The Role of Geometric Isomers in Polymer Chemistry

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geometric Isomers in Polymer Evolution

The evolution of geometric isomers in polymer chemistry has been a significant area of study, contributing to the development of advanced materials with tailored properties. This progression can be traced through several key stages, each marked by important technological advancements and scientific breakthroughs.

In the early stages of polymer science, the focus was primarily on linear polymers with simple structures. The recognition of geometric isomerism in polymers emerged as researchers began to explore more complex molecular architectures. The discovery of cis-trans isomerism in polydienes, such as polyisoprene and polybutadiene, marked a crucial turning point in understanding the role of geometric isomers in polymer properties.

The 1950s and 1960s saw a surge in research on stereoregular polymers, leading to the development of Ziegler-Natta catalysts. This breakthrough allowed for the controlled synthesis of polymers with specific geometric configurations, such as isotactic and syndiotactic polypropylene. The ability to manipulate the spatial arrangement of polymer chains opened up new possibilities for tailoring material properties.

As analytical techniques advanced, particularly with the development of high-resolution NMR spectroscopy and X-ray crystallography, researchers gained deeper insights into the molecular structure of polymers. This led to a better understanding of how geometric isomerism affects polymer crystallinity, mechanical properties, and thermal behavior.

The late 20th century saw the emergence of living polymerization techniques, which allowed for precise control over polymer architecture. This advancement facilitated the synthesis of block copolymers with defined geometric isomer sequences, leading to materials with unique phase behaviors and self-assembly properties.

Recent developments in polymer chemistry have focused on the design of smart materials that can respond to external stimuli. Geometric isomerism plays a crucial role in this field, with photoisomerizable polymers being a prime example. These materials can undergo reversible changes in their geometric configuration upon exposure to light, leading to applications in areas such as drug delivery and adaptive optics.

The evolution of geometric isomers in polymer chemistry continues to drive innovation in material science. Current research is exploring the potential of geometric isomerism in the development of sustainable polymers, self-healing materials, and advanced composites. As our understanding of structure-property relationships in polymers deepens, the role of geometric isomers is likely to become even more central to the design of next-generation materials with enhanced functionalities and performance characteristics.

In the early stages of polymer science, the focus was primarily on linear polymers with simple structures. The recognition of geometric isomerism in polymers emerged as researchers began to explore more complex molecular architectures. The discovery of cis-trans isomerism in polydienes, such as polyisoprene and polybutadiene, marked a crucial turning point in understanding the role of geometric isomers in polymer properties.

The 1950s and 1960s saw a surge in research on stereoregular polymers, leading to the development of Ziegler-Natta catalysts. This breakthrough allowed for the controlled synthesis of polymers with specific geometric configurations, such as isotactic and syndiotactic polypropylene. The ability to manipulate the spatial arrangement of polymer chains opened up new possibilities for tailoring material properties.

As analytical techniques advanced, particularly with the development of high-resolution NMR spectroscopy and X-ray crystallography, researchers gained deeper insights into the molecular structure of polymers. This led to a better understanding of how geometric isomerism affects polymer crystallinity, mechanical properties, and thermal behavior.

The late 20th century saw the emergence of living polymerization techniques, which allowed for precise control over polymer architecture. This advancement facilitated the synthesis of block copolymers with defined geometric isomer sequences, leading to materials with unique phase behaviors and self-assembly properties.

Recent developments in polymer chemistry have focused on the design of smart materials that can respond to external stimuli. Geometric isomerism plays a crucial role in this field, with photoisomerizable polymers being a prime example. These materials can undergo reversible changes in their geometric configuration upon exposure to light, leading to applications in areas such as drug delivery and adaptive optics.

The evolution of geometric isomers in polymer chemistry continues to drive innovation in material science. Current research is exploring the potential of geometric isomerism in the development of sustainable polymers, self-healing materials, and advanced composites. As our understanding of structure-property relationships in polymers deepens, the role of geometric isomers is likely to become even more central to the design of next-generation materials with enhanced functionalities and performance characteristics.

Market Demand Analysis

The market demand for polymers with controlled geometric isomerism has been steadily increasing across various industries. This growing interest is driven by the unique properties and functionalities that geometric isomers can impart to polymer materials. In the automotive sector, there is a rising demand for polymers with specific geometric configurations that enhance fuel efficiency and reduce vehicle weight. These materials are crucial for developing lightweight components without compromising strength and durability.

The pharmaceutical industry has also shown significant interest in polymers with controlled geometric isomerism. These materials play a vital role in drug delivery systems, where the precise arrangement of polymer chains can influence drug release rates and bioavailability. As personalized medicine gains traction, the demand for tailored polymer-based drug carriers is expected to surge, creating new opportunities for geometric isomer-controlled polymers.

In the field of electronics and optoelectronics, the market for polymers with specific geometric configurations is expanding rapidly. These materials are essential for developing high-performance organic light-emitting diodes (OLEDs), photovoltaic cells, and flexible displays. The ability to control geometric isomerism in polymers allows for fine-tuning of electronic and optical properties, leading to improved device efficiency and longevity.

The packaging industry is another significant driver of market demand for geometrically controlled polymers. With increasing environmental concerns, there is a growing need for biodegradable and recyclable packaging materials. Polymers with specific geometric isomers can offer enhanced barrier properties, improved mechanical strength, and better recyclability, addressing the industry's sustainability goals.

In the construction sector, the demand for advanced polymer materials with controlled geometric isomerism is on the rise. These materials are sought after for their superior thermal insulation properties, weather resistance, and structural integrity. As energy-efficient building practices become more prevalent, the market for such specialized polymers is expected to grow substantially.

The textile industry is also exploring the potential of polymers with controlled geometric isomerism. These materials can lead to the development of smart textiles with enhanced moisture-wicking properties, improved durability, and even self-cleaning capabilities. As consumers increasingly demand high-performance and multifunctional clothing, the market for these advanced polymer materials is projected to expand.

Overall, the market demand for polymers with controlled geometric isomerism is diverse and growing across multiple sectors. As research and development in this field continue to advance, new applications and market opportunities are likely to emerge, further driving the demand for these specialized materials.

The pharmaceutical industry has also shown significant interest in polymers with controlled geometric isomerism. These materials play a vital role in drug delivery systems, where the precise arrangement of polymer chains can influence drug release rates and bioavailability. As personalized medicine gains traction, the demand for tailored polymer-based drug carriers is expected to surge, creating new opportunities for geometric isomer-controlled polymers.

In the field of electronics and optoelectronics, the market for polymers with specific geometric configurations is expanding rapidly. These materials are essential for developing high-performance organic light-emitting diodes (OLEDs), photovoltaic cells, and flexible displays. The ability to control geometric isomerism in polymers allows for fine-tuning of electronic and optical properties, leading to improved device efficiency and longevity.

The packaging industry is another significant driver of market demand for geometrically controlled polymers. With increasing environmental concerns, there is a growing need for biodegradable and recyclable packaging materials. Polymers with specific geometric isomers can offer enhanced barrier properties, improved mechanical strength, and better recyclability, addressing the industry's sustainability goals.

In the construction sector, the demand for advanced polymer materials with controlled geometric isomerism is on the rise. These materials are sought after for their superior thermal insulation properties, weather resistance, and structural integrity. As energy-efficient building practices become more prevalent, the market for such specialized polymers is expected to grow substantially.

The textile industry is also exploring the potential of polymers with controlled geometric isomerism. These materials can lead to the development of smart textiles with enhanced moisture-wicking properties, improved durability, and even self-cleaning capabilities. As consumers increasingly demand high-performance and multifunctional clothing, the market for these advanced polymer materials is projected to expand.

Overall, the market demand for polymers with controlled geometric isomerism is diverse and growing across multiple sectors. As research and development in this field continue to advance, new applications and market opportunities are likely to emerge, further driving the demand for these specialized materials.

Current Challenges

The field of polymer chemistry faces several significant challenges when it comes to understanding and utilizing geometric isomers. One of the primary obstacles is the complexity of controlling and predicting the formation of specific geometric isomers during polymerization processes. This unpredictability can lead to inconsistencies in polymer properties and performance, making it difficult to achieve desired material characteristics consistently.

Another major challenge lies in the characterization and quantification of geometric isomers within polymer structures. Current analytical techniques often struggle to accurately differentiate between various isomeric forms, especially in complex polymer systems. This limitation hampers our ability to fully understand the relationship between isomeric composition and material properties, hindering the development of tailored polymeric materials.

The impact of geometric isomers on polymer properties presents yet another hurdle. While it is known that the presence and distribution of geometric isomers can significantly affect a polymer's physical, chemical, and mechanical properties, the exact mechanisms and extent of these influences are not always well understood. This knowledge gap makes it challenging to design polymers with precise property profiles based on isomeric composition.

Furthermore, the industry faces difficulties in scaling up production processes that can maintain control over geometric isomerism. What works in laboratory settings may not always translate effectively to industrial-scale manufacturing, leading to inconsistencies in product quality and performance. This scalability issue is particularly pronounced when attempting to produce polymers with specific ratios of geometric isomers for specialized applications.

The environmental stability and long-term performance of polymers containing geometric isomers also pose significant challenges. Some isomeric forms may be more susceptible to degradation or transformation under certain environmental conditions, potentially altering the polymer's properties over time. This instability can limit the applicability of such materials in demanding environments or long-life applications.

Additionally, there is a growing need to develop sustainable and eco-friendly methods for controlling geometric isomerism in polymers. Current techniques often rely on harsh chemicals or energy-intensive processes, which are not aligned with the increasing focus on green chemistry and sustainable manufacturing practices.

Lastly, the integration of geometric isomer control with other aspects of polymer design, such as molecular weight distribution, branching, and functionalization, remains a complex challenge. Balancing these various factors to achieve optimal material properties requires a deep understanding of structure-property relationships and advanced synthetic strategies, which are still evolving in the field of polymer chemistry.

Another major challenge lies in the characterization and quantification of geometric isomers within polymer structures. Current analytical techniques often struggle to accurately differentiate between various isomeric forms, especially in complex polymer systems. This limitation hampers our ability to fully understand the relationship between isomeric composition and material properties, hindering the development of tailored polymeric materials.

The impact of geometric isomers on polymer properties presents yet another hurdle. While it is known that the presence and distribution of geometric isomers can significantly affect a polymer's physical, chemical, and mechanical properties, the exact mechanisms and extent of these influences are not always well understood. This knowledge gap makes it challenging to design polymers with precise property profiles based on isomeric composition.

Furthermore, the industry faces difficulties in scaling up production processes that can maintain control over geometric isomerism. What works in laboratory settings may not always translate effectively to industrial-scale manufacturing, leading to inconsistencies in product quality and performance. This scalability issue is particularly pronounced when attempting to produce polymers with specific ratios of geometric isomers for specialized applications.

The environmental stability and long-term performance of polymers containing geometric isomers also pose significant challenges. Some isomeric forms may be more susceptible to degradation or transformation under certain environmental conditions, potentially altering the polymer's properties over time. This instability can limit the applicability of such materials in demanding environments or long-life applications.

Additionally, there is a growing need to develop sustainable and eco-friendly methods for controlling geometric isomerism in polymers. Current techniques often rely on harsh chemicals or energy-intensive processes, which are not aligned with the increasing focus on green chemistry and sustainable manufacturing practices.

Lastly, the integration of geometric isomer control with other aspects of polymer design, such as molecular weight distribution, branching, and functionalization, remains a complex challenge. Balancing these various factors to achieve optimal material properties requires a deep understanding of structure-property relationships and advanced synthetic strategies, which are still evolving in the field of polymer chemistry.

Existing Isomer Solutions

01 Synthesis and separation of geometric isomers

Methods for synthesizing and separating geometric isomers, including techniques for controlling the formation of specific isomers during chemical reactions and processes for isolating desired isomers from mixtures. This may involve the use of catalysts, specific reaction conditions, or separation techniques such as chromatography.- Synthesis and separation of geometric isomers: Methods for synthesizing and separating geometric isomers, including techniques for controlling the formation of specific isomers during chemical reactions and processes for isolating desired isomers from mixtures. These methods may involve catalysts, reaction conditions, or separation techniques such as chromatography.

- Geometric isomers in pharmaceutical compounds: The importance of geometric isomers in pharmaceutical compounds, including their effects on drug efficacy, safety, and bioavailability. This includes methods for producing specific isomers of pharmaceutical compounds and techniques for analyzing and characterizing geometric isomers in drug formulations.

- Computational methods for analyzing geometric isomers: Development of computational methods and software for analyzing, predicting, and visualizing geometric isomers. These tools may include molecular modeling, quantum chemical calculations, and machine learning approaches to study the properties and behavior of geometric isomers.

- Geometric isomers in materials science and engineering: Applications of geometric isomers in materials science and engineering, including their role in developing new materials with specific properties. This may involve the use of geometric isomers in polymers, liquid crystals, or other advanced materials to achieve desired physical or chemical characteristics.

- Analytical techniques for identifying geometric isomers: Development and application of analytical techniques for identifying and characterizing geometric isomers in various samples. These methods may include spectroscopic techniques such as NMR, IR, or mass spectrometry, as well as chromatographic methods for separating and quantifying geometric isomers.

02 Characterization and identification of geometric isomers

Techniques for characterizing and identifying geometric isomers, including spectroscopic methods such as NMR, IR, and X-ray crystallography. These methods allow for the determination of the spatial arrangement of atoms in molecules and the differentiation between geometric isomers.Expand Specific Solutions03 Applications of geometric isomers in pharmaceuticals

The use of geometric isomers in pharmaceutical development, including the synthesis and evaluation of different isomers for their biological activity and therapeutic potential. This may involve the development of drugs with improved efficacy or reduced side effects based on specific geometric configurations.Expand Specific Solutions04 Geometric isomers in materials science and engineering

The role of geometric isomers in materials science and engineering applications, including their influence on the properties of polymers, liquid crystals, and other advanced materials. This may involve the design of materials with specific optical, electrical, or mechanical properties based on the arrangement of geometric isomers.Expand Specific Solutions05 Computational methods for studying geometric isomers

The use of computational methods and modeling techniques to study geometric isomers, including molecular dynamics simulations, quantum chemical calculations, and machine learning approaches. These methods can be used to predict the properties and behavior of geometric isomers and guide experimental research.Expand Specific Solutions

Key Industry Players

The field of geometric isomers in polymer chemistry is in a mature stage of development, with established market players and ongoing research. The global market for polymers is substantial, estimated at over $500 billion annually, with geometric isomers playing a crucial role in various applications. Technologically, the field is well-developed, with companies like Schlumberger Technology BV, Novartis AG, and AbbVie, Inc. leading in research and development. These firms, along with academic institutions such as Harvard College and Ningbo University, are pushing the boundaries of polymer science, focusing on enhancing material properties and exploring new applications in industries ranging from pharmaceuticals to oil and gas.

Rohm & Haas Co.

Technical Solution: Rohm & Haas Co. has developed advanced techniques for controlling geometric isomerism in polymer synthesis. Their approach involves using stereospecific catalysts to produce polymers with precise spatial arrangements of side groups. This allows for the creation of materials with tailored properties, such as improved thermal stability and mechanical strength. The company has also pioneered the use of post-polymerization modification techniques to alter the geometric configuration of existing polymers, enabling the fine-tuning of material properties without the need for complete re-synthesis[1][3].

Strengths: Precise control over polymer structure, ability to tailor material properties. Weaknesses: Potentially higher production costs, limited to certain polymer types.

President & Fellows of Harvard College

Technical Solution: Harvard University researchers have made fundamental contributions to understanding the role of geometric isomers in polymer chemistry. Their work includes the development of theoretical models to predict the impact of geometric isomerism on polymer properties. They have also pioneered new synthetic methods for creating polymers with controlled geometric isomerism, including the use of light-triggered catalysts to switch between different isomeric forms. This research has implications for the development of responsive materials and biomimetic polymers[9][10].

Strengths: Cutting-edge fundamental research, potential for breakthrough applications. Weaknesses: Early-stage research, may require significant development for commercial applications.

Core Isomer Innovations

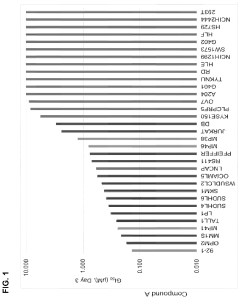

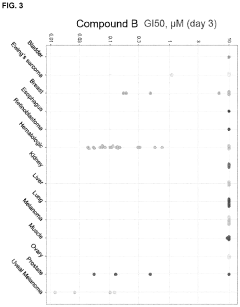

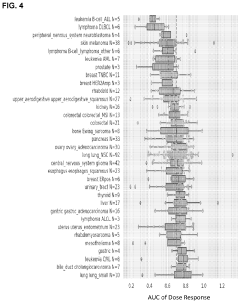

Compounds and uses thereof

PatentPendingUS20230145003A1

Innovation

- Development of specific compounds that modulate the BAF complex by inhibiting BRG1 and/or BRM activity, which can be used alone or in combination with other pharmaceutically active agents to treat disorders like cancer.

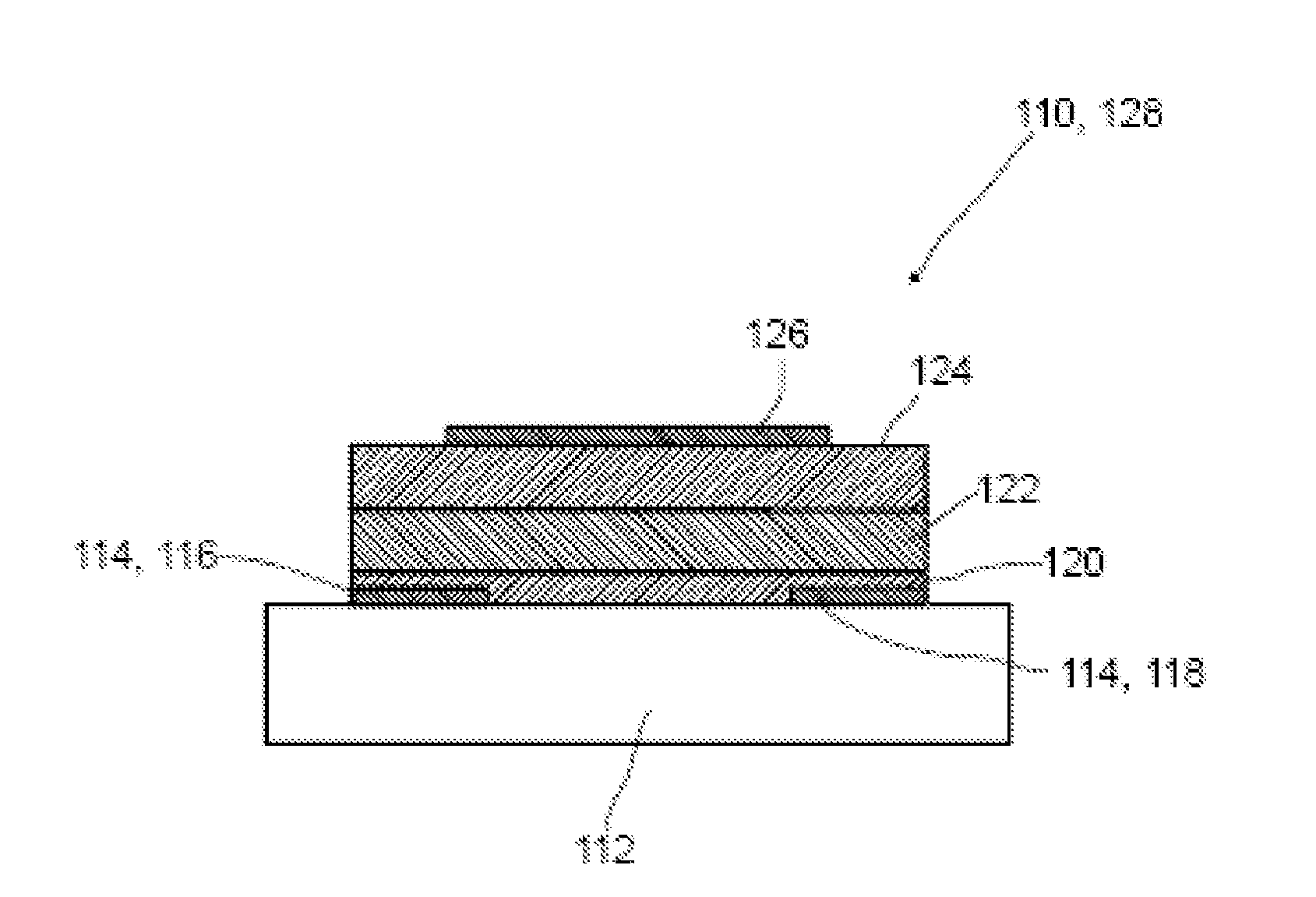

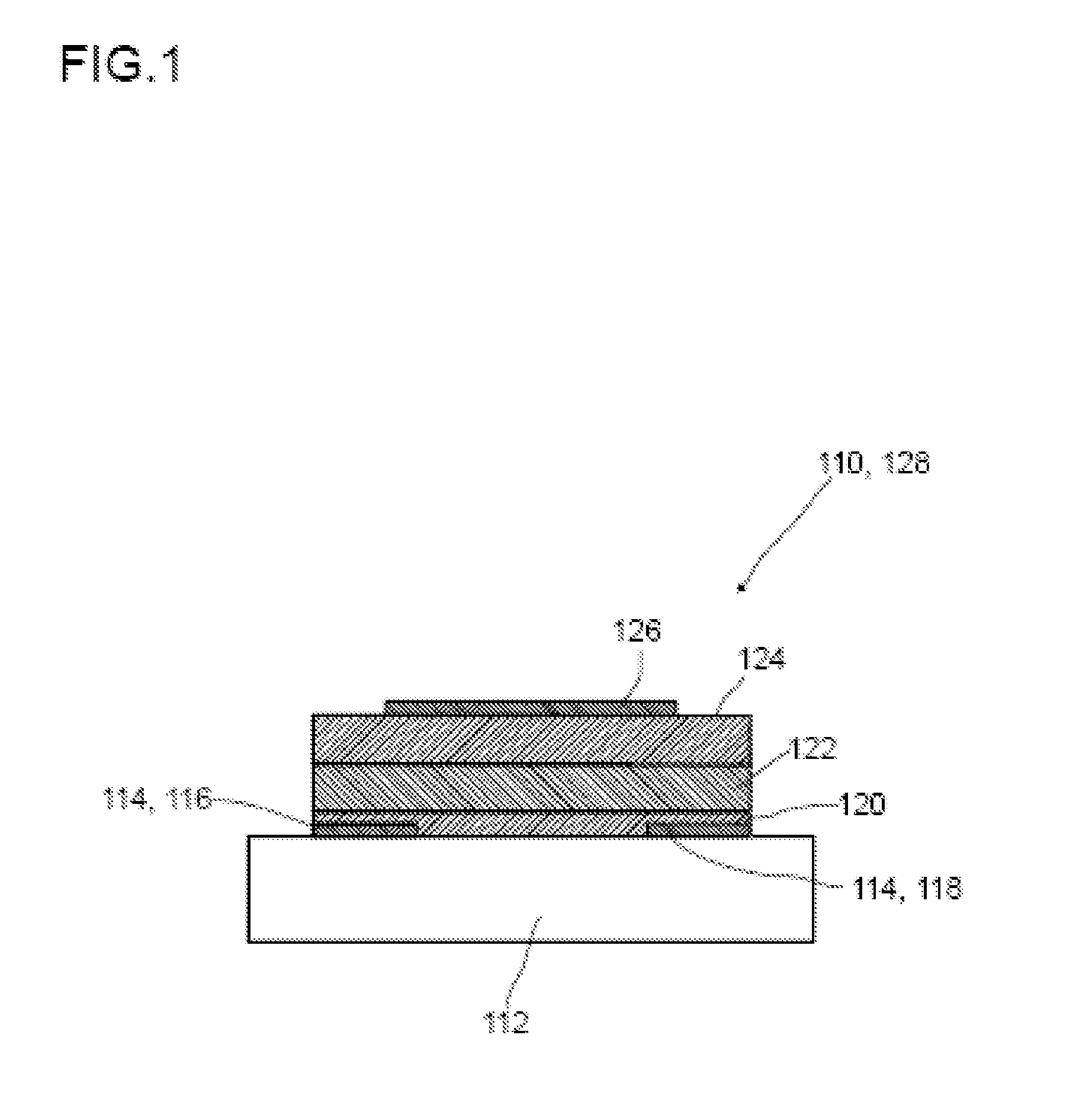

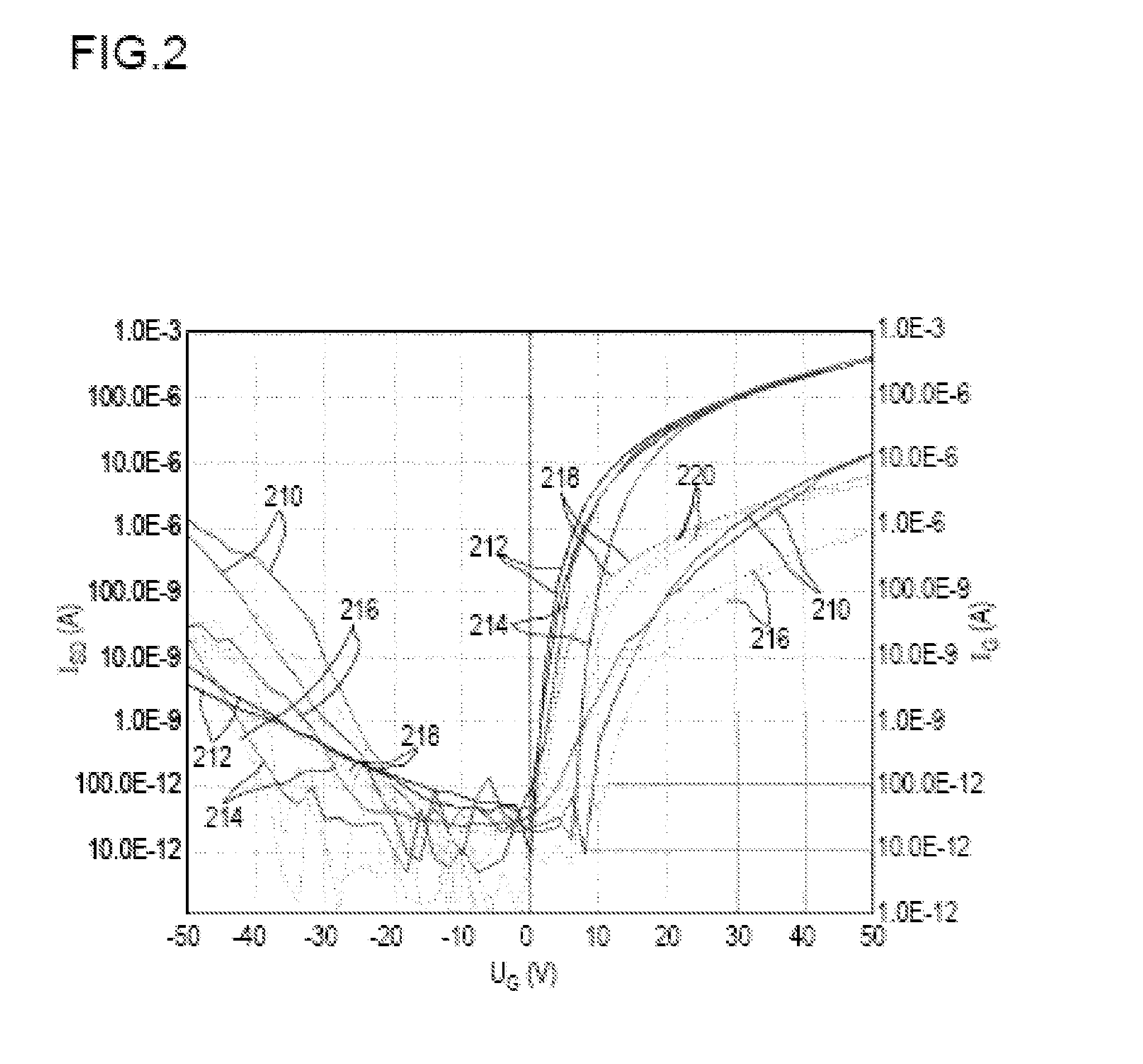

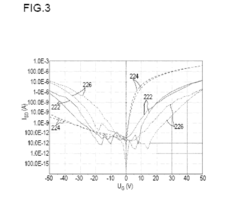

Method for producing an organic semiconductor device

PatentActiveUS20130200336A1

Innovation

- The introduction of a thin intermediate layer comprising thiol compounds with specific dipole moments between the organic semiconducting material and electrodes to suppress ambipolar charge carrier transport, favoring unipolar transport by adjusting the energy levels and reducing contact resistance.

Regulatory Considerations

The regulatory landscape surrounding geometric isomers in polymer chemistry is complex and multifaceted, requiring careful consideration by manufacturers, researchers, and industry stakeholders. Regulatory bodies such as the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and Environmental Protection Agency (EPA) have established guidelines and regulations that directly impact the use of geometric isomers in polymer production and applications.

One of the primary regulatory concerns is the potential impact of geometric isomers on human health and the environment. Regulatory agencies often require extensive toxicological studies and environmental impact assessments to ensure the safety of polymers containing geometric isomers. These studies must demonstrate that the isomers do not pose significant risks to human health or ecosystems throughout the product lifecycle, from manufacturing to disposal.

In the pharmaceutical industry, regulatory considerations for geometric isomers are particularly stringent. The FDA and EMA have specific guidelines for the development and manufacturing of drug products containing geometric isomers. These guidelines often require detailed characterization of the isomeric composition, stability studies, and demonstration of consistent manufacturing processes to ensure product quality and safety.

For industrial applications, regulations often focus on the potential for geometric isomers to affect the performance and safety of polymer products. Standards organizations such as ASTM International and the International Organization for Standardization (ISO) have developed testing methods and specifications that manufacturers must adhere to when producing polymers with geometric isomers.

Environmental regulations also play a crucial role in the use of geometric isomers in polymer chemistry. Many countries have implemented regulations to control the release of potentially harmful substances into the environment. Manufacturers must comply with these regulations by implementing appropriate waste management practices and pollution control measures during the production and disposal of polymers containing geometric isomers.

The regulatory landscape is continually evolving as new research emerges on the properties and potential impacts of geometric isomers. Industry stakeholders must stay informed about regulatory changes and adapt their practices accordingly. This may involve investing in new technologies for isomer characterization, developing more environmentally friendly production processes, or reformulating products to meet updated safety standards.

Compliance with these regulations often requires significant investment in research, testing, and documentation. Companies must maintain detailed records of their manufacturing processes, quality control measures, and safety assessments to demonstrate compliance during regulatory inspections or audits. Failure to meet regulatory requirements can result in severe consequences, including product recalls, fines, and damage to a company's reputation.

One of the primary regulatory concerns is the potential impact of geometric isomers on human health and the environment. Regulatory agencies often require extensive toxicological studies and environmental impact assessments to ensure the safety of polymers containing geometric isomers. These studies must demonstrate that the isomers do not pose significant risks to human health or ecosystems throughout the product lifecycle, from manufacturing to disposal.

In the pharmaceutical industry, regulatory considerations for geometric isomers are particularly stringent. The FDA and EMA have specific guidelines for the development and manufacturing of drug products containing geometric isomers. These guidelines often require detailed characterization of the isomeric composition, stability studies, and demonstration of consistent manufacturing processes to ensure product quality and safety.

For industrial applications, regulations often focus on the potential for geometric isomers to affect the performance and safety of polymer products. Standards organizations such as ASTM International and the International Organization for Standardization (ISO) have developed testing methods and specifications that manufacturers must adhere to when producing polymers with geometric isomers.

Environmental regulations also play a crucial role in the use of geometric isomers in polymer chemistry. Many countries have implemented regulations to control the release of potentially harmful substances into the environment. Manufacturers must comply with these regulations by implementing appropriate waste management practices and pollution control measures during the production and disposal of polymers containing geometric isomers.

The regulatory landscape is continually evolving as new research emerges on the properties and potential impacts of geometric isomers. Industry stakeholders must stay informed about regulatory changes and adapt their practices accordingly. This may involve investing in new technologies for isomer characterization, developing more environmentally friendly production processes, or reformulating products to meet updated safety standards.

Compliance with these regulations often requires significant investment in research, testing, and documentation. Companies must maintain detailed records of their manufacturing processes, quality control measures, and safety assessments to demonstrate compliance during regulatory inspections or audits. Failure to meet regulatory requirements can result in severe consequences, including product recalls, fines, and damage to a company's reputation.

Environmental Impact

The environmental impact of geometric isomers in polymer chemistry is a critical consideration in the development and application of polymeric materials. These isomers, which have the same molecular formula but different spatial arrangements of atoms, can significantly influence the properties and behavior of polymers throughout their lifecycle.

One of the primary environmental concerns related to geometric isomers in polymers is their potential for biodegradability. Certain isomeric configurations may be more resistant to natural breakdown processes, leading to prolonged persistence in the environment. This can contribute to the accumulation of plastic waste in ecosystems, particularly in marine environments where polymer debris poses a significant threat to wildlife.

The production processes involving geometric isomers can also have varying environmental footprints. Some isomeric forms may require more energy-intensive synthesis methods or the use of potentially harmful catalysts, resulting in increased greenhouse gas emissions and the generation of hazardous waste. Conversely, other isomeric configurations might enable more efficient production techniques, reducing overall environmental impact.

Geometric isomers can affect the recyclability of polymeric materials. The presence of different isomeric forms within a polymer matrix may complicate recycling processes, as these variations can lead to inconsistencies in the properties of recycled materials. This challenge underscores the importance of developing advanced sorting and recycling technologies that can effectively handle diverse isomeric compositions.

The leaching of additives and monomers from polymers containing geometric isomers is another environmental concern. Depending on their spatial arrangement, certain isomers may be more prone to releasing potentially harmful substances into the surrounding environment, particularly when exposed to heat, UV radiation, or chemical agents. This can lead to soil and water contamination, affecting both ecosystems and human health.

On a positive note, the strategic use of geometric isomers in polymer design can contribute to the development of more environmentally friendly materials. For instance, some isomeric configurations may enhance the durability and weather resistance of polymers, extending their useful life and reducing the need for frequent replacement. This can lead to a decrease in overall material consumption and waste generation.

Furthermore, the study of geometric isomers in polymer chemistry has opened up new avenues for creating biodegradable and compostable plastics. By manipulating the spatial arrangement of atoms within polymer chains, researchers are exploring ways to design materials that maintain desired performance characteristics while being more susceptible to controlled degradation under specific environmental conditions.

One of the primary environmental concerns related to geometric isomers in polymers is their potential for biodegradability. Certain isomeric configurations may be more resistant to natural breakdown processes, leading to prolonged persistence in the environment. This can contribute to the accumulation of plastic waste in ecosystems, particularly in marine environments where polymer debris poses a significant threat to wildlife.

The production processes involving geometric isomers can also have varying environmental footprints. Some isomeric forms may require more energy-intensive synthesis methods or the use of potentially harmful catalysts, resulting in increased greenhouse gas emissions and the generation of hazardous waste. Conversely, other isomeric configurations might enable more efficient production techniques, reducing overall environmental impact.

Geometric isomers can affect the recyclability of polymeric materials. The presence of different isomeric forms within a polymer matrix may complicate recycling processes, as these variations can lead to inconsistencies in the properties of recycled materials. This challenge underscores the importance of developing advanced sorting and recycling technologies that can effectively handle diverse isomeric compositions.

The leaching of additives and monomers from polymers containing geometric isomers is another environmental concern. Depending on their spatial arrangement, certain isomers may be more prone to releasing potentially harmful substances into the surrounding environment, particularly when exposed to heat, UV radiation, or chemical agents. This can lead to soil and water contamination, affecting both ecosystems and human health.

On a positive note, the strategic use of geometric isomers in polymer design can contribute to the development of more environmentally friendly materials. For instance, some isomeric configurations may enhance the durability and weather resistance of polymers, extending their useful life and reducing the need for frequent replacement. This can lead to a decrease in overall material consumption and waste generation.

Furthermore, the study of geometric isomers in polymer chemistry has opened up new avenues for creating biodegradable and compostable plastics. By manipulating the spatial arrangement of atoms within polymer chains, researchers are exploring ways to design materials that maintain desired performance characteristics while being more susceptible to controlled degradation under specific environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!