The Importance of Testing in Half Wave Rectifier Development

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rectifier Testing Goals

Testing plays a crucial role in the development of half wave rectifiers, serving as a cornerstone for ensuring their reliability, efficiency, and overall performance. The primary goal of rectifier testing is to validate the device's ability to convert alternating current (AC) into pulsating direct current (DC) effectively. This process involves a comprehensive evaluation of various parameters and characteristics that directly impact the rectifier's functionality.

One of the key objectives in rectifier testing is to assess the device's forward voltage drop. This parameter is critical as it determines the efficiency of the rectification process and the amount of power dissipated within the rectifier. By measuring the forward voltage drop under different load conditions, engineers can optimize the rectifier's design to minimize losses and improve overall system efficiency.

Another essential testing goal is to evaluate the rectifier's reverse recovery time. This characteristic is particularly important in high-frequency applications, where the rectifier must switch rapidly between conducting and non-conducting states. Minimizing the reverse recovery time helps reduce switching losses and improves the rectifier's performance in fast-switching circuits.

Thermal management is also a crucial aspect of rectifier testing. The goal is to assess the device's ability to dissipate heat effectively under various operating conditions. This involves measuring junction temperatures, thermal resistance, and overall thermal stability. By identifying potential hotspots and thermal bottlenecks, engineers can refine the rectifier's design and packaging to ensure reliable operation across a wide range of environmental conditions.

Rectifier testing also aims to evaluate the device's breakdown voltage and leakage current characteristics. These parameters are essential for determining the rectifier's maximum operating voltage and its ability to withstand reverse bias conditions. By thoroughly testing these aspects, developers can ensure that the rectifier meets safety standards and performs reliably in high-voltage applications.

Furthermore, testing goals include assessing the rectifier's response to transient events, such as voltage spikes and surges. This involves subjecting the device to various stress conditions to evaluate its robustness and ability to withstand momentary overloads. By identifying potential vulnerabilities, engineers can implement appropriate protection mechanisms and improve the rectifier's overall reliability.

Lastly, long-term reliability testing is a critical goal in rectifier development. This involves subjecting the device to accelerated life tests and environmental stress screening to predict its performance over extended periods. By simulating years of operation in a compressed timeframe, developers can identify potential failure modes and implement design improvements to enhance the rectifier's lifespan and reliability.

One of the key objectives in rectifier testing is to assess the device's forward voltage drop. This parameter is critical as it determines the efficiency of the rectification process and the amount of power dissipated within the rectifier. By measuring the forward voltage drop under different load conditions, engineers can optimize the rectifier's design to minimize losses and improve overall system efficiency.

Another essential testing goal is to evaluate the rectifier's reverse recovery time. This characteristic is particularly important in high-frequency applications, where the rectifier must switch rapidly between conducting and non-conducting states. Minimizing the reverse recovery time helps reduce switching losses and improves the rectifier's performance in fast-switching circuits.

Thermal management is also a crucial aspect of rectifier testing. The goal is to assess the device's ability to dissipate heat effectively under various operating conditions. This involves measuring junction temperatures, thermal resistance, and overall thermal stability. By identifying potential hotspots and thermal bottlenecks, engineers can refine the rectifier's design and packaging to ensure reliable operation across a wide range of environmental conditions.

Rectifier testing also aims to evaluate the device's breakdown voltage and leakage current characteristics. These parameters are essential for determining the rectifier's maximum operating voltage and its ability to withstand reverse bias conditions. By thoroughly testing these aspects, developers can ensure that the rectifier meets safety standards and performs reliably in high-voltage applications.

Furthermore, testing goals include assessing the rectifier's response to transient events, such as voltage spikes and surges. This involves subjecting the device to various stress conditions to evaluate its robustness and ability to withstand momentary overloads. By identifying potential vulnerabilities, engineers can implement appropriate protection mechanisms and improve the rectifier's overall reliability.

Lastly, long-term reliability testing is a critical goal in rectifier development. This involves subjecting the device to accelerated life tests and environmental stress screening to predict its performance over extended periods. By simulating years of operation in a compressed timeframe, developers can identify potential failure modes and implement design improvements to enhance the rectifier's lifespan and reliability.

Market Demand Analysis

The market demand for half wave rectifiers continues to grow steadily, driven by the increasing need for power conversion and signal processing across various industries. The global power electronics market, which includes rectifiers, is projected to reach significant growth in the coming years. This expansion is primarily fueled by the rising adoption of renewable energy systems, electric vehicles, and smart grid technologies.

In the renewable energy sector, half wave rectifiers play a crucial role in converting AC power generated by solar panels and wind turbines into usable DC power. As countries worldwide push for cleaner energy solutions, the demand for efficient power conversion devices, including half wave rectifiers, is expected to surge. The automotive industry, particularly the electric vehicle segment, also contributes substantially to the market growth. Half wave rectifiers are essential components in charging systems and power management units for electric vehicles.

The consumer electronics market remains a significant driver for half wave rectifier demand. With the proliferation of smartphones, tablets, laptops, and other portable devices, the need for compact and efficient power conversion solutions continues to rise. Half wave rectifiers are integral to many charging adapters and power supplies used in these devices.

Industrial automation and control systems represent another key market segment for half wave rectifiers. As industries increasingly adopt smart manufacturing technologies and Internet of Things (IoT) devices, the demand for reliable power conversion components grows. Half wave rectifiers are used in various industrial applications, including motor drives, sensors, and control circuits.

The telecommunications sector also contributes to the market demand for half wave rectifiers. With the ongoing rollout of 5G networks and the expansion of data centers, there is a growing need for efficient power conversion solutions in network infrastructure equipment.

However, the market faces challenges related to efficiency and power quality. As energy efficiency regulations become more stringent, there is a push towards more advanced rectifier technologies, such as full wave and bridge rectifiers. This trend underscores the importance of continuous innovation and testing in half wave rectifier development to improve performance and meet evolving market requirements.

The Asia-Pacific region is expected to dominate the market for half wave rectifiers, driven by rapid industrialization, urbanization, and the presence of major electronics manufacturing hubs. North America and Europe also represent significant markets, particularly in sectors such as renewable energy and electric vehicles.

In the renewable energy sector, half wave rectifiers play a crucial role in converting AC power generated by solar panels and wind turbines into usable DC power. As countries worldwide push for cleaner energy solutions, the demand for efficient power conversion devices, including half wave rectifiers, is expected to surge. The automotive industry, particularly the electric vehicle segment, also contributes substantially to the market growth. Half wave rectifiers are essential components in charging systems and power management units for electric vehicles.

The consumer electronics market remains a significant driver for half wave rectifier demand. With the proliferation of smartphones, tablets, laptops, and other portable devices, the need for compact and efficient power conversion solutions continues to rise. Half wave rectifiers are integral to many charging adapters and power supplies used in these devices.

Industrial automation and control systems represent another key market segment for half wave rectifiers. As industries increasingly adopt smart manufacturing technologies and Internet of Things (IoT) devices, the demand for reliable power conversion components grows. Half wave rectifiers are used in various industrial applications, including motor drives, sensors, and control circuits.

The telecommunications sector also contributes to the market demand for half wave rectifiers. With the ongoing rollout of 5G networks and the expansion of data centers, there is a growing need for efficient power conversion solutions in network infrastructure equipment.

However, the market faces challenges related to efficiency and power quality. As energy efficiency regulations become more stringent, there is a push towards more advanced rectifier technologies, such as full wave and bridge rectifiers. This trend underscores the importance of continuous innovation and testing in half wave rectifier development to improve performance and meet evolving market requirements.

The Asia-Pacific region is expected to dominate the market for half wave rectifiers, driven by rapid industrialization, urbanization, and the presence of major electronics manufacturing hubs. North America and Europe also represent significant markets, particularly in sectors such as renewable energy and electric vehicles.

Current Challenges

The development of half wave rectifiers faces several significant challenges that require comprehensive testing to overcome. One of the primary issues is the inherent inefficiency of the half wave rectification process. Due to its nature of only utilizing one half of the AC cycle, this type of rectifier wastes a considerable amount of potential power. This inefficiency not only results in lower output but also leads to increased power consumption and heat generation, which can be particularly problematic in compact or power-sensitive applications.

Another critical challenge is the presence of ripple in the output voltage. The pulsating nature of the half wave rectified signal introduces a significant AC component in the DC output, which can cause unwanted noise and interference in sensitive electronic circuits. This ripple effect necessitates additional filtering components, increasing the complexity and cost of the overall system. The design of effective smoothing circuits becomes crucial, yet challenging, especially when dealing with varying load conditions.

Voltage regulation presents another hurdle in half wave rectifier development. The output voltage of these rectifiers can fluctuate significantly with changes in input voltage or load current. This instability can lead to unreliable performance in connected devices and potentially damage sensitive components. Implementing robust voltage regulation mechanisms without compromising the simplicity and cost-effectiveness of the half wave rectifier design remains a persistent challenge.

The issue of electromagnetic interference (EMI) generation is also a significant concern. The abrupt current flow during the conduction phase of the rectifier can create high-frequency harmonics, leading to EMI that may affect nearby electronic equipment. Mitigating this EMI while maintaining the rectifier's performance and efficiency is a complex balancing act that requires careful design and extensive testing.

Furthermore, the selection and reliability of diodes used in half wave rectifiers pose ongoing challenges. These components must withstand reverse voltage stresses and forward current surges, which can lead to premature failure if not properly managed. The trade-off between diode performance, cost, and longevity is a critical factor that demands thorough testing and validation.

Thermal management is another area of concern, particularly in high-power applications. The inefficiency of half wave rectification results in significant heat generation, which can affect the long-term reliability and performance of the rectifier and surrounding components. Developing effective cooling solutions without substantially increasing the size or cost of the system remains a persistent challenge.

Lastly, the integration of half wave rectifiers into modern, compact electronic designs presents its own set of challenges. As devices become smaller and more power-dense, the space available for rectification circuits diminishes. This constraint necessitates innovative approaches to component selection, layout design, and thermal management, all of which require extensive testing to ensure optimal performance within these tight physical constraints.

Another critical challenge is the presence of ripple in the output voltage. The pulsating nature of the half wave rectified signal introduces a significant AC component in the DC output, which can cause unwanted noise and interference in sensitive electronic circuits. This ripple effect necessitates additional filtering components, increasing the complexity and cost of the overall system. The design of effective smoothing circuits becomes crucial, yet challenging, especially when dealing with varying load conditions.

Voltage regulation presents another hurdle in half wave rectifier development. The output voltage of these rectifiers can fluctuate significantly with changes in input voltage or load current. This instability can lead to unreliable performance in connected devices and potentially damage sensitive components. Implementing robust voltage regulation mechanisms without compromising the simplicity and cost-effectiveness of the half wave rectifier design remains a persistent challenge.

The issue of electromagnetic interference (EMI) generation is also a significant concern. The abrupt current flow during the conduction phase of the rectifier can create high-frequency harmonics, leading to EMI that may affect nearby electronic equipment. Mitigating this EMI while maintaining the rectifier's performance and efficiency is a complex balancing act that requires careful design and extensive testing.

Furthermore, the selection and reliability of diodes used in half wave rectifiers pose ongoing challenges. These components must withstand reverse voltage stresses and forward current surges, which can lead to premature failure if not properly managed. The trade-off between diode performance, cost, and longevity is a critical factor that demands thorough testing and validation.

Thermal management is another area of concern, particularly in high-power applications. The inefficiency of half wave rectification results in significant heat generation, which can affect the long-term reliability and performance of the rectifier and surrounding components. Developing effective cooling solutions without substantially increasing the size or cost of the system remains a persistent challenge.

Lastly, the integration of half wave rectifiers into modern, compact electronic designs presents its own set of challenges. As devices become smaller and more power-dense, the space available for rectification circuits diminishes. This constraint necessitates innovative approaches to component selection, layout design, and thermal management, all of which require extensive testing to ensure optimal performance within these tight physical constraints.

Testing Methodologies

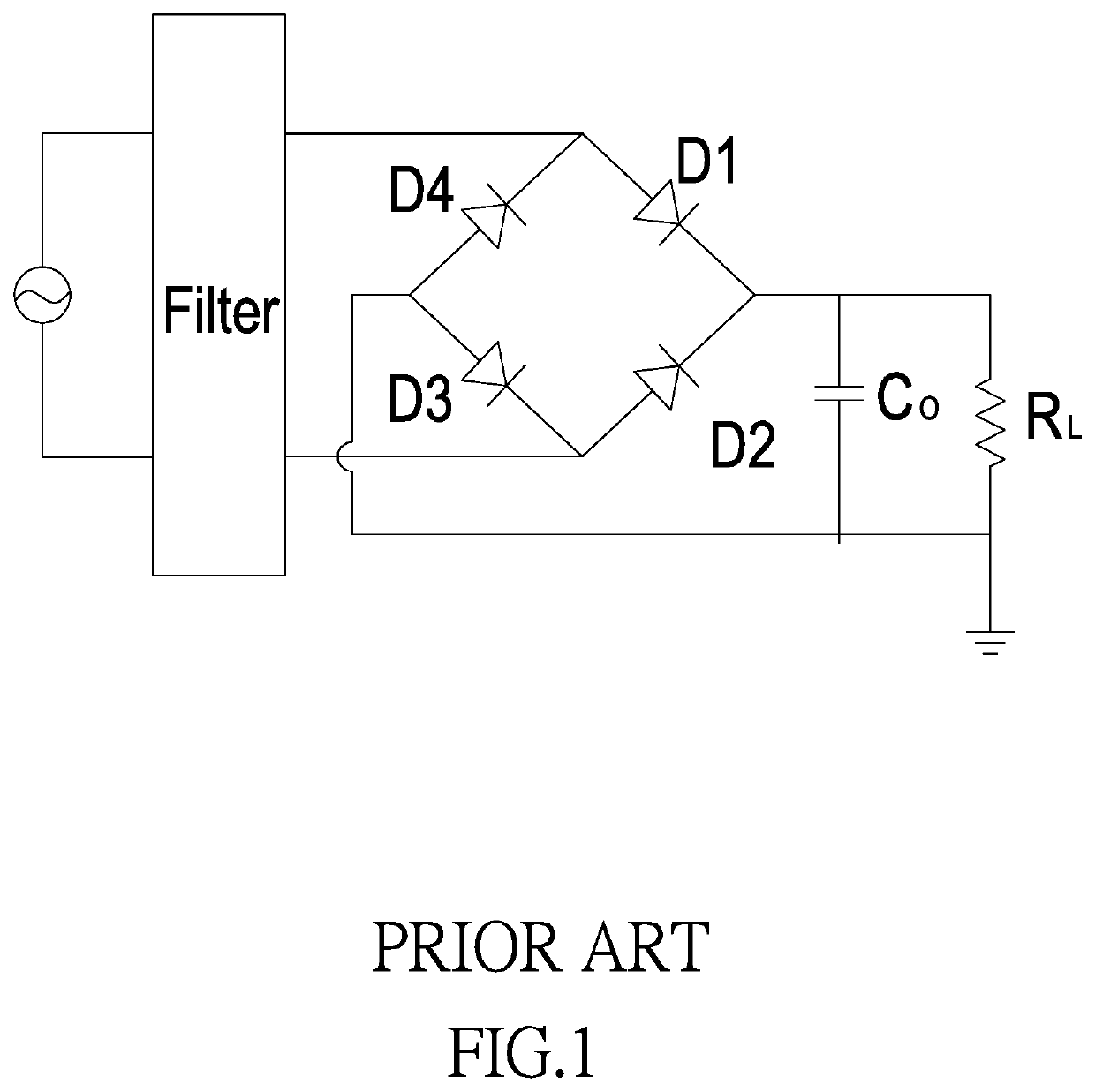

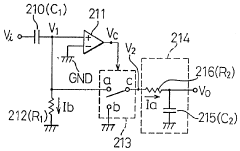

01 Circuit design and components for half-wave rectifiers

Half-wave rectifier circuits typically include diodes, capacitors, and resistors. The design focuses on converting alternating current (AC) to pulsating direct current (DC) by allowing current flow in only one direction. Testing involves verifying the proper functioning of these components and their arrangement to ensure efficient rectification.- Circuit design and components for half wave rectifiers: Half wave rectifier circuits typically include diodes, transformers, and capacitors. The design focuses on converting AC to pulsating DC by allowing current flow in only one direction. Testing involves verifying the proper functioning of these components and their arrangement to ensure efficient rectification.

- Testing methods and equipment for half wave rectifiers: Various testing methods and equipment are used to evaluate half wave rectifiers. These may include oscilloscopes, multimeters, and specialized testing devices. Tests typically measure output voltage, ripple, and efficiency to ensure the rectifier meets performance specifications.

- Applications and integration of half wave rectifiers: Half wave rectifiers are used in various applications, including power supplies, signal processing, and electronic devices. Testing in these contexts involves evaluating the rectifier's performance within the larger system and its interaction with other components.

- Efficiency and performance optimization: Testing procedures for half wave rectifiers often focus on optimizing efficiency and performance. This includes evaluating power loss, heat generation, and voltage regulation. Advanced testing methods may involve computer simulations and thermal imaging to identify areas for improvement.

- Quality control and reliability testing: Quality control measures for half wave rectifiers involve rigorous testing to ensure reliability and longevity. This includes stress testing, environmental testing, and long-term performance evaluation. Such tests help identify potential failure modes and verify the rectifier's ability to withstand various operating conditions.

02 Measurement and analysis techniques for half-wave rectifiers

Testing half-wave rectifiers involves measuring input and output voltages, current, and waveforms. Oscilloscopes and multimeters are commonly used to analyze the rectified signal's characteristics, including ripple voltage and efficiency. Advanced testing may include harmonic analysis and power factor measurements.Expand Specific Solutions03 Integration of half-wave rectifiers in electronic systems

Half-wave rectifiers are often integrated into larger electronic systems, such as power supplies or signal processing circuits. Testing in these contexts involves evaluating the rectifier's performance within the overall system, including its impact on other components and the system's overall efficiency.Expand Specific Solutions04 Thermal and reliability testing of half-wave rectifiers

Thermal testing is crucial for half-wave rectifiers, as they can generate heat during operation. Reliability testing involves subjecting the rectifier to various environmental conditions and stress tests to ensure long-term performance and stability. This may include temperature cycling, humidity testing, and accelerated life testing.Expand Specific Solutions05 Advanced testing methods for high-frequency applications

In high-frequency applications, specialized testing methods are required for half-wave rectifiers. These may include S-parameter measurements, time-domain reflectometry, and vector network analysis. Such tests help evaluate the rectifier's performance at higher frequencies and its suitability for specific applications like RF circuits or high-speed communications.Expand Specific Solutions

Key Industry Players

The development of half wave rectifiers is currently in a mature phase, with established technologies and widespread applications across various industries. The market size for this technology is substantial, driven by its essential role in power electronics and signal processing. Technologically, half wave rectifiers have reached a high level of maturity, with ongoing refinements focused on efficiency and miniaturization. Key players like Infineon Technologies AG, FormFactor, Inc., and Teradyne, Inc. are at the forefront of innovation, continuously improving testing methodologies and component reliability. The competitive landscape is characterized by a mix of established semiconductor manufacturers and specialized testing equipment providers, each contributing to the advancement of half wave rectifier technology.

FormFactor, Inc.

Technical Solution: FormFactor has developed advanced probe card technologies for testing half wave rectifiers in semiconductor devices. Their SmartMatrix probe technology enables high-density, high-speed testing of rectifier circuits on wafer[1]. The company's advanced probe cards incorporate precise alignment and planarity control to ensure accurate measurements of rectifier performance parameters such as forward voltage drop and reverse leakage current[2]. FormFactor's testing solutions support a wide range of rectifier designs, from discrete components to integrated circuits, allowing comprehensive characterization across different operating conditions and temperatures[3].

Strengths: High-density testing capabilities, precise measurements, and support for various rectifier designs. Weaknesses: Potentially higher cost compared to simpler testing methods, may require specialized training to operate.

Teradyne, Inc.

Technical Solution: Teradyne has developed the J750 family of semiconductor testers, which includes capabilities for testing half wave rectifiers. Their testing platform incorporates high-speed digital and analog measurement capabilities, allowing for accurate characterization of rectifier performance[1]. The J750 system supports both DC and AC testing of rectifiers, enabling measurement of key parameters such as forward voltage drop, reverse breakdown voltage, and rectification efficiency[2]. Teradyne's test solutions also feature advanced waveform generation and analysis tools, allowing for detailed examination of rectifier behavior under various input conditions[3]. The company's automated test equipment (ATE) supports high-volume production testing, ensuring consistent quality control for rectifier manufacturers[4].

Strengths: Comprehensive testing capabilities, high-volume production support, and advanced waveform analysis. Weaknesses: High initial investment cost, may be overly complex for simple rectifier designs.

Core Testing Innovations

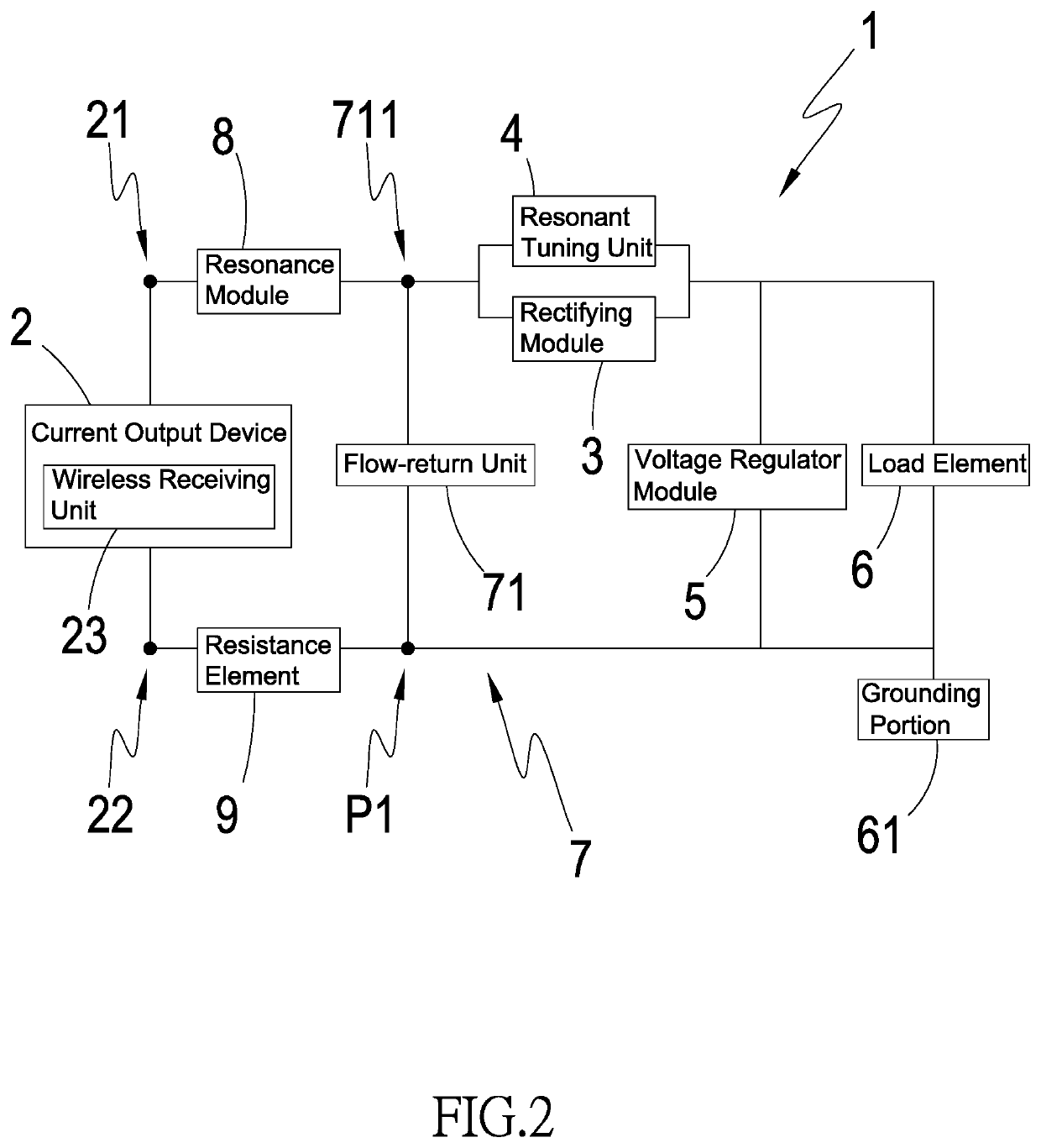

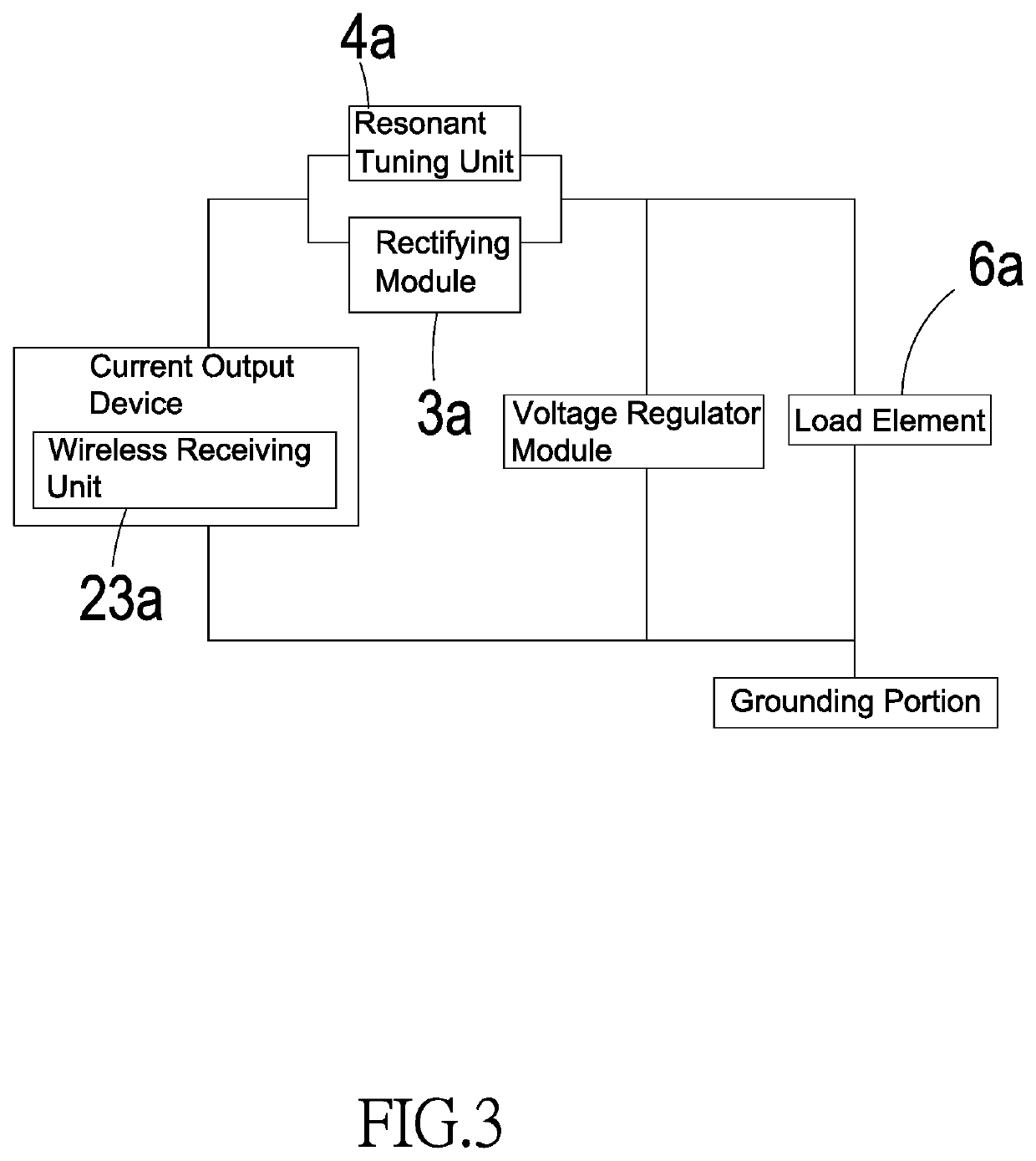

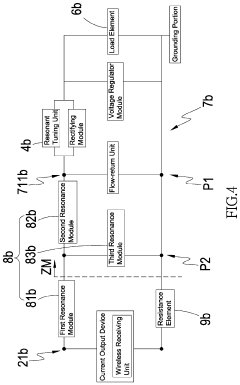

High-frequency half-wave rectifier system of low-harmonicity and high-efficiency

PatentInactiveUS10594205B2

Innovation

- A high-frequency half-wave rectifier system with a simplified structure and reduced electronic components, utilizing a resonant tuning unit and voltage regulator module to control the duty cycle and capacitance, thereby reducing harmonic content and electromagnetic interference, and improving conversion efficiency.

Half-wave rectifier circuit

PatentInactiveUS5579214A

Innovation

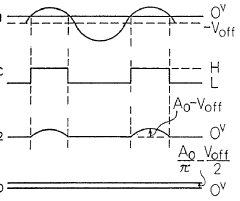

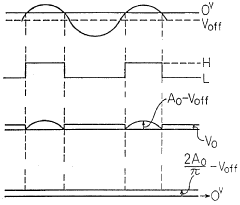

- The proposed half-wave rectifier circuit design includes a capacitor to remove DC components, a comparator with an operational amplifier and capacitor to accumulate offset voltage, and a switch circuit with high input impedance during the OFF state to eliminate the influence of offset voltage, ensuring accurate output voltage generation.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and testing of half wave rectifiers, ensuring that these electronic components meet established standards for safety, performance, and electromagnetic compatibility. As half wave rectifiers are widely used in power supply circuits and various electronic devices, adherence to regulatory requirements is essential for market acceptance and consumer safety.

One of the primary regulatory bodies governing electronic components is the International Electrotechnical Commission (IEC). The IEC sets global standards for electrical and electronic technologies, including specifications for half wave rectifiers. Manufacturers must comply with IEC standards such as IEC 60060 for high-voltage test techniques and IEC 61000 for electromagnetic compatibility.

In the United States, the Federal Communications Commission (FCC) regulates electronic devices to prevent harmful interference with radio communications. Half wave rectifiers, as components of power supplies, must comply with FCC Part 15 regulations for unintentional radiators. This requires thorough testing to ensure that the rectifier does not emit excessive electromagnetic interference (EMI) that could disrupt other electronic devices.

The European Union's CE marking is another critical regulatory consideration for half wave rectifiers. To obtain CE certification, manufacturers must demonstrate compliance with relevant EU directives, such as the Low Voltage Directive (LVD) and the Electromagnetic Compatibility (EMC) Directive. This involves rigorous testing and documentation to prove that the rectifier meets safety and performance standards.

Testing for regulatory compliance often includes a range of assessments, such as dielectric strength tests, insulation resistance measurements, and EMI/EMC testing. These tests ensure that the half wave rectifier can withstand specified voltage levels, maintain proper insulation, and operate without causing electromagnetic disturbances.

Environmental regulations also impact half wave rectifier development and testing. The Restriction of Hazardous Substances (RoHS) directive, for instance, limits the use of certain hazardous materials in electronic components. Manufacturers must conduct material composition tests to verify compliance with RoHS requirements, ensuring that their rectifiers do not contain restricted substances above permissible levels.

As technology advances and regulatory standards evolve, manufacturers must stay informed about changes in compliance requirements. This may involve periodic retesting of existing products and updating testing protocols for new designs. Failure to meet regulatory standards can result in product recalls, legal liabilities, and damage to a company's reputation.

In conclusion, regulatory compliance is an integral aspect of half wave rectifier development and testing. It ensures that these components meet global safety and performance standards, protect consumers, and maintain market access. By prioritizing compliance testing throughout the development process, manufacturers can mitigate risks and deliver reliable, high-quality rectifiers that meet the stringent demands of modern electronic applications.

One of the primary regulatory bodies governing electronic components is the International Electrotechnical Commission (IEC). The IEC sets global standards for electrical and electronic technologies, including specifications for half wave rectifiers. Manufacturers must comply with IEC standards such as IEC 60060 for high-voltage test techniques and IEC 61000 for electromagnetic compatibility.

In the United States, the Federal Communications Commission (FCC) regulates electronic devices to prevent harmful interference with radio communications. Half wave rectifiers, as components of power supplies, must comply with FCC Part 15 regulations for unintentional radiators. This requires thorough testing to ensure that the rectifier does not emit excessive electromagnetic interference (EMI) that could disrupt other electronic devices.

The European Union's CE marking is another critical regulatory consideration for half wave rectifiers. To obtain CE certification, manufacturers must demonstrate compliance with relevant EU directives, such as the Low Voltage Directive (LVD) and the Electromagnetic Compatibility (EMC) Directive. This involves rigorous testing and documentation to prove that the rectifier meets safety and performance standards.

Testing for regulatory compliance often includes a range of assessments, such as dielectric strength tests, insulation resistance measurements, and EMI/EMC testing. These tests ensure that the half wave rectifier can withstand specified voltage levels, maintain proper insulation, and operate without causing electromagnetic disturbances.

Environmental regulations also impact half wave rectifier development and testing. The Restriction of Hazardous Substances (RoHS) directive, for instance, limits the use of certain hazardous materials in electronic components. Manufacturers must conduct material composition tests to verify compliance with RoHS requirements, ensuring that their rectifiers do not contain restricted substances above permissible levels.

As technology advances and regulatory standards evolve, manufacturers must stay informed about changes in compliance requirements. This may involve periodic retesting of existing products and updating testing protocols for new designs. Failure to meet regulatory standards can result in product recalls, legal liabilities, and damage to a company's reputation.

In conclusion, regulatory compliance is an integral aspect of half wave rectifier development and testing. It ensures that these components meet global safety and performance standards, protect consumers, and maintain market access. By prioritizing compliance testing throughout the development process, manufacturers can mitigate risks and deliver reliable, high-quality rectifiers that meet the stringent demands of modern electronic applications.

Performance Metrics

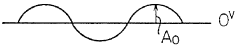

Performance metrics play a crucial role in evaluating the effectiveness and efficiency of half wave rectifier circuits. These metrics provide quantitative measures to assess the rectifier's ability to convert alternating current (AC) to pulsating direct current (DC), which is essential for various electronic applications.

One of the primary performance metrics for half wave rectifiers is the rectification efficiency. This metric quantifies the ratio of DC power output to the total AC power input. A higher rectification efficiency indicates that the rectifier is more effective in converting AC to DC, resulting in less power loss during the conversion process. Typical half wave rectifiers have relatively low efficiency, often ranging from 40% to 50%, due to the fact that they only utilize one half of the AC waveform.

Another important metric is the ripple factor, which measures the amount of AC component remaining in the output waveform after rectification. A lower ripple factor indicates a smoother DC output, which is desirable for most applications. Half wave rectifiers generally have a higher ripple factor compared to full wave rectifiers, as they only rectify one half of the AC cycle.

The peak inverse voltage (PIV) is a critical parameter that determines the maximum reverse voltage the rectifier diode can withstand without breakdown. This metric is essential for selecting appropriate components and ensuring the longevity of the rectifier circuit. In half wave rectifiers, the PIV is typically twice the peak voltage of the AC input.

Form factor is another performance metric that compares the RMS (Root Mean Square) value of the output waveform to its average value. This metric provides insight into the shape of the output waveform and its deviation from an ideal DC signal. Half wave rectifiers typically have a form factor of 1.57, which is higher than that of full wave rectifiers.

The transformer utilization factor (TUF) is particularly relevant for rectifier circuits that employ transformers. This metric indicates how effectively the transformer is utilized in the rectification process. Half wave rectifiers generally have a lower TUF compared to full wave rectifiers, as they only use one half of the transformer's secondary winding.

Output voltage regulation is another crucial performance metric, which measures the rectifier's ability to maintain a stable DC output voltage under varying load conditions. This metric is especially important in applications where a consistent voltage supply is required.

Lastly, the total harmonic distortion (THD) is a metric that quantifies the presence of harmonic components in the output waveform. A lower THD indicates a cleaner output signal with fewer unwanted frequency components, which is desirable for many electronic applications.

These performance metrics collectively provide a comprehensive evaluation of half wave rectifier circuits, enabling engineers to optimize their designs and select the most suitable components for specific applications. Regular testing and measurement of these metrics throughout the development process ensure that the final rectifier design meets the required performance standards and reliability criteria.

One of the primary performance metrics for half wave rectifiers is the rectification efficiency. This metric quantifies the ratio of DC power output to the total AC power input. A higher rectification efficiency indicates that the rectifier is more effective in converting AC to DC, resulting in less power loss during the conversion process. Typical half wave rectifiers have relatively low efficiency, often ranging from 40% to 50%, due to the fact that they only utilize one half of the AC waveform.

Another important metric is the ripple factor, which measures the amount of AC component remaining in the output waveform after rectification. A lower ripple factor indicates a smoother DC output, which is desirable for most applications. Half wave rectifiers generally have a higher ripple factor compared to full wave rectifiers, as they only rectify one half of the AC cycle.

The peak inverse voltage (PIV) is a critical parameter that determines the maximum reverse voltage the rectifier diode can withstand without breakdown. This metric is essential for selecting appropriate components and ensuring the longevity of the rectifier circuit. In half wave rectifiers, the PIV is typically twice the peak voltage of the AC input.

Form factor is another performance metric that compares the RMS (Root Mean Square) value of the output waveform to its average value. This metric provides insight into the shape of the output waveform and its deviation from an ideal DC signal. Half wave rectifiers typically have a form factor of 1.57, which is higher than that of full wave rectifiers.

The transformer utilization factor (TUF) is particularly relevant for rectifier circuits that employ transformers. This metric indicates how effectively the transformer is utilized in the rectification process. Half wave rectifiers generally have a lower TUF compared to full wave rectifiers, as they only use one half of the transformer's secondary winding.

Output voltage regulation is another crucial performance metric, which measures the rectifier's ability to maintain a stable DC output voltage under varying load conditions. This metric is especially important in applications where a consistent voltage supply is required.

Lastly, the total harmonic distortion (THD) is a metric that quantifies the presence of harmonic components in the output waveform. A lower THD indicates a cleaner output signal with fewer unwanted frequency components, which is desirable for many electronic applications.

These performance metrics collectively provide a comprehensive evaluation of half wave rectifier circuits, enabling engineers to optimize their designs and select the most suitable components for specific applications. Regular testing and measurement of these metrics throughout the development process ensure that the final rectifier design meets the required performance standards and reliability criteria.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!