Solutions for Reducing Solenoid Valve Actuation Time in Critical Applications

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Actuation Time Reduction Goals

The primary goal of reducing solenoid valve actuation time in critical applications is to enhance system responsiveness and overall performance. This objective is driven by the increasing demands for faster and more precise control in various industries, including aerospace, automotive, and industrial automation. By minimizing the time required for a solenoid valve to open or close, engineers aim to improve the efficiency and reliability of systems that rely on rapid fluid or gas control.

One of the key targets is to achieve actuation times in the millisecond range, typically between 1-10 ms, depending on the specific application requirements. This level of speed is crucial for applications such as fuel injection systems in internal combustion engines, where precise timing and rapid valve operation directly impact engine performance and emissions. In aerospace applications, faster solenoid valve response times can lead to more accurate control of hydraulic and pneumatic systems, enhancing aircraft maneuverability and safety.

Another important goal is to maintain consistent actuation times across a wide range of operating conditions. This includes variations in temperature, pressure, and voltage supply. Achieving this consistency ensures that the system performs reliably in diverse environments, which is particularly critical for applications in harsh industrial settings or extreme weather conditions.

Reducing power consumption during valve actuation is also a significant objective. As systems become more compact and energy-efficient, there is a growing need for solenoid valves that can operate with lower power inputs while still maintaining rapid response times. This goal aligns with broader industry trends towards energy conservation and the development of more sustainable technologies.

Furthermore, engineers are striving to extend the operational lifespan of solenoid valves while maintaining fast actuation times. This involves developing materials and designs that can withstand the stress of rapid cycling without degradation in performance over time. Increasing the durability and reliability of fast-acting solenoid valves is essential for reducing maintenance requirements and improving the overall cost-effectiveness of systems in which they are employed.

Lastly, there is a push to miniaturize solenoid valves without compromising on actuation speed. This goal is particularly relevant in applications where space is at a premium, such as in portable medical devices or compact automotive systems. Achieving faster actuation times in smaller valve packages presents significant engineering challenges but offers substantial benefits in terms of system integration and design flexibility.

One of the key targets is to achieve actuation times in the millisecond range, typically between 1-10 ms, depending on the specific application requirements. This level of speed is crucial for applications such as fuel injection systems in internal combustion engines, where precise timing and rapid valve operation directly impact engine performance and emissions. In aerospace applications, faster solenoid valve response times can lead to more accurate control of hydraulic and pneumatic systems, enhancing aircraft maneuverability and safety.

Another important goal is to maintain consistent actuation times across a wide range of operating conditions. This includes variations in temperature, pressure, and voltage supply. Achieving this consistency ensures that the system performs reliably in diverse environments, which is particularly critical for applications in harsh industrial settings or extreme weather conditions.

Reducing power consumption during valve actuation is also a significant objective. As systems become more compact and energy-efficient, there is a growing need for solenoid valves that can operate with lower power inputs while still maintaining rapid response times. This goal aligns with broader industry trends towards energy conservation and the development of more sustainable technologies.

Furthermore, engineers are striving to extend the operational lifespan of solenoid valves while maintaining fast actuation times. This involves developing materials and designs that can withstand the stress of rapid cycling without degradation in performance over time. Increasing the durability and reliability of fast-acting solenoid valves is essential for reducing maintenance requirements and improving the overall cost-effectiveness of systems in which they are employed.

Lastly, there is a push to miniaturize solenoid valves without compromising on actuation speed. This goal is particularly relevant in applications where space is at a premium, such as in portable medical devices or compact automotive systems. Achieving faster actuation times in smaller valve packages presents significant engineering challenges but offers substantial benefits in terms of system integration and design flexibility.

Market Demand for Rapid Response Valves

The market demand for rapid response valves has been steadily increasing across various critical applications, driven by the need for enhanced efficiency, safety, and precision in industrial processes. Industries such as aerospace, automotive, medical devices, and process control systems are particularly seeking solutions that can significantly reduce solenoid valve actuation time.

In the aerospace sector, rapid response valves are crucial for flight control systems, where millisecond-level improvements in actuation time can translate to substantial gains in aircraft maneuverability and safety. The growing commercial and military aviation markets are fueling demand for advanced valve technologies that can meet stringent performance requirements.

The automotive industry is another major driver of demand for fast-acting valves. With the rise of electric and hybrid vehicles, there is an increasing need for valves that can rapidly control coolant flow, battery thermal management systems, and regenerative braking systems. Additionally, traditional internal combustion engines require quick-acting valves for fuel injection and exhaust gas recirculation systems to meet stringent emissions standards.

In the medical device sector, the demand for rapid response valves is growing due to the development of advanced life support systems, ventilators, and diagnostic equipment. These applications require precise and instantaneous control of gas and fluid flow, where even minor improvements in valve actuation time can have significant impacts on patient outcomes.

Process control industries, including chemical manufacturing, oil and gas, and water treatment, are also seeking faster valve response times to improve overall system efficiency and reduce waste. Rapid actuation allows for more precise control of flow rates, pressure, and temperature, leading to optimized production processes and reduced energy consumption.

The market for rapid response valves is further bolstered by the ongoing trend towards Industry 4.0 and smart manufacturing. As industrial processes become more automated and interconnected, the need for valves that can respond quickly to real-time data and control signals is becoming increasingly critical.

Emerging technologies such as additive manufacturing and advanced materials are opening up new possibilities for valve design and performance improvement. This is creating opportunities for innovative solutions that can meet the growing demand for faster actuation times while maintaining reliability and durability.

As industries continue to push the boundaries of performance and efficiency, the market for rapid response valves is expected to expand further. Manufacturers who can develop and commercialize solutions that significantly reduce solenoid valve actuation time are likely to gain a competitive edge in this growing market segment.

In the aerospace sector, rapid response valves are crucial for flight control systems, where millisecond-level improvements in actuation time can translate to substantial gains in aircraft maneuverability and safety. The growing commercial and military aviation markets are fueling demand for advanced valve technologies that can meet stringent performance requirements.

The automotive industry is another major driver of demand for fast-acting valves. With the rise of electric and hybrid vehicles, there is an increasing need for valves that can rapidly control coolant flow, battery thermal management systems, and regenerative braking systems. Additionally, traditional internal combustion engines require quick-acting valves for fuel injection and exhaust gas recirculation systems to meet stringent emissions standards.

In the medical device sector, the demand for rapid response valves is growing due to the development of advanced life support systems, ventilators, and diagnostic equipment. These applications require precise and instantaneous control of gas and fluid flow, where even minor improvements in valve actuation time can have significant impacts on patient outcomes.

Process control industries, including chemical manufacturing, oil and gas, and water treatment, are also seeking faster valve response times to improve overall system efficiency and reduce waste. Rapid actuation allows for more precise control of flow rates, pressure, and temperature, leading to optimized production processes and reduced energy consumption.

The market for rapid response valves is further bolstered by the ongoing trend towards Industry 4.0 and smart manufacturing. As industrial processes become more automated and interconnected, the need for valves that can respond quickly to real-time data and control signals is becoming increasingly critical.

Emerging technologies such as additive manufacturing and advanced materials are opening up new possibilities for valve design and performance improvement. This is creating opportunities for innovative solutions that can meet the growing demand for faster actuation times while maintaining reliability and durability.

As industries continue to push the boundaries of performance and efficiency, the market for rapid response valves is expected to expand further. Manufacturers who can develop and commercialize solutions that significantly reduce solenoid valve actuation time are likely to gain a competitive edge in this growing market segment.

Current Challenges in Solenoid Valve Speed

Solenoid valves are critical components in many industrial and automotive applications, but their actuation speed remains a significant challenge. The primary issue lies in the inherent physical limitations of electromagnetic systems, which require time to build up magnetic fields and overcome mechanical inertia. This delay in actuation can lead to reduced system efficiency, precision, and overall performance in time-sensitive applications.

One of the main challenges is the trade-off between speed and power consumption. Faster actuation typically requires higher current levels, which in turn leads to increased heat generation and energy consumption. This presents a particular problem in battery-powered or energy-efficient systems where power conservation is crucial. Engineers must carefully balance the need for rapid response times with the constraints of power availability and thermal management.

Another significant hurdle is the mechanical design of the valve itself. The mass of the moving parts, such as the plunger and spring, directly impacts the actuation time. Reducing the mass can improve speed, but it often comes at the cost of reduced durability or compromised sealing capabilities. This challenge is particularly acute in high-pressure or high-temperature environments where robust construction is essential.

The control electronics and drive circuits also play a crucial role in valve actuation speed. Traditional control methods may not provide the level of precision and responsiveness required for ultra-fast actuation. Advanced control algorithms and high-speed switching technologies are needed to optimize the current profile and minimize response times. However, implementing these sophisticated control systems can increase complexity and cost.

Material limitations further compound the challenges in solenoid valve speed. The magnetic properties of materials used in the core and armature affect the speed at which magnetic fields can be established and collapsed. While advanced materials exist, their cost and manufacturing complexity often limit widespread adoption in commercial applications.

Environmental factors also contribute to the challenges in achieving consistent high-speed actuation. Temperature fluctuations can affect the viscosity of fluids, the magnetic properties of materials, and the mechanical properties of components, all of which impact valve performance. Designing valves that maintain rapid actuation across a wide range of operating conditions remains a significant engineering challenge.

Lastly, the miniaturization trend in many industries poses additional difficulties. As systems become more compact, the space available for solenoid valves decreases, limiting options for design optimization. Smaller valves generally have lower magnetic force and may struggle to achieve the same actuation speeds as their larger counterparts, especially when dealing with high pressures or viscous fluids.

One of the main challenges is the trade-off between speed and power consumption. Faster actuation typically requires higher current levels, which in turn leads to increased heat generation and energy consumption. This presents a particular problem in battery-powered or energy-efficient systems where power conservation is crucial. Engineers must carefully balance the need for rapid response times with the constraints of power availability and thermal management.

Another significant hurdle is the mechanical design of the valve itself. The mass of the moving parts, such as the plunger and spring, directly impacts the actuation time. Reducing the mass can improve speed, but it often comes at the cost of reduced durability or compromised sealing capabilities. This challenge is particularly acute in high-pressure or high-temperature environments where robust construction is essential.

The control electronics and drive circuits also play a crucial role in valve actuation speed. Traditional control methods may not provide the level of precision and responsiveness required for ultra-fast actuation. Advanced control algorithms and high-speed switching technologies are needed to optimize the current profile and minimize response times. However, implementing these sophisticated control systems can increase complexity and cost.

Material limitations further compound the challenges in solenoid valve speed. The magnetic properties of materials used in the core and armature affect the speed at which magnetic fields can be established and collapsed. While advanced materials exist, their cost and manufacturing complexity often limit widespread adoption in commercial applications.

Environmental factors also contribute to the challenges in achieving consistent high-speed actuation. Temperature fluctuations can affect the viscosity of fluids, the magnetic properties of materials, and the mechanical properties of components, all of which impact valve performance. Designing valves that maintain rapid actuation across a wide range of operating conditions remains a significant engineering challenge.

Lastly, the miniaturization trend in many industries poses additional difficulties. As systems become more compact, the space available for solenoid valves decreases, limiting options for design optimization. Smaller valves generally have lower magnetic force and may struggle to achieve the same actuation speeds as their larger counterparts, especially when dealing with high pressures or viscous fluids.

Existing Fast-Acting Solenoid Valve Solutions

01 Optimization of solenoid valve response time

Various techniques are employed to optimize the actuation time of solenoid valves. These include adjusting the magnetic circuit design, improving the armature and plunger assembly, and utilizing advanced control algorithms. Such optimizations can significantly reduce the valve's response time, enhancing overall system performance in applications requiring rapid valve operation.- Optimization of solenoid valve response time: Various techniques are employed to optimize the actuation time of solenoid valves. These include adjusting the magnetic circuit design, using high-performance materials, and implementing advanced control algorithms. By reducing the response time, the overall efficiency and precision of systems utilizing solenoid valves can be significantly improved.

- Electronic control systems for solenoid valve timing: Advanced electronic control systems are developed to precisely manage the actuation timing of solenoid valves. These systems often incorporate microprocessors, sensors, and sophisticated software to achieve accurate and repeatable valve operation. By fine-tuning the timing parameters, the performance of various applications can be optimized.

- Rapid actuation mechanisms for solenoid valves: Innovative designs focus on creating rapid actuation mechanisms for solenoid valves. These may include novel armature designs, spring configurations, or the use of auxiliary forces to accelerate valve movement. The goal is to minimize the time between the electrical signal and the physical valve response, enhancing system responsiveness.

- Energy-efficient solenoid valve actuation: Efforts are made to develop energy-efficient actuation methods for solenoid valves. This involves optimizing the power consumption during valve operation, implementing energy recovery systems, and designing low-power holding mechanisms. These innovations aim to reduce energy usage while maintaining rapid and reliable valve actuation.

- Adaptive control strategies for solenoid valve timing: Advanced control strategies are implemented to adapt solenoid valve timing based on real-time operating conditions. These systems may use feedback from sensors, machine learning algorithms, or predictive models to dynamically adjust valve actuation timing. This approach allows for optimal performance across varying conditions and system requirements.

02 Electronic control systems for solenoid valve timing

Advanced electronic control systems are implemented to precisely manage solenoid valve actuation timing. These systems often incorporate microprocessors, sensors, and sophisticated software to adjust valve timing based on various operating conditions. This approach allows for dynamic control of valve operation, improving efficiency and performance in complex fluid control applications.Expand Specific Solutions03 Energy-efficient actuation methods

Innovative actuation methods are developed to improve the energy efficiency of solenoid valves. These methods may include pulse-width modulation techniques, energy recovery circuits, or low-power holding mechanisms. By reducing power consumption during valve operation, these approaches can extend battery life in portable systems or decrease overall energy usage in industrial applications.Expand Specific Solutions04 High-speed solenoid valve designs

Specialized solenoid valve designs are created to achieve extremely fast actuation times. These designs may incorporate lightweight materials, optimized magnetic circuits, or novel spring mechanisms. High-speed valves are crucial in applications such as fuel injection systems, pneumatic controls, and high-frequency fluid switching operations.Expand Specific Solutions05 Adaptive control strategies for variable actuation times

Adaptive control strategies are implemented to adjust solenoid valve actuation times based on changing system requirements or environmental conditions. These strategies may use machine learning algorithms, real-time feedback systems, or predictive models to optimize valve timing. Such approaches enable solenoid valves to maintain optimal performance across a wide range of operating conditions.Expand Specific Solutions

Key Players in Solenoid Valve Industry

The market for solutions to reduce solenoid valve actuation time in critical applications is in a growth phase, driven by increasing demand for high-performance systems across industries. The global market size is expanding, with key players like Robert Bosch GmbH, Eaton Corp., and Hitachi Automotive Systems Ltd. leading innovation. These companies are investing heavily in R&D to develop advanced solenoid valve technologies, leveraging their extensive experience in automotive and industrial sectors. The technology is maturing rapidly, with companies like Festo SE & Co. KG and Danfoss A/S pushing boundaries in precision control and response times. Emerging players from Asia, such as Huawei Technologies Co., Ltd., are also entering the market, potentially disrupting traditional dynamics with new approaches to solenoid valve design and actuation.

Robert Bosch GmbH

Technical Solution: Bosch has developed a high-speed solenoid valve with reduced actuation time for critical applications. Their solution incorporates advanced materials and optimized electromagnetic design. The valve uses a lightweight armature made of high-strength alloys, reducing inertia and improving response time[1]. Additionally, Bosch implements a dual-coil system with a high-power activation coil and a low-power holding coil, allowing for rapid initial actuation and efficient sustained operation[3]. The company also utilizes sophisticated control algorithms that predict and compensate for valve behavior, further reducing response times[5].

Strengths: Comprehensive approach combining materials science, electromagnetic optimization, and advanced control algorithms. Weaknesses: Potentially higher cost due to complex design and materials.

Eaton Corp.

Technical Solution: Eaton's approach to reducing solenoid valve actuation time focuses on innovative valve design and advanced electronic control. Their solution includes a patented "soft-landing" technology that allows for faster valve opening while minimizing impact and wear[2]. Eaton also employs a high-frequency pulse-width modulation (PWM) control strategy, which enables precise regulation of current to the solenoid, resulting in faster response times and reduced power consumption[4]. Furthermore, Eaton has developed a unique magnetic circuit design that optimizes flux distribution, leading to improved force generation and quicker armature movement[6].

Strengths: Balanced approach addressing both mechanical and electrical aspects of valve actuation. Weaknesses: May require specialized electronic controllers, potentially increasing system complexity.

Core Innovations in Rapid Actuation Technology

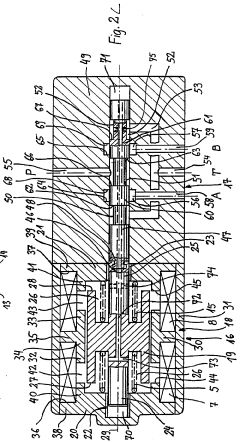

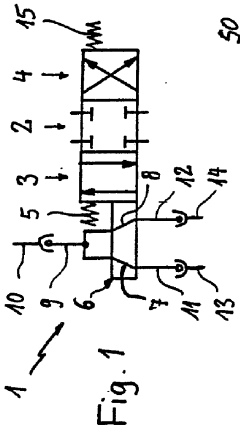

Magnetic valve

PatentWO1991006110A1

Innovation

- A solenoid valve design where a quiescent current constantly flows through control windings, inducing a permanent magnetization in the stator, armature, and pole shoes, allowing the armature to be quickly moved between positions without reorienting the magnetic field, thus reducing response time by a factor of 10 to 1-2 ms.

Method for actuating a solenoid valve and associated device

PatentInactiveEP2203635A1

Innovation

- The method involves reducing the actuation current before the desired switch-off time from a holding level to minimize magnetic energy storage and eddy current-induced delays, allowing for quicker switching by leveraging mechanical inertia and reducing the actuation current stepwise or continuously to the switch-off level, and applying a counter-voltage to eliminate residual current.

Safety Considerations for High-Speed Valves

The implementation of high-speed solenoid valves in critical applications necessitates a comprehensive approach to safety considerations. As these valves operate at significantly reduced actuation times, the potential for rapid pressure changes and fluid dynamics issues increases, requiring careful attention to system design and operation.

One primary safety concern is the prevention of pressure surges and water hammer effects. The rapid opening and closing of high-speed valves can create sudden pressure fluctuations within the system, potentially leading to pipe damage, component failure, or even catastrophic system breakdown. To mitigate these risks, engineers must incorporate pressure relief mechanisms, such as accumulators or surge tanks, and implement sophisticated control algorithms that manage valve actuation sequences to minimize abrupt pressure changes.

Material selection plays a crucial role in ensuring the safety and longevity of high-speed valve systems. Components must withstand frequent cycling, high-pressure differentials, and potential erosion from fluid flow. Advanced materials like high-grade stainless steels, ceramics, or specialized alloys are often employed to enhance durability and resist wear. Additionally, proper sealing technologies must be implemented to prevent leakage, which is particularly critical in applications involving hazardous fluids or gases.

Thermal management is another key safety consideration for high-speed valves. Rapid actuation can generate significant heat through friction and electrical resistance, potentially leading to component degradation or failure. Effective cooling strategies, such as forced air circulation or liquid cooling systems, may be necessary to maintain safe operating temperatures and ensure consistent performance over time.

Electrical safety is paramount, especially in solenoid-operated valves. The high currents required for rapid actuation can pose risks of electrical shorts, overheating, or electromagnetic interference. Proper insulation, grounding, and shielding techniques must be employed to protect both the valve system and surrounding equipment. Furthermore, fail-safe mechanisms should be integrated to ensure that the valve defaults to a safe position in the event of power loss or control system failure.

Monitoring and diagnostics systems are essential for maintaining safe operation of high-speed valves. Real-time sensors and advanced analytics can detect anomalies in valve performance, pressure fluctuations, or signs of wear before they escalate into safety hazards. Predictive maintenance strategies, supported by machine learning algorithms, can help anticipate potential failures and schedule interventions proactively, minimizing the risk of unexpected breakdowns during critical operations.

Human factors and operator training are often overlooked but crucial aspects of safety in high-speed valve applications. Operators must be thoroughly trained in the proper use and maintenance of these systems, including emergency procedures and troubleshooting protocols. Clear, intuitive interfaces and control systems should be designed to minimize the risk of human error, particularly in high-stress or time-sensitive situations.

One primary safety concern is the prevention of pressure surges and water hammer effects. The rapid opening and closing of high-speed valves can create sudden pressure fluctuations within the system, potentially leading to pipe damage, component failure, or even catastrophic system breakdown. To mitigate these risks, engineers must incorporate pressure relief mechanisms, such as accumulators or surge tanks, and implement sophisticated control algorithms that manage valve actuation sequences to minimize abrupt pressure changes.

Material selection plays a crucial role in ensuring the safety and longevity of high-speed valve systems. Components must withstand frequent cycling, high-pressure differentials, and potential erosion from fluid flow. Advanced materials like high-grade stainless steels, ceramics, or specialized alloys are often employed to enhance durability and resist wear. Additionally, proper sealing technologies must be implemented to prevent leakage, which is particularly critical in applications involving hazardous fluids or gases.

Thermal management is another key safety consideration for high-speed valves. Rapid actuation can generate significant heat through friction and electrical resistance, potentially leading to component degradation or failure. Effective cooling strategies, such as forced air circulation or liquid cooling systems, may be necessary to maintain safe operating temperatures and ensure consistent performance over time.

Electrical safety is paramount, especially in solenoid-operated valves. The high currents required for rapid actuation can pose risks of electrical shorts, overheating, or electromagnetic interference. Proper insulation, grounding, and shielding techniques must be employed to protect both the valve system and surrounding equipment. Furthermore, fail-safe mechanisms should be integrated to ensure that the valve defaults to a safe position in the event of power loss or control system failure.

Monitoring and diagnostics systems are essential for maintaining safe operation of high-speed valves. Real-time sensors and advanced analytics can detect anomalies in valve performance, pressure fluctuations, or signs of wear before they escalate into safety hazards. Predictive maintenance strategies, supported by machine learning algorithms, can help anticipate potential failures and schedule interventions proactively, minimizing the risk of unexpected breakdowns during critical operations.

Human factors and operator training are often overlooked but crucial aspects of safety in high-speed valve applications. Operators must be thoroughly trained in the proper use and maintenance of these systems, including emergency procedures and troubleshooting protocols. Clear, intuitive interfaces and control systems should be designed to minimize the risk of human error, particularly in high-stress or time-sensitive situations.

Energy Efficiency in Fast-Acting Solenoids

Energy efficiency in fast-acting solenoids is a critical consideration in the quest to reduce solenoid valve actuation time in critical applications. As the demand for faster response times increases, so does the need for more efficient energy utilization. Traditional solenoid designs often prioritize speed over energy consumption, leading to significant power losses and heat generation.

One of the primary challenges in improving energy efficiency is the trade-off between actuation speed and power consumption. Faster actuation typically requires higher current levels, which in turn lead to increased energy dissipation. However, recent advancements in materials science and electromagnetic design have opened new avenues for optimizing this balance.

The use of low-loss magnetic materials, such as advanced silicon steel alloys or nanocrystalline soft magnetic composites, has shown promising results in reducing core losses. These materials exhibit lower hysteresis and eddy current losses, allowing for faster magnetic field buildup and collapse while consuming less energy. Additionally, optimized lamination techniques further minimize eddy currents, contributing to overall efficiency gains.

Another approach to enhancing energy efficiency involves the implementation of smart driving circuits. These circuits employ sophisticated control algorithms that modulate the applied voltage and current profiles during the actuation cycle. By providing an initial high-current pulse for rapid actuation followed by a lower holding current, these systems can significantly reduce the average power consumption without compromising response time.

Mechanical design innovations also play a crucial role in improving energy efficiency. The development of lightweight armatures and optimized spring designs helps reduce the inertia and opposing forces that the solenoid must overcome. This allows for faster actuation with lower energy input. Furthermore, precision manufacturing techniques enable tighter tolerances and reduced air gaps, leading to more efficient energy transfer between the electrical and mechanical domains.

The integration of energy recovery systems represents another frontier in solenoid efficiency. These systems capture and store the energy typically dissipated during de-energization, allowing it to be reused in subsequent actuation cycles. While still in the early stages of development, such technologies show great potential for dramatically reducing the overall energy footprint of fast-acting solenoids.

As the industry continues to push the boundaries of solenoid performance, the focus on energy efficiency becomes increasingly important. Not only does it contribute to reduced operational costs and environmental impact, but it also enables the development of more compact and reliable systems. The ongoing research in this field promises to deliver solenoid valves that can meet the demanding requirements of critical applications while maintaining optimal energy utilization.

One of the primary challenges in improving energy efficiency is the trade-off between actuation speed and power consumption. Faster actuation typically requires higher current levels, which in turn lead to increased energy dissipation. However, recent advancements in materials science and electromagnetic design have opened new avenues for optimizing this balance.

The use of low-loss magnetic materials, such as advanced silicon steel alloys or nanocrystalline soft magnetic composites, has shown promising results in reducing core losses. These materials exhibit lower hysteresis and eddy current losses, allowing for faster magnetic field buildup and collapse while consuming less energy. Additionally, optimized lamination techniques further minimize eddy currents, contributing to overall efficiency gains.

Another approach to enhancing energy efficiency involves the implementation of smart driving circuits. These circuits employ sophisticated control algorithms that modulate the applied voltage and current profiles during the actuation cycle. By providing an initial high-current pulse for rapid actuation followed by a lower holding current, these systems can significantly reduce the average power consumption without compromising response time.

Mechanical design innovations also play a crucial role in improving energy efficiency. The development of lightweight armatures and optimized spring designs helps reduce the inertia and opposing forces that the solenoid must overcome. This allows for faster actuation with lower energy input. Furthermore, precision manufacturing techniques enable tighter tolerances and reduced air gaps, leading to more efficient energy transfer between the electrical and mechanical domains.

The integration of energy recovery systems represents another frontier in solenoid efficiency. These systems capture and store the energy typically dissipated during de-energization, allowing it to be reused in subsequent actuation cycles. While still in the early stages of development, such technologies show great potential for dramatically reducing the overall energy footprint of fast-acting solenoids.

As the industry continues to push the boundaries of solenoid performance, the focus on energy efficiency becomes increasingly important. Not only does it contribute to reduced operational costs and environmental impact, but it also enables the development of more compact and reliable systems. The ongoing research in this field promises to deliver solenoid valves that can meet the demanding requirements of critical applications while maintaining optimal energy utilization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!