Sodium alginate, a naturally occurring polysaccharide derived from brown seaweed, has emerged as a critical functional material in diverse scientific and industrial applications. With its unique ability to form gels in the presence of divalent cations, sodium alginate is widely adopted in biomedical, food, textile, and environmental sectors.

This blog provides an in-depth exploration of sodium alginate’s material characteristics, comparative advantages and limitations, real-world applications, and emerging innovations—supplemented with insights from the PatSnap Eureka AI Agent.

Material Composition & Functional Properties of Sodium Alginate

Sodium alginate is primarily composed of mannuronic acid (M) and guluronic acid (G) units arranged in varying block configurations (M-blocks, G-blocks, and MG-blocks). These structural units govern the physical behavior of alginate chains in aqueous solutions and influence their gelation properties, viscosity, and ion-binding capacity.

Key Functional Attributes:

- Excellent water solubility

- Ionotropic gelation with Ca²⁺, Sr²⁺, or Ba²⁺

- Biocompatibility and non-toxicity

- High film-forming ability

- Thermal stability up to ~150°C

- pH-responsive behavior in hydrogel formulations

Comparative Advantages & Limitations of Sodium Alginate

Before diving into applications, it is important to contextualize sodium alginate’s material strengths and technical challenges.

✅ Advantages of Sodium Alginate

| Category | Description |

|---|---|

| Biocompatibility | Safe for biomedical, pharmaceutical, and food uses |

| Renewable Source | Extracted from brown algae—abundant and sustainable |

| Mild Processing | Gelation occurs under ambient conditions with no need for organic solvents |

| Tunable Viscosity | Viscosity adjustable via molecular weight or concentration |

| Custom Gelation | Gel strength modulated via Ca²⁺/Na⁺ exchange ratio and block composition |

| Eco-friendly | Biodegradable and non-toxic to aquatic environments |

| Surface Functionalization | Easily modified with amines, peptides, or other bioactive molecules |

Limitations of Sodium Alginate

| Category | Description |

|---|---|

| Mechanical Fragility | Gels are often brittle and require blending with other polymers |

| Ion Sensitivity | Susceptible to gel shrinkage or dissolution in high-ionic-strength environments |

| Microbial Instability | Can degrade over time without preservatives |

| Limited Solvent Resistance | Insoluble in non-aqueous media |

| Batch Variability | Properties vary with alginate source and extraction method |

| Low Long-Term Stability | Especially under cyclic stress or load-bearing conditions |

Application Domains of Sodium Alginate

Sodium alginate’s functionality extends well beyond traditional hydrocolloid applications. Its biocompatibility, gel-forming ability, and tunable viscosity make it indispensable across medical, food, environmental, and advanced material industries. The following sections explore how sodium alginate is transforming various sectors and technologies.

🏥 Biomedical Engineering & Healthcare

Sodium alginate’s non-toxicity, bio-inertness, and moisture-retentive properties make it ideal for medical applications. It is widely used in wound dressings, tissue scaffolds, and cell encapsulation platforms, enabling regenerative medicine and advanced biomedical systems.

📍Relevant Reports:

To support innovation in biomedical contexts, these insights delve into alginate’s biomedical mechanisms and design strategies:

- How to Enhance Drug Delivery Using Sodium Alginate?

- Future of Sodium Alginate in Wound Healing Technologies

- Sodium Alginate Innovations in Tissue Engineering

- How Sodium Alginate Supports Cell Encapsulation Techniques?

- Sodium Alginate Integration in 3D Bioprinting Solutions

- How to Perfect Drug Encapsulation with Sodium Alginate?

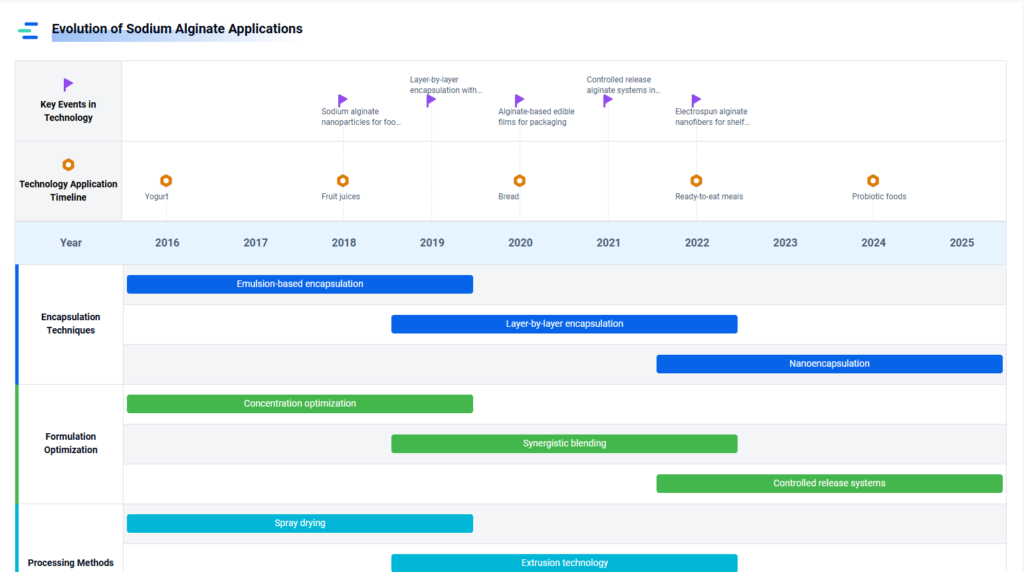

🍽️ Food & Nutraceuticals

In food systems, sodium alginate functions as a stabilizer, thickener, and gelling agent—enhancing shelf life, texture, and nutrient delivery. Its ability to form cold-set gels enables the creation of low-calorie, structured, and fortified products.

📍Relevant Reports:

Explore the following reports to understand alginate’s impact on food texture design and functional nutrition:

- Sodium Alginate: Revolutionizing Food Industry Stabilizers

- How Sodium Alginate Transforms Meat Products’ Texture?

- How Sodium Alginate Elevates Nutraceutical Product Quality?

- How to Design Better Food Textures Using Sodium Alginate?

- How Sodium Alginate Contributes to Weight Management Foods?

- Sodium Alginate: Driving Innovations in Oral Care Products

- How Sodium Alginate Combats Oxidative Stress in Nutraceuticals?

- How to Facilitate Innovation in Textured Food Products Using Sodium Alginate?

- How Sodium Alginate Enhances Shelf Stability in Food Products

💄 Cosmetics & Personal Care

With excellent viscosity control and skin-friendly characteristics, sodium alginate is used in face masks, emulsions, and thickeners in sustainable personal care products. Its moisture retention and compatibility with natural actives make it ideal for green formulations.

📍Relevant Reports:

These insights explore alginate’s growing role in eco-conscious cosmetic formulations:

- Sodium Alginate: A Catalyst for Cosmetic Stabilization

- Sodium Alginate Innovations in Personal Care Industry

- How Sodium Alginate Enhances Retention in Hair Care Formulations?

- How to Boost Skin Absorption with Sodium Alginate Compositions?

- Sodium Alginate: Enhancing Digital Dentistry Technologies

- How to Increase Viscosity for Textiles Using Sodium Alginate?

- Sodium Alginate: Enhancing Textile Printing Efficiency

💊 Pharmaceuticals & Drug Delivery

As a pH-sensitive polymer, sodium alginate facilitates targeted drug release, particularly in oral and injectable systems. Its ionotropic gelation behavior enables controlled delivery and improved therapeutic efficacy.

📍Relevant Reports:

The following Eureka reports spotlight alginate’s role in modern drug delivery strategies:

- How Sodium Alginate Supports Cancer Therapeutic Delivery?

- Sodium Alginate in Advanced Wound Management Systems

- Sodium Alginate for Improved Oral Medication Compliance

- How Sodium Alginate Enhances Sophisticated Drug Delivery Systems?

- Sodium Alginate Applications in Novel Drug Delivery Vehicles

- How Sodium Alginate Supports Pharmaceutical Delivery Breakthroughs?

🌿 Environmental & Packaging Solutions

Sodium alginate contributes to sustainable practices through biodegradable films, controlled-release agrochemicals, and water purification. Its binding and retention capabilities enable ecological formulations that minimize environmental footprint.

📍Relevant Reports:

To explore sodium alginate’s eco-impact, these insights examine its use in green materials and sustainable yield solutions:

- How to Develop Sustainable Packaging with Sodium Alginate?

- Sodium Alginate: Future in Eco-Friendly Packaging Materials

🏭 Advanced Materials & Industrial Manufacturing

In industrial R&D, sodium alginate is utilized to design high-performance membranes, fiber composites, and biopolymer-based inks. It offers a renewable route to materials engineering with tunable rheology, printability, and heat resistance.

📍Relevant Reports:

Explore these applications where sodium alginate plays a role in next-gen sustainable manufacturing:

- How to Engineer Better Coatings Using Sodium Alginate?

- How Sodium Alginate Enhances Water Resistance in Coatings?

- How Sodium Alginate Improves Coating Efficiency in Nanotech?

- Sodium Alginate in Tissue Scaffold Engineering Advances

- How Sodium Alginate Strengthens Pharmaceutics Packing Integrity?

Emerging Innovations

Sodium alginate research is advancing beyond traditional formulations. Key innovation trajectories include:

- Nanostructured Alginate Systems: Integration with nanoparticles for targeted delivery, enhanced mechanical properties, and biosensing.

- Conductive Alginate Hydrogels: Embedded with carbon nanotubes or graphene for bioelectronics and soft robotics.

- Stimuli-Responsive Alginate Networks: Thermo-, pH-, and light-responsive systems for smart actuators.

- CRISPR/Drug Co-delivery Platforms: Dual-delivery microspheres combining gene editing and drug action in alginate matrices.

- 3D Bioprinting & Organ-on-Chip: High-fidelity bioprinting inks enabling complex biological architecture.

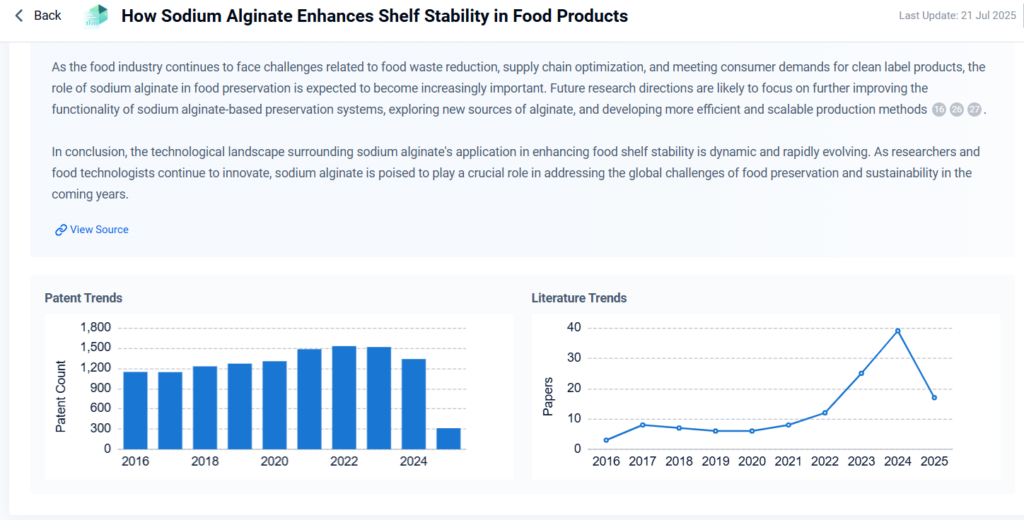

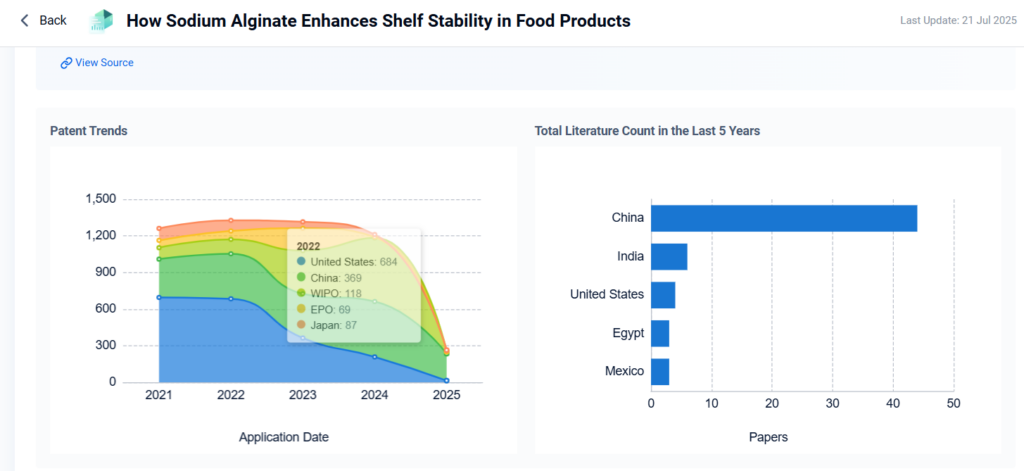

Future Outlook

The development of modified alginate derivatives—such as oxidized alginate, methacrylated alginate, or thiolated alginate—will unlock more robust and application-specific formulations. Cross-sectoral integration with machine learning, AI-based material design, and additive manufacturing promises to accelerate commercialization.

Additionally, regulatory frameworks and standardization of alginate quality will be vital in pharmaceutical and biomedical markets.

FAQ: Sodium Alginate

A: No. Sodium alginate is the sodium salt form of alginic acid and is water-soluble, while alginic acid is insoluble in water.

A: Typically 1–2 weeks when stored at 4°C. Microbial growth can reduce shelf stability unless preservatives are used.

A: Yes. It is a common bioink in 3D bioprinting when crosslinked with calcium chloride during extrusion.

A: It is extracted from brown algae such as Laminaria and Ascophyllum via alkaline extraction and neutralization processes.

A: Yes. Being derived from seaweed, it is compatible with vegan, halal, and kosher certifications.

Ready to Power Innovation with Sodium Alginate Intelligence?

PatSnap Eureka AI Agent gives engineers, material scientists, and formulators access to thousands of curated reports and insights on sodium alginate innovations—tracking patent activity, technical performance data, and emerging formulation strategies.

👉 Book a Eureka demo nd future-proof your R&D with real-time sodium alginate intelligence.