How to Develop Sustainable Packaging with Sodium Alginate?

JUL 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate Packaging Background and Objectives

Sodium alginate, a versatile biopolymer derived from brown seaweed, has emerged as a promising material for sustainable packaging solutions. The development of packaging using sodium alginate aligns with the growing global demand for environmentally friendly alternatives to traditional plastic packaging. This technology aims to address the urgent need for reducing plastic waste and its detrimental impact on ecosystems.

The evolution of sodium alginate packaging technology can be traced back to the early 2000s when researchers began exploring its potential as a biodegradable film-forming agent. Over the past two decades, significant advancements have been made in understanding the properties and applications of sodium alginate in packaging materials. The technology has progressed from basic film formation to more complex structures with enhanced barrier properties and mechanical strength.

Current trends in sodium alginate packaging research focus on improving its functionality, scalability, and cost-effectiveness. Key areas of development include enhancing water resistance, increasing tensile strength, and incorporating active compounds for extended shelf life of packaged products. The integration of nanotechnology and composite materials with sodium alginate is also gaining traction, opening up new possibilities for high-performance sustainable packaging.

The primary objective of developing sustainable packaging with sodium alginate is to create a viable alternative to conventional plastic packaging that can significantly reduce environmental pollution. This involves designing packaging solutions that are not only biodegradable and compostable but also meet the performance requirements of various industries, including food, pharmaceuticals, and consumer goods.

Another crucial goal is to optimize the production processes of sodium alginate packaging to ensure economic feasibility and large-scale adoption. This includes developing efficient extraction methods for sodium alginate from seaweed, as well as streamlining manufacturing techniques for packaging production. Researchers are also working on improving the compatibility of sodium alginate with existing packaging machinery to facilitate seamless integration into current industrial processes.

Furthermore, the development of sodium alginate packaging aims to contribute to the circular economy by creating a closed-loop system where packaging materials can be easily recycled or composted. This aligns with global sustainability initiatives and regulations aimed at reducing single-use plastics and promoting eco-friendly packaging solutions.

In conclusion, the background and objectives of sodium alginate packaging development reflect a comprehensive approach to addressing environmental concerns while meeting the functional needs of modern packaging. As research continues to advance, sodium alginate holds the potential to revolutionize the packaging industry and play a significant role in sustainable material innovation.

The evolution of sodium alginate packaging technology can be traced back to the early 2000s when researchers began exploring its potential as a biodegradable film-forming agent. Over the past two decades, significant advancements have been made in understanding the properties and applications of sodium alginate in packaging materials. The technology has progressed from basic film formation to more complex structures with enhanced barrier properties and mechanical strength.

Current trends in sodium alginate packaging research focus on improving its functionality, scalability, and cost-effectiveness. Key areas of development include enhancing water resistance, increasing tensile strength, and incorporating active compounds for extended shelf life of packaged products. The integration of nanotechnology and composite materials with sodium alginate is also gaining traction, opening up new possibilities for high-performance sustainable packaging.

The primary objective of developing sustainable packaging with sodium alginate is to create a viable alternative to conventional plastic packaging that can significantly reduce environmental pollution. This involves designing packaging solutions that are not only biodegradable and compostable but also meet the performance requirements of various industries, including food, pharmaceuticals, and consumer goods.

Another crucial goal is to optimize the production processes of sodium alginate packaging to ensure economic feasibility and large-scale adoption. This includes developing efficient extraction methods for sodium alginate from seaweed, as well as streamlining manufacturing techniques for packaging production. Researchers are also working on improving the compatibility of sodium alginate with existing packaging machinery to facilitate seamless integration into current industrial processes.

Furthermore, the development of sodium alginate packaging aims to contribute to the circular economy by creating a closed-loop system where packaging materials can be easily recycled or composted. This aligns with global sustainability initiatives and regulations aimed at reducing single-use plastics and promoting eco-friendly packaging solutions.

In conclusion, the background and objectives of sodium alginate packaging development reflect a comprehensive approach to addressing environmental concerns while meeting the functional needs of modern packaging. As research continues to advance, sodium alginate holds the potential to revolutionize the packaging industry and play a significant role in sustainable material innovation.

Market Demand for Sustainable Packaging Solutions

The demand for sustainable packaging solutions has been growing exponentially in recent years, driven by increasing environmental awareness, stringent regulations, and changing consumer preferences. The global sustainable packaging market is projected to reach $305.31 billion by 2027, growing at a CAGR of 6.1% from 2020 to 2027. This surge in demand is particularly evident in the food and beverage, personal care, and healthcare industries.

Consumers are increasingly seeking eco-friendly packaging options, with 74% of consumers willing to pay more for sustainable packaging. This shift in consumer behavior has prompted major brands and retailers to commit to ambitious sustainability goals, further driving the demand for innovative packaging solutions. Many companies have pledged to make their packaging 100% recyclable, reusable, or compostable by 2025 or 2030.

The use of sodium alginate in sustainable packaging aligns well with these market trends. Derived from brown seaweed, sodium alginate is biodegradable, renewable, and non-toxic, making it an attractive alternative to conventional plastic packaging materials. Its versatility allows for applications in various forms, including films, coatings, and hydrogels, which can be tailored to meet specific packaging requirements.

In the food industry, there is a growing demand for edible packaging solutions to reduce waste and enhance product shelf life. Sodium alginate-based edible films and coatings have shown promise in preserving food quality and extending shelf life, addressing both sustainability and food waste concerns. The pharmaceutical and personal care sectors are also exploring sodium alginate-based packaging for its barrier properties and potential for controlled release applications.

E-commerce growth has further accelerated the need for sustainable packaging solutions. With online sales surging, especially in the wake of the COVID-19 pandemic, there is an increased focus on developing packaging that is not only environmentally friendly but also robust enough to withstand the rigors of shipping and handling. Sodium alginate-based materials offer potential solutions in this area, particularly when combined with other bio-based materials to enhance strength and durability.

However, challenges remain in scaling up production and reducing costs to compete with traditional packaging materials. The market demands cost-effective solutions that do not compromise on performance or sustainability. As research and development in sodium alginate-based packaging progresses, addressing these challenges will be crucial to meeting market demands and achieving widespread adoption in various industries.

Consumers are increasingly seeking eco-friendly packaging options, with 74% of consumers willing to pay more for sustainable packaging. This shift in consumer behavior has prompted major brands and retailers to commit to ambitious sustainability goals, further driving the demand for innovative packaging solutions. Many companies have pledged to make their packaging 100% recyclable, reusable, or compostable by 2025 or 2030.

The use of sodium alginate in sustainable packaging aligns well with these market trends. Derived from brown seaweed, sodium alginate is biodegradable, renewable, and non-toxic, making it an attractive alternative to conventional plastic packaging materials. Its versatility allows for applications in various forms, including films, coatings, and hydrogels, which can be tailored to meet specific packaging requirements.

In the food industry, there is a growing demand for edible packaging solutions to reduce waste and enhance product shelf life. Sodium alginate-based edible films and coatings have shown promise in preserving food quality and extending shelf life, addressing both sustainability and food waste concerns. The pharmaceutical and personal care sectors are also exploring sodium alginate-based packaging for its barrier properties and potential for controlled release applications.

E-commerce growth has further accelerated the need for sustainable packaging solutions. With online sales surging, especially in the wake of the COVID-19 pandemic, there is an increased focus on developing packaging that is not only environmentally friendly but also robust enough to withstand the rigors of shipping and handling. Sodium alginate-based materials offer potential solutions in this area, particularly when combined with other bio-based materials to enhance strength and durability.

However, challenges remain in scaling up production and reducing costs to compete with traditional packaging materials. The market demands cost-effective solutions that do not compromise on performance or sustainability. As research and development in sodium alginate-based packaging progresses, addressing these challenges will be crucial to meeting market demands and achieving widespread adoption in various industries.

Current State and Challenges in Sodium Alginate Packaging

Sodium alginate packaging has gained significant attention in recent years as a sustainable alternative to traditional plastic packaging. The current state of this technology is characterized by promising advancements, yet it faces several challenges that need to be addressed for widespread adoption.

One of the primary advantages of sodium alginate packaging is its biodegradability and eco-friendliness. Derived from brown seaweed, sodium alginate is a natural polymer that can decompose without leaving harmful residues in the environment. This aligns well with the growing consumer demand for sustainable packaging solutions and the increasing regulatory pressure on reducing plastic waste.

In terms of technical development, sodium alginate packaging has shown remarkable progress in improving its barrier properties. Recent research has focused on enhancing the material's resistance to moisture and oxygen, which are crucial factors for food preservation. Some studies have demonstrated successful incorporation of nanoparticles or other additives to improve these properties, making sodium alginate films more suitable for a wider range of applications.

However, the current state of sodium alginate packaging also presents several challenges. One of the main obstacles is its relatively high production cost compared to conventional plastic packaging. The extraction and processing of sodium alginate from seaweed can be resource-intensive, leading to higher material costs. This economic factor has limited its widespread adoption in the packaging industry.

Another significant challenge is the material's inherent sensitivity to moisture. While progress has been made in improving water resistance, sodium alginate packaging still tends to lose its structural integrity when exposed to high humidity or direct contact with water. This limitation restricts its use in certain food packaging applications, particularly for products with high moisture content or those requiring long shelf lives.

Scalability remains a concern in the current state of sodium alginate packaging. The production processes for creating large quantities of consistent, high-quality packaging materials are still being refined. This includes challenges in achieving uniform thickness, strength, and barrier properties across large-scale production runs.

Furthermore, the mechanical properties of sodium alginate films, such as tensile strength and flexibility, often fall short of those offered by traditional plastic packaging. This can lead to limitations in packaging design and functionality, potentially restricting the types of products that can be packaged using this material.

Regulatory hurdles also pose a challenge to the widespread adoption of sodium alginate packaging. While generally recognized as safe, the use of novel additives or processing methods to enhance the material's properties may require additional safety assessments and approvals from food safety authorities.

In conclusion, while sodium alginate packaging shows great promise as a sustainable alternative, it currently faces a complex landscape of technical, economic, and regulatory challenges. Overcoming these obstacles will be crucial for its future development and widespread adoption in the packaging industry.

One of the primary advantages of sodium alginate packaging is its biodegradability and eco-friendliness. Derived from brown seaweed, sodium alginate is a natural polymer that can decompose without leaving harmful residues in the environment. This aligns well with the growing consumer demand for sustainable packaging solutions and the increasing regulatory pressure on reducing plastic waste.

In terms of technical development, sodium alginate packaging has shown remarkable progress in improving its barrier properties. Recent research has focused on enhancing the material's resistance to moisture and oxygen, which are crucial factors for food preservation. Some studies have demonstrated successful incorporation of nanoparticles or other additives to improve these properties, making sodium alginate films more suitable for a wider range of applications.

However, the current state of sodium alginate packaging also presents several challenges. One of the main obstacles is its relatively high production cost compared to conventional plastic packaging. The extraction and processing of sodium alginate from seaweed can be resource-intensive, leading to higher material costs. This economic factor has limited its widespread adoption in the packaging industry.

Another significant challenge is the material's inherent sensitivity to moisture. While progress has been made in improving water resistance, sodium alginate packaging still tends to lose its structural integrity when exposed to high humidity or direct contact with water. This limitation restricts its use in certain food packaging applications, particularly for products with high moisture content or those requiring long shelf lives.

Scalability remains a concern in the current state of sodium alginate packaging. The production processes for creating large quantities of consistent, high-quality packaging materials are still being refined. This includes challenges in achieving uniform thickness, strength, and barrier properties across large-scale production runs.

Furthermore, the mechanical properties of sodium alginate films, such as tensile strength and flexibility, often fall short of those offered by traditional plastic packaging. This can lead to limitations in packaging design and functionality, potentially restricting the types of products that can be packaged using this material.

Regulatory hurdles also pose a challenge to the widespread adoption of sodium alginate packaging. While generally recognized as safe, the use of novel additives or processing methods to enhance the material's properties may require additional safety assessments and approvals from food safety authorities.

In conclusion, while sodium alginate packaging shows great promise as a sustainable alternative, it currently faces a complex landscape of technical, economic, and regulatory challenges. Overcoming these obstacles will be crucial for its future development and widespread adoption in the packaging industry.

Existing Sodium Alginate Packaging Solutions

01 Sustainable production methods

Various sustainable methods for producing sodium alginate have been developed, including eco-friendly extraction processes from seaweed and algae. These methods aim to reduce environmental impact and improve resource efficiency in the production of this versatile compound.- Sustainable production methods: Various sustainable methods for producing sodium alginate have been developed, including using renewable resources and optimizing extraction processes. These methods aim to reduce environmental impact and improve resource efficiency in sodium alginate production.

- Biodegradable applications: Sodium alginate is being utilized in biodegradable applications, such as packaging materials and disposable products. This contributes to sustainability by reducing plastic waste and promoting eco-friendly alternatives in various industries.

- Water treatment and purification: Sodium alginate is employed in sustainable water treatment and purification processes. It can be used as a flocculant or adsorbent to remove contaminants from water, contributing to environmental protection and resource conservation.

- Sustainable agriculture applications: Sodium alginate is used in sustainable agriculture practices, such as soil conditioning, seed coating, and controlled release of fertilizers. These applications help improve crop yields while reducing environmental impact and promoting sustainable farming methods.

- Eco-friendly personal care products: Sodium alginate is incorporated into eco-friendly personal care products, such as natural cosmetics and biodegradable hygiene items. This supports sustainability in the personal care industry by reducing the use of synthetic and potentially harmful ingredients.

02 Biodegradable packaging applications

Sodium alginate is being utilized in the development of biodegradable packaging materials, offering a sustainable alternative to traditional plastic packaging. These applications contribute to reducing plastic waste and promoting environmental conservation.Expand Specific Solutions03 Sustainable agriculture and soil improvement

Sodium alginate is being employed in sustainable agriculture practices, including soil improvement and plant growth promotion. Its use in this field contributes to more environmentally friendly farming methods and improved crop yields.Expand Specific Solutions04 Wastewater treatment and environmental remediation

Innovative applications of sodium alginate in wastewater treatment and environmental remediation processes have been developed. These applications help in removing pollutants and contaminants from water and soil, contributing to environmental sustainability.Expand Specific Solutions05 Sustainable biomedical and pharmaceutical applications

Sodium alginate is being used in various sustainable biomedical and pharmaceutical applications, including drug delivery systems and tissue engineering. These applications promote the development of more environmentally friendly medical treatments and technologies.Expand Specific Solutions

Key Players in Sustainable Packaging Industry

The development of sustainable packaging using sodium alginate is in an emerging phase, with growing market potential driven by increasing environmental concerns. The global market for biodegradable packaging is expanding rapidly, expected to reach $21.6 billion by 2025. While the technology is still evolving, several key players are making significant strides. Companies like Notpla Ltd. and Qingdao Bright Moon Seaweed Group Co., Ltd. are at the forefront, developing innovative seaweed-based packaging solutions. Academic institutions such as the National University of Singapore and Zhejiang University are contributing to research and development efforts. Major consumer goods companies like Unilever and Colgate-Palmolive are also exploring sustainable packaging alternatives, indicating a shift towards more environmentally friendly solutions in the industry.

Notpla Ltd.

Technical Solution: Notpla has developed a revolutionary sustainable packaging solution using sodium alginate as a key ingredient. Their flagship product, Ooho, is an edible and biodegradable packaging made from seaweed extract. The company has created a proprietary material called Notpla, which is a combination of seaweed and plants that can be used to create flexible films and coatings. This material is used to produce sachets for condiments, bubbles for beverages, and even takeaway food containers. The production process involves extracting sodium alginate from brown seaweed, which is then combined with other natural materials to create a flexible, strong, and water-resistant packaging material[1][2]. Notpla's technology allows for the creation of packaging that dissolves naturally in water or can be consumed along with the product, leaving no waste behind.

Strengths: Fully biodegradable and edible packaging, reducing plastic waste. Versatile application in various food and beverage industries. Weaknesses: Limited shelf life compared to traditional plastics, potential scalability challenges for mass production.

Qingdao Bright Moon Seaweed Group Co., Ltd.

Technical Solution: Qingdao Bright Moon Seaweed Group has developed an innovative approach to sustainable packaging using sodium alginate extracted from seaweed. Their process involves refining high-quality sodium alginate from brown algae, which is then used to create biodegradable films and coatings for food packaging. The company has invested in advanced extraction and purification technologies to ensure the sodium alginate meets food-grade standards. Their packaging solutions include edible films for fresh produce, dissolvable sachets for single-use condiments, and protective coatings for fruits and vegetables to extend shelf life. The company has also developed a proprietary blend of sodium alginate with other natural polymers to enhance the mechanical properties and water resistance of their packaging materials[3][4]. This technology allows for the creation of packaging that can withstand various environmental conditions while remaining fully biodegradable.

Strengths: Vertically integrated production from seaweed cultivation to final packaging products, ensuring quality control. Large-scale production capabilities. Weaknesses: Potential limitations in certain high-moisture applications, ongoing research needed for broader market adoption.

Core Innovations in Sodium Alginate-based Materials

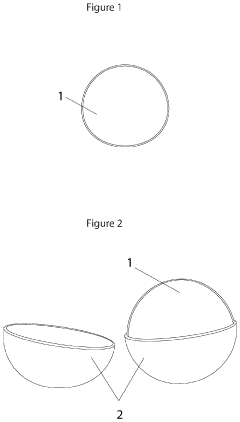

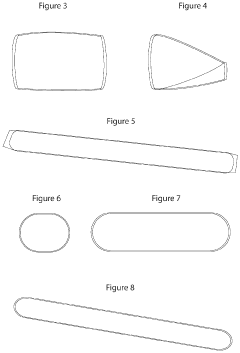

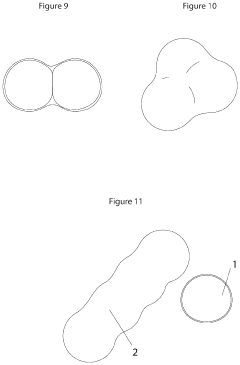

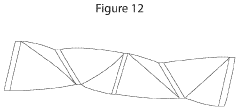

Method of encapsulating liquid products

PatentActiveUS20200047927A1

Innovation

- A method involving blending alginate with a thickener, extruding the mixture to form a membrane, applying a calcium-rich ion solution to crosslink it, and sealing the membrane around the liquid product to create a water-insoluble, biodegradable or edible capsule that can encapsulate larger volumes with minimal leakage.

Environmental Impact Assessment

The environmental impact assessment of sustainable packaging using sodium alginate reveals significant potential for reducing the ecological footprint of packaging materials. Sodium alginate, derived from brown seaweed, offers a biodegradable and renewable alternative to conventional plastic packaging.

One of the primary environmental benefits of sodium alginate-based packaging is its biodegradability. Unlike traditional plastics that persist in the environment for hundreds of years, sodium alginate packaging can decompose naturally within weeks to months, depending on environmental conditions. This rapid decomposition significantly reduces the accumulation of packaging waste in landfills and oceans, mitigating long-term environmental damage.

The production process of sodium alginate packaging also demonstrates lower environmental impact compared to petroleum-based plastics. The cultivation and harvesting of seaweed for alginate extraction require minimal land use and do not compete with food crops. Additionally, seaweed cultivation can contribute to carbon sequestration, potentially offsetting some of the emissions associated with packaging production.

Water consumption in the production of sodium alginate packaging is another area of environmental consideration. While the process does require water, it is generally less water-intensive than the production of many synthetic polymers. Furthermore, the water used in alginate extraction can often be recycled within the production process, reducing overall water demand.

In terms of energy consumption, the production of sodium alginate packaging typically requires less energy compared to the manufacture of conventional plastics. This lower energy demand translates to reduced greenhouse gas emissions throughout the product lifecycle. However, it is important to note that the specific energy requirements can vary depending on the exact production methods and scale of operation.

The end-of-life scenario for sodium alginate packaging presents further environmental advantages. As a biodegradable material, it can be composted in industrial facilities, returning nutrients to the soil and closing the material loop. This composting potential reduces the need for incineration or landfilling, both of which have negative environmental impacts.

However, it is crucial to consider the potential environmental trade-offs. The increased demand for seaweed cultivation could impact marine ecosystems if not managed sustainably. Careful monitoring and regulation of seaweed harvesting practices are necessary to prevent overexploitation and maintain the ecological balance of coastal areas.

In conclusion, the environmental impact assessment of sodium alginate packaging indicates a promising direction for sustainable packaging solutions. While challenges remain in scaling production and optimizing material properties, the overall environmental benefits make it a compelling alternative to traditional plastic packaging. Further research and development in this area could lead to significant reductions in packaging-related environmental impacts across various industries.

One of the primary environmental benefits of sodium alginate-based packaging is its biodegradability. Unlike traditional plastics that persist in the environment for hundreds of years, sodium alginate packaging can decompose naturally within weeks to months, depending on environmental conditions. This rapid decomposition significantly reduces the accumulation of packaging waste in landfills and oceans, mitigating long-term environmental damage.

The production process of sodium alginate packaging also demonstrates lower environmental impact compared to petroleum-based plastics. The cultivation and harvesting of seaweed for alginate extraction require minimal land use and do not compete with food crops. Additionally, seaweed cultivation can contribute to carbon sequestration, potentially offsetting some of the emissions associated with packaging production.

Water consumption in the production of sodium alginate packaging is another area of environmental consideration. While the process does require water, it is generally less water-intensive than the production of many synthetic polymers. Furthermore, the water used in alginate extraction can often be recycled within the production process, reducing overall water demand.

In terms of energy consumption, the production of sodium alginate packaging typically requires less energy compared to the manufacture of conventional plastics. This lower energy demand translates to reduced greenhouse gas emissions throughout the product lifecycle. However, it is important to note that the specific energy requirements can vary depending on the exact production methods and scale of operation.

The end-of-life scenario for sodium alginate packaging presents further environmental advantages. As a biodegradable material, it can be composted in industrial facilities, returning nutrients to the soil and closing the material loop. This composting potential reduces the need for incineration or landfilling, both of which have negative environmental impacts.

However, it is crucial to consider the potential environmental trade-offs. The increased demand for seaweed cultivation could impact marine ecosystems if not managed sustainably. Careful monitoring and regulation of seaweed harvesting practices are necessary to prevent overexploitation and maintain the ecological balance of coastal areas.

In conclusion, the environmental impact assessment of sodium alginate packaging indicates a promising direction for sustainable packaging solutions. While challenges remain in scaling production and optimizing material properties, the overall environmental benefits make it a compelling alternative to traditional plastic packaging. Further research and development in this area could lead to significant reductions in packaging-related environmental impacts across various industries.

Regulatory Compliance for Biobased Packaging

Regulatory compliance is a critical aspect of developing sustainable packaging with sodium alginate, particularly in the context of biobased materials. As the global focus on environmental sustainability intensifies, governments and regulatory bodies worldwide have implemented stringent guidelines for packaging materials, especially those derived from biological sources.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating food contact materials, including those made from sodium alginate. Manufacturers must ensure that their packaging complies with FDA regulations, particularly 21 CFR 176.170, which outlines the requirements for components of paper and paperboard in contact with aqueous and fatty foods. Additionally, the Environmental Protection Agency (EPA) enforces regulations related to the environmental impact of packaging materials, including their biodegradability and potential for pollution.

The European Union has established comprehensive regulations for food contact materials through Regulation (EC) No 1935/2004. This framework ensures that materials do not transfer their constituents to food in quantities that could endanger human health or change the composition of the food. For biobased packaging like those incorporating sodium alginate, compliance with EU 10/2011 on plastic materials and articles intended to come into contact with food is essential.

Biodegradability claims for packaging materials are subject to strict verification processes. In the United States, the Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability. The ASTM D6400 standard for compostable plastics is often used as a benchmark for biodegradability claims. In Europe, the EN 13432 standard serves a similar purpose, providing criteria for packaging recoverable through composting and biodegradation.

Manufacturers must also consider regulations related to waste management and recycling. The EU's Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, encouraging the use of materials that can be easily recycled or composted. In the United States, regulations vary by state, but many have implemented extended producer responsibility (EPR) laws that hold manufacturers accountable for the entire lifecycle of their packaging.

Certification programs play a crucial role in demonstrating regulatory compliance. Organizations such as the Biodegradable Products Institute (BPI) in North America and TÜV Austria in Europe offer certification for compostable materials, providing assurance to consumers and regulators alike. These certifications often require extensive testing to verify the material's biodegradability, compostability, and absence of harmful substances.

As the regulatory landscape continues to evolve, manufacturers developing sustainable packaging with sodium alginate must stay informed of changes in legislation and standards. This includes monitoring developments in nanomaterials regulations, as some applications of sodium alginate may involve nanostructures. Proactive engagement with regulatory bodies and participation in industry associations can help ensure ongoing compliance and contribute to the development of future standards in this rapidly advancing field.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating food contact materials, including those made from sodium alginate. Manufacturers must ensure that their packaging complies with FDA regulations, particularly 21 CFR 176.170, which outlines the requirements for components of paper and paperboard in contact with aqueous and fatty foods. Additionally, the Environmental Protection Agency (EPA) enforces regulations related to the environmental impact of packaging materials, including their biodegradability and potential for pollution.

The European Union has established comprehensive regulations for food contact materials through Regulation (EC) No 1935/2004. This framework ensures that materials do not transfer their constituents to food in quantities that could endanger human health or change the composition of the food. For biobased packaging like those incorporating sodium alginate, compliance with EU 10/2011 on plastic materials and articles intended to come into contact with food is essential.

Biodegradability claims for packaging materials are subject to strict verification processes. In the United States, the Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability. The ASTM D6400 standard for compostable plastics is often used as a benchmark for biodegradability claims. In Europe, the EN 13432 standard serves a similar purpose, providing criteria for packaging recoverable through composting and biodegradation.

Manufacturers must also consider regulations related to waste management and recycling. The EU's Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, encouraging the use of materials that can be easily recycled or composted. In the United States, regulations vary by state, but many have implemented extended producer responsibility (EPR) laws that hold manufacturers accountable for the entire lifecycle of their packaging.

Certification programs play a crucial role in demonstrating regulatory compliance. Organizations such as the Biodegradable Products Institute (BPI) in North America and TÜV Austria in Europe offer certification for compostable materials, providing assurance to consumers and regulators alike. These certifications often require extensive testing to verify the material's biodegradability, compostability, and absence of harmful substances.

As the regulatory landscape continues to evolve, manufacturers developing sustainable packaging with sodium alginate must stay informed of changes in legislation and standards. This includes monitoring developments in nanomaterials regulations, as some applications of sodium alginate may involve nanostructures. Proactive engagement with regulatory bodies and participation in industry associations can help ensure ongoing compliance and contribute to the development of future standards in this rapidly advancing field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!