Solenoid Valves in High-Pressure Steam Applications: A Safety Perspective

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steam Valve Safety Evolution

The evolution of steam valve safety has been a critical journey in industrial engineering, marked by significant advancements in design, materials, and control mechanisms. Early steam valves, while revolutionary for their time, often lacked robust safety features, leading to frequent accidents and inefficiencies. As industrial processes became more complex and demanding, the need for safer and more reliable steam valves became paramount.

The mid-20th century saw a surge in research and development focused on improving valve safety. Engineers began incorporating fail-safe mechanisms, such as spring-loaded designs that would automatically close the valve in case of power failure or system malfunction. This period also witnessed the introduction of more durable materials capable of withstanding high pressures and temperatures, significantly reducing the risk of valve failure under extreme conditions.

The advent of electronic control systems in the latter half of the 20th century marked a turning point in steam valve safety. Programmable logic controllers (PLCs) and distributed control systems (DCS) enabled real-time monitoring and precise control of valve operations. These systems could detect anomalies and respond instantaneously, greatly enhancing overall system safety and reliability.

In recent decades, the integration of smart technologies has further revolutionized steam valve safety. Advanced sensors and IoT connectivity now allow for predictive maintenance, identifying potential issues before they escalate into critical failures. Machine learning algorithms analyze operational data to optimize valve performance and predict wear patterns, significantly extending the lifespan of components and reducing the risk of unexpected breakdowns.

The focus on environmental safety has also driven innovations in steam valve design. Modern valves incorporate features to minimize steam leakage, reducing energy waste and potential hazards to personnel. Additionally, the development of low-emission packing materials has helped in complying with stringent environmental regulations while maintaining operational efficiency.

Today's high-pressure steam applications benefit from a comprehensive approach to valve safety. This includes redundant safety systems, advanced materials resistant to corrosion and erosion, and sophisticated control algorithms that can adapt to changing operational conditions. The integration of these technologies has not only improved safety but also enhanced overall system efficiency and reliability.

As we look to the future, the evolution of steam valve safety continues to be driven by emerging technologies. Artificial intelligence and advanced simulation models are being employed to design next-generation valves capable of handling even more extreme conditions with unprecedented levels of safety and efficiency. This ongoing evolution underscores the critical importance of valve safety in high-pressure steam applications and its role in shaping the future of industrial processes.

The mid-20th century saw a surge in research and development focused on improving valve safety. Engineers began incorporating fail-safe mechanisms, such as spring-loaded designs that would automatically close the valve in case of power failure or system malfunction. This period also witnessed the introduction of more durable materials capable of withstanding high pressures and temperatures, significantly reducing the risk of valve failure under extreme conditions.

The advent of electronic control systems in the latter half of the 20th century marked a turning point in steam valve safety. Programmable logic controllers (PLCs) and distributed control systems (DCS) enabled real-time monitoring and precise control of valve operations. These systems could detect anomalies and respond instantaneously, greatly enhancing overall system safety and reliability.

In recent decades, the integration of smart technologies has further revolutionized steam valve safety. Advanced sensors and IoT connectivity now allow for predictive maintenance, identifying potential issues before they escalate into critical failures. Machine learning algorithms analyze operational data to optimize valve performance and predict wear patterns, significantly extending the lifespan of components and reducing the risk of unexpected breakdowns.

The focus on environmental safety has also driven innovations in steam valve design. Modern valves incorporate features to minimize steam leakage, reducing energy waste and potential hazards to personnel. Additionally, the development of low-emission packing materials has helped in complying with stringent environmental regulations while maintaining operational efficiency.

Today's high-pressure steam applications benefit from a comprehensive approach to valve safety. This includes redundant safety systems, advanced materials resistant to corrosion and erosion, and sophisticated control algorithms that can adapt to changing operational conditions. The integration of these technologies has not only improved safety but also enhanced overall system efficiency and reliability.

As we look to the future, the evolution of steam valve safety continues to be driven by emerging technologies. Artificial intelligence and advanced simulation models are being employed to design next-generation valves capable of handling even more extreme conditions with unprecedented levels of safety and efficiency. This ongoing evolution underscores the critical importance of valve safety in high-pressure steam applications and its role in shaping the future of industrial processes.

High-Pressure Steam Market Trends

The high-pressure steam market has been experiencing significant growth in recent years, driven by increasing industrialization and the rising demand for energy-efficient processes. This trend is particularly evident in sectors such as power generation, chemical manufacturing, and food processing, where high-pressure steam plays a crucial role in various applications.

In the power generation sector, the shift towards more efficient and cleaner energy production has led to a surge in demand for high-pressure steam systems. Combined cycle power plants, which utilize high-pressure steam turbines, have gained popularity due to their higher efficiency and lower emissions compared to traditional coal-fired plants. This transition has created a robust market for high-pressure steam components, including solenoid valves designed for safety-critical applications.

The chemical manufacturing industry has also contributed to the growth of the high-pressure steam market. As chemical processes become more complex and require higher operating temperatures and pressures, the demand for reliable and safe high-pressure steam systems has increased. This has led to a focus on developing advanced solenoid valves capable of withstanding extreme conditions while maintaining optimal safety standards.

Food processing is another sector driving the high-pressure steam market trends. With the growing emphasis on food safety and quality, high-pressure steam sterilization has become a preferred method for ensuring product integrity. This has resulted in a higher demand for specialized solenoid valves that can operate reliably in high-pressure steam environments while meeting stringent hygiene requirements.

The global push for energy efficiency has further bolstered the high-pressure steam market. Industries are increasingly adopting high-pressure steam systems to improve overall energy utilization and reduce operational costs. This trend has led to innovations in solenoid valve design, focusing on minimizing steam losses and improving system efficiency without compromising safety.

Geographically, emerging economies in Asia-Pacific, particularly China and India, are showing the fastest growth in the high-pressure steam market. Rapid industrialization and infrastructure development in these regions have created a substantial demand for high-pressure steam applications across various industries. This has opened up new opportunities for solenoid valve manufacturers to expand their presence in these markets, with a focus on safety-oriented products.

The market is also witnessing a trend towards the integration of smart technologies in high-pressure steam systems. IoT-enabled solenoid valves with advanced monitoring and control capabilities are gaining traction, allowing for predictive maintenance and enhanced safety features. This shift towards smart systems is expected to drive further growth in the high-pressure steam market, particularly in safety-critical applications.

In the power generation sector, the shift towards more efficient and cleaner energy production has led to a surge in demand for high-pressure steam systems. Combined cycle power plants, which utilize high-pressure steam turbines, have gained popularity due to their higher efficiency and lower emissions compared to traditional coal-fired plants. This transition has created a robust market for high-pressure steam components, including solenoid valves designed for safety-critical applications.

The chemical manufacturing industry has also contributed to the growth of the high-pressure steam market. As chemical processes become more complex and require higher operating temperatures and pressures, the demand for reliable and safe high-pressure steam systems has increased. This has led to a focus on developing advanced solenoid valves capable of withstanding extreme conditions while maintaining optimal safety standards.

Food processing is another sector driving the high-pressure steam market trends. With the growing emphasis on food safety and quality, high-pressure steam sterilization has become a preferred method for ensuring product integrity. This has resulted in a higher demand for specialized solenoid valves that can operate reliably in high-pressure steam environments while meeting stringent hygiene requirements.

The global push for energy efficiency has further bolstered the high-pressure steam market. Industries are increasingly adopting high-pressure steam systems to improve overall energy utilization and reduce operational costs. This trend has led to innovations in solenoid valve design, focusing on minimizing steam losses and improving system efficiency without compromising safety.

Geographically, emerging economies in Asia-Pacific, particularly China and India, are showing the fastest growth in the high-pressure steam market. Rapid industrialization and infrastructure development in these regions have created a substantial demand for high-pressure steam applications across various industries. This has opened up new opportunities for solenoid valve manufacturers to expand their presence in these markets, with a focus on safety-oriented products.

The market is also witnessing a trend towards the integration of smart technologies in high-pressure steam systems. IoT-enabled solenoid valves with advanced monitoring and control capabilities are gaining traction, allowing for predictive maintenance and enhanced safety features. This shift towards smart systems is expected to drive further growth in the high-pressure steam market, particularly in safety-critical applications.

Solenoid Valve Challenges in Steam Systems

Solenoid valves play a crucial role in controlling the flow of high-pressure steam in various industrial applications. However, their implementation in such demanding environments presents several significant challenges that must be addressed to ensure safe and reliable operation.

One of the primary challenges is the extreme temperature conditions associated with high-pressure steam. Solenoid valves must withstand temperatures that can exceed 400°C (752°F) while maintaining their structural integrity and functional performance. This requires careful selection of materials that can resist thermal degradation, creep, and fatigue under prolonged exposure to high temperatures.

The high pressure of steam systems, which can reach up to 200 bar (2900 psi) or more, poses another critical challenge. Solenoid valves must be designed to withstand these pressures without leakage or failure. This necessitates robust construction, precise machining, and appropriate sealing technologies to prevent steam escape and maintain system integrity.

Corrosion resistance is a significant concern in steam applications. The presence of moisture, combined with high temperatures and pressures, creates a highly corrosive environment. Solenoid valves must be constructed from materials that can resist corrosion, such as stainless steel or specialized alloys, to prevent premature failure and maintain long-term reliability.

The rapid cycling of solenoid valves in steam systems can lead to accelerated wear and fatigue. The frequent opening and closing of the valve, combined with the harsh operating conditions, can cause premature failure of components such as springs, seals, and actuators. Designing valves that can withstand millions of cycles without degradation is a significant engineering challenge.

Steam quality is another factor that impacts solenoid valve performance. Impurities in the steam, such as mineral deposits or particulates, can accumulate on valve components, leading to sticking, erosion, or blockages. Implementing effective filtration systems and designing valves that are resistant to fouling are essential considerations.

The potential for water hammer effects in steam systems presents a safety concern for solenoid valves. Rapid valve closure can create pressure spikes that may damage the valve or surrounding piping. Mitigating these effects through proper valve sizing, actuation speed control, and system design is crucial for safe operation.

Ensuring fail-safe operation is paramount in high-pressure steam applications. Solenoid valves must be designed to fail in a safe position (typically closed) in the event of power loss or control system failure. This requires careful consideration of valve design, actuation mechanisms, and backup systems to prevent hazardous situations.

One of the primary challenges is the extreme temperature conditions associated with high-pressure steam. Solenoid valves must withstand temperatures that can exceed 400°C (752°F) while maintaining their structural integrity and functional performance. This requires careful selection of materials that can resist thermal degradation, creep, and fatigue under prolonged exposure to high temperatures.

The high pressure of steam systems, which can reach up to 200 bar (2900 psi) or more, poses another critical challenge. Solenoid valves must be designed to withstand these pressures without leakage or failure. This necessitates robust construction, precise machining, and appropriate sealing technologies to prevent steam escape and maintain system integrity.

Corrosion resistance is a significant concern in steam applications. The presence of moisture, combined with high temperatures and pressures, creates a highly corrosive environment. Solenoid valves must be constructed from materials that can resist corrosion, such as stainless steel or specialized alloys, to prevent premature failure and maintain long-term reliability.

The rapid cycling of solenoid valves in steam systems can lead to accelerated wear and fatigue. The frequent opening and closing of the valve, combined with the harsh operating conditions, can cause premature failure of components such as springs, seals, and actuators. Designing valves that can withstand millions of cycles without degradation is a significant engineering challenge.

Steam quality is another factor that impacts solenoid valve performance. Impurities in the steam, such as mineral deposits or particulates, can accumulate on valve components, leading to sticking, erosion, or blockages. Implementing effective filtration systems and designing valves that are resistant to fouling are essential considerations.

The potential for water hammer effects in steam systems presents a safety concern for solenoid valves. Rapid valve closure can create pressure spikes that may damage the valve or surrounding piping. Mitigating these effects through proper valve sizing, actuation speed control, and system design is crucial for safe operation.

Ensuring fail-safe operation is paramount in high-pressure steam applications. Solenoid valves must be designed to fail in a safe position (typically closed) in the event of power loss or control system failure. This requires careful consideration of valve design, actuation mechanisms, and backup systems to prevent hazardous situations.

Current High-Pressure Steam Valve Solutions

01 Fail-safe mechanisms for solenoid valves

Implementing fail-safe mechanisms in solenoid valves ensures that the valve defaults to a safe position in case of power failure or system malfunction. This can include spring-return mechanisms or backup power sources to maintain safety in critical applications.- Fail-safe mechanisms for solenoid valves: Implementing fail-safe mechanisms in solenoid valves ensures that the valve returns to a safe position in case of power failure or system malfunction. This can include spring-return designs, redundant solenoids, or emergency shutdown systems that automatically close the valve in hazardous situations.

- Monitoring and diagnostic systems: Incorporating monitoring and diagnostic systems into solenoid valve assemblies can enhance safety by detecting potential issues before they become critical. These systems may include sensors for pressure, temperature, or position, as well as electronic control units that can analyze valve performance and alert operators to maintenance needs or impending failures.

- Explosion-proof solenoid valve designs: Developing explosion-proof solenoid valve designs is crucial for applications in hazardous environments. These designs may include sealed enclosures, flame-proof materials, and special electrical components that prevent sparks or excessive heat generation, reducing the risk of ignition in potentially explosive atmospheres.

- Redundancy and backup systems: Implementing redundancy and backup systems in solenoid valve installations can significantly improve safety. This may involve using multiple valves in parallel, installing backup power supplies, or designing systems with alternative flow paths to ensure continued operation or safe shutdown in case of valve failure.

- Safety certification and testing protocols: Developing and adhering to rigorous safety certification and testing protocols for solenoid valves is essential to ensure their reliability and performance in critical applications. This includes standardized testing procedures, quality control measures during manufacturing, and regular in-service inspections to verify continued safe operation throughout the valve's lifecycle.

02 Monitoring and diagnostic systems

Incorporating monitoring and diagnostic systems in solenoid valve installations helps detect potential issues before they become critical. These systems can include sensors for pressure, temperature, and flow, as well as electronic controllers that can analyze valve performance and alert operators to potential safety concerns.Expand Specific Solutions03 Redundancy and backup systems

Implementing redundancy in solenoid valve systems enhances safety by providing backup valves or alternative flow paths. This ensures continued operation and safety in case of primary valve failure, particularly in critical applications where valve malfunction could lead to hazardous conditions.Expand Specific Solutions04 Explosion-proof and intrinsically safe designs

Developing explosion-proof and intrinsically safe solenoid valve designs is crucial for use in hazardous environments. These designs incorporate features that prevent the valve from becoming an ignition source, such as sealed enclosures and low-power electronics, ensuring safe operation in potentially explosive atmospheres.Expand Specific Solutions05 Integration with safety control systems

Integrating solenoid valves with broader safety control systems enhances overall system safety. This integration allows for coordinated emergency shutdowns, automated safety responses, and improved communication between various safety-critical components in industrial processes.Expand Specific Solutions

Key Solenoid Valve Manufacturers

The market for solenoid valves in high-pressure steam applications is in a mature growth phase, characterized by established players and ongoing technological advancements. The global market size is substantial, driven by industrial automation and safety requirements. Technologically, the field is moderately mature, with companies like Robert Bosch GmbH, Parker-Hannifin Corp., and Eaton Corp. leading innovation. These firms, along with others such as Continental Automotive Systems, Inc. and Anshan Electromagnetic Valve Co. Ltd., are focusing on enhancing valve reliability, efficiency, and safety features for high-pressure steam environments. The competitive landscape is diverse, with both large multinational corporations and specialized manufacturers vying for market share through product differentiation and technological expertise.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid valves for high-pressure steam applications with a focus on safety. Their technology incorporates a dual-seal design with redundant safety features[1]. The valves use high-temperature resistant materials and advanced coatings to withstand extreme conditions. Bosch's solenoid valves feature integrated pressure sensors and temperature monitoring systems, allowing real-time diagnostics and predictive maintenance[2]. The company has also implemented a fail-safe mechanism that ensures the valve closes in case of power failure or system malfunction, preventing potential hazards[3]. Additionally, Bosch's valves are equipped with smart control systems that can adjust valve operation based on steam pressure and flow rate, optimizing performance and enhancing safety[4].

Strengths: Robust safety features, advanced materials, and smart control systems. Weaknesses: Potentially higher cost due to advanced technology, may require specialized maintenance.

Parker-Hannifin Corp.

Technical Solution: Parker-Hannifin has developed a comprehensive range of solenoid valves for high-pressure steam applications with a strong emphasis on safety. Their valves feature a patented dual-poppet design that provides redundant sealing and improved leak protection[1]. Parker's technology incorporates high-temperature elastomers and specialty alloys that maintain performance integrity in extreme steam conditions[2]. The company has implemented an advanced electronic control system that allows for precise flow control and rapid shut-off in emergency situations[3]. Parker's valves also include integrated pressure and temperature sensors that provide real-time data for system monitoring and predictive maintenance[4]. Additionally, they have developed a unique self-cleaning mechanism that reduces the risk of valve sticking or clogging, enhancing long-term reliability and safety[5].

Strengths: Dual-poppet design for enhanced sealing, advanced materials, and self-cleaning mechanism. Weaknesses: May have higher complexity leading to potential maintenance challenges, possibly higher cost compared to simpler designs.

Innovative Solenoid Valve Safety Features

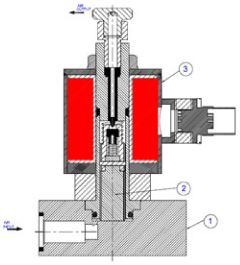

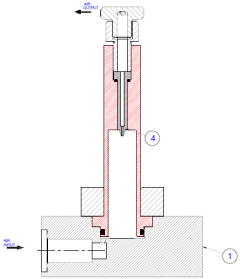

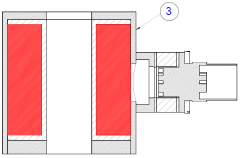

High pressure solenoid valve (normally open) for aerospace application

PatentActiveIN201741001914A

Innovation

- A high-pressure normally open solenoid vent valve with a floating seat on a spring pack and independent port tube assembly, utilizing a 28 V DC electromagnetic solenoid coil for fast ON/OFF responses and ensuring leak tightness across a wide temperature range, with a focus on specialized seal design and material selection.

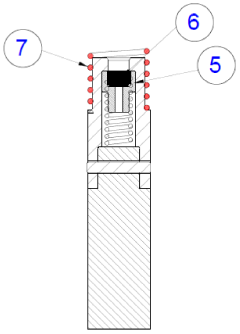

SOLENOID VALVE FOR AGGRESSIVE LIQUIDS AND GASES OF HIGH PRESSURE

PatentInactiveRU2003128337A

Innovation

- The use of mutually repulsive magnets in the internal valve and plate-limiter to ensure closure of both valves when the control electromagnet is de-energized.

- The armature of the control electromagnet is made of magnetic material enclosed in a stainless shell, providing protection against aggressive media.

- The precise gap specification (0.5 ± 0.2 mm) between the internal valve and the restrictive ring, optimizing valve performance.

Regulatory Framework for Steam Systems

The regulatory framework for steam systems is a critical aspect of ensuring safety in high-pressure steam applications, particularly when considering the use of solenoid valves. This framework encompasses a wide range of standards, codes, and regulations that govern the design, installation, operation, and maintenance of steam systems and their components.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) provide guidelines that are often adopted or adapted by national regulatory bodies. These standards address various aspects of steam system safety, including pressure vessel design, piping systems, and control devices like solenoid valves.

In the United States, the American Society of Mechanical Engineers (ASME) plays a pivotal role in developing and maintaining standards for pressure vessels and piping systems. The ASME Boiler and Pressure Vessel Code (BPVC) is widely recognized and adopted, providing comprehensive guidelines for the construction of steam boilers and pressure vessels. Additionally, the National Fire Protection Association (NFPA) offers standards such as NFPA 85, which covers boiler and combustion systems hazards.

European regulations, such as the Pressure Equipment Directive (PED) and the Machinery Directive, set requirements for pressure equipment and safety components used in steam systems within the European Union. These directives are supported by harmonized standards that provide detailed technical specifications for compliance.

Specific to solenoid valves in high-pressure steam applications, regulations often focus on factors such as pressure ratings, temperature limits, materials compatibility, and fail-safe mechanisms. Standards like IEC 60534 for industrial-process control valves and ISO 4126 for safety devices for protection against excessive pressure are particularly relevant.

Regulatory bodies also emphasize the importance of regular inspection and maintenance protocols. For instance, the U.S. Occupational Safety and Health Administration (OSHA) mandates periodic inspections of boilers and pressure vessels, which would include associated control systems like solenoid valves.

As technology advances, regulatory frameworks are continuously evolving to address new safety challenges and incorporate innovative solutions. This includes considerations for smart valve technologies, remote monitoring systems, and advanced materials that can enhance the safety and efficiency of high-pressure steam applications.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) provide guidelines that are often adopted or adapted by national regulatory bodies. These standards address various aspects of steam system safety, including pressure vessel design, piping systems, and control devices like solenoid valves.

In the United States, the American Society of Mechanical Engineers (ASME) plays a pivotal role in developing and maintaining standards for pressure vessels and piping systems. The ASME Boiler and Pressure Vessel Code (BPVC) is widely recognized and adopted, providing comprehensive guidelines for the construction of steam boilers and pressure vessels. Additionally, the National Fire Protection Association (NFPA) offers standards such as NFPA 85, which covers boiler and combustion systems hazards.

European regulations, such as the Pressure Equipment Directive (PED) and the Machinery Directive, set requirements for pressure equipment and safety components used in steam systems within the European Union. These directives are supported by harmonized standards that provide detailed technical specifications for compliance.

Specific to solenoid valves in high-pressure steam applications, regulations often focus on factors such as pressure ratings, temperature limits, materials compatibility, and fail-safe mechanisms. Standards like IEC 60534 for industrial-process control valves and ISO 4126 for safety devices for protection against excessive pressure are particularly relevant.

Regulatory bodies also emphasize the importance of regular inspection and maintenance protocols. For instance, the U.S. Occupational Safety and Health Administration (OSHA) mandates periodic inspections of boilers and pressure vessels, which would include associated control systems like solenoid valves.

As technology advances, regulatory frameworks are continuously evolving to address new safety challenges and incorporate innovative solutions. This includes considerations for smart valve technologies, remote monitoring systems, and advanced materials that can enhance the safety and efficiency of high-pressure steam applications.

Environmental Impact of Steam Valves

The environmental impact of steam valves, particularly solenoid valves in high-pressure steam applications, is a critical consideration in industrial settings. These valves play a crucial role in controlling steam flow, which directly affects energy efficiency and emissions. Properly functioning steam valves can significantly reduce energy waste and minimize the carbon footprint of industrial processes.

One of the primary environmental concerns associated with steam valves is the potential for steam leakage. Even small leaks can result in substantial energy losses over time, leading to increased fuel consumption and higher greenhouse gas emissions. High-pressure steam applications are particularly susceptible to this issue, as the elevated pressures can exacerbate leakage problems. Implementing regular maintenance schedules and using high-quality solenoid valves can help mitigate these risks.

The materials used in the construction of steam valves also have environmental implications. Many valves contain metals and alloys that require energy-intensive mining and manufacturing processes. Choosing valves made from recycled materials or those designed for easy recycling at the end of their lifecycle can help reduce the overall environmental impact. Additionally, selecting valves with longer operational lifespans can decrease the frequency of replacements, further minimizing resource consumption and waste generation.

Water conservation is another important aspect of the environmental impact of steam valves. In steam systems, condensate recovery is essential for maximizing efficiency and reducing water usage. Properly functioning valves ensure that condensate is effectively returned to the boiler, minimizing the need for fresh water input and the energy required to heat it. This not only conserves water resources but also reduces the chemical treatment necessary for boiler feed water.

The noise pollution generated by steam valves, especially in high-pressure applications, is an often-overlooked environmental concern. Excessive noise can have negative impacts on both human health and local ecosystems. Implementing noise reduction technologies and selecting valves designed for quiet operation can help mitigate this issue, creating a more environmentally friendly industrial environment.

Lastly, the proper disposal of steam valves at the end of their useful life is crucial for minimizing environmental impact. Many valves contain materials that can be harmful if not disposed of correctly. Implementing recycling programs and partnering with specialized waste management facilities can ensure that valve components are properly handled, reducing the risk of soil and water contamination.

One of the primary environmental concerns associated with steam valves is the potential for steam leakage. Even small leaks can result in substantial energy losses over time, leading to increased fuel consumption and higher greenhouse gas emissions. High-pressure steam applications are particularly susceptible to this issue, as the elevated pressures can exacerbate leakage problems. Implementing regular maintenance schedules and using high-quality solenoid valves can help mitigate these risks.

The materials used in the construction of steam valves also have environmental implications. Many valves contain metals and alloys that require energy-intensive mining and manufacturing processes. Choosing valves made from recycled materials or those designed for easy recycling at the end of their lifecycle can help reduce the overall environmental impact. Additionally, selecting valves with longer operational lifespans can decrease the frequency of replacements, further minimizing resource consumption and waste generation.

Water conservation is another important aspect of the environmental impact of steam valves. In steam systems, condensate recovery is essential for maximizing efficiency and reducing water usage. Properly functioning valves ensure that condensate is effectively returned to the boiler, minimizing the need for fresh water input and the energy required to heat it. This not only conserves water resources but also reduces the chemical treatment necessary for boiler feed water.

The noise pollution generated by steam valves, especially in high-pressure applications, is an often-overlooked environmental concern. Excessive noise can have negative impacts on both human health and local ecosystems. Implementing noise reduction technologies and selecting valves designed for quiet operation can help mitigate this issue, creating a more environmentally friendly industrial environment.

Lastly, the proper disposal of steam valves at the end of their useful life is crucial for minimizing environmental impact. Many valves contain materials that can be harmful if not disposed of correctly. Implementing recycling programs and partnering with specialized waste management facilities can ensure that valve components are properly handled, reducing the risk of soil and water contamination.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!