THz Imaging For Food Safety: Contaminant And Foreign Object Detection

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

THz Imaging Evolution and Food Safety Objectives

Terahertz (THz) imaging technology has evolved significantly over the past three decades, transitioning from laboratory curiosity to practical application. Initially developed in the 1990s as a non-destructive testing method, THz imaging leverages electromagnetic radiation in the frequency range of 0.1 to 10 THz, occupying the spectrum between microwave and infrared regions. This unique position grants THz waves distinctive properties: they can penetrate non-metallic materials while being non-ionizing and safe for biological tissues, unlike X-rays.

The evolution of THz imaging technology has been marked by several key milestones. Early systems in the 1990s utilized photoconductive antennas for THz generation and detection, but suffered from slow acquisition speeds and limited resolution. The 2000s witnessed significant advancements with the development of time-domain spectroscopy (TDS) systems, enabling both spectral and spatial information acquisition. Recent years have seen the emergence of compact, more affordable systems utilizing quantum cascade lasers and CMOS technology, dramatically improving accessibility and practical deployment potential.

In the context of food safety, THz imaging addresses critical challenges in contaminant and foreign object detection that conventional technologies struggle with. Current food inspection methods like X-ray, ultrasound, and optical imaging each have significant limitations: X-rays detect primarily dense materials but miss many plastic contaminants; ultrasound requires contact with food products; optical methods only detect surface contamination.

The primary objectives for THz imaging in food safety applications are multifaceted. First, to achieve reliable detection of diverse foreign objects including low-density materials like plastics, wood splinters, and organic contaminants that conventional technologies miss. Second, to enable non-destructive, non-contact inspection that preserves food integrity while maintaining production line speeds. Third, to develop systems capable of detecting contaminants within sealed packages, reducing waste and improving efficiency.

Additional objectives include miniaturization and cost reduction of THz systems to make the technology economically viable for widespread industry adoption. Current research also aims to improve imaging resolution below 100 micrometers and increase scanning speeds to match industrial production rates of up to 1-2 meters per second. The ultimate goal is to establish THz imaging as a complementary or replacement technology for existing food inspection methods, providing comprehensive safety assurance across the food production chain.

The evolution of THz imaging technology has been marked by several key milestones. Early systems in the 1990s utilized photoconductive antennas for THz generation and detection, but suffered from slow acquisition speeds and limited resolution. The 2000s witnessed significant advancements with the development of time-domain spectroscopy (TDS) systems, enabling both spectral and spatial information acquisition. Recent years have seen the emergence of compact, more affordable systems utilizing quantum cascade lasers and CMOS technology, dramatically improving accessibility and practical deployment potential.

In the context of food safety, THz imaging addresses critical challenges in contaminant and foreign object detection that conventional technologies struggle with. Current food inspection methods like X-ray, ultrasound, and optical imaging each have significant limitations: X-rays detect primarily dense materials but miss many plastic contaminants; ultrasound requires contact with food products; optical methods only detect surface contamination.

The primary objectives for THz imaging in food safety applications are multifaceted. First, to achieve reliable detection of diverse foreign objects including low-density materials like plastics, wood splinters, and organic contaminants that conventional technologies miss. Second, to enable non-destructive, non-contact inspection that preserves food integrity while maintaining production line speeds. Third, to develop systems capable of detecting contaminants within sealed packages, reducing waste and improving efficiency.

Additional objectives include miniaturization and cost reduction of THz systems to make the technology economically viable for widespread industry adoption. Current research also aims to improve imaging resolution below 100 micrometers and increase scanning speeds to match industrial production rates of up to 1-2 meters per second. The ultimate goal is to establish THz imaging as a complementary or replacement technology for existing food inspection methods, providing comprehensive safety assurance across the food production chain.

Market Demand for Advanced Food Contaminant Detection

The global food safety testing market has witnessed substantial growth in recent years, driven by increasing consumer awareness, stringent regulatory frameworks, and high-profile food contamination incidents. According to market research, the global food safety testing market was valued at approximately $19.7 billion in 2021 and is projected to reach $32.5 billion by 2027, growing at a CAGR of 8.1% during the forecast period.

Foreign object detection represents a critical segment within this market, with traditional detection methods like metal detection and X-ray imaging showing limitations in identifying non-metallic contaminants such as plastics, glass fragments, wood splinters, and organic matter. These limitations have created a significant demand gap that THz imaging technology is uniquely positioned to address.

Food processing companies face mounting pressure from both regulatory bodies and consumers to implement more comprehensive inspection systems. The FDA's Food Safety Modernization Act (FSMA) in the United States and similar regulations worldwide have shifted focus from responding to contamination to preventing it, necessitating more advanced detection technologies throughout the production chain.

Consumer expectations regarding food safety have reached unprecedented levels, with 78% of consumers in developed markets indicating they would switch brands after a food safety incident. This consumer sentiment has pushed food manufacturers to invest in cutting-edge inspection technologies that can detect a wider range of contaminants with greater accuracy.

The economic impact of food recalls presents another significant market driver. The average cost of a food recall to a company exceeds $10 million in direct costs alone, not including brand damage and lost sales. Implementing advanced detection systems like THz imaging represents a compelling return on investment when compared to these potential losses.

Specific industry segments demonstrate particularly strong demand for advanced contaminant detection. The ready-to-eat meals sector, with its complex production processes and multiple ingredients, shows heightened vulnerability to contamination. Similarly, the baby food segment, where safety standards are exceptionally stringent, presents a premium market opportunity for THz imaging solutions.

Geographically, North America and Europe currently lead in adoption of advanced food safety technologies, driven by strict regulatory environments and high consumer awareness. However, rapidly developing markets in Asia-Pacific, particularly China and India, are expected to show the highest growth rates as their food export industries seek to meet international standards and domestic consumers increasingly demand safer food products.

Foreign object detection represents a critical segment within this market, with traditional detection methods like metal detection and X-ray imaging showing limitations in identifying non-metallic contaminants such as plastics, glass fragments, wood splinters, and organic matter. These limitations have created a significant demand gap that THz imaging technology is uniquely positioned to address.

Food processing companies face mounting pressure from both regulatory bodies and consumers to implement more comprehensive inspection systems. The FDA's Food Safety Modernization Act (FSMA) in the United States and similar regulations worldwide have shifted focus from responding to contamination to preventing it, necessitating more advanced detection technologies throughout the production chain.

Consumer expectations regarding food safety have reached unprecedented levels, with 78% of consumers in developed markets indicating they would switch brands after a food safety incident. This consumer sentiment has pushed food manufacturers to invest in cutting-edge inspection technologies that can detect a wider range of contaminants with greater accuracy.

The economic impact of food recalls presents another significant market driver. The average cost of a food recall to a company exceeds $10 million in direct costs alone, not including brand damage and lost sales. Implementing advanced detection systems like THz imaging represents a compelling return on investment when compared to these potential losses.

Specific industry segments demonstrate particularly strong demand for advanced contaminant detection. The ready-to-eat meals sector, with its complex production processes and multiple ingredients, shows heightened vulnerability to contamination. Similarly, the baby food segment, where safety standards are exceptionally stringent, presents a premium market opportunity for THz imaging solutions.

Geographically, North America and Europe currently lead in adoption of advanced food safety technologies, driven by strict regulatory environments and high consumer awareness. However, rapidly developing markets in Asia-Pacific, particularly China and India, are expected to show the highest growth rates as their food export industries seek to meet international standards and domestic consumers increasingly demand safer food products.

Current THz Imaging Capabilities and Limitations

Terahertz (THz) imaging technology has demonstrated significant potential for food safety applications, particularly in detecting contaminants and foreign objects. Current THz imaging systems operate in the frequency range of 0.1-10 THz, occupying the electromagnetic spectrum between microwave and infrared regions. This unique spectral position provides THz imaging with distinctive capabilities for non-destructive and non-ionizing inspection of food products.

The primary advantage of THz imaging lies in its ability to penetrate non-metallic packaging materials while being highly sensitive to water content. This enables the detection of various contaminants including metal fragments, glass shards, plastic pieces, insects, and certain chemical contaminants that may be invisible to conventional imaging techniques. Modern THz systems can achieve spatial resolutions ranging from 0.5 to 2 mm, depending on the specific configuration and frequency used.

Current THz imaging systems employ two main approaches: continuous-wave (CW) and pulsed THz imaging. CW systems offer higher signal-to-noise ratios and faster acquisition speeds but provide limited depth information. Pulsed THz systems, while slower, can generate depth profiles through time-domain analysis, enabling three-dimensional inspection capabilities critical for identifying contaminants embedded within food products.

Despite these promising capabilities, THz imaging faces several significant limitations. The technology struggles with highly hydrated or thick food products due to strong water absorption of THz radiation. This restricts its application primarily to dry, low-moisture foods or thin-sliced products. The penetration depth typically ranges from a few millimeters to approximately 1 cm in low-moisture foods, severely limiting inspection capabilities for larger food items.

Speed remains another critical limitation. Current commercial THz imaging systems operate at scanning rates that are too slow for high-throughput food processing lines, which typically require inspection speeds of several meters per second. Most laboratory THz systems achieve scanning rates of only a few centimeters per second, creating a significant barrier to industrial adoption.

Cost factors present additional challenges, with high-performance THz imaging systems ranging from $100,000 to over $500,000, making them substantially more expensive than conventional food inspection technologies like X-ray or optical systems. The complexity of THz components, including specialized sources and detectors, contributes significantly to these high costs.

Data processing capabilities also present limitations, as the interpretation of THz images requires sophisticated algorithms to distinguish between normal product variations and actual contaminants. Current systems still struggle with high false-positive rates, particularly in heterogeneous food products with varying moisture content or complex internal structures.

The primary advantage of THz imaging lies in its ability to penetrate non-metallic packaging materials while being highly sensitive to water content. This enables the detection of various contaminants including metal fragments, glass shards, plastic pieces, insects, and certain chemical contaminants that may be invisible to conventional imaging techniques. Modern THz systems can achieve spatial resolutions ranging from 0.5 to 2 mm, depending on the specific configuration and frequency used.

Current THz imaging systems employ two main approaches: continuous-wave (CW) and pulsed THz imaging. CW systems offer higher signal-to-noise ratios and faster acquisition speeds but provide limited depth information. Pulsed THz systems, while slower, can generate depth profiles through time-domain analysis, enabling three-dimensional inspection capabilities critical for identifying contaminants embedded within food products.

Despite these promising capabilities, THz imaging faces several significant limitations. The technology struggles with highly hydrated or thick food products due to strong water absorption of THz radiation. This restricts its application primarily to dry, low-moisture foods or thin-sliced products. The penetration depth typically ranges from a few millimeters to approximately 1 cm in low-moisture foods, severely limiting inspection capabilities for larger food items.

Speed remains another critical limitation. Current commercial THz imaging systems operate at scanning rates that are too slow for high-throughput food processing lines, which typically require inspection speeds of several meters per second. Most laboratory THz systems achieve scanning rates of only a few centimeters per second, creating a significant barrier to industrial adoption.

Cost factors present additional challenges, with high-performance THz imaging systems ranging from $100,000 to over $500,000, making them substantially more expensive than conventional food inspection technologies like X-ray or optical systems. The complexity of THz components, including specialized sources and detectors, contributes significantly to these high costs.

Data processing capabilities also present limitations, as the interpretation of THz images requires sophisticated algorithms to distinguish between normal product variations and actual contaminants. Current systems still struggle with high false-positive rates, particularly in heterogeneous food products with varying moisture content or complex internal structures.

Existing THz Detection Methods for Foreign Objects

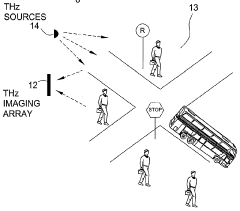

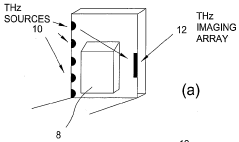

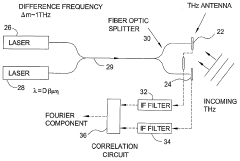

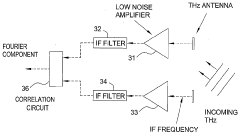

01 THz imaging systems for contaminant detection

Terahertz (THz) imaging systems can be used to detect contaminants and foreign objects in various materials. These systems utilize THz radiation, which can penetrate through many non-metallic materials while being absorbed or reflected by others, making it ideal for detecting hidden contaminants. The systems typically include THz sources, detectors, and image processing algorithms to identify anomalies that may represent contaminants or foreign objects.- THz imaging systems for contaminant detection in food products: Terahertz imaging systems can be used to detect contaminants and foreign objects in food products. These systems utilize THz radiation to penetrate packaging materials while providing high contrast between food products and foreign materials such as plastics, metals, or glass. The technology enables non-destructive inspection of packaged foods on production lines, enhancing food safety by identifying potentially harmful contaminants before products reach consumers.

- Advanced THz imaging techniques for improved detection sensitivity: Advanced terahertz imaging techniques have been developed to enhance detection sensitivity for contaminants and foreign objects. These techniques include spectroscopic imaging, polarization-sensitive imaging, and time-domain spectroscopy that can differentiate between materials based on their unique THz absorption and reflection characteristics. These methods improve the ability to detect small or concealed contaminants that might be missed by conventional imaging technologies.

- Portable and real-time THz imaging devices for contaminant detection: Portable and real-time terahertz imaging devices have been developed for on-site contaminant and foreign object detection. These systems are designed to be compact, user-friendly, and capable of providing immediate results in industrial environments. The technology enables rapid scanning of products on production lines or in storage facilities, allowing for quick identification and removal of contaminated items without disrupting operations.

- Multi-spectral THz imaging for enhanced foreign object discrimination: Multi-spectral terahertz imaging combines multiple frequency bands to enhance the discrimination between different types of foreign objects and contaminants. By analyzing the response of materials across various THz frequencies, these systems can better characterize and identify specific contaminants based on their unique spectral signatures. This approach reduces false positives and improves detection accuracy for a wide range of foreign materials in different product matrices.

- AI and machine learning integration with THz imaging for automated contaminant detection: Artificial intelligence and machine learning algorithms have been integrated with terahertz imaging systems to automate the detection and classification of contaminants and foreign objects. These intelligent systems can learn to recognize patterns associated with various types of contaminants, improving detection accuracy over time. The technology reduces the need for human interpretation of complex THz images and enables high-throughput screening in industrial applications.

02 Food safety applications of THz imaging

THz imaging technology is particularly valuable in food safety applications for detecting contaminants and foreign objects in food products. The non-ionizing nature of THz radiation makes it safe for food inspection without affecting quality. These systems can detect various contaminants including plastic, glass, metal fragments, and biological contaminants that might be invisible to conventional inspection methods, helping to ensure food safety standards are met during processing and packaging.Expand Specific Solutions03 Advanced signal processing for THz contaminant detection

Advanced signal processing techniques enhance the effectiveness of THz imaging for contaminant detection. These methods include machine learning algorithms, artificial intelligence, and specialized image processing that can distinguish between normal material variations and actual contaminants. By analyzing spectral signatures and spatial patterns in the THz data, these processing techniques can improve detection accuracy, reduce false positives, and enable real-time identification of foreign objects even in complex materials.Expand Specific Solutions04 Portable and inline THz inspection systems

Portable and inline THz inspection systems allow for flexible deployment in various industrial settings for contaminant detection. These systems are designed for integration into production lines for continuous monitoring or as handheld devices for spot-checking. They feature compact THz sources and detectors, optimized for speed and reliability in industrial environments, enabling non-destructive testing without disrupting production processes. Such systems provide immediate feedback on the presence of foreign objects, allowing for quick remediation.Expand Specific Solutions05 Multi-spectral and hybrid THz detection approaches

Multi-spectral and hybrid approaches combine THz imaging with other sensing technologies to enhance contaminant detection capabilities. These systems integrate THz with technologies such as infrared, X-ray, or optical imaging to provide complementary data. By leveraging the strengths of multiple detection methods, these hybrid systems can identify a wider range of contaminants and foreign objects with greater accuracy than single-technology approaches, particularly in complex materials where one method alone might be insufficient.Expand Specific Solutions

Leading Companies in THz Food Safety Solutions

THz imaging for food safety is emerging as a critical technology in the early growth phase of the food safety inspection market, which is projected to reach $24 billion by 2026. The technology demonstrates moderate maturity with significant advancements from key players across academic and industrial sectors. Leading research institutions like Tsinghua University, Zhejiang University, and Fraunhofer-Gesellschaft are driving fundamental innovations, while commercial entities including Nuctech, Nikon, and Sumitomo Electric are developing practical applications. Japanese companies such as Mayekawa MFG and Nikka Densok are particularly active in integrating THz imaging into food processing lines. The competitive landscape shows a balanced distribution between specialized equipment manufacturers and larger conglomerates, with increasing collaboration between academic institutions and industry partners to accelerate commercialization of this non-destructive inspection technology.

Battelle Memorial Institute

Technical Solution: Battelle has pioneered a comprehensive THz imaging platform for food safety that combines broadband THz spectroscopy with advanced image processing algorithms. Their system operates in the 0.3-3 THz range and utilizes both transmission and reflection modes to maximize detection capabilities across various food types. The technology incorporates a proprietary database of THz spectral signatures for common contaminants, enabling rapid identification of foreign objects as small as 0.5mm in size. Battelle's approach includes adaptive learning algorithms that continuously improve detection accuracy based on historical data, reducing false alarms over time. Their system architecture features modular components that can be customized for different food processing lines, from dry goods to dairy products, with specialized configurations for challenging food matrices like heterogeneous or high-fat content products.

Strengths: Exceptional sensitivity for detecting small contaminants; versatile application across multiple food types; continuous improvement through machine learning capabilities. Weaknesses: Complex calibration requirements for different food products; higher power consumption compared to some competing technologies; performance limitations in extremely high-speed processing environments.

NUCTECH Co., Ltd.

Technical Solution: NUCTECH has developed advanced THz imaging systems specifically for food safety applications, utilizing both passive and active THz imaging techniques. Their technology employs frequency ranges between 0.1-10 THz to detect various contaminants including metal fragments, glass, plastics, and organic materials that may be invisible to conventional inspection methods. The company's proprietary THz spectral imaging can identify chemical composition differences between food products and foreign objects based on their unique spectral signatures. NUCTECH's systems incorporate real-time processing algorithms that can analyze THz images at production line speeds (up to 60 meters per minute), making them suitable for industrial food processing environments. Their latest generation systems feature multi-angle THz imaging capabilities that significantly reduce false positives by providing 3D representations of detected anomalies.

Strengths: Superior detection capabilities for non-metallic contaminants that traditional methods miss; non-destructive and non-ionizing inspection process; high throughput suitable for industrial applications. Weaknesses: Higher initial equipment cost compared to conventional technologies; requires specialized technical expertise for maintenance and calibration; detection performance can be affected by high moisture content in certain food products.

Key Patents in THz Food Contaminant Detection

Meat product foreign body on-line detection system based on terahertz imaging and detection method

PatentActiveCN109001216A

Innovation

- Using an online detection system based on terahertz spectrum imaging technology, combined with visible light imaging and terahertz spectrum imaging units, through visual image processing and terahertz image processing, the identification and positioning of foreign matter in meat products is achieved, using linear terahertz light sources and The detector increases the detection speed, acquires transmission and reflection images, expands the detection area, and reduces misjudgments.

Terahertz imaging for near field objects

PatentWO2005112130A2

Innovation

- A Terahertz imaging system with a curved interferometric detector array that matches the curvature of the wave front, either through a physically curved surface or adjustable detector elements, to correct for the distortion caused by curved wave fronts in near-field imaging.

Integration with Food Processing Production Lines

The integration of THz imaging systems into existing food processing production lines represents a critical challenge for widespread industrial adoption. Current food production facilities operate at high speeds, with conveyor systems moving products at rates of 1-3 meters per second. THz imaging systems must therefore be engineered to capture and process images at these velocities without compromising detection accuracy or throughput.

Several architectural approaches have emerged for production line integration. The inline configuration positions THz scanners directly above conveyor belts, requiring compact form factors and robust vibration resistance. Alternatively, side-stream configurations divert random samples for more thorough inspection, offering deeper analysis but sacrificing comprehensive screening. The choice between these approaches depends on production volume, contamination risk profiles, and regulatory requirements.

Data processing infrastructure presents another integration consideration. Real-time THz image analysis demands significant computational resources, necessitating edge computing solutions positioned near scanning points. These systems must interface with existing production management software while maintaining compliance with food industry data standards and traceability requirements.

Physical installation constraints include limited space availability, harsh environmental conditions (temperature fluctuations, humidity, cleaning chemicals), and electromagnetic interference from nearby machinery. THz systems require appropriate shielding and environmental controls to maintain calibration and performance stability. Additionally, retrofitting existing lines typically proves more challenging than designing new production facilities with THz imaging capabilities incorporated from inception.

Operational integration must address maintenance accessibility, calibration procedures, and cleaning protocols. Systems should feature modular designs allowing for rapid component replacement to minimize downtime. Self-diagnostic capabilities that alert operators to performance degradation before failure occurs represent an emerging best practice in advanced implementations.

Cost considerations remain significant, with current integration expenses ranging from $150,000 to $500,000 depending on production line complexity and throughput requirements. Return on investment calculations must account for reduced recall risks, enhanced quality assurance, and potential insurance premium reductions. Industry leaders have reported break-even periods of 18-36 months for comprehensive THz imaging integration projects.

Several architectural approaches have emerged for production line integration. The inline configuration positions THz scanners directly above conveyor belts, requiring compact form factors and robust vibration resistance. Alternatively, side-stream configurations divert random samples for more thorough inspection, offering deeper analysis but sacrificing comprehensive screening. The choice between these approaches depends on production volume, contamination risk profiles, and regulatory requirements.

Data processing infrastructure presents another integration consideration. Real-time THz image analysis demands significant computational resources, necessitating edge computing solutions positioned near scanning points. These systems must interface with existing production management software while maintaining compliance with food industry data standards and traceability requirements.

Physical installation constraints include limited space availability, harsh environmental conditions (temperature fluctuations, humidity, cleaning chemicals), and electromagnetic interference from nearby machinery. THz systems require appropriate shielding and environmental controls to maintain calibration and performance stability. Additionally, retrofitting existing lines typically proves more challenging than designing new production facilities with THz imaging capabilities incorporated from inception.

Operational integration must address maintenance accessibility, calibration procedures, and cleaning protocols. Systems should feature modular designs allowing for rapid component replacement to minimize downtime. Self-diagnostic capabilities that alert operators to performance degradation before failure occurs represent an emerging best practice in advanced implementations.

Cost considerations remain significant, with current integration expenses ranging from $150,000 to $500,000 depending on production line complexity and throughput requirements. Return on investment calculations must account for reduced recall risks, enhanced quality assurance, and potential insurance premium reductions. Industry leaders have reported break-even periods of 18-36 months for comprehensive THz imaging integration projects.

Regulatory Standards for Food Safety Inspection Technologies

The regulatory landscape for food safety inspection technologies is complex and continuously evolving to address emerging threats and technological advancements. In the context of THz imaging for contaminant and foreign object detection, several key regulatory frameworks govern implementation and compliance requirements.

The U.S. Food and Drug Administration (FDA) has established guidelines under the Food Safety Modernization Act (FSMA) that emphasize preventive controls rather than reactive measures. These regulations require food manufacturers to implement science-based preventive controls, including appropriate testing technologies for foreign object detection. While THz imaging is not explicitly mentioned in current FDA guidelines, it falls under the broader category of "novel detection technologies" that must demonstrate reliability, accuracy, and consistency in identifying contaminants.

European Food Safety Authority (EFSA) regulations are generally more prescriptive, with specific requirements outlined in EC Regulation 852/2004 on food hygiene and EC Regulation 178/2002 on general food safety principles. These frameworks mandate hazard analysis and critical control points (HACCP) systems that must incorporate effective detection methods for physical contaminants.

International standards such as ISO 22000 for food safety management systems provide additional guidance on validation protocols for inspection technologies. For THz imaging systems to achieve regulatory compliance, they must meet performance criteria including minimum detection thresholds, false positive/negative rates, and operational reliability under varying environmental conditions.

Japan's Ministry of Health, Labour and Welfare has recently updated its inspection technology guidelines to include specific parameters for non-destructive testing methods, potentially creating a pathway for THz imaging adoption. Similarly, China's National Food Safety Standard GB 14881-2013 outlines requirements for food production facilities that increasingly emphasize advanced detection capabilities.

Regulatory bodies are currently addressing the validation gap for emerging technologies like THz imaging. The Codex Alimentarius Commission is developing standardized protocols specifically for non-destructive imaging technologies in food inspection, expected to be finalized within the next two years. These standards will likely establish performance benchmarks, calibration requirements, and verification procedures.

For THz imaging technology developers, navigating this regulatory environment requires ongoing engagement with standards organizations and regulatory bodies. Successful implementation will depend on generating validation data that demonstrates compliance with both current requirements and anticipated future standards.

The U.S. Food and Drug Administration (FDA) has established guidelines under the Food Safety Modernization Act (FSMA) that emphasize preventive controls rather than reactive measures. These regulations require food manufacturers to implement science-based preventive controls, including appropriate testing technologies for foreign object detection. While THz imaging is not explicitly mentioned in current FDA guidelines, it falls under the broader category of "novel detection technologies" that must demonstrate reliability, accuracy, and consistency in identifying contaminants.

European Food Safety Authority (EFSA) regulations are generally more prescriptive, with specific requirements outlined in EC Regulation 852/2004 on food hygiene and EC Regulation 178/2002 on general food safety principles. These frameworks mandate hazard analysis and critical control points (HACCP) systems that must incorporate effective detection methods for physical contaminants.

International standards such as ISO 22000 for food safety management systems provide additional guidance on validation protocols for inspection technologies. For THz imaging systems to achieve regulatory compliance, they must meet performance criteria including minimum detection thresholds, false positive/negative rates, and operational reliability under varying environmental conditions.

Japan's Ministry of Health, Labour and Welfare has recently updated its inspection technology guidelines to include specific parameters for non-destructive testing methods, potentially creating a pathway for THz imaging adoption. Similarly, China's National Food Safety Standard GB 14881-2013 outlines requirements for food production facilities that increasingly emphasize advanced detection capabilities.

Regulatory bodies are currently addressing the validation gap for emerging technologies like THz imaging. The Codex Alimentarius Commission is developing standardized protocols specifically for non-destructive imaging technologies in food inspection, expected to be finalized within the next two years. These standards will likely establish performance benchmarks, calibration requirements, and verification procedures.

For THz imaging technology developers, navigating this regulatory environment requires ongoing engagement with standards organizations and regulatory bodies. Successful implementation will depend on generating validation data that demonstrates compliance with both current requirements and anticipated future standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!