Use of Solenoid Valves in Subsea Drilling Operations

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Subsea Solenoid Valve Evolution and Objectives

Solenoid valves have played a crucial role in subsea drilling operations since their introduction in the 1970s. These electromechanical devices have revolutionized the control of fluid flow in deep-sea environments, offering precise and reliable operation under extreme conditions. The evolution of subsea solenoid valves has been driven by the increasing demands of offshore oil and gas exploration, pushing the boundaries of technology to meet the challenges of greater depths and harsher environments.

Initially, solenoid valves used in subsea applications were adaptations of surface designs, with limited pressure and depth ratings. As the industry ventured into deeper waters, the need for more robust and specialized valves became apparent. The 1980s and 1990s saw significant advancements in materials science and sealing technologies, enabling the development of valves capable of withstanding higher pressures and corrosive environments.

The turn of the millennium marked a new era for subsea solenoid valves, with the introduction of all-electric control systems. This shift from hydraulic to electric actuation improved response times, reduced maintenance requirements, and enhanced overall system reliability. Manufacturers focused on developing compact, high-performance valves that could operate efficiently at depths exceeding 3,000 meters.

Recent technological trends have centered on improving the longevity and reliability of subsea solenoid valves. Innovations in corrosion-resistant alloys, advanced polymer seals, and smart diagnostics have extended the operational life of these critical components. The integration of sensors and communication capabilities has enabled real-time monitoring and predictive maintenance, reducing downtime and improving safety in subsea operations.

Looking forward, the objectives for subsea solenoid valve technology are multifaceted. One primary goal is to further extend operational depths, targeting ultra-deepwater environments beyond 4,000 meters. This requires overcoming challenges related to extreme pressure, temperature fluctuations, and material limitations. Another key objective is to enhance energy efficiency, developing low-power consumption valves that can operate reliably with minimal electrical input.

Improving the environmental impact of subsea operations is also a critical focus. Manufacturers are working on developing leak-free valve designs and exploring the use of biodegradable fluids to minimize the risk of contamination in case of failure. Additionally, there is a push towards standardization and modular designs to simplify installation, maintenance, and replacement processes in challenging subsea environments.

As the oil and gas industry continues to explore more remote and challenging offshore locations, the evolution of subsea solenoid valve technology remains crucial. Future developments will likely focus on integrating advanced materials, smart technologies, and sustainable practices to meet the growing demands of subsea drilling operations while ensuring safety, reliability, and environmental stewardship.

Initially, solenoid valves used in subsea applications were adaptations of surface designs, with limited pressure and depth ratings. As the industry ventured into deeper waters, the need for more robust and specialized valves became apparent. The 1980s and 1990s saw significant advancements in materials science and sealing technologies, enabling the development of valves capable of withstanding higher pressures and corrosive environments.

The turn of the millennium marked a new era for subsea solenoid valves, with the introduction of all-electric control systems. This shift from hydraulic to electric actuation improved response times, reduced maintenance requirements, and enhanced overall system reliability. Manufacturers focused on developing compact, high-performance valves that could operate efficiently at depths exceeding 3,000 meters.

Recent technological trends have centered on improving the longevity and reliability of subsea solenoid valves. Innovations in corrosion-resistant alloys, advanced polymer seals, and smart diagnostics have extended the operational life of these critical components. The integration of sensors and communication capabilities has enabled real-time monitoring and predictive maintenance, reducing downtime and improving safety in subsea operations.

Looking forward, the objectives for subsea solenoid valve technology are multifaceted. One primary goal is to further extend operational depths, targeting ultra-deepwater environments beyond 4,000 meters. This requires overcoming challenges related to extreme pressure, temperature fluctuations, and material limitations. Another key objective is to enhance energy efficiency, developing low-power consumption valves that can operate reliably with minimal electrical input.

Improving the environmental impact of subsea operations is also a critical focus. Manufacturers are working on developing leak-free valve designs and exploring the use of biodegradable fluids to minimize the risk of contamination in case of failure. Additionally, there is a push towards standardization and modular designs to simplify installation, maintenance, and replacement processes in challenging subsea environments.

As the oil and gas industry continues to explore more remote and challenging offshore locations, the evolution of subsea solenoid valve technology remains crucial. Future developments will likely focus on integrating advanced materials, smart technologies, and sustainable practices to meet the growing demands of subsea drilling operations while ensuring safety, reliability, and environmental stewardship.

Offshore Drilling Market Demand Analysis

The offshore drilling market has experienced significant growth in recent years, driven by increasing global energy demand and the need to explore and extract oil and gas resources from deep-water and ultra-deep-water locations. This market segment is characterized by high-value projects and substantial investments in advanced technologies, including subsea drilling equipment and control systems.

The demand for offshore drilling services is closely tied to oil prices and global economic conditions. As oil prices have stabilized and shown signs of recovery in recent years, there has been a resurgence in offshore exploration and production activities. This has led to increased demand for sophisticated drilling technologies, including those utilizing solenoid valves in subsea operations.

Subsea drilling operations present unique challenges due to the harsh environmental conditions, high pressures, and remote locations. These factors have created a strong market demand for reliable, efficient, and precise control systems in subsea drilling equipment. Solenoid valves play a crucial role in these systems, offering rapid and accurate control of fluid flow in various subsea applications, such as blowout preventers (BOPs), hydraulic power units, and wellhead control systems.

The market for subsea solenoid valves is expected to grow as offshore drilling activities expand into deeper waters and more challenging environments. This growth is driven by the need for enhanced safety measures, improved operational efficiency, and increased automation in subsea drilling operations. Solenoid valves contribute to these objectives by providing fast response times, high reliability, and the ability to operate in extreme conditions.

Geographically, the demand for solenoid valves in subsea drilling operations is concentrated in regions with significant offshore oil and gas activities. These include the Gulf of Mexico, the North Sea, Brazil's pre-salt basin, West Africa, and the Asia-Pacific region. Each of these areas has unique geological and operational characteristics that influence the specific requirements for subsea equipment, including solenoid valves.

The market is also influenced by regulatory factors, particularly those related to safety and environmental protection. Stricter regulations following incidents such as the Deepwater Horizon oil spill have led to increased demand for advanced, reliable control systems in subsea drilling operations. This has further boosted the market for high-quality solenoid valves that can meet stringent safety and performance standards.

As the offshore drilling industry continues to evolve, there is a growing emphasis on digitalization and the integration of smart technologies. This trend is creating new opportunities for solenoid valve manufacturers to develop advanced products with enhanced monitoring and diagnostic capabilities, further driving market growth and innovation in this sector.

The demand for offshore drilling services is closely tied to oil prices and global economic conditions. As oil prices have stabilized and shown signs of recovery in recent years, there has been a resurgence in offshore exploration and production activities. This has led to increased demand for sophisticated drilling technologies, including those utilizing solenoid valves in subsea operations.

Subsea drilling operations present unique challenges due to the harsh environmental conditions, high pressures, and remote locations. These factors have created a strong market demand for reliable, efficient, and precise control systems in subsea drilling equipment. Solenoid valves play a crucial role in these systems, offering rapid and accurate control of fluid flow in various subsea applications, such as blowout preventers (BOPs), hydraulic power units, and wellhead control systems.

The market for subsea solenoid valves is expected to grow as offshore drilling activities expand into deeper waters and more challenging environments. This growth is driven by the need for enhanced safety measures, improved operational efficiency, and increased automation in subsea drilling operations. Solenoid valves contribute to these objectives by providing fast response times, high reliability, and the ability to operate in extreme conditions.

Geographically, the demand for solenoid valves in subsea drilling operations is concentrated in regions with significant offshore oil and gas activities. These include the Gulf of Mexico, the North Sea, Brazil's pre-salt basin, West Africa, and the Asia-Pacific region. Each of these areas has unique geological and operational characteristics that influence the specific requirements for subsea equipment, including solenoid valves.

The market is also influenced by regulatory factors, particularly those related to safety and environmental protection. Stricter regulations following incidents such as the Deepwater Horizon oil spill have led to increased demand for advanced, reliable control systems in subsea drilling operations. This has further boosted the market for high-quality solenoid valves that can meet stringent safety and performance standards.

As the offshore drilling industry continues to evolve, there is a growing emphasis on digitalization and the integration of smart technologies. This trend is creating new opportunities for solenoid valve manufacturers to develop advanced products with enhanced monitoring and diagnostic capabilities, further driving market growth and innovation in this sector.

Subsea Valve Technology Challenges

Subsea valve technology faces numerous challenges in the harsh underwater environment of offshore drilling operations. The extreme pressures, corrosive seawater, and remote locations pose significant obstacles to valve performance and reliability. One of the primary challenges is maintaining valve integrity under high-pressure conditions, often exceeding 10,000 psi. This requires advanced materials and robust designs to prevent leaks and ensure consistent operation.

Corrosion resistance is another critical challenge for subsea valves. The constant exposure to saltwater and various chemicals used in drilling operations can rapidly degrade valve components. Engineers must develop specialized coatings and alloys that can withstand these corrosive elements while maintaining operational efficiency over extended periods.

The remote nature of subsea operations presents unique challenges for valve maintenance and repair. Access to valves located on the seafloor is limited and expensive, requiring specialized equipment and personnel. This necessitates the development of highly reliable valve systems with extended service lives and minimal maintenance requirements. Additionally, remote monitoring and control capabilities are essential for efficient operation and troubleshooting.

Temperature fluctuations in deep-sea environments pose another significant challenge. Valves must operate reliably in cold water temperatures, which can affect material properties and fluid viscosity. Conversely, they must also withstand high temperatures generated by drilling operations. This wide temperature range demands materials and designs that can maintain consistent performance across varying thermal conditions.

The need for precise flow control in subsea drilling operations adds another layer of complexity to valve technology. Valves must accurately regulate the flow of various fluids, including drilling mud, hydraulic fluids, and production fluids. This requires advanced actuation systems and control mechanisms that can operate reliably in the subsea environment.

Scaling valve technology for deep-water applications presents additional challenges. As drilling operations move into deeper waters, valves must be designed to withstand even greater pressures and operate at longer distances from the surface. This pushes the limits of current materials and technologies, driving the need for innovative solutions in valve design and manufacturing.

Environmental concerns and regulatory requirements also impact subsea valve technology. Valves must meet stringent standards for leak prevention and environmental protection. This drives the development of fail-safe mechanisms and redundant systems to minimize the risk of environmental damage in case of valve failure.

Corrosion resistance is another critical challenge for subsea valves. The constant exposure to saltwater and various chemicals used in drilling operations can rapidly degrade valve components. Engineers must develop specialized coatings and alloys that can withstand these corrosive elements while maintaining operational efficiency over extended periods.

The remote nature of subsea operations presents unique challenges for valve maintenance and repair. Access to valves located on the seafloor is limited and expensive, requiring specialized equipment and personnel. This necessitates the development of highly reliable valve systems with extended service lives and minimal maintenance requirements. Additionally, remote monitoring and control capabilities are essential for efficient operation and troubleshooting.

Temperature fluctuations in deep-sea environments pose another significant challenge. Valves must operate reliably in cold water temperatures, which can affect material properties and fluid viscosity. Conversely, they must also withstand high temperatures generated by drilling operations. This wide temperature range demands materials and designs that can maintain consistent performance across varying thermal conditions.

The need for precise flow control in subsea drilling operations adds another layer of complexity to valve technology. Valves must accurately regulate the flow of various fluids, including drilling mud, hydraulic fluids, and production fluids. This requires advanced actuation systems and control mechanisms that can operate reliably in the subsea environment.

Scaling valve technology for deep-water applications presents additional challenges. As drilling operations move into deeper waters, valves must be designed to withstand even greater pressures and operate at longer distances from the surface. This pushes the limits of current materials and technologies, driving the need for innovative solutions in valve design and manufacturing.

Environmental concerns and regulatory requirements also impact subsea valve technology. Valves must meet stringent standards for leak prevention and environmental protection. This drives the development of fail-safe mechanisms and redundant systems to minimize the risk of environmental damage in case of valve failure.

Current Subsea Solenoid Valve Solutions

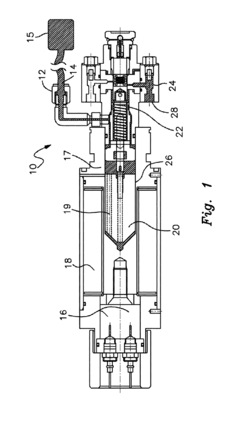

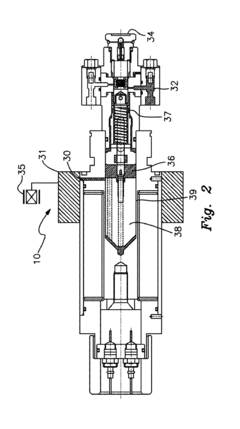

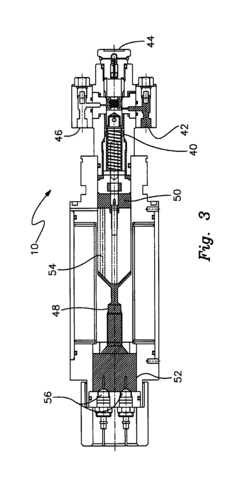

01 Design and structure of solenoid valves

Solenoid valves are designed with specific structures to control fluid flow. They typically consist of a coil, plunger, and valve body. The design may include features for improved performance, such as optimized magnetic circuits, specialized sealing mechanisms, or compact arrangements for specific applications.- Solenoid valve design and structure: Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, including improvements in sealing, response time, and durability.

- Application in fuel injection systems: Solenoid valves play a crucial role in fuel injection systems for internal combustion engines. They precisely control the timing and amount of fuel delivered to the engine, improving efficiency and reducing emissions. Advanced designs incorporate features like multiple injection events per cycle and high-speed operation.

- Integration with electronic control systems: Modern solenoid valves are often integrated with electronic control systems, allowing for precise and programmable operation. This integration enables features such as pulse-width modulation for fine control of fluid flow, diagnostic capabilities, and adaptive control based on various sensor inputs.

- Energy-efficient solenoid valve designs: Innovations in solenoid valve design focus on improving energy efficiency. This includes the development of low-power solenoids, latching designs that maintain valve position without continuous power, and optimized magnetic circuit designs to reduce power consumption while maintaining performance.

- Specialized solenoid valves for harsh environments: Solenoid valves designed for harsh environments incorporate features to withstand extreme temperatures, pressures, and corrosive media. These may include special materials for seals and valve bodies, protective coatings, and reinforced structures to ensure reliable operation under challenging conditions.

02 Control systems for solenoid valves

Advanced control systems are implemented to enhance the operation of solenoid valves. These may include electronic control units, feedback mechanisms, or integrated sensors for precise regulation of fluid flow. Such systems can improve valve response time, accuracy, and overall efficiency in various industrial applications.Expand Specific Solutions03 Energy-efficient solenoid valve designs

Innovations in solenoid valve design focus on improving energy efficiency. This may involve using low-power actuators, optimizing the magnetic circuit, or implementing energy-saving control strategies. These designs aim to reduce power consumption while maintaining reliable valve operation.Expand Specific Solutions04 Specialized solenoid valves for specific applications

Solenoid valves are developed for specialized applications such as automotive systems, industrial processes, or medical devices. These valves may have unique features tailored to their specific use, such as high-temperature resistance, corrosion resistance, or miniaturized designs for space-constrained environments.Expand Specific Solutions05 Maintenance and reliability improvements

Advancements in solenoid valve technology focus on enhancing reliability and ease of maintenance. This may include self-diagnostic features, modular designs for easy replacement of components, or materials that resist wear and corrosion. These improvements aim to extend valve lifespan and reduce downtime in industrial settings.Expand Specific Solutions

Key Subsea Equipment Manufacturers

The use of solenoid valves in subsea drilling operations is in a mature stage of development, with a significant market size driven by ongoing offshore exploration and production activities. The technology is well-established, with major players like Eaton Corp., Moog, Inc., and Baker Hughes Energy Technology UK Ltd. offering advanced solutions. These companies have extensive experience in developing reliable and high-performance solenoid valves capable of withstanding harsh subsea environments. The market is characterized by continuous innovation, focusing on improving valve efficiency, durability, and remote operation capabilities to meet the demanding requirements of deepwater drilling operations.

Eaton Corp.

Technical Solution: Eaton Corp. has developed advanced solenoid valve solutions for subsea drilling operations, focusing on reliability and performance in extreme conditions. Their technology incorporates pressure-balanced designs to ensure consistent operation at high depths[1]. Eaton's solenoid valves feature corrosion-resistant materials and redundant sealing systems to withstand harsh subsea environments[2]. The company has also implemented smart diagnostics and condition monitoring capabilities, allowing real-time performance assessment and predictive maintenance[3]. Eaton's valves are designed for long-term deployment, with extended service intervals to minimize operational downtime[4].

Strengths: Robust design for extreme conditions, advanced diagnostics, and long service life. Weaknesses: Potentially higher initial cost due to advanced features and materials.

Vetco Gray Scandinavia AS

Technical Solution: Vetco Gray Scandinavia AS, now part of Baker Hughes, has pioneered subsea solenoid valve technology for drilling operations. Their solutions focus on high-pressure, high-temperature (HPHT) applications, with valves rated for pressures up to 20,000 psi and temperatures exceeding 350°F[1]. The company has developed proprietary sealing technologies to ensure zero-leakage performance in these extreme conditions[2]. Vetco Gray's solenoid valves incorporate advanced materials such as super duplex stainless steel and specialized elastomers to resist corrosion and erosion[3]. They have also implemented fail-safe designs with redundant actuation mechanisms to enhance reliability in critical subsea applications[4].

Strengths: Expertise in HPHT environments, advanced sealing technology, and fail-safe designs. Weaknesses: Specialized nature may limit applicability in less demanding environments.

Innovative Solenoid Valve Designs

Methods and apparatus to exclude function fluid or seawater from solenoid armature cavities in subsea or surface solenoid valves

PatentActiveUS8376314B2

Innovation

- The use of a non-electrolytic dielectric fluid, such as oil, is introduced into the armature chamber to prevent corrosion and contamination, with features like external or internal pressurization and sealed passages to maintain internal pressure and isolate the armature from external fluids, and the integration of pressure monitoring systems to anticipate potential failures.

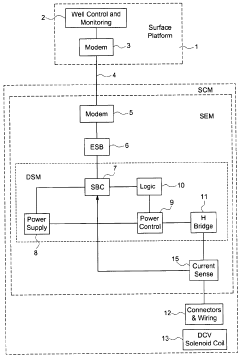

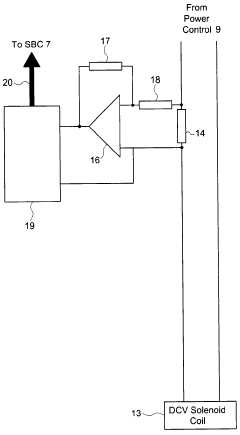

Testing a control system including a valve

PatentActiveAU2011239286A1

Innovation

- A method and system for testing the communications, control circuitry, monitoring circuitry, wiring, and solenoid coil of a solenoid-operated valve by applying a non-operating current through the solenoid coil and monitoring the response, allowing for regular testing during scheduled maintenance to prevent unexpected failures.

Environmental Impact Assessment

The use of solenoid valves in subsea drilling operations has significant environmental implications that require careful assessment. These valves play a crucial role in controlling fluid flow and pressure in various subsea systems, including blowout preventers and hydraulic control systems. Their reliability and performance directly impact the safety and environmental integrity of drilling operations.

One of the primary environmental concerns is the potential for fluid leakage. Solenoid valves are designed to provide tight shut-off, but in the harsh subsea environment, there is always a risk of seal degradation or valve malfunction. Any leakage of hydraulic fluids or drilling muds can have detrimental effects on marine ecosystems, potentially harming benthic organisms and contaminating the water column. To mitigate this risk, advanced sealing technologies and materials resistant to high pressures and corrosive environments are continuously being developed and implemented.

The energy efficiency of solenoid valves is another important environmental consideration. More efficient valves require less power to operate, reducing the overall energy consumption of subsea drilling operations. This, in turn, leads to lower greenhouse gas emissions associated with power generation on offshore platforms or vessels. Manufacturers are focusing on developing low-power solenoid valves that maintain high performance standards while minimizing energy use.

Noise pollution is an often-overlooked aspect of subsea operations that can affect marine life. The rapid opening and closing of solenoid valves can generate underwater noise, potentially disrupting the communication and behavior of marine mammals and fish. Research is ongoing to design quieter valve systems and to implement operational procedures that minimize acoustic disturbances.

The materials used in solenoid valve construction also have environmental implications. Many valves contain metals and alloys that can corrode over time, releasing potentially harmful substances into the marine environment. The development of corrosion-resistant materials and coatings is crucial for extending valve life and reducing the need for frequent replacement, which in turn minimizes the environmental impact of manufacturing and disposal processes.

End-of-life management of solenoid valves is an important consideration in the environmental impact assessment. Proper decommissioning and recycling procedures must be established to prevent the release of hazardous materials into the environment when subsea equipment is retired. This includes the safe recovery of valves from the seafloor and the responsible disposal or recycling of components.

In conclusion, while solenoid valves are essential for safe and efficient subsea drilling operations, their environmental impact must be carefully managed. Ongoing research and development efforts are focused on improving valve design, materials, and operational practices to minimize negative environmental effects while maintaining the high performance standards required in challenging subsea conditions.

One of the primary environmental concerns is the potential for fluid leakage. Solenoid valves are designed to provide tight shut-off, but in the harsh subsea environment, there is always a risk of seal degradation or valve malfunction. Any leakage of hydraulic fluids or drilling muds can have detrimental effects on marine ecosystems, potentially harming benthic organisms and contaminating the water column. To mitigate this risk, advanced sealing technologies and materials resistant to high pressures and corrosive environments are continuously being developed and implemented.

The energy efficiency of solenoid valves is another important environmental consideration. More efficient valves require less power to operate, reducing the overall energy consumption of subsea drilling operations. This, in turn, leads to lower greenhouse gas emissions associated with power generation on offshore platforms or vessels. Manufacturers are focusing on developing low-power solenoid valves that maintain high performance standards while minimizing energy use.

Noise pollution is an often-overlooked aspect of subsea operations that can affect marine life. The rapid opening and closing of solenoid valves can generate underwater noise, potentially disrupting the communication and behavior of marine mammals and fish. Research is ongoing to design quieter valve systems and to implement operational procedures that minimize acoustic disturbances.

The materials used in solenoid valve construction also have environmental implications. Many valves contain metals and alloys that can corrode over time, releasing potentially harmful substances into the marine environment. The development of corrosion-resistant materials and coatings is crucial for extending valve life and reducing the need for frequent replacement, which in turn minimizes the environmental impact of manufacturing and disposal processes.

End-of-life management of solenoid valves is an important consideration in the environmental impact assessment. Proper decommissioning and recycling procedures must be established to prevent the release of hazardous materials into the environment when subsea equipment is retired. This includes the safe recovery of valves from the seafloor and the responsible disposal or recycling of components.

In conclusion, while solenoid valves are essential for safe and efficient subsea drilling operations, their environmental impact must be carefully managed. Ongoing research and development efforts are focused on improving valve design, materials, and operational practices to minimize negative environmental effects while maintaining the high performance standards required in challenging subsea conditions.

Regulatory Framework for Subsea Operations

The regulatory framework for subsea operations, particularly in the context of solenoid valve usage in subsea drilling, is a complex and evolving landscape. International bodies, such as the International Maritime Organization (IMO) and the International Association of Oil & Gas Producers (IOGP), play crucial roles in setting global standards and guidelines for offshore operations.

At the forefront of regulatory compliance is the International Safety Management (ISM) Code, which provides a framework for the safe management and operation of ships and pollution prevention. This code, while not specifically addressing solenoid valves, sets the foundation for safety management systems that encompass all aspects of subsea operations, including equipment reliability and maintenance.

The American Petroleum Institute (API) has developed several standards directly applicable to subsea equipment, including API Specification 17D for subsea wellhead and tree equipment. These standards often reference the use of solenoid valves and provide guidelines for their selection, installation, and maintenance in subsea environments.

In the United States, the Bureau of Safety and Environmental Enforcement (BSEE) oversees offshore oil and gas operations. The BSEE's regulations, particularly 30 CFR Part 250, outline specific requirements for subsea systems, including those that utilize solenoid valves. These regulations emphasize the importance of reliable control systems and the need for redundancy in critical components.

The European Union has established the Offshore Safety Directive (Directive 2013/30/EU), which aims to reduce the occurrence of major accidents related to offshore oil and gas operations. This directive indirectly impacts the use of solenoid valves by requiring comprehensive risk assessments and the implementation of safety and environmental management systems.

Classification societies, such as DNV GL and ABS, provide additional layers of regulation through their rules and standards for subsea systems. These organizations often conduct independent verifications of subsea equipment, including solenoid valves, to ensure compliance with industry standards and regulatory requirements.

Environmental regulations also play a significant role in shaping the use of solenoid valves in subsea drilling. For instance, the US Environmental Protection Agency's (EPA) regulations on oil spill prevention and response indirectly influence the design and operation of subsea control systems, including those utilizing solenoid valves.

As technology advances and environmental concerns grow, regulatory frameworks continue to evolve. There is an increasing focus on the reliability and environmental impact of subsea equipment, driving the development of more stringent standards for components like solenoid valves. This ongoing regulatory evolution necessitates continuous adaptation and improvement in the design, manufacture, and implementation of solenoid valves in subsea drilling operations.

At the forefront of regulatory compliance is the International Safety Management (ISM) Code, which provides a framework for the safe management and operation of ships and pollution prevention. This code, while not specifically addressing solenoid valves, sets the foundation for safety management systems that encompass all aspects of subsea operations, including equipment reliability and maintenance.

The American Petroleum Institute (API) has developed several standards directly applicable to subsea equipment, including API Specification 17D for subsea wellhead and tree equipment. These standards often reference the use of solenoid valves and provide guidelines for their selection, installation, and maintenance in subsea environments.

In the United States, the Bureau of Safety and Environmental Enforcement (BSEE) oversees offshore oil and gas operations. The BSEE's regulations, particularly 30 CFR Part 250, outline specific requirements for subsea systems, including those that utilize solenoid valves. These regulations emphasize the importance of reliable control systems and the need for redundancy in critical components.

The European Union has established the Offshore Safety Directive (Directive 2013/30/EU), which aims to reduce the occurrence of major accidents related to offshore oil and gas operations. This directive indirectly impacts the use of solenoid valves by requiring comprehensive risk assessments and the implementation of safety and environmental management systems.

Classification societies, such as DNV GL and ABS, provide additional layers of regulation through their rules and standards for subsea systems. These organizations often conduct independent verifications of subsea equipment, including solenoid valves, to ensure compliance with industry standards and regulatory requirements.

Environmental regulations also play a significant role in shaping the use of solenoid valves in subsea drilling. For instance, the US Environmental Protection Agency's (EPA) regulations on oil spill prevention and response indirectly influence the design and operation of subsea control systems, including those utilizing solenoid valves.

As technology advances and environmental concerns grow, regulatory frameworks continue to evolve. There is an increasing focus on the reliability and environmental impact of subsea equipment, driving the development of more stringent standards for components like solenoid valves. This ongoing regulatory evolution necessitates continuous adaptation and improvement in the design, manufacture, and implementation of solenoid valves in subsea drilling operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!