safety standards for solenoid valves in fire protection systems often focus on key performance criteria such as response time, flow capacity, and pressure ratings. These standards typically require valves to undergo rigorous testing to ensure they can withstand extreme temperatures, pressures, and corrosive environments commonly encountered in fire protection applications.

Manufacturers of solenoid valves for fire protection systems must adhere to these safety standards throughout the design, production, and testing processes. Compliance with these standards is often verified through third-party certification programs, which provide assurance to end-users that the valves meet the necessary safety and performance requirements.

As technology advances and new innovations emerge in solenoid valve design, safety standards continue to evolve to address new challenges and opportunities. This ongoing development of standards ensures that fire protection systems remain effective and reliable, incorporating the latest advancements in solenoid valve technology while maintaining the highest levels of safety.

IoT Integration

The integration of Internet of Things (IoT) technology into solenoid valve systems for fire protection represents a significant leap forward in enhancing the efficiency, reliability, and responsiveness of these critical safety systems. IoT-enabled solenoid valves can provide real-time monitoring, remote control capabilities, and predictive maintenance features that greatly improve the overall performance of fire protection systems.

One of the key advantages of IoT integration is the ability to continuously monitor valve status and performance. Sensors embedded within the solenoid valves can collect data on various parameters such as pressure, flow rate, temperature, and valve position. This information is then transmitted to a central control system or cloud-based platform, allowing for real-time monitoring and analysis. This constant stream of data enables facility managers and fire safety personnel to have an up-to-the-minute understanding of the system's operational status.

Remote control capabilities are another significant benefit of IoT integration in solenoid valves. Through secure network connections, authorized personnel can remotely activate or deactivate valves, adjust flow rates, or initiate system tests. This feature is particularly valuable in large facilities or in situations where immediate on-site access may be challenging. In the event of a fire, remote activation can ensure rapid response times, potentially limiting damage and saving lives.

Predictive maintenance is a game-changing aspect of IoT-enabled solenoid valves. By analyzing the data collected from the valves over time, advanced algorithms can identify patterns and anomalies that may indicate potential issues or impending failures. This proactive approach allows maintenance teams to address problems before they escalate, reducing downtime and improving overall system reliability. It also helps in optimizing maintenance schedules, potentially reducing costs associated with unnecessary routine checks or emergency repairs.

IoT integration also facilitates improved system interoperability. Solenoid valves can be seamlessly integrated with other building management systems, such as HVAC, security, and energy management. This interconnectedness allows for more coordinated and efficient responses to fire incidents. For example, in the event of a fire, the system could automatically shut down HVAC systems to prevent smoke spread while activating the appropriate fire suppression measures.

Enhanced data analytics capabilities are another significant advantage of IoT integration. The vast amount of data collected from solenoid valves and other system components can be analyzed to identify trends, optimize system performance, and inform future design improvements. This data-driven approach can lead to more effective and efficient fire protection systems over time.

One of the key advantages of IoT integration is the ability to continuously monitor valve status and performance. Sensors embedded within the solenoid valves can collect data on various parameters such as pressure, flow rate, temperature, and valve position. This information is then transmitted to a central control system or cloud-based platform, allowing for real-time monitoring and analysis. This constant stream of data enables facility managers and fire safety personnel to have an up-to-the-minute understanding of the system's operational status.

Remote control capabilities are another significant benefit of IoT integration in solenoid valves. Through secure network connections, authorized personnel can remotely activate or deactivate valves, adjust flow rates, or initiate system tests. This feature is particularly valuable in large facilities or in situations where immediate on-site access may be challenging. In the event of a fire, remote activation can ensure rapid response times, potentially limiting damage and saving lives.

Predictive maintenance is a game-changing aspect of IoT-enabled solenoid valves. By analyzing the data collected from the valves over time, advanced algorithms can identify patterns and anomalies that may indicate potential issues or impending failures. This proactive approach allows maintenance teams to address problems before they escalate, reducing downtime and improving overall system reliability. It also helps in optimizing maintenance schedules, potentially reducing costs associated with unnecessary routine checks or emergency repairs.

IoT integration also facilitates improved system interoperability. Solenoid valves can be seamlessly integrated with other building management systems, such as HVAC, security, and energy management. This interconnectedness allows for more coordinated and efficient responses to fire incidents. For example, in the event of a fire, the system could automatically shut down HVAC systems to prevent smoke spread while activating the appropriate fire suppression measures.

Enhanced data analytics capabilities are another significant advantage of IoT integration. The vast amount of data collected from solenoid valves and other system components can be analyzed to identify trends, optimize system performance, and inform future design improvements. This data-driven approach can lead to more effective and efficient fire protection systems over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!