Unveiling the Next Generation of Half Wave Rectifiers

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Evolution and Objectives

Half wave rectifiers have been a fundamental component in electronic circuits since the early days of electrical engineering. Their evolution has been closely tied to the advancement of semiconductor technology and the growing demands for more efficient power conversion systems. The journey of half wave rectifiers began with simple diode-based designs, which were effective but limited in their efficiency and application scope.

As technology progressed, the objectives for half wave rectifiers expanded beyond basic AC to DC conversion. Engineers sought to improve power efficiency, reduce harmonics, and minimize voltage drop across the rectifying element. These goals led to the development of more sophisticated rectifier designs, incorporating advanced semiconductor materials and novel circuit topologies.

The advent of silicon-based semiconductors in the mid-20th century marked a significant milestone in rectifier technology. Silicon diodes offered superior performance compared to their predecessors, enabling higher current handling capabilities and lower forward voltage drops. This advancement paved the way for more compact and efficient rectifier designs, expanding their use in a wide range of applications from consumer electronics to industrial power systems.

In recent decades, the focus has shifted towards addressing the limitations of traditional half wave rectifiers. One key objective has been to mitigate the inherent inefficiency of half wave rectification, where only one half of the AC cycle is utilized. This led to the exploration of synchronous rectification techniques, which employ actively controlled switches to improve efficiency and reduce power losses.

Another important goal in the evolution of half wave rectifiers has been the reduction of electromagnetic interference (EMI) and harmonic distortion. As electronic devices became more sensitive and regulatory standards more stringent, the need for cleaner power conversion became paramount. This drove research into soft-switching techniques and advanced filtering methods to minimize the generation of high-frequency noise and harmonics.

The miniaturization trend in electronics has also influenced rectifier development. Engineers have been working on integrating rectifier circuits into smaller packages, often combining them with other power management functions. This integration aims to reduce overall system size, improve reliability, and lower manufacturing costs.

Looking towards the future, the objectives for next-generation half wave rectifiers are becoming even more ambitious. There is a growing emphasis on developing "smart" rectifiers that can adapt to varying load conditions and input voltages, optimizing their performance in real-time. Additionally, researchers are exploring the use of wide-bandgap semiconductors, such as silicon carbide and gallium nitride, to push the boundaries of rectifier efficiency and power density.

As technology progressed, the objectives for half wave rectifiers expanded beyond basic AC to DC conversion. Engineers sought to improve power efficiency, reduce harmonics, and minimize voltage drop across the rectifying element. These goals led to the development of more sophisticated rectifier designs, incorporating advanced semiconductor materials and novel circuit topologies.

The advent of silicon-based semiconductors in the mid-20th century marked a significant milestone in rectifier technology. Silicon diodes offered superior performance compared to their predecessors, enabling higher current handling capabilities and lower forward voltage drops. This advancement paved the way for more compact and efficient rectifier designs, expanding their use in a wide range of applications from consumer electronics to industrial power systems.

In recent decades, the focus has shifted towards addressing the limitations of traditional half wave rectifiers. One key objective has been to mitigate the inherent inefficiency of half wave rectification, where only one half of the AC cycle is utilized. This led to the exploration of synchronous rectification techniques, which employ actively controlled switches to improve efficiency and reduce power losses.

Another important goal in the evolution of half wave rectifiers has been the reduction of electromagnetic interference (EMI) and harmonic distortion. As electronic devices became more sensitive and regulatory standards more stringent, the need for cleaner power conversion became paramount. This drove research into soft-switching techniques and advanced filtering methods to minimize the generation of high-frequency noise and harmonics.

The miniaturization trend in electronics has also influenced rectifier development. Engineers have been working on integrating rectifier circuits into smaller packages, often combining them with other power management functions. This integration aims to reduce overall system size, improve reliability, and lower manufacturing costs.

Looking towards the future, the objectives for next-generation half wave rectifiers are becoming even more ambitious. There is a growing emphasis on developing "smart" rectifiers that can adapt to varying load conditions and input voltages, optimizing their performance in real-time. Additionally, researchers are exploring the use of wide-bandgap semiconductors, such as silicon carbide and gallium nitride, to push the boundaries of rectifier efficiency and power density.

Market Demand Analysis for Advanced Rectification

The market demand for advanced rectification technologies, particularly in the realm of half-wave rectifiers, has been experiencing significant growth driven by the increasing need for efficient power conversion and management across various industries. The global power electronics market, which encompasses rectification technologies, is projected to reach substantial market value in the coming years, with a considerable portion attributed to advancements in rectification systems.

The automotive sector stands out as a key driver for this demand, particularly with the rapid expansion of electric vehicles (EVs) and hybrid electric vehicles (HEVs). These vehicles require sophisticated power management systems, where advanced half-wave rectifiers play a crucial role in converting AC to DC power efficiently. The growing adoption of EVs worldwide is creating a surge in demand for high-performance rectification solutions that can handle higher power densities while maintaining optimal efficiency.

In the renewable energy sector, the integration of solar and wind power into the grid necessitates advanced rectification technologies. As the world shifts towards cleaner energy sources, the need for efficient power conversion becomes paramount. Half-wave rectifiers with improved characteristics are essential for maximizing energy harvest from these intermittent sources and ensuring smooth grid integration.

The consumer electronics industry also contributes significantly to the market demand for advanced rectification. With the proliferation of smart devices, wearables, and Internet of Things (IoT) applications, there is a growing need for compact, efficient power management solutions. Next-generation half-wave rectifiers that offer higher efficiency and smaller form factors are highly sought after in this segment.

Industrial automation and robotics represent another substantial market for advanced rectification technologies. As factories become increasingly automated, the demand for precise power control and conversion grows. Advanced half-wave rectifiers that can handle high-frequency switching and provide clean DC output are crucial for ensuring the reliability and performance of industrial equipment.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, is driving demand for advanced power management solutions. Base stations and network infrastructure require efficient rectification to manage power consumption and maintain network reliability. This sector's expansion is expected to contribute significantly to the growth of the advanced rectification market.

In the healthcare industry, medical devices and diagnostic equipment rely on stable and efficient power supplies. Advanced half-wave rectifiers that can provide clean, reliable power are essential for ensuring the accuracy and safety of these critical devices. As healthcare technology continues to advance, the demand for sophisticated rectification solutions is expected to increase.

The aerospace and defense sectors also present significant opportunities for advanced rectification technologies. These industries require high-reliability power conversion solutions capable of operating in extreme conditions. The development of next-generation half-wave rectifiers that can meet these stringent requirements is likely to drive innovation and market growth in this segment.

The automotive sector stands out as a key driver for this demand, particularly with the rapid expansion of electric vehicles (EVs) and hybrid electric vehicles (HEVs). These vehicles require sophisticated power management systems, where advanced half-wave rectifiers play a crucial role in converting AC to DC power efficiently. The growing adoption of EVs worldwide is creating a surge in demand for high-performance rectification solutions that can handle higher power densities while maintaining optimal efficiency.

In the renewable energy sector, the integration of solar and wind power into the grid necessitates advanced rectification technologies. As the world shifts towards cleaner energy sources, the need for efficient power conversion becomes paramount. Half-wave rectifiers with improved characteristics are essential for maximizing energy harvest from these intermittent sources and ensuring smooth grid integration.

The consumer electronics industry also contributes significantly to the market demand for advanced rectification. With the proliferation of smart devices, wearables, and Internet of Things (IoT) applications, there is a growing need for compact, efficient power management solutions. Next-generation half-wave rectifiers that offer higher efficiency and smaller form factors are highly sought after in this segment.

Industrial automation and robotics represent another substantial market for advanced rectification technologies. As factories become increasingly automated, the demand for precise power control and conversion grows. Advanced half-wave rectifiers that can handle high-frequency switching and provide clean DC output are crucial for ensuring the reliability and performance of industrial equipment.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, is driving demand for advanced power management solutions. Base stations and network infrastructure require efficient rectification to manage power consumption and maintain network reliability. This sector's expansion is expected to contribute significantly to the growth of the advanced rectification market.

In the healthcare industry, medical devices and diagnostic equipment rely on stable and efficient power supplies. Advanced half-wave rectifiers that can provide clean, reliable power are essential for ensuring the accuracy and safety of these critical devices. As healthcare technology continues to advance, the demand for sophisticated rectification solutions is expected to increase.

The aerospace and defense sectors also present significant opportunities for advanced rectification technologies. These industries require high-reliability power conversion solutions capable of operating in extreme conditions. The development of next-generation half-wave rectifiers that can meet these stringent requirements is likely to drive innovation and market growth in this segment.

Current Challenges in Half Wave Rectification

Half wave rectification, while a fundamental technique in power electronics, faces several challenges in modern applications. The primary issue lies in its inherent inefficiency, as it only utilizes half of the input waveform. This results in significant power loss and reduced overall system efficiency, which is particularly problematic in energy-sensitive applications.

Another major challenge is the presence of ripple in the output voltage. The pulsating nature of half wave rectification produces a DC output with considerable AC ripple, necessitating additional filtering components. This not only increases circuit complexity but also adds to the overall cost and size of the system, making it less suitable for compact and cost-sensitive designs.

The non-linear behavior of half wave rectifiers presents difficulties in maintaining power quality. The rectification process introduces harmonic distortion into the power system, potentially causing electromagnetic interference (EMI) and affecting the performance of nearby electronic equipment. This issue becomes more pronounced in high-power applications or when multiple rectifiers are used in close proximity.

Voltage regulation is another significant challenge. The output voltage of a half wave rectifier is highly dependent on the load current, leading to poor voltage regulation. This characteristic makes it challenging to maintain a stable output voltage across varying load conditions, limiting its applicability in precision electronics or systems requiring consistent power delivery.

The reverse recovery time of diodes used in half wave rectifiers also poses a challenge, especially in high-frequency applications. During the transition from forward to reverse bias, diodes require a finite time to stop conducting, leading to switching losses and reduced efficiency at higher frequencies. This limitation becomes more critical as modern power systems trend towards higher switching frequencies for improved performance and miniaturization.

Furthermore, the unidirectional current flow in half wave rectifiers can lead to DC magnetization of transformers when used in AC-DC conversion systems. This phenomenon can cause core saturation, reducing the transformer's efficiency and potentially leading to overheating and failure.

Lastly, the environmental impact of half wave rectifiers is becoming an increasing concern. Their lower efficiency compared to full wave rectifiers or more advanced topologies results in higher energy consumption and increased heat generation. This not only affects the carbon footprint of electronic devices but also poses challenges in thermal management, particularly in compact or high-density applications.

Another major challenge is the presence of ripple in the output voltage. The pulsating nature of half wave rectification produces a DC output with considerable AC ripple, necessitating additional filtering components. This not only increases circuit complexity but also adds to the overall cost and size of the system, making it less suitable for compact and cost-sensitive designs.

The non-linear behavior of half wave rectifiers presents difficulties in maintaining power quality. The rectification process introduces harmonic distortion into the power system, potentially causing electromagnetic interference (EMI) and affecting the performance of nearby electronic equipment. This issue becomes more pronounced in high-power applications or when multiple rectifiers are used in close proximity.

Voltage regulation is another significant challenge. The output voltage of a half wave rectifier is highly dependent on the load current, leading to poor voltage regulation. This characteristic makes it challenging to maintain a stable output voltage across varying load conditions, limiting its applicability in precision electronics or systems requiring consistent power delivery.

The reverse recovery time of diodes used in half wave rectifiers also poses a challenge, especially in high-frequency applications. During the transition from forward to reverse bias, diodes require a finite time to stop conducting, leading to switching losses and reduced efficiency at higher frequencies. This limitation becomes more critical as modern power systems trend towards higher switching frequencies for improved performance and miniaturization.

Furthermore, the unidirectional current flow in half wave rectifiers can lead to DC magnetization of transformers when used in AC-DC conversion systems. This phenomenon can cause core saturation, reducing the transformer's efficiency and potentially leading to overheating and failure.

Lastly, the environmental impact of half wave rectifiers is becoming an increasing concern. Their lower efficiency compared to full wave rectifiers or more advanced topologies results in higher energy consumption and increased heat generation. This not only affects the carbon footprint of electronic devices but also poses challenges in thermal management, particularly in compact or high-density applications.

State-of-the-Art Half Wave Rectifier Designs

01 Circuit design for half-wave rectifiers

Half-wave rectifiers are designed to convert alternating current (AC) to pulsating direct current (DC). The circuit typically consists of a diode that allows current to flow in one direction during the positive half-cycle of the AC input, while blocking the negative half-cycle. This results in a pulsating DC output that can be further smoothed with additional components.- Circuit design for half-wave rectifiers: Half-wave rectifiers are designed to convert alternating current (AC) to pulsating direct current (DC) by allowing current flow in only one direction. The circuit typically consists of a diode and a load resistor. During the positive half-cycle of the AC input, the diode conducts, allowing current to flow through the load. During the negative half-cycle, the diode blocks current flow, resulting in a pulsating DC output.

- Efficiency improvements in half-wave rectifiers: Various techniques are employed to improve the efficiency of half-wave rectifiers. These may include the use of high-speed switching diodes, optimized circuit layouts to reduce parasitic capacitance, and the implementation of snubber circuits to suppress voltage spikes. Some designs incorporate synchronous rectification, where MOSFETs replace diodes to reduce forward voltage drop and improve overall efficiency.

- Applications of half-wave rectifiers in power supplies: Half-wave rectifiers find applications in various power supply designs, particularly in low-power or cost-sensitive applications. They are used in simple AC adapters, battery chargers, and some types of voltage regulators. In some cases, half-wave rectifiers are combined with voltage doubler circuits to achieve higher output voltages from a given AC input.

- Control and protection mechanisms for half-wave rectifiers: To ensure reliable operation and protect the circuit and connected loads, half-wave rectifiers often incorporate various control and protection mechanisms. These may include overvoltage protection circuits, current limiting features, and thermal shutdown capabilities. Some designs use feedback loops to regulate the output voltage or current, improving the stability of the rectified output.

- Integration of half-wave rectifiers in specialized applications: Half-wave rectifiers are integrated into specialized applications such as RF signal detection, envelope tracking in power amplifiers, and energy harvesting systems. In these contexts, the rectifier may be optimized for high-frequency operation, low power consumption, or maximum power transfer efficiency. Some designs incorporate multiple half-wave rectifiers in parallel or series configurations to achieve specific performance characteristics.

02 Efficiency improvements in half-wave rectifiers

Various techniques are employed to improve the efficiency of half-wave rectifiers. These may include the use of high-speed switching diodes, optimized circuit layouts to reduce parasitic effects, and the implementation of control strategies to minimize power losses during the rectification process.Expand Specific Solutions03 Applications of half-wave rectifiers in power supplies

Half-wave rectifiers are commonly used in power supply circuits for various electronic devices. They are particularly useful in low-power applications where simplicity and cost-effectiveness are prioritized over output smoothness. These rectifiers can be found in small household appliances, battery chargers, and some LED lighting systems.Expand Specific Solutions04 Integration of half-wave rectifiers in IC designs

Half-wave rectifiers are increasingly being integrated into integrated circuit (IC) designs for compact and efficient power management solutions. This integration allows for better control of the rectification process, reduced component count, and improved overall system performance in applications such as energy harvesting and wireless power transfer.Expand Specific Solutions05 Filtering and smoothing techniques for half-wave rectifier outputs

To improve the quality of the output from half-wave rectifiers, various filtering and smoothing techniques are employed. These may include the use of capacitors to reduce ripple, inductors to smooth current flow, and active filtering circuits to further refine the DC output. Such techniques are crucial in applications requiring a more stable and consistent power supply.Expand Specific Solutions

Key Players in Rectifier Industry

The next generation of half wave rectifiers is emerging in a competitive landscape characterized by rapid technological advancements and growing market demand. The industry is in a growth phase, with increasing applications in power electronics and energy conversion systems driving market expansion. While the technology is mature, innovations are focusing on improving efficiency and miniaturization. Key players like Renesas Electronics, Fujitsu, and Intel are investing in research and development to enhance performance and reduce power losses. Emerging companies such as Mixed-Signal Devices and SiOnyx are also contributing to the field with novel approaches, indicating a dynamic and evolving competitive environment.

Renesas Electronics Corp.

Technical Solution: Renesas has introduced innovative half-wave rectifier designs for their power management solutions, focusing on automotive and industrial applications. Their next-generation rectifiers utilize advanced wide-bandgap materials such as silicon carbide (SiC) to achieve higher breakdown voltages and lower on-resistance[2]. Renesas has also implemented synchronous rectification techniques to reduce conduction losses and improve overall efficiency. The company's rectifiers feature integrated thermal management systems and advanced packaging technologies to enhance reliability and power density[4]. Additionally, Renesas has developed intelligent control schemes that enable dynamic adjustment of rectifier parameters based on real-time operating conditions[5].

Strengths: Wide-bandgap materials, high reliability, intelligent control. Weaknesses: Higher initial cost, limited to specific application areas.

Fujitsu Ltd.

Technical Solution: Fujitsu has made significant strides in developing next-generation half-wave rectifiers for their power supply units and energy harvesting systems. Their approach focuses on miniaturization and integration, utilizing advanced CMOS processes to create highly efficient rectifiers with minimal footprint[6]. Fujitsu's design incorporates novel circuit topologies that reduce reverse recovery losses and improve overall power conversion efficiency. The company has also implemented adaptive threshold voltage techniques to optimize rectifier performance across a wide range of input power levels, making their solution particularly suitable for IoT and wearable devices[7]. Furthermore, Fujitsu has explored the use of organic semiconductors in rectifier designs, potentially opening up new applications in flexible and printed electronics[8].

Strengths: Miniaturization, wide input range, potential for flexible electronics. Weaknesses: Limited power handling capacity, potential reliability issues with new materials.

Innovative Half Wave Rectifier Patents

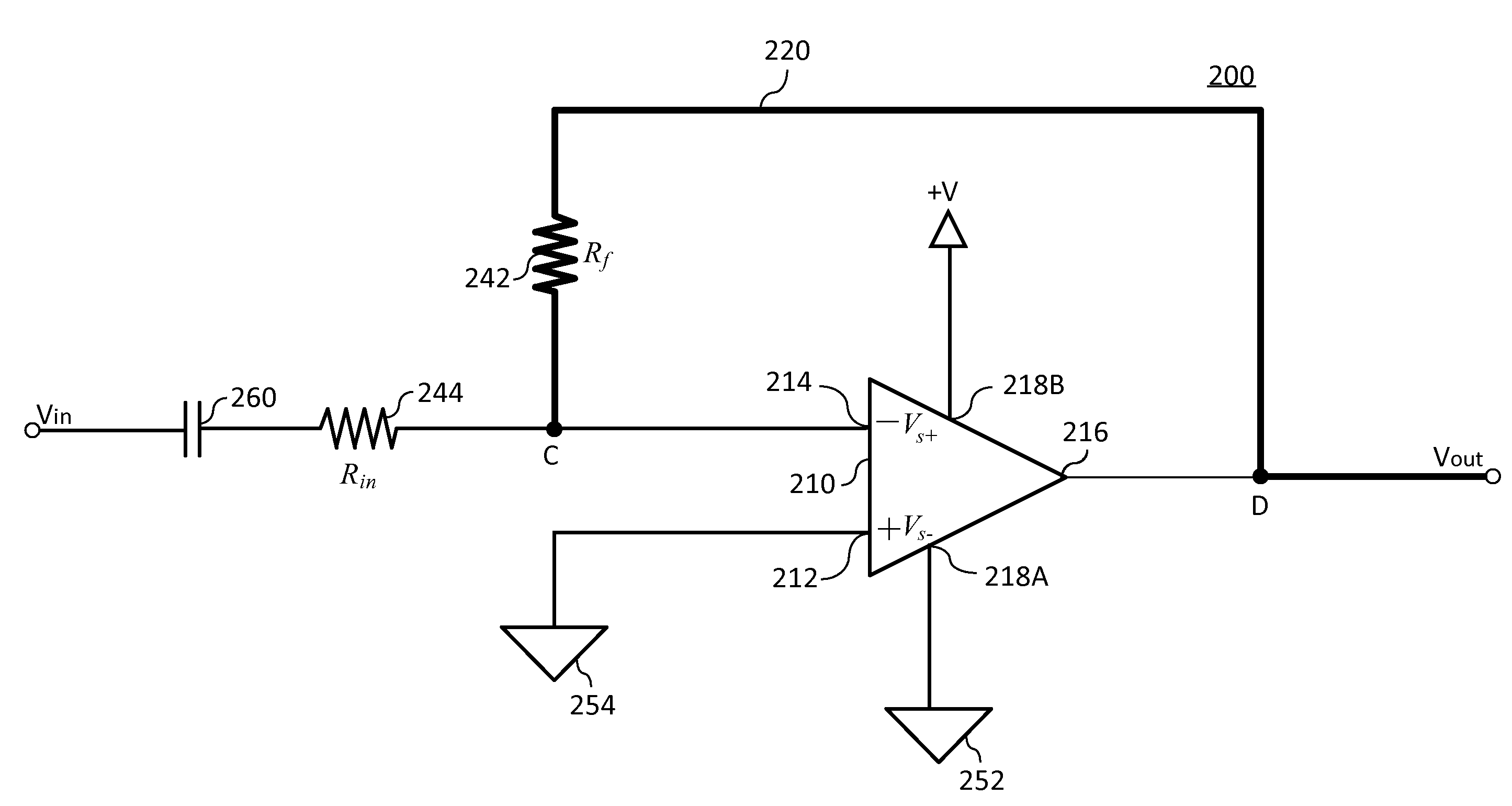

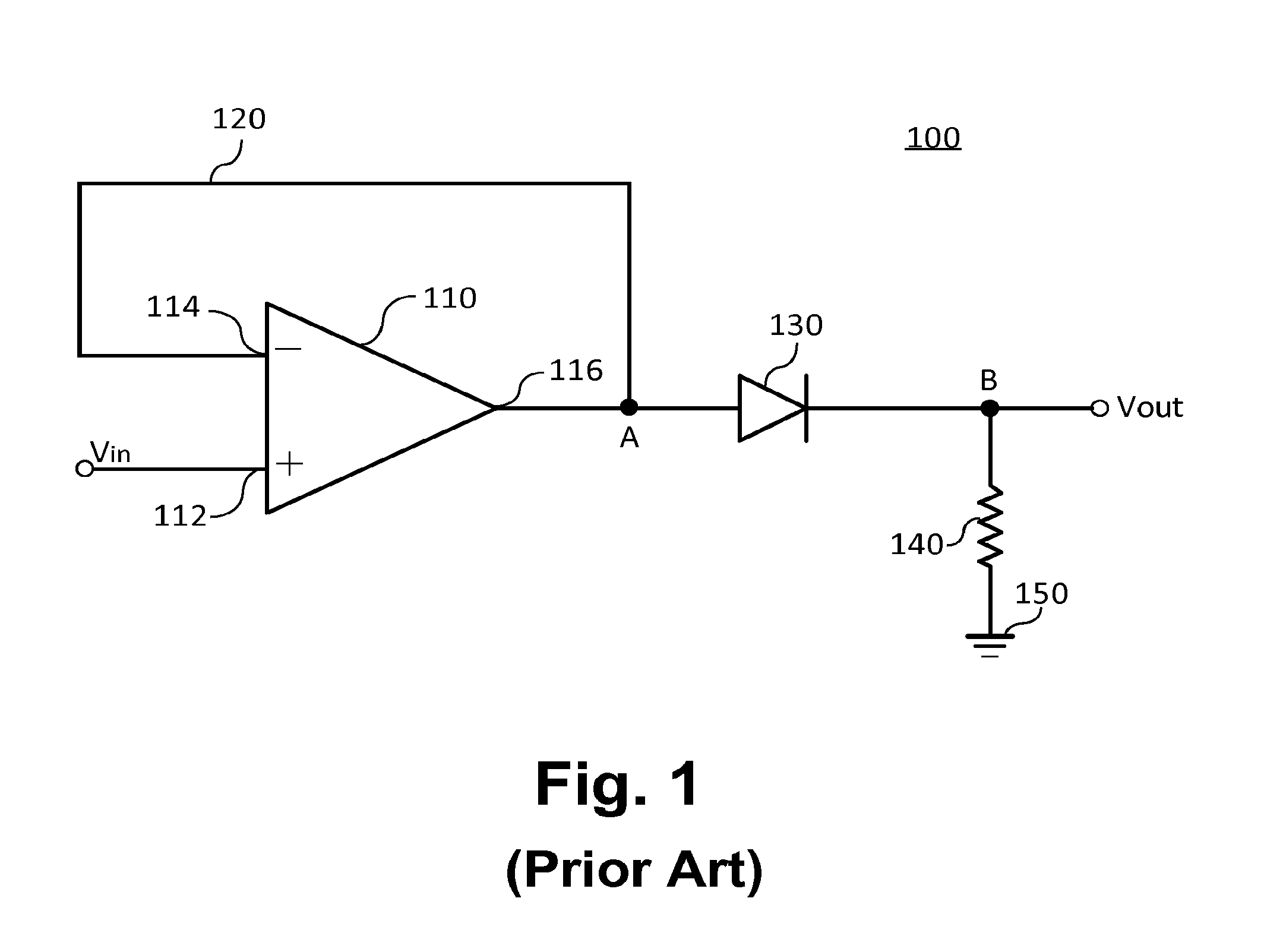

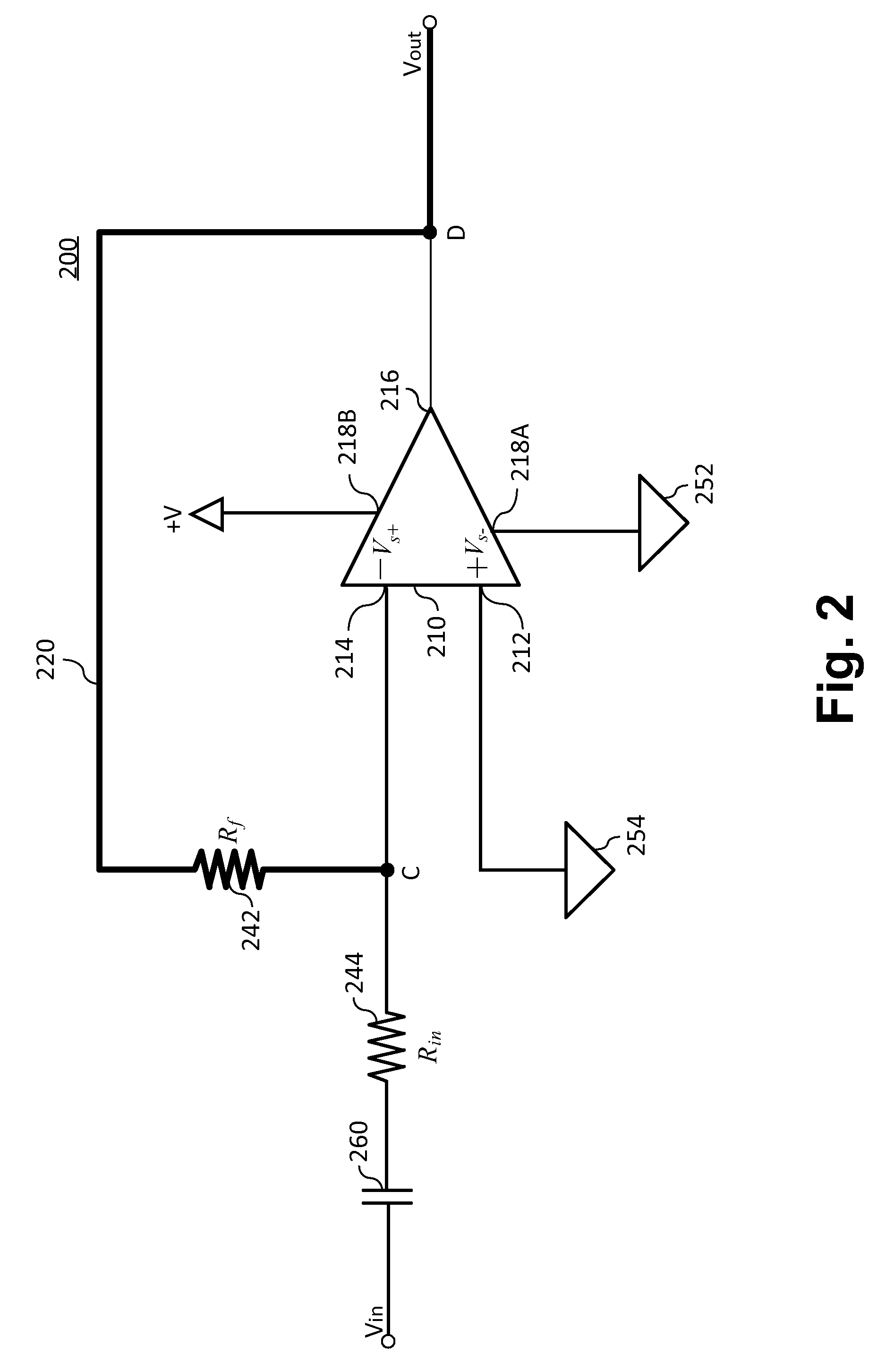

AC to DC conversion circuit

PatentActiveUS7764528B2

Innovation

- A diode-less half-wave rectifier circuit utilizing an operational amplifier with a capacitor and resistors in a negative feedback loop, allowing low-level signals to be converted to half-wave rectified DC signals, thereby extending the dynamic range of rectification.

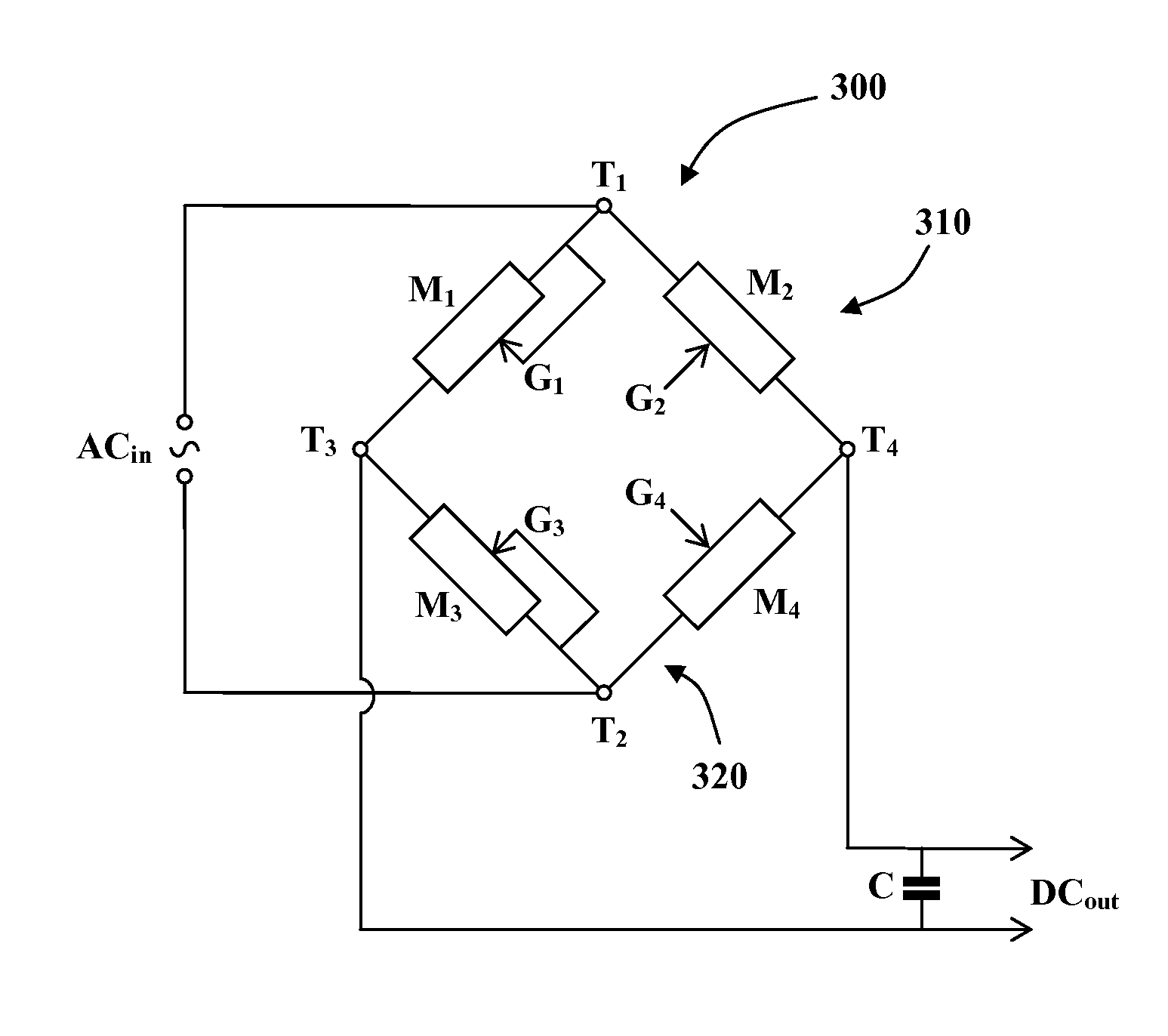

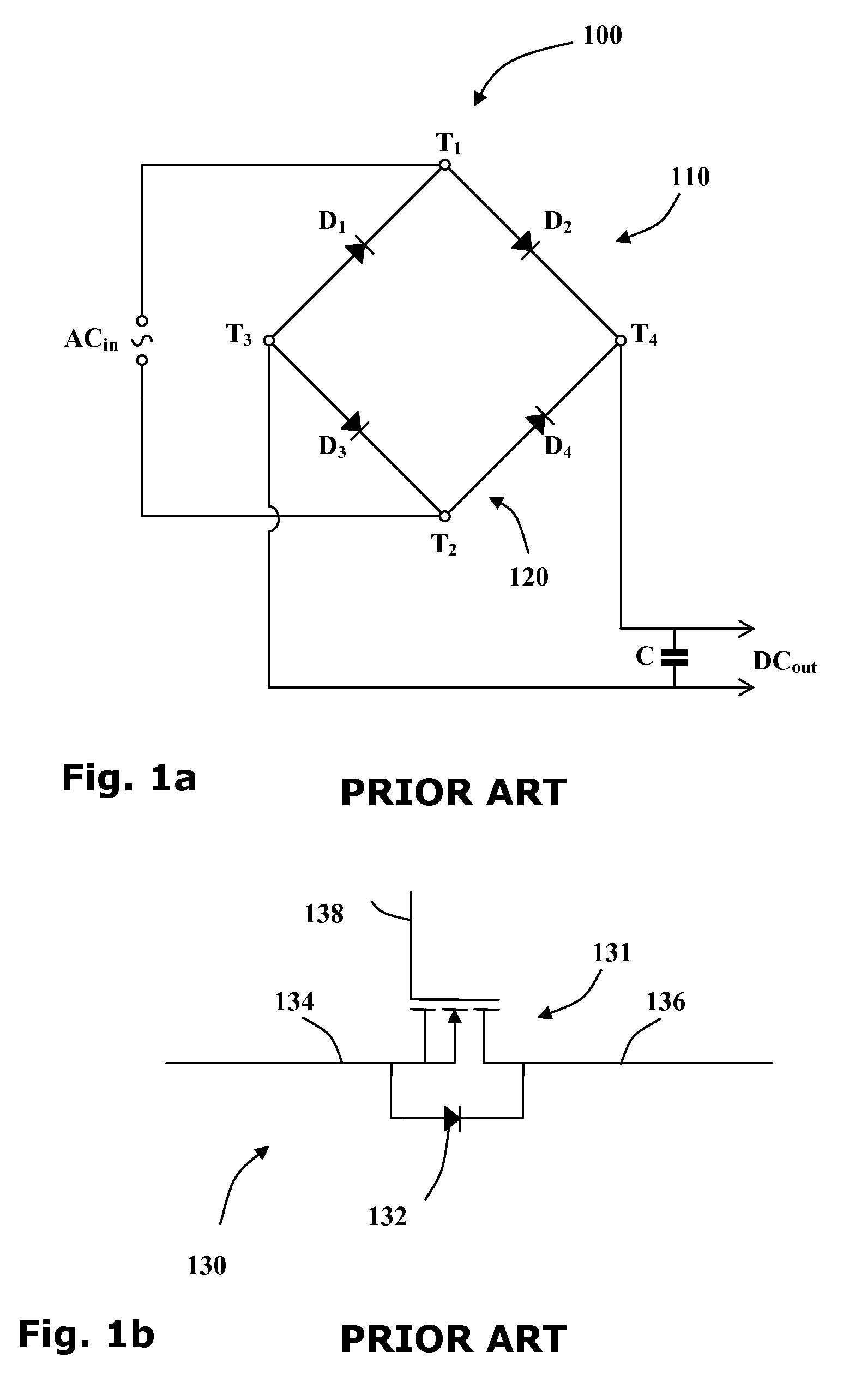

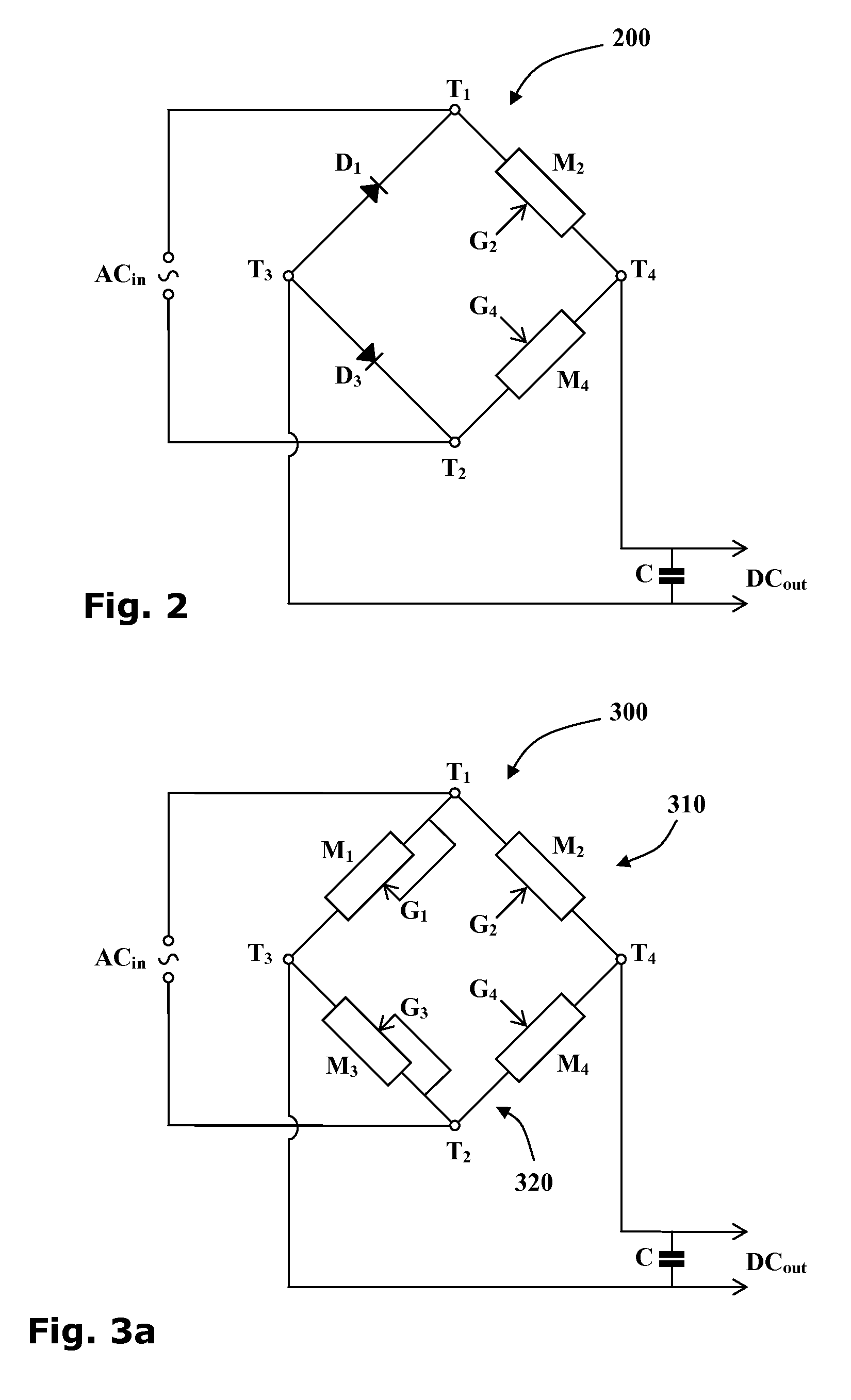

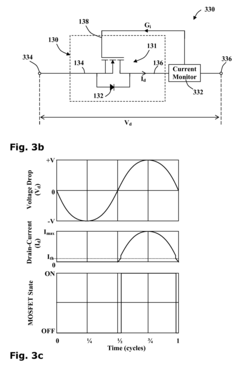

Bridge synchronous rectifier

PatentActiveUS8320143B2

Innovation

- A current-triggered synchronous rectifier is developed, utilizing MOSFET devices with a current monitor to switch between ON and OFF states based on predetermined current thresholds, replacing diodes in a full-wave rectifier configuration to minimize heat loss and prevent short circuits.

Efficiency and Power Loss Considerations

Efficiency and power loss considerations are crucial aspects in the development of next-generation half-wave rectifiers. These factors directly impact the overall performance and viability of rectifier circuits in various applications, from small-scale electronics to large power systems.

The efficiency of half-wave rectifiers is primarily determined by the amount of power lost during the rectification process. Traditional half-wave rectifiers suffer from significant power losses due to the forward voltage drop across the diode and the inability to utilize the negative half-cycle of the input waveform. This results in a theoretical maximum efficiency of only 40.6% for ideal components, with practical implementations often achieving even lower efficiencies.

To address these limitations, researchers and engineers are exploring innovative approaches to improve the efficiency of half-wave rectifiers. One promising direction is the use of advanced semiconductor materials with lower forward voltage drops, such as Schottky diodes or silicon carbide (SiC) devices. These materials can significantly reduce conduction losses and improve overall efficiency.

Another area of focus is the development of active rectification techniques. By replacing passive diodes with actively controlled switches, such as MOSFETs or IGBTs, the forward voltage drop can be minimized, and the negative half-cycle can be utilized more effectively. This approach can potentially increase the efficiency of half-wave rectifiers to levels comparable to full-wave rectifiers.

Power loss in half-wave rectifiers can be categorized into several components: conduction losses, switching losses, and reverse recovery losses. Conduction losses occur due to the voltage drop across the rectifying element during the conduction period. Switching losses arise from the transition between on and off states, while reverse recovery losses are associated with the time required for the rectifying element to switch from the conducting to the blocking state.

To mitigate these losses, researchers are investigating advanced circuit topologies and control strategies. Soft-switching techniques, such as zero-voltage switching (ZVS) and zero-current switching (ZCS), are being explored to reduce switching losses. Additionally, the implementation of synchronous rectification, where the rectifying element is precisely controlled to conduct only during the appropriate portions of the waveform, can significantly reduce both conduction and switching losses.

The impact of parasitic elements, such as junction capacitance and lead inductance, on efficiency and power loss is also being carefully examined. Minimizing these parasitic effects through improved packaging techniques and circuit layout optimization is crucial for achieving high-efficiency operation, especially at higher frequencies.

As the demand for more efficient power conversion continues to grow, the development of next-generation half-wave rectifiers with improved efficiency and reduced power losses remains a critical area of research and innovation in power electronics.

The efficiency of half-wave rectifiers is primarily determined by the amount of power lost during the rectification process. Traditional half-wave rectifiers suffer from significant power losses due to the forward voltage drop across the diode and the inability to utilize the negative half-cycle of the input waveform. This results in a theoretical maximum efficiency of only 40.6% for ideal components, with practical implementations often achieving even lower efficiencies.

To address these limitations, researchers and engineers are exploring innovative approaches to improve the efficiency of half-wave rectifiers. One promising direction is the use of advanced semiconductor materials with lower forward voltage drops, such as Schottky diodes or silicon carbide (SiC) devices. These materials can significantly reduce conduction losses and improve overall efficiency.

Another area of focus is the development of active rectification techniques. By replacing passive diodes with actively controlled switches, such as MOSFETs or IGBTs, the forward voltage drop can be minimized, and the negative half-cycle can be utilized more effectively. This approach can potentially increase the efficiency of half-wave rectifiers to levels comparable to full-wave rectifiers.

Power loss in half-wave rectifiers can be categorized into several components: conduction losses, switching losses, and reverse recovery losses. Conduction losses occur due to the voltage drop across the rectifying element during the conduction period. Switching losses arise from the transition between on and off states, while reverse recovery losses are associated with the time required for the rectifying element to switch from the conducting to the blocking state.

To mitigate these losses, researchers are investigating advanced circuit topologies and control strategies. Soft-switching techniques, such as zero-voltage switching (ZVS) and zero-current switching (ZCS), are being explored to reduce switching losses. Additionally, the implementation of synchronous rectification, where the rectifying element is precisely controlled to conduct only during the appropriate portions of the waveform, can significantly reduce both conduction and switching losses.

The impact of parasitic elements, such as junction capacitance and lead inductance, on efficiency and power loss is also being carefully examined. Minimizing these parasitic effects through improved packaging techniques and circuit layout optimization is crucial for achieving high-efficiency operation, especially at higher frequencies.

As the demand for more efficient power conversion continues to grow, the development of next-generation half-wave rectifiers with improved efficiency and reduced power losses remains a critical area of research and innovation in power electronics.

Environmental Impact of Rectifier Technologies

The environmental impact of rectifier technologies has become an increasingly important consideration in the development and deployment of power electronics systems. Half-wave rectifiers, while simple in design, have traditionally been associated with higher levels of power loss and electromagnetic interference (EMI) compared to their full-wave counterparts. However, the next generation of half-wave rectifiers is poised to address these environmental concerns through innovative design approaches and advanced materials.

One of the primary environmental challenges associated with conventional half-wave rectifiers is their relatively low efficiency. This inefficiency results in increased power consumption and heat generation, contributing to higher energy demands and potentially larger carbon footprints for systems employing these devices. The new generation of half-wave rectifiers aims to mitigate this issue by incorporating advanced semiconductor materials with lower on-state resistance and faster switching capabilities, significantly reducing power losses during operation.

Electromagnetic interference is another environmental concern associated with rectifier technologies. Traditional half-wave rectifiers can generate substantial EMI due to their pulsating output and abrupt current transitions. This interference can affect nearby electronic equipment and potentially contribute to electromagnetic pollution. Next-generation half-wave rectifiers are being designed with improved EMI suppression techniques, such as soft-switching topologies and integrated EMI filters, to minimize their impact on the surrounding electromagnetic environment.

The manufacturing processes for rectifier components also play a crucial role in their overall environmental impact. The production of conventional silicon-based rectifiers often involves energy-intensive processes and the use of potentially harmful chemicals. Emerging half-wave rectifier technologies are exploring the use of more environmentally friendly materials, such as wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN). These materials not only offer superior performance characteristics but also have the potential for more sustainable manufacturing processes.

Recycling and end-of-life considerations are becoming increasingly important in the evaluation of rectifier technologies. The next generation of half-wave rectifiers is being developed with a focus on recyclability and reduced use of hazardous materials. This approach aims to minimize the environmental impact of electronic waste and promote a more circular economy in the electronics industry.

As the demand for energy-efficient and environmentally friendly power electronics continues to grow, the development of next-generation half-wave rectifiers is likely to play a significant role in reducing the overall environmental footprint of electronic systems. By addressing issues such as power efficiency, EMI, sustainable manufacturing, and recyclability, these advanced rectifier technologies have the potential to contribute to a more sustainable future for power electronics applications.

One of the primary environmental challenges associated with conventional half-wave rectifiers is their relatively low efficiency. This inefficiency results in increased power consumption and heat generation, contributing to higher energy demands and potentially larger carbon footprints for systems employing these devices. The new generation of half-wave rectifiers aims to mitigate this issue by incorporating advanced semiconductor materials with lower on-state resistance and faster switching capabilities, significantly reducing power losses during operation.

Electromagnetic interference is another environmental concern associated with rectifier technologies. Traditional half-wave rectifiers can generate substantial EMI due to their pulsating output and abrupt current transitions. This interference can affect nearby electronic equipment and potentially contribute to electromagnetic pollution. Next-generation half-wave rectifiers are being designed with improved EMI suppression techniques, such as soft-switching topologies and integrated EMI filters, to minimize their impact on the surrounding electromagnetic environment.

The manufacturing processes for rectifier components also play a crucial role in their overall environmental impact. The production of conventional silicon-based rectifiers often involves energy-intensive processes and the use of potentially harmful chemicals. Emerging half-wave rectifier technologies are exploring the use of more environmentally friendly materials, such as wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN). These materials not only offer superior performance characteristics but also have the potential for more sustainable manufacturing processes.

Recycling and end-of-life considerations are becoming increasingly important in the evaluation of rectifier technologies. The next generation of half-wave rectifiers is being developed with a focus on recyclability and reduced use of hazardous materials. This approach aims to minimize the environmental impact of electronic waste and promote a more circular economy in the electronics industry.

As the demand for energy-efficient and environmentally friendly power electronics continues to grow, the development of next-generation half-wave rectifiers is likely to play a significant role in reducing the overall environmental footprint of electronic systems. By addressing issues such as power efficiency, EMI, sustainable manufacturing, and recyclability, these advanced rectifier technologies have the potential to contribute to a more sustainable future for power electronics applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!