Solenoid Valves in Food Processing: Ensuring Hygienic Standards

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Food Industry

The evolution of solenoid valves in the food industry has been marked by significant technological advancements and a growing emphasis on hygienic standards. Initially introduced in the mid-20th century, these valves have undergone substantial transformations to meet the stringent requirements of food processing operations.

In the early stages, solenoid valves were primarily designed for general industrial applications, with limited consideration for the specific needs of the food sector. These early models were often constructed from materials that were not ideal for food contact, such as brass or standard stainless steel, which posed risks of contamination and corrosion.

The 1970s and 1980s saw a shift towards more specialized designs for the food industry. Manufacturers began incorporating food-grade materials, such as 316L stainless steel and FDA-approved elastomers, to enhance the valves' suitability for food processing environments. This period also witnessed the introduction of cleanable designs, featuring smoother surfaces and fewer crevices where bacteria could accumulate.

The 1990s brought about a revolution in hygienic design principles for food processing equipment, including solenoid valves. This era saw the development of valves with improved cleanability, featuring self-draining designs and minimized dead spaces. The integration of Clean-In-Place (CIP) compatibility became a standard feature, allowing for more efficient and thorough cleaning processes without disassembly.

As we entered the 21st century, the focus shifted towards enhancing the precision and reliability of solenoid valves in food processing applications. Advanced sealing technologies were introduced to prevent product leakage and contamination. The incorporation of smart technologies, such as position sensors and diagnostic capabilities, allowed for better monitoring and control of valve operations.

Recent years have seen further innovations in materials science, with the introduction of advanced polymers and composites that offer superior chemical resistance and durability. These materials have enabled the development of lighter, more compact valve designs without compromising on hygiene or performance.

The latest trend in solenoid valve evolution for the food industry is the integration of Industry 4.0 principles. Modern valves are increasingly equipped with IoT capabilities, allowing for real-time monitoring, predictive maintenance, and seamless integration with automated production systems. This connectivity not only improves operational efficiency but also enhances traceability and quality control throughout the food processing chain.

In the early stages, solenoid valves were primarily designed for general industrial applications, with limited consideration for the specific needs of the food sector. These early models were often constructed from materials that were not ideal for food contact, such as brass or standard stainless steel, which posed risks of contamination and corrosion.

The 1970s and 1980s saw a shift towards more specialized designs for the food industry. Manufacturers began incorporating food-grade materials, such as 316L stainless steel and FDA-approved elastomers, to enhance the valves' suitability for food processing environments. This period also witnessed the introduction of cleanable designs, featuring smoother surfaces and fewer crevices where bacteria could accumulate.

The 1990s brought about a revolution in hygienic design principles for food processing equipment, including solenoid valves. This era saw the development of valves with improved cleanability, featuring self-draining designs and minimized dead spaces. The integration of Clean-In-Place (CIP) compatibility became a standard feature, allowing for more efficient and thorough cleaning processes without disassembly.

As we entered the 21st century, the focus shifted towards enhancing the precision and reliability of solenoid valves in food processing applications. Advanced sealing technologies were introduced to prevent product leakage and contamination. The incorporation of smart technologies, such as position sensors and diagnostic capabilities, allowed for better monitoring and control of valve operations.

Recent years have seen further innovations in materials science, with the introduction of advanced polymers and composites that offer superior chemical resistance and durability. These materials have enabled the development of lighter, more compact valve designs without compromising on hygiene or performance.

The latest trend in solenoid valve evolution for the food industry is the integration of Industry 4.0 principles. Modern valves are increasingly equipped with IoT capabilities, allowing for real-time monitoring, predictive maintenance, and seamless integration with automated production systems. This connectivity not only improves operational efficiency but also enhances traceability and quality control throughout the food processing chain.

Market Demand for Hygienic Valves

The market demand for hygienic valves in food processing has been steadily increasing due to stringent food safety regulations and growing consumer awareness. Solenoid valves play a crucial role in maintaining hygienic standards throughout the food production process, from ingredient handling to packaging.

Food and beverage manufacturers are increasingly seeking valves that meet or exceed industry standards such as 3-A Sanitary Standards and EHEDG (European Hygienic Engineering & Design Group) guidelines. These standards emphasize the importance of cleanability, material compatibility, and design features that prevent bacterial growth and contamination.

The global food processing equipment market, which includes hygienic valves, is projected to grow significantly in the coming years. This growth is driven by factors such as increasing automation in food processing, the need for more efficient and hygienic production lines, and the expansion of the processed food industry in emerging markets.

Solenoid valves designed for hygienic applications are in high demand due to their ability to control the flow of liquids and gases precisely while maintaining sanitary conditions. These valves are particularly valuable in CIP (Clean-in-Place) systems, where they facilitate the cleaning and sanitization of processing equipment without disassembly.

The dairy industry represents a substantial portion of the market for hygienic solenoid valves. With the rising consumption of dairy products worldwide, manufacturers are investing in advanced processing equipment that ensures product safety and quality. Solenoid valves are essential in controlling the flow of milk, cream, and other dairy products through various stages of processing.

Beverage production is another key sector driving demand for hygienic solenoid valves. The need for precise control over ingredient mixing, carbonation, and filling processes has led to increased adoption of sophisticated valve systems that can maintain sterile conditions and handle a wide range of liquids.

The meat and poultry processing industry also contributes significantly to the demand for hygienic valves. As food safety concerns intensify, processors are upgrading their equipment to minimize contamination risks. Solenoid valves that can withstand frequent cleaning and sterilization cycles are particularly sought after in this sector.

Emerging trends in food processing, such as the growing popularity of plant-based products and functional foods, are creating new opportunities for hygienic valve manufacturers. These novel food categories often require specialized processing techniques and equipment, including valves that can handle unique ingredient formulations while maintaining strict hygiene standards.

As the food industry continues to evolve, the demand for more advanced, efficient, and hygienic solenoid valves is expected to grow. Manufacturers are likely to focus on developing valves with improved cleanability, enhanced durability, and smart features that integrate with automated control systems to meet the evolving needs of food processors.

Food and beverage manufacturers are increasingly seeking valves that meet or exceed industry standards such as 3-A Sanitary Standards and EHEDG (European Hygienic Engineering & Design Group) guidelines. These standards emphasize the importance of cleanability, material compatibility, and design features that prevent bacterial growth and contamination.

The global food processing equipment market, which includes hygienic valves, is projected to grow significantly in the coming years. This growth is driven by factors such as increasing automation in food processing, the need for more efficient and hygienic production lines, and the expansion of the processed food industry in emerging markets.

Solenoid valves designed for hygienic applications are in high demand due to their ability to control the flow of liquids and gases precisely while maintaining sanitary conditions. These valves are particularly valuable in CIP (Clean-in-Place) systems, where they facilitate the cleaning and sanitization of processing equipment without disassembly.

The dairy industry represents a substantial portion of the market for hygienic solenoid valves. With the rising consumption of dairy products worldwide, manufacturers are investing in advanced processing equipment that ensures product safety and quality. Solenoid valves are essential in controlling the flow of milk, cream, and other dairy products through various stages of processing.

Beverage production is another key sector driving demand for hygienic solenoid valves. The need for precise control over ingredient mixing, carbonation, and filling processes has led to increased adoption of sophisticated valve systems that can maintain sterile conditions and handle a wide range of liquids.

The meat and poultry processing industry also contributes significantly to the demand for hygienic valves. As food safety concerns intensify, processors are upgrading their equipment to minimize contamination risks. Solenoid valves that can withstand frequent cleaning and sterilization cycles are particularly sought after in this sector.

Emerging trends in food processing, such as the growing popularity of plant-based products and functional foods, are creating new opportunities for hygienic valve manufacturers. These novel food categories often require specialized processing techniques and equipment, including valves that can handle unique ingredient formulations while maintaining strict hygiene standards.

As the food industry continues to evolve, the demand for more advanced, efficient, and hygienic solenoid valves is expected to grow. Manufacturers are likely to focus on developing valves with improved cleanability, enhanced durability, and smart features that integrate with automated control systems to meet the evolving needs of food processors.

Challenges in Hygienic Solenoid Valves

The implementation of hygienic solenoid valves in food processing environments faces several significant challenges that must be addressed to ensure compliance with stringent sanitary standards. One of the primary concerns is the prevention of bacterial growth and contamination within the valve components. The intricate internal structures of solenoid valves can create potential harboring sites for microorganisms, making thorough cleaning and sterilization difficult.

Material selection poses another critical challenge. Valve components must be constructed from materials that are not only corrosion-resistant but also capable of withstanding frequent exposure to aggressive cleaning agents and high-temperature sterilization processes. Additionally, these materials must not leach harmful substances into the food products, further complicating the design and manufacturing process.

The design of hygienic solenoid valves must also account for the elimination of dead spaces and crevices where food particles or liquids can accumulate. Such areas are particularly problematic as they can become breeding grounds for bacteria and are often hard to access during cleaning procedures. Engineers must develop innovative designs that promote smooth internal surfaces and self-draining capabilities to mitigate these risks.

Sealing technology presents another hurdle in the development of hygienic solenoid valves. The seals must maintain their integrity under varying pressure and temperature conditions while also being resistant to degradation from both food products and cleaning chemicals. Achieving a balance between effective sealing and ease of maintenance is crucial for long-term operational efficiency.

The challenge of maintaining consistent performance under diverse operating conditions is also significant. Solenoid valves in food processing must function reliably across a wide range of temperatures, pressures, and viscosities of different food products. This variability demands robust design and precise control mechanisms to ensure accurate and repeatable operation.

Compliance with regulatory standards adds another layer of complexity. Hygienic solenoid valves must meet the requirements set by various food safety authorities, such as the FDA in the United States or EHEDG in Europe. These standards often necessitate extensive documentation, testing, and certification processes, which can be time-consuming and costly for manufacturers.

Lastly, the integration of hygienic solenoid valves into existing food processing systems presents logistical and technical challenges. Retrofitting older equipment with new, hygienic valves may require significant modifications to piping systems and control interfaces, potentially leading to production downtime and additional expenses for food processing facilities.

Material selection poses another critical challenge. Valve components must be constructed from materials that are not only corrosion-resistant but also capable of withstanding frequent exposure to aggressive cleaning agents and high-temperature sterilization processes. Additionally, these materials must not leach harmful substances into the food products, further complicating the design and manufacturing process.

The design of hygienic solenoid valves must also account for the elimination of dead spaces and crevices where food particles or liquids can accumulate. Such areas are particularly problematic as they can become breeding grounds for bacteria and are often hard to access during cleaning procedures. Engineers must develop innovative designs that promote smooth internal surfaces and self-draining capabilities to mitigate these risks.

Sealing technology presents another hurdle in the development of hygienic solenoid valves. The seals must maintain their integrity under varying pressure and temperature conditions while also being resistant to degradation from both food products and cleaning chemicals. Achieving a balance between effective sealing and ease of maintenance is crucial for long-term operational efficiency.

The challenge of maintaining consistent performance under diverse operating conditions is also significant. Solenoid valves in food processing must function reliably across a wide range of temperatures, pressures, and viscosities of different food products. This variability demands robust design and precise control mechanisms to ensure accurate and repeatable operation.

Compliance with regulatory standards adds another layer of complexity. Hygienic solenoid valves must meet the requirements set by various food safety authorities, such as the FDA in the United States or EHEDG in Europe. These standards often necessitate extensive documentation, testing, and certification processes, which can be time-consuming and costly for manufacturers.

Lastly, the integration of hygienic solenoid valves into existing food processing systems presents logistical and technical challenges. Retrofitting older equipment with new, hygienic valves may require significant modifications to piping systems and control interfaces, potentially leading to production downtime and additional expenses for food processing facilities.

Current Hygienic Solenoid Solutions

01 Hygienic design of solenoid valves

Solenoid valves designed for hygienic applications incorporate features that prevent contamination and facilitate easy cleaning. These designs often include smooth surfaces, minimal crevices, and materials that are resistant to corrosion and microbial growth. The valves are constructed to meet specific sanitary standards for use in food, beverage, pharmaceutical, and other industries where cleanliness is critical.- Hygienic design of solenoid valves: Solenoid valves designed for hygienic applications incorporate features that prevent contamination and facilitate easy cleaning. These designs may include smooth surfaces, minimal crevices, and materials that are resistant to bacterial growth. The valves are often constructed using food-grade materials and may have special seals to prevent product ingress into the valve mechanism.

- Cleaning and sterilization methods for solenoid valves: Hygienic standards for solenoid valves often require specific cleaning and sterilization procedures. These may include Clean-In-Place (CIP) or Steam-In-Place (SIP) capabilities, allowing for thorough cleaning without disassembly. The valve design should withstand high temperatures and aggressive cleaning agents used in these processes.

- Material selection for hygienic solenoid valves: The choice of materials for solenoid valves in hygienic applications is crucial. Commonly used materials include stainless steel, PTFE, and other FDA-approved polymers. These materials should be corrosion-resistant, non-reactive with the process fluids, and able to withstand repeated cleaning and sterilization cycles without degradation.

- Compliance with industry standards and regulations: Hygienic solenoid valves must comply with various industry standards and regulations, such as those set by the FDA, 3-A Sanitary Standards, or EHEDG. These standards often dictate design requirements, material specifications, and performance criteria to ensure the valves meet hygienic standards for use in food, beverage, pharmaceutical, and other sensitive industries.

- Testing and certification of hygienic solenoid valves: To ensure compliance with hygienic standards, solenoid valves undergo rigorous testing and certification processes. These may include pressure tests, leakage tests, and microbial ingress tests. Certification from recognized bodies may be required to validate the hygienic design and performance of the valves for use in sensitive applications.

02 Cleaning and sterilization methods for solenoid valves

Various cleaning and sterilization methods are employed to maintain the hygienic standards of solenoid valves. These may include Clean-In-Place (CIP) systems, Steam-In-Place (SIP) processes, and the use of specialized cleaning agents. The valves are designed to withstand high temperatures and pressures during sterilization procedures without compromising their functionality or hygienic properties.Expand Specific Solutions03 Materials selection for hygienic solenoid valves

The choice of materials for solenoid valves in hygienic applications is crucial. Common materials include stainless steel, PTFE, and other FDA-approved polymers that are resistant to chemicals, corrosion, and microbial growth. These materials must also be able to withstand frequent cleaning and sterilization processes without degradation or leaching of harmful substances.Expand Specific Solutions04 Compliance with industry standards and regulations

Solenoid valves used in hygienic applications must comply with various industry standards and regulations. These may include FDA guidelines, 3-A Sanitary Standards, EHEDG requirements, and ISO standards specific to hygienic equipment design. Manufacturers must ensure their valves meet these standards through proper design, testing, and certification processes.Expand Specific Solutions05 Sealing and connection technologies

Advanced sealing and connection technologies are employed in hygienic solenoid valves to prevent leakage and contamination. These may include specialized gaskets, O-rings, and connection systems designed to maintain a hygienic seal under various operating conditions. The sealing materials and methods must be compatible with the process fluids and cleaning agents used in the application.Expand Specific Solutions

Key Players in Food-Grade Valves

The market for solenoid valves in food processing is in a mature growth stage, with a global market size estimated to be in the billions of dollars. The technology is well-established, with key players like Parker-Hannifin Corp. and Emerson Electric Co. (through its Fisher Controls International LLC subsidiary) dominating the market. These companies offer advanced solutions that meet stringent hygienic standards required in food processing. The competitive landscape is characterized by a mix of large multinational corporations and specialized manufacturers like RPE Srl and Koganei Corp., which focus on niche applications. Technological advancements are primarily driven by the need for improved efficiency, reliability, and compliance with evolving food safety regulations, with companies like SmartWash Solutions LLC introducing innovative process control systems.

Feldmeier Equipment, Inc.

Technical Solution: Feldmeier Equipment, Inc. has developed specialized solenoid valve solutions for the dairy and food processing industries. Their technology focuses on sanitary design principles, incorporating materials that meet 3-A Sanitary Standards and EHEDG guidelines[10]. Feldmeier's solenoid valves feature a unique "clean-in-place" (CIP) design that allows for thorough cleaning without disassembly, reducing downtime and contamination risks[11]. The company has also implemented a patented seat design that minimizes product retention and ensures complete drainage, further enhancing hygienic performance. Additionally, their valves incorporate a high-temperature resistant actuator, capable of withstanding sterilization processes up to 150°C[12].

Strengths: CIP-compatible design, minimal product retention, high-temperature resistance. Weaknesses: May be more expensive due to specialized sanitary features.

Parker-Hannifin Corp.

Technical Solution: Parker-Hannifin Corp. has developed advanced solenoid valves specifically designed for food processing applications. Their technology focuses on hygienic design principles, incorporating materials that meet FDA and 3-A Sanitary Standards[1]. The company's solenoid valves feature smooth, crevice-free surfaces and use food-grade elastomers to prevent bacterial growth. They have implemented a unique self-draining design that eliminates liquid retention, reducing the risk of contamination[2]. Parker's valves also incorporate a patented sealing technology that ensures leak-free operation, even under high-pressure cleaning processes commonly used in food processing environments[3].

Strengths: Hygienic design, FDA-compliant materials, self-draining feature, and leak-free operation. Weaknesses: Potentially higher cost due to specialized materials and design features.

Innovations in Valve Materials

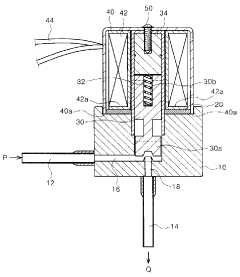

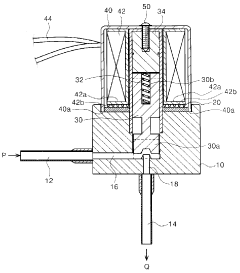

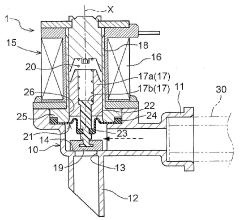

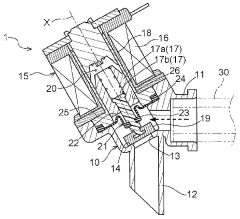

Solenoid valve for food storage

PatentInactiveKR1020020063748A

Innovation

- The solenoid valve design incorporates fixing protrusions on the lower plate of the coil or magnetic field forming plate, and a cover that does not directly contact the valve body, minimizing heat transfer to the refrigerant passage.

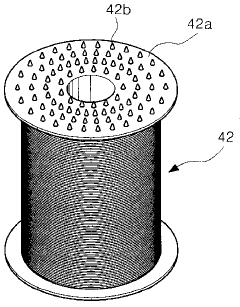

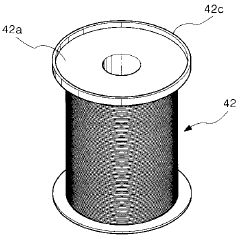

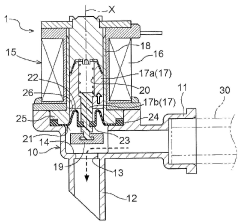

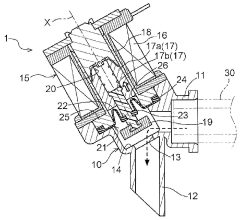

Solenoid valve

PatentInactiveKR1020200104943A

Innovation

- A solenoid valve design with a diaphragm isolating the drive unit from the valve box, separate valve body and diaphragm configuration, and positioning the valve seat at the upstream end of the outlet, allowing for simplified sterilization and reduced complexity, using fluid pressure for valve closure, and minimizing the need for strong elastic forces.

Regulatory Standards for Food Equipment

Regulatory standards for food equipment play a crucial role in ensuring the safety and hygiene of food processing operations. In the context of solenoid valves used in food processing, these standards are particularly stringent to maintain the highest levels of food safety and prevent contamination.

The Food and Drug Administration (FDA) in the United States sets forth guidelines for food contact materials and equipment through its Code of Federal Regulations (CFR). Specifically, 21 CFR Part 177 outlines the requirements for indirect food additives, which includes materials used in food processing equipment such as solenoid valves. These regulations mandate that materials used in food contact applications must be of a purity suitable for their intended use and must not impart harmful substances to food products.

In Europe, the European Hygienic Engineering and Design Group (EHEDG) provides guidelines for hygienic equipment design. These guidelines are widely recognized and adopted by food processing industries worldwide. For solenoid valves, EHEDG emphasizes the importance of cleanability, materials of construction, and surface finish to prevent microbial growth and ensure easy cleaning and sanitization.

The 3-A Sanitary Standards, Inc. is another key organization that develops standards for equipment used in the food, beverage, and pharmaceutical industries. Their standards for valves used in sanitary applications (3-A Sanitary Standard 53-06) provide detailed specifications for design, materials, and fabrication to ensure hygienic operation.

International Organization for Standardization (ISO) also contributes to the regulatory landscape with standards such as ISO 14159:2002, which specifies hygiene requirements for the design of machinery used in food processing. This standard is particularly relevant for the design and construction of solenoid valves to ensure they meet hygienic requirements.

The National Sanitation Foundation (NSF) International develops standards and provides certification for food equipment. NSF/ANSI 51: Food Equipment Materials is a key standard that addresses the materials used in food equipment, including those used in solenoid valves. This standard ensures that materials do not leach harmful substances into food products and can withstand the rigors of food processing environments.

Compliance with these regulatory standards is not only a legal requirement but also a critical factor in maintaining consumer trust and ensuring product quality. Manufacturers of solenoid valves for food processing applications must demonstrate that their products meet or exceed these standards through rigorous testing and certification processes.

As food safety regulations continue to evolve, there is an increasing focus on traceability and documentation. This trend is likely to impact the design and manufacturing of solenoid valves, requiring more comprehensive documentation of materials, processes, and quality control measures throughout the supply chain.

The Food and Drug Administration (FDA) in the United States sets forth guidelines for food contact materials and equipment through its Code of Federal Regulations (CFR). Specifically, 21 CFR Part 177 outlines the requirements for indirect food additives, which includes materials used in food processing equipment such as solenoid valves. These regulations mandate that materials used in food contact applications must be of a purity suitable for their intended use and must not impart harmful substances to food products.

In Europe, the European Hygienic Engineering and Design Group (EHEDG) provides guidelines for hygienic equipment design. These guidelines are widely recognized and adopted by food processing industries worldwide. For solenoid valves, EHEDG emphasizes the importance of cleanability, materials of construction, and surface finish to prevent microbial growth and ensure easy cleaning and sanitization.

The 3-A Sanitary Standards, Inc. is another key organization that develops standards for equipment used in the food, beverage, and pharmaceutical industries. Their standards for valves used in sanitary applications (3-A Sanitary Standard 53-06) provide detailed specifications for design, materials, and fabrication to ensure hygienic operation.

International Organization for Standardization (ISO) also contributes to the regulatory landscape with standards such as ISO 14159:2002, which specifies hygiene requirements for the design of machinery used in food processing. This standard is particularly relevant for the design and construction of solenoid valves to ensure they meet hygienic requirements.

The National Sanitation Foundation (NSF) International develops standards and provides certification for food equipment. NSF/ANSI 51: Food Equipment Materials is a key standard that addresses the materials used in food equipment, including those used in solenoid valves. This standard ensures that materials do not leach harmful substances into food products and can withstand the rigors of food processing environments.

Compliance with these regulatory standards is not only a legal requirement but also a critical factor in maintaining consumer trust and ensuring product quality. Manufacturers of solenoid valves for food processing applications must demonstrate that their products meet or exceed these standards through rigorous testing and certification processes.

As food safety regulations continue to evolve, there is an increasing focus on traceability and documentation. This trend is likely to impact the design and manufacturing of solenoid valves, requiring more comprehensive documentation of materials, processes, and quality control measures throughout the supply chain.

Cleaning and Maintenance Protocols

Maintaining the hygiene of solenoid valves in food processing is crucial for ensuring food safety and compliance with industry standards. Effective cleaning and maintenance protocols are essential to prevent contamination and extend the lifespan of these critical components. A comprehensive cleaning regimen typically involves a combination of mechanical, chemical, and thermal processes.

Regular cleaning schedules should be established based on the specific food product, processing conditions, and regulatory requirements. Daily cleaning often includes flushing the system with hot water and approved cleaning solutions to remove product residues and prevent microbial growth. More thorough cleaning, such as disassembly and manual scrubbing, may be performed weekly or monthly, depending on the application.

Chemical cleaning agents must be carefully selected to ensure compatibility with valve materials and effectiveness against potential contaminants. Common cleaning solutions include alkaline detergents for removing organic matter and acid-based cleaners for mineral deposits. Sanitizers, such as chlorine-based or quaternary ammonium compounds, are used to reduce microbial load. It is crucial to follow manufacturer guidelines for concentration, contact time, and rinsing procedures.

Clean-in-place (CIP) systems are increasingly popular for automated cleaning of solenoid valves and associated piping. These systems circulate cleaning solutions through the valves at high velocities, ensuring thorough cleaning without disassembly. CIP cycles typically include pre-rinse, detergent wash, intermediate rinse, sanitization, and final rinse stages. Proper valve design, including smooth internal surfaces and self-draining configurations, is essential for effective CIP performance.

Maintenance protocols for solenoid valves in food processing should include regular inspections for wear, damage, or leaks. Seals, gaskets, and other elastomeric components should be checked for signs of degradation and replaced as needed. Lubrication of moving parts with food-grade lubricants may be necessary, following manufacturer recommendations.

Documentation of cleaning and maintenance activities is critical for regulatory compliance and traceability. Detailed records should be kept, including cleaning schedules, procedures followed, chemicals used, and any maintenance or repairs performed. Regular audits and validation of cleaning effectiveness through microbial testing or ATP swabs help ensure the ongoing efficacy of the protocols.

Training of personnel in proper cleaning and maintenance procedures is essential. This includes understanding the importance of hygiene, proper use of cleaning chemicals, and recognition of potential issues. Personal protective equipment (PPE) should be provided and used during cleaning and maintenance activities to ensure worker safety.

Implementing these comprehensive cleaning and maintenance protocols for solenoid valves in food processing helps maintain hygienic standards, ensures product safety, and optimizes valve performance and longevity. Regular review and updating of these protocols in line with evolving industry standards and technological advancements are necessary to maintain best practices in food safety management.

Regular cleaning schedules should be established based on the specific food product, processing conditions, and regulatory requirements. Daily cleaning often includes flushing the system with hot water and approved cleaning solutions to remove product residues and prevent microbial growth. More thorough cleaning, such as disassembly and manual scrubbing, may be performed weekly or monthly, depending on the application.

Chemical cleaning agents must be carefully selected to ensure compatibility with valve materials and effectiveness against potential contaminants. Common cleaning solutions include alkaline detergents for removing organic matter and acid-based cleaners for mineral deposits. Sanitizers, such as chlorine-based or quaternary ammonium compounds, are used to reduce microbial load. It is crucial to follow manufacturer guidelines for concentration, contact time, and rinsing procedures.

Clean-in-place (CIP) systems are increasingly popular for automated cleaning of solenoid valves and associated piping. These systems circulate cleaning solutions through the valves at high velocities, ensuring thorough cleaning without disassembly. CIP cycles typically include pre-rinse, detergent wash, intermediate rinse, sanitization, and final rinse stages. Proper valve design, including smooth internal surfaces and self-draining configurations, is essential for effective CIP performance.

Maintenance protocols for solenoid valves in food processing should include regular inspections for wear, damage, or leaks. Seals, gaskets, and other elastomeric components should be checked for signs of degradation and replaced as needed. Lubrication of moving parts with food-grade lubricants may be necessary, following manufacturer recommendations.

Documentation of cleaning and maintenance activities is critical for regulatory compliance and traceability. Detailed records should be kept, including cleaning schedules, procedures followed, chemicals used, and any maintenance or repairs performed. Regular audits and validation of cleaning effectiveness through microbial testing or ATP swabs help ensure the ongoing efficacy of the protocols.

Training of personnel in proper cleaning and maintenance procedures is essential. This includes understanding the importance of hygiene, proper use of cleaning chemicals, and recognition of potential issues. Personal protective equipment (PPE) should be provided and used during cleaning and maintenance activities to ensure worker safety.

Implementing these comprehensive cleaning and maintenance protocols for solenoid valves in food processing helps maintain hygienic standards, ensures product safety, and optimizes valve performance and longevity. Regular review and updating of these protocols in line with evolving industry standards and technological advancements are necessary to maintain best practices in food safety management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!