The Role of Geometric Isomers in the Design of Smart Materials

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geometric Isomers in Smart Materials: Background and Objectives

Geometric isomers have emerged as a crucial element in the design and development of smart materials, marking a significant advancement in materials science and engineering. The concept of geometric isomerism, which refers to molecules with the same molecular formula but different spatial arrangements of atoms, has been known to chemists for over a century. However, its application in the realm of smart materials is a relatively recent and rapidly evolving field.

The evolution of smart materials has been driven by the need for materials that can respond dynamically to external stimuli such as light, temperature, pressure, or electric fields. Geometric isomers, with their ability to switch between different conformations, offer a unique opportunity to create materials with programmable and reversible properties. This characteristic makes them ideal candidates for developing responsive and adaptive systems.

The primary objective of incorporating geometric isomers into smart materials is to harness their structural flexibility to create materials with switchable properties. These properties can include changes in optical, mechanical, or electrical characteristics, which can be triggered by specific external stimuli. The potential applications of such materials span a wide range of fields, including sensors, actuators, drug delivery systems, and energy storage devices.

One of the key technological trends in this area is the development of photoswitchable materials based on azobenzene derivatives. These compounds can undergo reversible trans-cis isomerization when exposed to light of specific wavelengths, leading to significant changes in molecular geometry and properties. This photoswitching behavior has been exploited to create materials with light-controlled surface properties, mechanical actuators, and optical data storage systems.

Another important trend is the use of geometric isomers in the design of shape-memory polymers. By incorporating isomeric units into polymer chains, researchers have been able to create materials that can remember and return to their original shape when exposed to specific stimuli. This technology has potential applications in biomedical devices, aerospace engineering, and smart textiles.

The integration of geometric isomers into smart materials also aligns with the broader technological goal of creating multifunctional and adaptive materials. By combining the responsiveness of geometric isomers with other smart material technologies, such as piezoelectric or magnetostrictive materials, researchers aim to develop next-generation materials capable of responding to multiple stimuli and performing complex functions.

As research in this field progresses, the objectives extend beyond simply creating responsive materials. There is a growing focus on developing materials with precise control over the isomerization process, improved cycling stability, and enhanced efficiency in energy conversion. Additionally, there is an increasing emphasis on designing environmentally friendly and sustainable smart materials, aligning with global efforts towards green technology and circular economy principles.

The evolution of smart materials has been driven by the need for materials that can respond dynamically to external stimuli such as light, temperature, pressure, or electric fields. Geometric isomers, with their ability to switch between different conformations, offer a unique opportunity to create materials with programmable and reversible properties. This characteristic makes them ideal candidates for developing responsive and adaptive systems.

The primary objective of incorporating geometric isomers into smart materials is to harness their structural flexibility to create materials with switchable properties. These properties can include changes in optical, mechanical, or electrical characteristics, which can be triggered by specific external stimuli. The potential applications of such materials span a wide range of fields, including sensors, actuators, drug delivery systems, and energy storage devices.

One of the key technological trends in this area is the development of photoswitchable materials based on azobenzene derivatives. These compounds can undergo reversible trans-cis isomerization when exposed to light of specific wavelengths, leading to significant changes in molecular geometry and properties. This photoswitching behavior has been exploited to create materials with light-controlled surface properties, mechanical actuators, and optical data storage systems.

Another important trend is the use of geometric isomers in the design of shape-memory polymers. By incorporating isomeric units into polymer chains, researchers have been able to create materials that can remember and return to their original shape when exposed to specific stimuli. This technology has potential applications in biomedical devices, aerospace engineering, and smart textiles.

The integration of geometric isomers into smart materials also aligns with the broader technological goal of creating multifunctional and adaptive materials. By combining the responsiveness of geometric isomers with other smart material technologies, such as piezoelectric or magnetostrictive materials, researchers aim to develop next-generation materials capable of responding to multiple stimuli and performing complex functions.

As research in this field progresses, the objectives extend beyond simply creating responsive materials. There is a growing focus on developing materials with precise control over the isomerization process, improved cycling stability, and enhanced efficiency in energy conversion. Additionally, there is an increasing emphasis on designing environmentally friendly and sustainable smart materials, aligning with global efforts towards green technology and circular economy principles.

Market Analysis for Smart Material Applications

The smart materials market has been experiencing significant growth in recent years, driven by advancements in material science and increasing demand for innovative solutions across various industries. The global smart materials market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many traditional material sectors.

Geometric isomers play a crucial role in the design and functionality of smart materials, particularly in applications requiring precise molecular structures and responsive behaviors. The market for smart materials incorporating geometric isomers is expanding rapidly, with key growth areas including shape memory alloys, piezoelectric materials, and stimuli-responsive polymers.

In the automotive industry, smart materials with geometric isomers are finding applications in adaptive structures, self-healing coatings, and energy harvesting systems. The aerospace sector is also adopting these materials for lightweight, high-performance components and smart sensors. The construction industry is leveraging smart materials for self-repairing concrete and energy-efficient building envelopes.

The healthcare and medical devices market presents significant opportunities for smart materials utilizing geometric isomers. Applications include drug delivery systems, tissue engineering scaffolds, and responsive implants. The growing focus on personalized medicine and minimally invasive procedures is driving demand for these advanced materials.

Consumer electronics represent another key market for smart materials, with applications in flexible displays, haptic feedback systems, and wearable technology. The integration of geometric isomers in these materials enables enhanced user experiences and improved device functionality.

The energy sector is also embracing smart materials, particularly in the development of more efficient solar cells, thermoelectric generators, and energy storage systems. Geometric isomers contribute to the design of materials with improved energy conversion and storage capabilities.

While the market potential for smart materials incorporating geometric isomers is substantial, challenges remain. These include high production costs, scalability issues, and the need for standardization across industries. However, ongoing research and development efforts are addressing these challenges, paving the way for wider adoption and market growth.

As the technology matures and production processes improve, the market for smart materials is expected to expand into new application areas. Emerging opportunities include smart textiles, responsive packaging materials, and advanced sensors for Internet of Things (IoT) devices. The continued integration of geometric isomers in smart material design will be crucial in unlocking these new market potentials and driving innovation across industries.

Geometric isomers play a crucial role in the design and functionality of smart materials, particularly in applications requiring precise molecular structures and responsive behaviors. The market for smart materials incorporating geometric isomers is expanding rapidly, with key growth areas including shape memory alloys, piezoelectric materials, and stimuli-responsive polymers.

In the automotive industry, smart materials with geometric isomers are finding applications in adaptive structures, self-healing coatings, and energy harvesting systems. The aerospace sector is also adopting these materials for lightweight, high-performance components and smart sensors. The construction industry is leveraging smart materials for self-repairing concrete and energy-efficient building envelopes.

The healthcare and medical devices market presents significant opportunities for smart materials utilizing geometric isomers. Applications include drug delivery systems, tissue engineering scaffolds, and responsive implants. The growing focus on personalized medicine and minimally invasive procedures is driving demand for these advanced materials.

Consumer electronics represent another key market for smart materials, with applications in flexible displays, haptic feedback systems, and wearable technology. The integration of geometric isomers in these materials enables enhanced user experiences and improved device functionality.

The energy sector is also embracing smart materials, particularly in the development of more efficient solar cells, thermoelectric generators, and energy storage systems. Geometric isomers contribute to the design of materials with improved energy conversion and storage capabilities.

While the market potential for smart materials incorporating geometric isomers is substantial, challenges remain. These include high production costs, scalability issues, and the need for standardization across industries. However, ongoing research and development efforts are addressing these challenges, paving the way for wider adoption and market growth.

As the technology matures and production processes improve, the market for smart materials is expected to expand into new application areas. Emerging opportunities include smart textiles, responsive packaging materials, and advanced sensors for Internet of Things (IoT) devices. The continued integration of geometric isomers in smart material design will be crucial in unlocking these new market potentials and driving innovation across industries.

Current Challenges in Geometric Isomer-based Smart Materials

The development of smart materials based on geometric isomers faces several significant challenges that hinder their widespread application and commercialization. One of the primary obstacles is the limited range of stimuli-responsive behaviors exhibited by current geometric isomer-based systems. While some materials can undergo reversible transformations in response to light or heat, the repertoire of stimuli and corresponding responses remains relatively narrow.

Another critical challenge lies in the stability and durability of these materials under repeated cycles of isomerization. The constant switching between geometric configurations can lead to fatigue and degradation of the material's structure, potentially compromising its long-term performance and reliability. This issue is particularly pronounced in applications requiring frequent or prolonged actuation.

The scalability of production processes for geometric isomer-based smart materials presents a significant hurdle. Many of the current synthesis methods are complex, time-consuming, and difficult to scale up for industrial production. This limitation not only affects the cost-effectiveness of these materials but also restricts their potential for large-scale applications in various sectors.

Control and precision in the isomerization process pose another challenge. Achieving precise control over the degree and rate of isomerization, especially in complex three-dimensional structures, remains difficult. This lack of fine control can result in unpredictable or inconsistent material behavior, limiting the accuracy and reliability of smart material systems in critical applications.

The integration of geometric isomer-based smart materials with other functional components or existing technologies is also challenging. Compatibility issues, such as chemical incompatibility or mechanical mismatch, can arise when attempting to incorporate these materials into more complex systems or devices. This integration challenge limits the potential applications and broader adoption of these smart materials.

Environmental sensitivity is another concern for geometric isomer-based smart materials. Many of these materials are susceptible to unintended isomerization triggered by ambient conditions, such as stray light or temperature fluctuations. This sensitivity can lead to undesired changes in material properties or premature activation, potentially compromising the reliability and performance of the smart material system.

Lastly, the development of multi-responsive and multi-functional geometric isomer-based smart materials remains a significant challenge. While single-stimulus responsive materials have been demonstrated, creating systems that can respond intelligently to multiple stimuli or perform multiple functions simultaneously is still an area of ongoing research and development.

Another critical challenge lies in the stability and durability of these materials under repeated cycles of isomerization. The constant switching between geometric configurations can lead to fatigue and degradation of the material's structure, potentially compromising its long-term performance and reliability. This issue is particularly pronounced in applications requiring frequent or prolonged actuation.

The scalability of production processes for geometric isomer-based smart materials presents a significant hurdle. Many of the current synthesis methods are complex, time-consuming, and difficult to scale up for industrial production. This limitation not only affects the cost-effectiveness of these materials but also restricts their potential for large-scale applications in various sectors.

Control and precision in the isomerization process pose another challenge. Achieving precise control over the degree and rate of isomerization, especially in complex three-dimensional structures, remains difficult. This lack of fine control can result in unpredictable or inconsistent material behavior, limiting the accuracy and reliability of smart material systems in critical applications.

The integration of geometric isomer-based smart materials with other functional components or existing technologies is also challenging. Compatibility issues, such as chemical incompatibility or mechanical mismatch, can arise when attempting to incorporate these materials into more complex systems or devices. This integration challenge limits the potential applications and broader adoption of these smart materials.

Environmental sensitivity is another concern for geometric isomer-based smart materials. Many of these materials are susceptible to unintended isomerization triggered by ambient conditions, such as stray light or temperature fluctuations. This sensitivity can lead to undesired changes in material properties or premature activation, potentially compromising the reliability and performance of the smart material system.

Lastly, the development of multi-responsive and multi-functional geometric isomer-based smart materials remains a significant challenge. While single-stimulus responsive materials have been demonstrated, creating systems that can respond intelligently to multiple stimuli or perform multiple functions simultaneously is still an area of ongoing research and development.

Existing Approaches to Geometric Isomer Integration in Smart Materials

01 Geometric isomers in smart materials

Geometric isomers play a crucial role in the development of smart materials. These isomers, which have the same molecular formula but different spatial arrangements, can exhibit unique properties that are exploited in various applications. The ability to control and manipulate geometric isomers allows for the creation of materials with switchable or responsive characteristics.- Geometric isomers in smart materials: Geometric isomers play a crucial role in the development of smart materials. These isomers, which have the same molecular formula but different spatial arrangements, can exhibit unique properties that are beneficial for creating responsive and adaptive materials. The ability to control and manipulate geometric isomers allows for the design of materials with switchable characteristics, such as changes in optical, mechanical, or electrical properties in response to external stimuli.

- Shape-memory polymers utilizing geometric isomerism: Shape-memory polymers that utilize geometric isomerism are an important class of smart materials. These polymers can change their shape in response to external stimuli, such as temperature or light, due to the reversible transformation between different geometric isomers. This property allows for the creation of materials that can remember and return to their original shape after deformation, making them useful in various applications including biomedical devices and aerospace engineering.

- Photochromic materials based on geometric isomerization: Photochromic materials that rely on geometric isomerization are a significant category of smart materials. These materials can change color or transparency when exposed to light due to the reversible transformation between geometric isomers. This property is utilized in various applications, including smart windows, optical data storage, and adaptive sunglasses. The ability to control the isomerization process allows for the development of materials with tunable optical properties.

- Geometric isomers in molecular machines and switches: Geometric isomers play a crucial role in the design of molecular machines and switches, which are fundamental components of smart materials at the nanoscale. These molecular-level devices can undergo controlled geometric isomerization in response to external stimuli, enabling the creation of materials with switchable properties. Such materials have potential applications in areas like molecular computing, drug delivery systems, and responsive surfaces.

- Synthesis and characterization of geometric isomers for smart materials: The synthesis and characterization of geometric isomers are essential for the development of smart materials. Advanced synthetic methods and analytical techniques are employed to create and study geometric isomers with specific properties. This research focuses on understanding the relationship between molecular structure and material properties, enabling the design of smart materials with tailored characteristics for various applications in fields such as electronics, energy storage, and biomedicine.

02 Shape-memory polymers and alloys

Shape-memory materials, including polymers and alloys, are a class of smart materials that can remember and return to their original shape when subjected to specific stimuli. These materials often utilize geometric isomerism to achieve their unique properties. The transformation between different geometric isomers can be triggered by factors such as temperature, light, or electrical current.Expand Specific Solutions03 Photochromic and thermochromic materials

Photochromic and thermochromic materials are smart materials that change color in response to light or temperature, respectively. These color-changing properties often rely on geometric isomerization of molecules within the material. The reversible transformation between different geometric isomers allows for the creation of responsive coatings, sensors, and displays.Expand Specific Solutions04 Liquid crystal-based smart materials

Liquid crystals are a unique class of materials that exhibit properties of both liquids and crystals. Smart materials based on liquid crystals often utilize geometric isomerism to achieve their responsive behavior. The orientation and arrangement of liquid crystal molecules can be controlled by external stimuli, leading to changes in optical, electrical, or mechanical properties.Expand Specific Solutions05 Stimuli-responsive polymers and gels

Stimuli-responsive polymers and gels are smart materials that can change their properties in response to environmental cues. These materials often incorporate geometric isomers in their molecular structure, allowing for reversible changes in conformation or configuration. Such changes can lead to alterations in material properties such as swelling, permeability, or mechanical strength.Expand Specific Solutions

Key Players in Smart Materials and Geometric Isomer Research

The field of geometric isomers in smart materials design is in a dynamic growth phase, with increasing market potential and technological advancements. The global smart materials market is expanding rapidly, driven by applications in various sectors such as aerospace, automotive, and healthcare. While the technology is still evolving, several key players are making significant strides. Universities like Nanjing University of Science & Technology, University of Washington, and Zhejiang University are conducting cutting-edge research, while companies such as Bausch & Lomb and BASF Corp. are developing commercial applications. The involvement of research institutions like Max Planck Society and The Broad Institute indicates a strong focus on fundamental science, suggesting that the field is poised for further breakthroughs and innovations in the coming years.

Cambridge Enterprise Ltd.

Technical Solution: Cambridge Enterprise, representing the commercialization arm of the University of Cambridge, has been involved in the development and licensing of smart materials technologies based on geometric isomers. Their portfolio includes innovations in photochromic materials that utilize the cis-trans isomerization of azobenzene derivatives to create responsive coatings and films[10]. These materials have applications in smart windows, adaptive optics, and data storage. Cambridge researchers have also explored the use of geometric isomers in the design of molecular machines and nanoscale actuators, where controlled isomerization can be used to generate mechanical motion at the molecular level[11]. Furthermore, they have investigated the role of geometric isomers in the development of biocompatible smart materials for drug delivery and tissue engineering applications[12].

Strengths: Access to world-class research from the University of Cambridge, strong intellectual property portfolio, established technology transfer processes. Weaknesses: Potential challenges in bridging the gap between academic research and commercial applications, competition from other leading universities and research institutions.

Zhejiang University

Technical Solution: Zhejiang University has been at the forefront of research on geometric isomers in smart materials, particularly in the field of responsive polymers and nanocomposites. Their researchers have developed novel methods for synthesizing and controlling geometric isomers in liquid crystalline polymers, resulting in materials with tunable optical and mechanical properties[7]. They have also explored the use of geometric isomers in the design of shape-memory materials, where different isomeric forms can be used to program complex shape transformations in response to various stimuli such as heat, light, or pH changes[8]. Additionally, Zhejiang University has made advancements in the incorporation of geometric isomers into self-healing materials, where isomerization reactions can be triggered to repair damage and restore material properties[9].

Strengths: Strong focus on practical applications, collaboration with industry partners, expertise in polymer science and nanotechnology. Weaknesses: Potential challenges in scaling up laboratory-scale innovations, competition from other leading research institutions.

Innovative Geometric Isomer Designs for Enhanced Material Properties

Compounds and uses thereof

PatentPendingUS20230145003A1

Innovation

- Development of specific compounds that modulate the BAF complex by inhibiting BRG1 and/or BRM activity, which can be used alone or in combination with other pharmaceutically active agents to treat disorders like cancer.

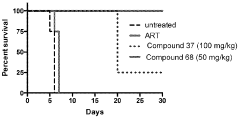

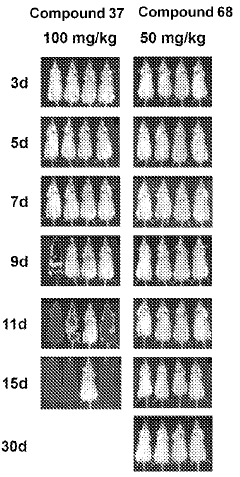

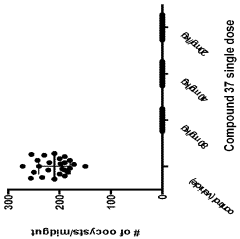

Compounds and methods for the treatment of malaria

PatentInactiveIN202118043692A

Innovation

- Development of specific compounds, such as those represented by Formula I and listed in Table 1, which offer new structural features and functional groups to target malaria parasites effectively, including those resistant to existing drugs.

Environmental Impact of Geometric Isomer-based Smart Materials

The environmental impact of geometric isomer-based smart materials is a critical consideration in their development and application. These materials, which leverage the unique properties of geometric isomers, have the potential to offer significant environmental benefits while also presenting certain challenges.

One of the primary environmental advantages of geometric isomer-based smart materials is their potential for energy efficiency. Many of these materials can respond to environmental stimuli, such as temperature or light, by changing their molecular configuration. This property can be harnessed in applications like smart windows, which can adjust their transparency based on sunlight intensity, potentially reducing the energy consumption of buildings for heating and cooling.

Furthermore, the reversible nature of geometric isomerization processes in these materials often leads to enhanced durability and longevity. This characteristic can contribute to a reduction in waste generation and resource consumption, as products incorporating these materials may require less frequent replacement or maintenance.

However, the environmental impact of these materials is not without concerns. The synthesis of geometric isomers often involves complex chemical processes that may require significant energy input and potentially harmful solvents. The environmental footprint of their production must be carefully evaluated and optimized to ensure that the benefits of their application outweigh the costs of their manufacture.

Another consideration is the end-of-life management of products containing geometric isomer-based smart materials. While these materials may offer extended product lifespans, their complex composition could pose challenges for recycling and disposal. Research into effective recycling methods and the development of biodegradable variants of these materials is crucial to mitigate potential environmental harm.

The use of geometric isomer-based smart materials in environmental sensing and remediation technologies presents an exciting avenue for positive environmental impact. These materials can be designed to detect and respond to specific pollutants, potentially aiding in environmental monitoring and cleanup efforts. For instance, smart materials that change color or shape in the presence of certain contaminants could serve as early warning systems for environmental pollution.

As the field of geometric isomer-based smart materials continues to evolve, it is imperative that lifecycle assessments be conducted to fully understand their environmental implications. This includes evaluating the sourcing of raw materials, energy consumption during production, performance benefits during use, and end-of-life management. Such comprehensive analyses will be crucial in guiding the sustainable development and application of these innovative materials.

One of the primary environmental advantages of geometric isomer-based smart materials is their potential for energy efficiency. Many of these materials can respond to environmental stimuli, such as temperature or light, by changing their molecular configuration. This property can be harnessed in applications like smart windows, which can adjust their transparency based on sunlight intensity, potentially reducing the energy consumption of buildings for heating and cooling.

Furthermore, the reversible nature of geometric isomerization processes in these materials often leads to enhanced durability and longevity. This characteristic can contribute to a reduction in waste generation and resource consumption, as products incorporating these materials may require less frequent replacement or maintenance.

However, the environmental impact of these materials is not without concerns. The synthesis of geometric isomers often involves complex chemical processes that may require significant energy input and potentially harmful solvents. The environmental footprint of their production must be carefully evaluated and optimized to ensure that the benefits of their application outweigh the costs of their manufacture.

Another consideration is the end-of-life management of products containing geometric isomer-based smart materials. While these materials may offer extended product lifespans, their complex composition could pose challenges for recycling and disposal. Research into effective recycling methods and the development of biodegradable variants of these materials is crucial to mitigate potential environmental harm.

The use of geometric isomer-based smart materials in environmental sensing and remediation technologies presents an exciting avenue for positive environmental impact. These materials can be designed to detect and respond to specific pollutants, potentially aiding in environmental monitoring and cleanup efforts. For instance, smart materials that change color or shape in the presence of certain contaminants could serve as early warning systems for environmental pollution.

As the field of geometric isomer-based smart materials continues to evolve, it is imperative that lifecycle assessments be conducted to fully understand their environmental implications. This includes evaluating the sourcing of raw materials, energy consumption during production, performance benefits during use, and end-of-life management. Such comprehensive analyses will be crucial in guiding the sustainable development and application of these innovative materials.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for smart materials utilizing geometric isomers present both challenges and opportunities. As these materials transition from laboratory-scale production to industrial manufacturing, several key factors must be addressed.

Firstly, the synthesis of geometric isomers often requires precise control over reaction conditions, including temperature, pressure, and catalyst concentrations. Scaling up these processes while maintaining the desired isomeric ratios can be complex. Advanced reactor designs and process control systems are essential to ensure consistent product quality at larger scales.

Material purity is another critical aspect. Separation and purification of geometric isomers can be challenging, especially when dealing with mixtures of multiple isomers. Industrial-scale chromatography, crystallization, or distillation techniques may need to be optimized to achieve the required purity levels cost-effectively.

The stability of geometric isomers during manufacturing and storage is also a significant consideration. Some isomers may be prone to interconversion or degradation under certain conditions. Developing robust stabilization methods and appropriate packaging solutions is crucial for maintaining product integrity throughout the supply chain.

Automation and process integration play vital roles in scaling up production. Continuous flow chemistry techniques offer promising solutions for the controlled synthesis of geometric isomers, allowing for better heat and mass transfer, improved safety, and increased productivity. Implementing such technologies requires significant investment in equipment and process development.

Quality control and characterization methods must be adapted for high-throughput manufacturing environments. Rapid analytical techniques, such as in-line spectroscopy or automated chromatography systems, are essential for monitoring isomeric composition and purity in real-time during production.

Cost considerations are paramount when scaling up smart materials based on geometric isomers. Optimizing raw material sourcing, reducing waste generation, and improving energy efficiency are critical for maintaining economic viability. Additionally, exploring alternative synthetic routes or developing novel catalysts may lead to more cost-effective production methods.

Regulatory compliance and safety considerations must be carefully addressed, particularly for materials intended for biomedical or environmental applications. Establishing robust documentation and traceability systems is essential for meeting regulatory requirements and ensuring product safety.

As the demand for smart materials grows, developing flexible and modular manufacturing platforms capable of producing a range of geometric isomer-based materials will be advantageous. This approach allows for rapid adaptation to market needs and facilitates the introduction of new products with minimal process modifications.

Firstly, the synthesis of geometric isomers often requires precise control over reaction conditions, including temperature, pressure, and catalyst concentrations. Scaling up these processes while maintaining the desired isomeric ratios can be complex. Advanced reactor designs and process control systems are essential to ensure consistent product quality at larger scales.

Material purity is another critical aspect. Separation and purification of geometric isomers can be challenging, especially when dealing with mixtures of multiple isomers. Industrial-scale chromatography, crystallization, or distillation techniques may need to be optimized to achieve the required purity levels cost-effectively.

The stability of geometric isomers during manufacturing and storage is also a significant consideration. Some isomers may be prone to interconversion or degradation under certain conditions. Developing robust stabilization methods and appropriate packaging solutions is crucial for maintaining product integrity throughout the supply chain.

Automation and process integration play vital roles in scaling up production. Continuous flow chemistry techniques offer promising solutions for the controlled synthesis of geometric isomers, allowing for better heat and mass transfer, improved safety, and increased productivity. Implementing such technologies requires significant investment in equipment and process development.

Quality control and characterization methods must be adapted for high-throughput manufacturing environments. Rapid analytical techniques, such as in-line spectroscopy or automated chromatography systems, are essential for monitoring isomeric composition and purity in real-time during production.

Cost considerations are paramount when scaling up smart materials based on geometric isomers. Optimizing raw material sourcing, reducing waste generation, and improving energy efficiency are critical for maintaining economic viability. Additionally, exploring alternative synthetic routes or developing novel catalysts may lead to more cost-effective production methods.

Regulatory compliance and safety considerations must be carefully addressed, particularly for materials intended for biomedical or environmental applications. Establishing robust documentation and traceability systems is essential for meeting regulatory requirements and ensuring product safety.

As the demand for smart materials grows, developing flexible and modular manufacturing platforms capable of producing a range of geometric isomer-based materials will be advantageous. This approach allows for rapid adaptation to market needs and facilitates the introduction of new products with minimal process modifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!