Solenoid Valve Research in Hydrogen Energy Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Solenoid Valve Evolution and Objectives

Solenoid valves have played a crucial role in the evolution of hydrogen energy systems, with their development closely tied to the advancement of hydrogen technologies. The journey of hydrogen solenoid valves began in the mid-20th century, primarily driven by aerospace applications. As the potential of hydrogen as a clean energy carrier became increasingly apparent, the focus on developing robust and efficient solenoid valves for hydrogen systems intensified.

In the 1960s and 1970s, early hydrogen solenoid valves were designed primarily for space exploration programs, where hydrogen was used as a propellant. These valves faced significant challenges due to the unique properties of hydrogen, including its low molecular weight and high diffusivity. The primary objectives during this period were to ensure leak-tightness and reliability under extreme conditions.

The 1980s and 1990s saw a shift towards terrestrial applications, with the emergence of hydrogen fuel cell technology. This transition brought new requirements for solenoid valves, including the need for more compact designs, lower power consumption, and compatibility with a wider range of operating conditions. The objectives expanded to include improved response times, reduced electromagnetic interference, and enhanced durability for frequent cycling.

As the 21st century dawned, the focus on hydrogen as a key player in the clean energy transition accelerated the development of solenoid valves. The automotive industry, in particular, drove significant advancements as hydrogen fuel cell vehicles gained traction. Objectives shifted towards miniaturization, weight reduction, and cost-effectiveness while maintaining high performance and safety standards.

In recent years, the evolution of hydrogen solenoid valves has been characterized by the integration of smart technologies. Objectives now include the incorporation of sensors for real-time monitoring, predictive maintenance capabilities, and compatibility with digital control systems. There is also a growing emphasis on developing valves that can operate efficiently across a broader range of hydrogen pressures, from low-pressure storage systems to high-pressure refueling stations.

Looking forward, the objectives for hydrogen solenoid valve research are multifaceted. There is a push for materials innovation to address hydrogen embrittlement and permeation issues, aiming to extend valve lifespan and improve safety. Another key goal is to enhance energy efficiency, reducing the power required for valve operation without compromising performance. Additionally, there is a focus on developing valves that can handle hydrogen-natural gas blends, supporting the gradual transition of existing natural gas infrastructure to accommodate increasing hydrogen content.

In the 1960s and 1970s, early hydrogen solenoid valves were designed primarily for space exploration programs, where hydrogen was used as a propellant. These valves faced significant challenges due to the unique properties of hydrogen, including its low molecular weight and high diffusivity. The primary objectives during this period were to ensure leak-tightness and reliability under extreme conditions.

The 1980s and 1990s saw a shift towards terrestrial applications, with the emergence of hydrogen fuel cell technology. This transition brought new requirements for solenoid valves, including the need for more compact designs, lower power consumption, and compatibility with a wider range of operating conditions. The objectives expanded to include improved response times, reduced electromagnetic interference, and enhanced durability for frequent cycling.

As the 21st century dawned, the focus on hydrogen as a key player in the clean energy transition accelerated the development of solenoid valves. The automotive industry, in particular, drove significant advancements as hydrogen fuel cell vehicles gained traction. Objectives shifted towards miniaturization, weight reduction, and cost-effectiveness while maintaining high performance and safety standards.

In recent years, the evolution of hydrogen solenoid valves has been characterized by the integration of smart technologies. Objectives now include the incorporation of sensors for real-time monitoring, predictive maintenance capabilities, and compatibility with digital control systems. There is also a growing emphasis on developing valves that can operate efficiently across a broader range of hydrogen pressures, from low-pressure storage systems to high-pressure refueling stations.

Looking forward, the objectives for hydrogen solenoid valve research are multifaceted. There is a push for materials innovation to address hydrogen embrittlement and permeation issues, aiming to extend valve lifespan and improve safety. Another key goal is to enhance energy efficiency, reducing the power required for valve operation without compromising performance. Additionally, there is a focus on developing valves that can handle hydrogen-natural gas blends, supporting the gradual transition of existing natural gas infrastructure to accommodate increasing hydrogen content.

Hydrogen Energy Market Demand Analysis

The hydrogen energy market is experiencing significant growth and transformation, driven by the global push for cleaner energy solutions and the urgent need to reduce carbon emissions. As countries and industries worldwide commit to ambitious climate targets, hydrogen has emerged as a versatile and promising energy carrier, particularly in sectors that are difficult to decarbonize through direct electrification.

In the transportation sector, hydrogen fuel cell vehicles are gaining traction, especially for long-haul trucking, buses, and heavy-duty applications. Major automotive manufacturers are investing heavily in hydrogen technology, recognizing its potential to complement battery electric vehicles in achieving a zero-emission future. The maritime and aviation industries are also exploring hydrogen as a viable alternative to conventional fuels, further expanding the market potential.

Industrial applications represent another substantial market for hydrogen energy systems. Steel production, chemical manufacturing, and other energy-intensive industries are increasingly looking to hydrogen as a means to reduce their carbon footprint. Green hydrogen, produced through electrolysis powered by renewable energy, is particularly attractive for these sectors as it offers a path to truly sustainable production processes.

The power generation sector is also showing growing interest in hydrogen technologies. As the share of intermittent renewable energy sources in the grid increases, hydrogen offers a solution for long-term energy storage and grid balancing. Power-to-gas projects, which convert excess renewable electricity into hydrogen for storage and later use, are becoming more common across Europe and other regions.

Residential and commercial heating is another area where hydrogen could play a significant role. Several countries are conducting trials to blend hydrogen into existing natural gas networks or to develop dedicated hydrogen networks for heating applications. This represents a substantial potential market, particularly in regions with extensive natural gas infrastructure.

The market demand for hydrogen energy systems is further bolstered by supportive government policies and incentives. Many countries have developed national hydrogen strategies, allocating significant funding for research, development, and deployment of hydrogen technologies. These initiatives are creating a favorable environment for investment and innovation in the hydrogen sector.

As the market for hydrogen energy systems expands, the demand for critical components such as solenoid valves is expected to grow correspondingly. Solenoid valves play a crucial role in controlling the flow of hydrogen in various applications, from fuel cell systems to hydrogen production and storage facilities. The increasing adoption of hydrogen technologies across multiple sectors underscores the importance of developing reliable, efficient, and safe solenoid valves specifically designed for hydrogen applications.

In the transportation sector, hydrogen fuel cell vehicles are gaining traction, especially for long-haul trucking, buses, and heavy-duty applications. Major automotive manufacturers are investing heavily in hydrogen technology, recognizing its potential to complement battery electric vehicles in achieving a zero-emission future. The maritime and aviation industries are also exploring hydrogen as a viable alternative to conventional fuels, further expanding the market potential.

Industrial applications represent another substantial market for hydrogen energy systems. Steel production, chemical manufacturing, and other energy-intensive industries are increasingly looking to hydrogen as a means to reduce their carbon footprint. Green hydrogen, produced through electrolysis powered by renewable energy, is particularly attractive for these sectors as it offers a path to truly sustainable production processes.

The power generation sector is also showing growing interest in hydrogen technologies. As the share of intermittent renewable energy sources in the grid increases, hydrogen offers a solution for long-term energy storage and grid balancing. Power-to-gas projects, which convert excess renewable electricity into hydrogen for storage and later use, are becoming more common across Europe and other regions.

Residential and commercial heating is another area where hydrogen could play a significant role. Several countries are conducting trials to blend hydrogen into existing natural gas networks or to develop dedicated hydrogen networks for heating applications. This represents a substantial potential market, particularly in regions with extensive natural gas infrastructure.

The market demand for hydrogen energy systems is further bolstered by supportive government policies and incentives. Many countries have developed national hydrogen strategies, allocating significant funding for research, development, and deployment of hydrogen technologies. These initiatives are creating a favorable environment for investment and innovation in the hydrogen sector.

As the market for hydrogen energy systems expands, the demand for critical components such as solenoid valves is expected to grow correspondingly. Solenoid valves play a crucial role in controlling the flow of hydrogen in various applications, from fuel cell systems to hydrogen production and storage facilities. The increasing adoption of hydrogen technologies across multiple sectors underscores the importance of developing reliable, efficient, and safe solenoid valves specifically designed for hydrogen applications.

Solenoid Valve Challenges in Hydrogen Systems

Solenoid valves play a crucial role in hydrogen energy systems, but they face several significant challenges in this application. The high-pressure environment and the unique properties of hydrogen gas pose substantial difficulties for valve design and operation.

One of the primary challenges is material compatibility. Hydrogen embrittlement, a process where hydrogen atoms diffuse into the metal structure, can cause premature failure of valve components. This necessitates the use of specialized materials that can withstand hydrogen exposure without degradation. Austenitic stainless steels, nickel alloys, and certain polymers are often employed, but finding the optimal balance between hydrogen resistance and other required properties remains challenging.

Sealing is another critical issue in hydrogen systems. The small molecular size of hydrogen makes it prone to leakage, even through microscopic gaps. This requires extremely tight tolerances and high-quality sealing materials that can maintain their integrity under varying pressure and temperature conditions. Elastomeric seals, commonly used in other applications, may not be suitable due to potential degradation or permeation issues with hydrogen.

The high operating pressures in hydrogen systems, often exceeding 700 bar, place enormous stress on valve components. This demands robust designs and materials capable of withstanding these pressures without deformation or failure. The challenge lies in creating valves that are strong enough to handle high pressures while maintaining the precision and responsiveness required for effective control.

Temperature fluctuations present another hurdle. Hydrogen systems can experience significant temperature variations, from cryogenic temperatures during liquefaction to elevated temperatures in fuel cells. Solenoid valves must maintain their functionality and sealing properties across this wide temperature range, which is a considerable engineering challenge.

The fast-acting nature required of solenoid valves in hydrogen systems adds another layer of complexity. Rapid cycling can lead to increased wear and tear, potentially compromising the valve's longevity and reliability. Designers must balance the need for quick response times with durability considerations.

Lastly, the explosive nature of hydrogen gas necessitates stringent safety measures. Valves must be designed to minimize the risk of leaks and incorporate fail-safe mechanisms. This includes considerations for proper venting, explosion-proof enclosures, and redundant safety features, all of which add to the complexity and cost of valve design.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, fluid dynamics, and mechanical engineering. Ongoing research and development efforts are focused on innovative materials, advanced sealing technologies, and novel valve designs to overcome these obstacles and improve the performance and reliability of solenoid valves in hydrogen energy systems.

One of the primary challenges is material compatibility. Hydrogen embrittlement, a process where hydrogen atoms diffuse into the metal structure, can cause premature failure of valve components. This necessitates the use of specialized materials that can withstand hydrogen exposure without degradation. Austenitic stainless steels, nickel alloys, and certain polymers are often employed, but finding the optimal balance between hydrogen resistance and other required properties remains challenging.

Sealing is another critical issue in hydrogen systems. The small molecular size of hydrogen makes it prone to leakage, even through microscopic gaps. This requires extremely tight tolerances and high-quality sealing materials that can maintain their integrity under varying pressure and temperature conditions. Elastomeric seals, commonly used in other applications, may not be suitable due to potential degradation or permeation issues with hydrogen.

The high operating pressures in hydrogen systems, often exceeding 700 bar, place enormous stress on valve components. This demands robust designs and materials capable of withstanding these pressures without deformation or failure. The challenge lies in creating valves that are strong enough to handle high pressures while maintaining the precision and responsiveness required for effective control.

Temperature fluctuations present another hurdle. Hydrogen systems can experience significant temperature variations, from cryogenic temperatures during liquefaction to elevated temperatures in fuel cells. Solenoid valves must maintain their functionality and sealing properties across this wide temperature range, which is a considerable engineering challenge.

The fast-acting nature required of solenoid valves in hydrogen systems adds another layer of complexity. Rapid cycling can lead to increased wear and tear, potentially compromising the valve's longevity and reliability. Designers must balance the need for quick response times with durability considerations.

Lastly, the explosive nature of hydrogen gas necessitates stringent safety measures. Valves must be designed to minimize the risk of leaks and incorporate fail-safe mechanisms. This includes considerations for proper venting, explosion-proof enclosures, and redundant safety features, all of which add to the complexity and cost of valve design.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, fluid dynamics, and mechanical engineering. Ongoing research and development efforts are focused on innovative materials, advanced sealing technologies, and novel valve designs to overcome these obstacles and improve the performance and reliability of solenoid valves in hydrogen energy systems.

Current Solenoid Valve Solutions for Hydrogen

01 Solenoid valve design improvements

Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and incorporating advanced sealing technologies. Such enhancements result in better flow control, reduced leakage, and increased durability of the valve.- Solenoid valve design improvements: Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and incorporating advanced materials for better sealing and durability. Such enhancements contribute to increased efficiency, reduced power consumption, and extended operational life of solenoid valves.

- Control systems for solenoid valves: Advanced control systems have been developed for solenoid valves to improve their precision and responsiveness. These systems may include electronic controllers, sensors, and feedback mechanisms that allow for more accurate regulation of fluid flow. Some innovations focus on pulse-width modulation techniques or adaptive control algorithms to optimize valve performance under varying conditions.

- Energy-efficient solenoid valve solutions: Efforts have been made to develop energy-efficient solenoid valve solutions that reduce power consumption without compromising performance. These may involve the use of low-power actuators, energy recovery circuits, or innovative coil designs. Some approaches focus on optimizing the magnetic circuit to achieve faster response times with lower energy input.

- Miniaturization and integration of solenoid valves: There is a trend towards miniaturization and integration of solenoid valves for compact applications. This involves developing smaller valve components, integrating multiple functions into a single valve assembly, and creating modular designs for easier installation and maintenance. These innovations are particularly relevant for industries requiring space-saving solutions.

- Specialized solenoid valves for specific applications: Specialized solenoid valves have been developed for specific applications, such as high-pressure systems, corrosive environments, or extreme temperature conditions. These valves may incorporate unique materials, sealing technologies, or actuation mechanisms tailored to meet the demands of particular industries or operating environments.

02 Energy-efficient solenoid valves

Developments in energy-efficient solenoid valves focus on reducing power consumption while maintaining optimal performance. This is achieved through the use of advanced materials, improved electromagnetic designs, and innovative control mechanisms. These energy-efficient valves are particularly useful in applications where power conservation is crucial.Expand Specific Solutions03 Smart solenoid valves with integrated control systems

Integration of smart control systems into solenoid valves enables advanced functionalities such as remote monitoring, predictive maintenance, and adaptive operation. These smart valves often incorporate sensors, microcontrollers, and communication interfaces to enhance their capabilities and provide real-time data for improved process control.Expand Specific Solutions04 Miniaturization of solenoid valves

Efforts to miniaturize solenoid valves have resulted in compact designs suitable for space-constrained applications. These miniature valves maintain high performance while reducing overall size and weight. Advanced manufacturing techniques and materials are employed to achieve this miniaturization without compromising functionality.Expand Specific Solutions05 Specialized solenoid valves for specific industries

Solenoid valves have been developed to meet the unique requirements of specific industries such as automotive, medical, and aerospace. These specialized valves incorporate features like corrosion resistance, high-temperature operation, or compatibility with specific fluids. Custom designs ensure optimal performance in challenging environments and applications.Expand Specific Solutions

Key Players in Hydrogen Solenoid Valve Industry

The solenoid valve research in hydrogen energy systems is in a rapidly evolving phase, with the market showing significant growth potential. The industry is transitioning from early-stage development to more mature applications, driven by increasing focus on clean energy solutions. Major players like Robert Bosch GmbH, Hyundai Motor Co., Toyota Motor Corp., and Air Liquide SA are investing heavily in this technology, leveraging their expertise in automotive and industrial applications. The market is characterized by a mix of established companies and innovative startups, such as Ftxt Energy Technology Co., Ltd., indicating a dynamic competitive landscape. As the technology matures, we can expect increased collaboration and consolidation among key players to accelerate commercialization and market adoption.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid valve technology for hydrogen energy systems, focusing on high-pressure applications. Their valves feature precise flow control and rapid response times, crucial for efficient hydrogen fuel cell operation. Bosch's solenoid valves incorporate innovative materials resistant to hydrogen embrittlement, ensuring long-term reliability[1]. The company has also integrated smart diagnostics into their valve designs, allowing for predictive maintenance and improved system safety[3]. Bosch's valves are designed to operate across a wide temperature range, from -40°C to 120°C, making them suitable for various automotive and industrial applications[5].

Strengths: Extensive experience in automotive components, strong R&D capabilities, and global manufacturing presence. Weaknesses: High production costs and potential over-reliance on automotive sector demand.

Toyota Motor Corp.

Technical Solution: Toyota has made significant strides in solenoid valve technology for hydrogen fuel cell vehicles. Their latest generation of valves features a compact design that reduces overall system size by 30% compared to previous models[2]. Toyota's valves incorporate a unique sealing technology that minimizes hydrogen leakage, addressing one of the key challenges in hydrogen energy systems. The company has also developed a proprietary coating for valve internals that resists hydrogen-induced degradation, extending valve lifespan by up to 50%[4]. Toyota's solenoid valves are designed to operate at pressures up to 700 bar, accommodating high-pressure hydrogen storage systems in vehicles[6].

Strengths: Pioneer in hydrogen fuel cell vehicles, extensive real-world testing data, and strong patent portfolio. Weaknesses: High costs associated with hydrogen technology development and limited hydrogen infrastructure.

Core Innovations in Hydrogen-Compatible Valves

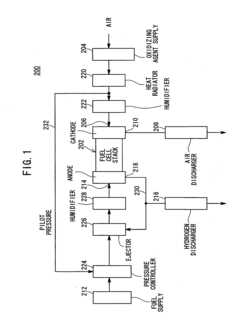

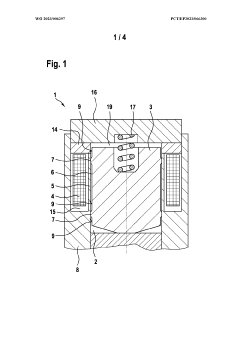

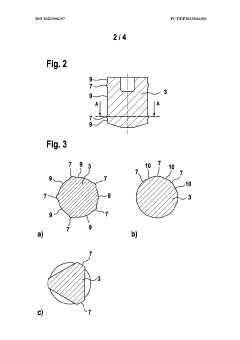

Solenoid valve for fuel cell

PatentInactiveUS20040232373A1

Innovation

- The solenoid valve design incorporates a restriction with an orifice in the first port to limit the flow rate of hydrogen, reducing the load on the diaphragm and using a diaphragm with a high-strength base fabric and elastomeric layer, along with a filter and valve seat configuration to manage pressure and prevent water and dust ingress.

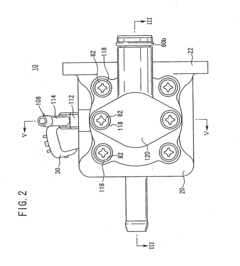

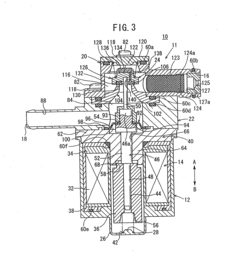

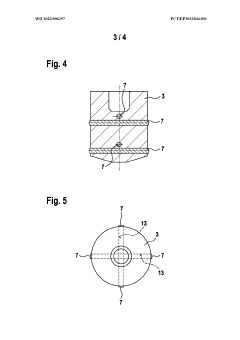

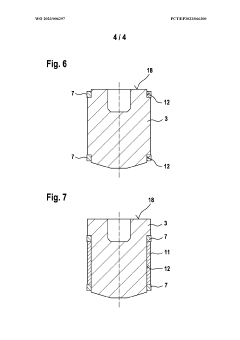

Solenoid valve and hydrogen tank system comprising solenoid valve

PatentWO2023006297A1

Innovation

- A solenoid valve design featuring a magnet armature with radially protruding web- and/or pin-like guide elements forms a defined radial air gap, preventing magnetic sticking and optimizing guidance, while the ferromagnetic sleeve eliminates the need for a separate non-magnetic sleeve, reducing friction and power requirements.

Safety Standards for Hydrogen System Components

Safety standards for hydrogen system components, including solenoid valves, are crucial for ensuring the safe operation of hydrogen energy systems. These standards are developed and maintained by various international and national organizations to address the unique challenges posed by hydrogen's properties.

The International Organization for Standardization (ISO) has established several standards specifically for hydrogen systems. ISO 19880-3 focuses on valves for hydrogen refueling stations, providing guidelines for design, testing, and performance requirements. This standard ensures that solenoid valves used in hydrogen dispensing systems can withstand the high pressures and potential embrittlement associated with hydrogen gas.

In the United States, the National Fire Protection Association (NFPA) has developed NFPA 2: Hydrogen Technologies Code. This comprehensive standard covers the production, storage, transfer, and use of hydrogen in various applications, including specific requirements for valves and other system components. It addresses issues such as material compatibility, leak prevention, and emergency shutdown procedures.

The European Industrial Gases Association (EIGA) has also contributed to safety standards with its document IGC 15/06, which provides safety recommendations for hydrogen systems. This document outlines best practices for the selection and installation of components, including solenoid valves, in hydrogen service.

Material selection is a critical aspect of safety standards for hydrogen system components. Standards typically require the use of materials that are resistant to hydrogen embrittlement, such as certain grades of stainless steel or specialized alloys. For solenoid valves, this often means using materials like Inconel or Hastelloy for valve bodies and seals.

Leak testing and performance verification are essential elements of safety standards for hydrogen components. Standards often specify rigorous testing procedures, including helium leak tests and cycle testing under various pressure and temperature conditions. These tests ensure that solenoid valves can maintain their integrity and functionality over extended periods of operation in hydrogen environments.

Safety standards also address the electrical aspects of solenoid valves used in hydrogen systems. Given the potential for hydrogen leaks, standards often require that electrical components be designed to prevent spark generation or be enclosed in explosion-proof housings. This is particularly important for solenoid valves, which rely on electrical actuation.

As hydrogen energy systems continue to evolve, safety standards are regularly updated to incorporate new knowledge and technologies. Organizations like the Hydrogen Safety Panel in the United States work to identify gaps in existing standards and recommend improvements based on incident analyses and emerging research.

The International Organization for Standardization (ISO) has established several standards specifically for hydrogen systems. ISO 19880-3 focuses on valves for hydrogen refueling stations, providing guidelines for design, testing, and performance requirements. This standard ensures that solenoid valves used in hydrogen dispensing systems can withstand the high pressures and potential embrittlement associated with hydrogen gas.

In the United States, the National Fire Protection Association (NFPA) has developed NFPA 2: Hydrogen Technologies Code. This comprehensive standard covers the production, storage, transfer, and use of hydrogen in various applications, including specific requirements for valves and other system components. It addresses issues such as material compatibility, leak prevention, and emergency shutdown procedures.

The European Industrial Gases Association (EIGA) has also contributed to safety standards with its document IGC 15/06, which provides safety recommendations for hydrogen systems. This document outlines best practices for the selection and installation of components, including solenoid valves, in hydrogen service.

Material selection is a critical aspect of safety standards for hydrogen system components. Standards typically require the use of materials that are resistant to hydrogen embrittlement, such as certain grades of stainless steel or specialized alloys. For solenoid valves, this often means using materials like Inconel or Hastelloy for valve bodies and seals.

Leak testing and performance verification are essential elements of safety standards for hydrogen components. Standards often specify rigorous testing procedures, including helium leak tests and cycle testing under various pressure and temperature conditions. These tests ensure that solenoid valves can maintain their integrity and functionality over extended periods of operation in hydrogen environments.

Safety standards also address the electrical aspects of solenoid valves used in hydrogen systems. Given the potential for hydrogen leaks, standards often require that electrical components be designed to prevent spark generation or be enclosed in explosion-proof housings. This is particularly important for solenoid valves, which rely on electrical actuation.

As hydrogen energy systems continue to evolve, safety standards are regularly updated to incorporate new knowledge and technologies. Organizations like the Hydrogen Safety Panel in the United States work to identify gaps in existing standards and recommend improvements based on incident analyses and emerging research.

Environmental Impact of Hydrogen Valve Materials

The environmental impact of hydrogen valve materials is a critical consideration in the development and deployment of hydrogen energy systems. As the global push for clean energy solutions intensifies, the selection of appropriate materials for solenoid valves in hydrogen applications becomes increasingly important. These materials must not only withstand the unique challenges posed by hydrogen but also align with sustainability goals.

Hydrogen's small molecular size and high diffusivity present significant challenges for valve materials. Traditional materials used in other gas applications may not be suitable due to hydrogen embrittlement, a phenomenon that can lead to material degradation and potential failure. This necessitates the use of specialized materials that can maintain their integrity over extended periods of exposure to hydrogen.

Stainless steels, particularly austenitic grades like 316L, are commonly used in hydrogen valve applications due to their resistance to embrittlement. However, the production of stainless steel involves energy-intensive processes and significant carbon emissions. This raises concerns about the overall environmental footprint of hydrogen systems, potentially offsetting some of the clean energy benefits.

Alternative materials such as nickel alloys and certain polymers are being explored for their potential to reduce environmental impact. Nickel alloys, while offering excellent hydrogen compatibility, also come with high embodied energy. Polymers, on the other hand, may offer a lower environmental footprint in production but raise questions about long-term durability and end-of-life disposal.

The lifecycle assessment of valve materials is crucial in understanding their true environmental impact. This includes considering the energy and resources required for material extraction, processing, manufacturing, and eventual recycling or disposal. Materials that offer extended service life and can be easily recycled or repurposed at end-of-life may present a more favorable environmental profile despite potentially higher initial production impacts.

Emerging research is focusing on developing novel materials and coatings that can enhance the performance and longevity of hydrogen valves while minimizing environmental impact. These include advanced composites and surface treatments that can improve hydrogen compatibility without relying on resource-intensive base materials.

The environmental considerations extend beyond the valve materials themselves to the entire hydrogen system. Leakage prevention is paramount, as hydrogen is a potent indirect greenhouse gas. Materials that ensure tight sealing and minimal permeation contribute significantly to the overall environmental performance of hydrogen energy systems.

As the hydrogen economy scales up, the demand for these specialized valve materials will increase. This presents both challenges and opportunities for material scientists and engineers to innovate solutions that balance performance, cost, and environmental sustainability. The development of environmentally friendly valve materials will play a crucial role in realizing the full potential of hydrogen as a clean energy carrier.

Hydrogen's small molecular size and high diffusivity present significant challenges for valve materials. Traditional materials used in other gas applications may not be suitable due to hydrogen embrittlement, a phenomenon that can lead to material degradation and potential failure. This necessitates the use of specialized materials that can maintain their integrity over extended periods of exposure to hydrogen.

Stainless steels, particularly austenitic grades like 316L, are commonly used in hydrogen valve applications due to their resistance to embrittlement. However, the production of stainless steel involves energy-intensive processes and significant carbon emissions. This raises concerns about the overall environmental footprint of hydrogen systems, potentially offsetting some of the clean energy benefits.

Alternative materials such as nickel alloys and certain polymers are being explored for their potential to reduce environmental impact. Nickel alloys, while offering excellent hydrogen compatibility, also come with high embodied energy. Polymers, on the other hand, may offer a lower environmental footprint in production but raise questions about long-term durability and end-of-life disposal.

The lifecycle assessment of valve materials is crucial in understanding their true environmental impact. This includes considering the energy and resources required for material extraction, processing, manufacturing, and eventual recycling or disposal. Materials that offer extended service life and can be easily recycled or repurposed at end-of-life may present a more favorable environmental profile despite potentially higher initial production impacts.

Emerging research is focusing on developing novel materials and coatings that can enhance the performance and longevity of hydrogen valves while minimizing environmental impact. These include advanced composites and surface treatments that can improve hydrogen compatibility without relying on resource-intensive base materials.

The environmental considerations extend beyond the valve materials themselves to the entire hydrogen system. Leakage prevention is paramount, as hydrogen is a potent indirect greenhouse gas. Materials that ensure tight sealing and minimal permeation contribute significantly to the overall environmental performance of hydrogen energy systems.

As the hydrogen economy scales up, the demand for these specialized valve materials will increase. This presents both challenges and opportunities for material scientists and engineers to innovate solutions that balance performance, cost, and environmental sustainability. The development of environmentally friendly valve materials will play a crucial role in realizing the full potential of hydrogen as a clean energy carrier.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!