How Sodium Alginate Supports Low-Fat Food Developments?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Alginate in Low-Fat Food: Background and Objectives

Sodium alginate, a versatile polysaccharide derived from brown seaweed, has emerged as a key ingredient in the development of low-fat food products. The increasing global focus on health and wellness has driven consumer demand for reduced-fat alternatives that maintain the taste, texture, and mouthfeel of their full-fat counterparts. This shift in consumer preferences has prompted food manufacturers to explore innovative solutions, with sodium alginate playing a crucial role in addressing these challenges.

The evolution of sodium alginate in food applications can be traced back to its initial use as a stabilizer and thickening agent. Over time, researchers and food technologists have uncovered its potential in fat replacement, leading to its widespread adoption in the low-fat food industry. The unique gelling and emulsifying properties of sodium alginate make it an ideal candidate for mimicking the sensory attributes typically associated with fat in various food products.

The primary objective of utilizing sodium alginate in low-fat food development is to create healthier alternatives without compromising on taste or texture. This aligns with the broader goal of combating obesity and related health issues while meeting consumer expectations for enjoyable, nutritious food options. By leveraging the functional properties of sodium alginate, food manufacturers aim to reduce the overall fat content in products such as dairy, baked goods, and processed meats, while maintaining their desirable organoleptic qualities.

From a technical perspective, sodium alginate's ability to form stable gels and emulsions in the presence of calcium ions is particularly valuable. This characteristic allows for the creation of fat-like structures that can replicate the mouthfeel and lubricity typically provided by lipids. Additionally, its water-binding capacity helps retain moisture in low-fat formulations, preventing the dryness often associated with reduced-fat products.

The ongoing research and development in this field focus on optimizing the use of sodium alginate in various food matrices. Scientists are exploring different molecular weights and compositions of sodium alginate to tailor its functionality for specific applications. Furthermore, the synergistic effects of combining sodium alginate with other hydrocolloids and functional ingredients are being investigated to enhance its fat-mimicking capabilities.

As the food industry continues to innovate, the role of sodium alginate in low-fat food development is expected to expand. The growing body of scientific literature and patent applications in this area underscores the significance of this technology in addressing the dual challenges of health consciousness and consumer satisfaction. By enabling the creation of low-fat products that closely resemble their full-fat counterparts, sodium alginate is poised to play a pivotal role in shaping the future of healthier food options.

The evolution of sodium alginate in food applications can be traced back to its initial use as a stabilizer and thickening agent. Over time, researchers and food technologists have uncovered its potential in fat replacement, leading to its widespread adoption in the low-fat food industry. The unique gelling and emulsifying properties of sodium alginate make it an ideal candidate for mimicking the sensory attributes typically associated with fat in various food products.

The primary objective of utilizing sodium alginate in low-fat food development is to create healthier alternatives without compromising on taste or texture. This aligns with the broader goal of combating obesity and related health issues while meeting consumer expectations for enjoyable, nutritious food options. By leveraging the functional properties of sodium alginate, food manufacturers aim to reduce the overall fat content in products such as dairy, baked goods, and processed meats, while maintaining their desirable organoleptic qualities.

From a technical perspective, sodium alginate's ability to form stable gels and emulsions in the presence of calcium ions is particularly valuable. This characteristic allows for the creation of fat-like structures that can replicate the mouthfeel and lubricity typically provided by lipids. Additionally, its water-binding capacity helps retain moisture in low-fat formulations, preventing the dryness often associated with reduced-fat products.

The ongoing research and development in this field focus on optimizing the use of sodium alginate in various food matrices. Scientists are exploring different molecular weights and compositions of sodium alginate to tailor its functionality for specific applications. Furthermore, the synergistic effects of combining sodium alginate with other hydrocolloids and functional ingredients are being investigated to enhance its fat-mimicking capabilities.

As the food industry continues to innovate, the role of sodium alginate in low-fat food development is expected to expand. The growing body of scientific literature and patent applications in this area underscores the significance of this technology in addressing the dual challenges of health consciousness and consumer satisfaction. By enabling the creation of low-fat products that closely resemble their full-fat counterparts, sodium alginate is poised to play a pivotal role in shaping the future of healthier food options.

Market Demand for Healthier Low-Fat Food Options

The market demand for healthier low-fat food options has been steadily increasing over the past decade, driven by growing consumer awareness of the link between diet and health. This trend is particularly evident in developed countries, where obesity rates and related health issues have become major public health concerns. Consumers are actively seeking alternatives to traditional high-fat foods, creating a significant opportunity for food manufacturers to innovate and develop new products.

The global low-fat food market has experienced substantial growth, with consumers showing a strong preference for products that offer reduced fat content without compromising on taste or texture. This demand spans across various food categories, including dairy products, baked goods, snacks, and ready-to-eat meals. The market is particularly robust in regions such as North America and Europe, where health-conscious consumers are willing to pay a premium for healthier food options.

One of the key drivers of this market trend is the increasing prevalence of lifestyle-related diseases such as obesity, diabetes, and cardiovascular disorders. Public health campaigns and government initiatives aimed at promoting healthier eating habits have further fueled consumer interest in low-fat alternatives. Additionally, the growing popularity of fitness and wellness lifestyles has contributed to the demand for foods that support weight management and overall health.

The food industry has responded to this demand by investing heavily in research and development to create innovative low-fat products. However, one of the main challenges in developing these products is maintaining the desirable sensory properties that consumers expect. Fat plays a crucial role in food texture, mouthfeel, and flavor, and its reduction often results in products that are less appealing to consumers. This is where ingredients like sodium alginate come into play, offering potential solutions to improve the quality of low-fat food products.

Consumer preferences within the low-fat food market are diverse, with different segments seeking specific attributes. Some consumers prioritize natural and clean-label ingredients, while others focus on functional benefits such as added fiber or protein. There is also a growing demand for plant-based low-fat options, aligning with the broader trend towards plant-based diets. This diversity in consumer preferences presents both challenges and opportunities for food manufacturers, requiring them to develop a range of products to cater to different market segments.

The market demand for healthier low-fat food options is expected to continue growing in the coming years, driven by ongoing health trends and increasing consumer education. As consumers become more sophisticated in their understanding of nutrition, there is likely to be a shift towards products that not only offer reduced fat content but also provide additional health benefits. This evolving landscape presents significant opportunities for innovation in food technology, including the use of novel ingredients and processing techniques to create low-fat products that meet consumer expectations for taste, texture, and nutritional value.

The global low-fat food market has experienced substantial growth, with consumers showing a strong preference for products that offer reduced fat content without compromising on taste or texture. This demand spans across various food categories, including dairy products, baked goods, snacks, and ready-to-eat meals. The market is particularly robust in regions such as North America and Europe, where health-conscious consumers are willing to pay a premium for healthier food options.

One of the key drivers of this market trend is the increasing prevalence of lifestyle-related diseases such as obesity, diabetes, and cardiovascular disorders. Public health campaigns and government initiatives aimed at promoting healthier eating habits have further fueled consumer interest in low-fat alternatives. Additionally, the growing popularity of fitness and wellness lifestyles has contributed to the demand for foods that support weight management and overall health.

The food industry has responded to this demand by investing heavily in research and development to create innovative low-fat products. However, one of the main challenges in developing these products is maintaining the desirable sensory properties that consumers expect. Fat plays a crucial role in food texture, mouthfeel, and flavor, and its reduction often results in products that are less appealing to consumers. This is where ingredients like sodium alginate come into play, offering potential solutions to improve the quality of low-fat food products.

Consumer preferences within the low-fat food market are diverse, with different segments seeking specific attributes. Some consumers prioritize natural and clean-label ingredients, while others focus on functional benefits such as added fiber or protein. There is also a growing demand for plant-based low-fat options, aligning with the broader trend towards plant-based diets. This diversity in consumer preferences presents both challenges and opportunities for food manufacturers, requiring them to develop a range of products to cater to different market segments.

The market demand for healthier low-fat food options is expected to continue growing in the coming years, driven by ongoing health trends and increasing consumer education. As consumers become more sophisticated in their understanding of nutrition, there is likely to be a shift towards products that not only offer reduced fat content but also provide additional health benefits. This evolving landscape presents significant opportunities for innovation in food technology, including the use of novel ingredients and processing techniques to create low-fat products that meet consumer expectations for taste, texture, and nutritional value.

Current Challenges in Low-Fat Food Development

The development of low-fat food products presents several significant challenges for food manufacturers and researchers. One of the primary obstacles is maintaining the desirable sensory attributes of full-fat products while reducing fat content. Fat plays a crucial role in food texture, mouthfeel, and flavor, making it difficult to replicate these qualities in low-fat alternatives.

Texture modification is a major hurdle in low-fat food development. Fat contributes to the creamy, smooth texture of many products, and its reduction often results in a less appealing mouthfeel. This is particularly evident in dairy products, baked goods, and processed meats. Achieving the right consistency and preventing a gritty or watery texture requires extensive research and formulation adjustments.

Flavor retention and enhancement pose another significant challenge. Fat acts as a flavor carrier and contributes to the overall taste profile of foods. When fat is reduced or removed, the intensity and perception of flavors can be diminished. This necessitates the use of flavor enhancers or alternative ingredients to compensate for the loss of taste, which can be complex and costly.

Stability and shelf life are also affected by fat reduction. Fat plays a role in emulsion stability, moisture retention, and microbial control in many food products. Low-fat formulations may be more prone to separation, drying out, or spoilage, requiring the development of new preservation techniques and stabilizing systems.

Nutritional balance is another consideration in low-fat food development. While reducing fat content can lower calorie density, it may also impact the absorption of fat-soluble vitamins and essential fatty acids. Ensuring that low-fat products still provide adequate nutrition without compromising health benefits is a complex task for food scientists.

Consumer acceptance remains a critical challenge. Despite health concerns, many consumers are accustomed to the taste and texture of full-fat products. Overcoming taste preferences and meeting expectations for familiar foods in their low-fat versions requires extensive sensory testing and consumer research.

Regulatory compliance adds another layer of complexity. Labeling requirements for low-fat claims vary across regions, and meeting these standards while delivering on taste and texture can be challenging. Additionally, the use of certain fat replacers or additives may be restricted in some markets, limiting formulation options.

Lastly, cost considerations play a significant role in low-fat food development. The ingredients and technologies required to replicate the properties of fat can be expensive, potentially increasing production costs. Balancing affordability with quality and nutritional value is an ongoing challenge for manufacturers in the competitive food industry.

Texture modification is a major hurdle in low-fat food development. Fat contributes to the creamy, smooth texture of many products, and its reduction often results in a less appealing mouthfeel. This is particularly evident in dairy products, baked goods, and processed meats. Achieving the right consistency and preventing a gritty or watery texture requires extensive research and formulation adjustments.

Flavor retention and enhancement pose another significant challenge. Fat acts as a flavor carrier and contributes to the overall taste profile of foods. When fat is reduced or removed, the intensity and perception of flavors can be diminished. This necessitates the use of flavor enhancers or alternative ingredients to compensate for the loss of taste, which can be complex and costly.

Stability and shelf life are also affected by fat reduction. Fat plays a role in emulsion stability, moisture retention, and microbial control in many food products. Low-fat formulations may be more prone to separation, drying out, or spoilage, requiring the development of new preservation techniques and stabilizing systems.

Nutritional balance is another consideration in low-fat food development. While reducing fat content can lower calorie density, it may also impact the absorption of fat-soluble vitamins and essential fatty acids. Ensuring that low-fat products still provide adequate nutrition without compromising health benefits is a complex task for food scientists.

Consumer acceptance remains a critical challenge. Despite health concerns, many consumers are accustomed to the taste and texture of full-fat products. Overcoming taste preferences and meeting expectations for familiar foods in their low-fat versions requires extensive sensory testing and consumer research.

Regulatory compliance adds another layer of complexity. Labeling requirements for low-fat claims vary across regions, and meeting these standards while delivering on taste and texture can be challenging. Additionally, the use of certain fat replacers or additives may be restricted in some markets, limiting formulation options.

Lastly, cost considerations play a significant role in low-fat food development. The ingredients and technologies required to replicate the properties of fat can be expensive, potentially increasing production costs. Balancing affordability with quality and nutritional value is an ongoing challenge for manufacturers in the competitive food industry.

Existing Applications of Sodium Alginate in Low-Fat Foods

01 Sodium alginate as a fat replacer in food products

Sodium alginate can be used as a fat replacer in various food products, helping to reduce the overall fat content while maintaining texture and mouthfeel. It forms gels and acts as a thickening agent, allowing for the creation of low-fat alternatives to traditional high-fat foods.- Sodium alginate as a fat replacer in food products: Sodium alginate can be used as a fat replacer in various food products, helping to reduce the overall fat content while maintaining texture and mouthfeel. It forms gels that can mimic the properties of fat, making it useful in low-fat or reduced-fat formulations.

- Encapsulation of fats using sodium alginate: Sodium alginate can be used to encapsulate fats or oils, creating a barrier that can control the release of fat content in food products or pharmaceuticals. This technique can be useful in managing fat content and improving the stability of fat-containing formulations.

- Sodium alginate in fat-reduced meat products: Sodium alginate is utilized in the production of fat-reduced meat products, such as sausages or patties. It helps to improve texture, water retention, and overall quality of the product while allowing for a reduction in fat content.

- Sodium alginate in dairy product fat reduction: In dairy products, sodium alginate can be used to create low-fat or reduced-fat versions of items like cheese, yogurt, or ice cream. It helps to maintain the creamy texture and mouthfeel typically associated with full-fat products while reducing overall fat content.

- Sodium alginate in fat-reduced baked goods: Sodium alginate can be incorporated into baked goods to reduce fat content while maintaining moisture and texture. It can act as a stabilizer and thickener, allowing for the reduction of oils or fats in recipes for items such as cakes, breads, or pastries.

02 Encapsulation of fats using sodium alginate

Sodium alginate can be used to encapsulate fats or oils, creating a barrier that can control the release of fat content in food products. This technique is useful in developing functional foods with improved nutritional profiles and controlled fat release.Expand Specific Solutions03 Sodium alginate in fat-reduced meat products

Sodium alginate is utilized in the production of fat-reduced meat products, such as sausages and patties. It helps to improve water retention, texture, and binding properties in low-fat meat formulations, compensating for the reduction in fat content.Expand Specific Solutions04 Sodium alginate in dairy product fat reduction

In dairy products, sodium alginate is employed to create low-fat alternatives while maintaining creamy textures. It can be used in yogurts, ice creams, and cheese products to reduce fat content without significantly altering the sensory properties of the final product.Expand Specific Solutions05 Sodium alginate in fat-reduced bakery products

Sodium alginate is used in the formulation of fat-reduced bakery products, such as cakes, pastries, and bread. It helps to improve moisture retention, texture, and shelf life in low-fat baked goods, compensating for the reduction in fat content.Expand Specific Solutions

Key Players in Food Additives and Low-Fat Food Industry

The market for sodium alginate in low-fat food development is in a growth phase, driven by increasing consumer demand for healthier food options. The global market size for this ingredient is expanding, with projections indicating continued growth due to its versatile applications in food formulation. Technologically, sodium alginate is well-established, with ongoing research focused on enhancing its functionality. Key players like Corbion Biotech, Ajinomoto, and FMC Biopolymer are at the forefront of innovation, developing advanced formulations and applications. Universities such as Ocean University of China and University of Groningen are contributing to the scientific understanding and potential new uses of sodium alginate, further driving technological advancements in this field.

Ajinomoto Co., Inc.

Technical Solution: Ajinomoto has developed a proprietary sodium alginate-based technology for low-fat food applications. Their approach involves using sodium alginate as a fat replacer and texture modifier in various food products. The company has created a specialized blend of sodium alginate with other hydrocolloids to mimic the mouthfeel and sensory properties of fat. This blend is particularly effective in dairy products, sauces, and dressings, where it can replace up to 50% of the fat content without significantly altering taste or texture[1]. Ajinomoto's research has also focused on optimizing the molecular weight and viscosity of sodium alginate to enhance its fat-mimicking properties, resulting in a more authentic fat-like experience in low-fat foods[3].

Strengths: Extensive R&D capabilities, proprietary blending technology, and a wide range of applications across food categories. Weaknesses: Potential challenges in matching the exact taste and texture of full-fat products, and the need for careful formulation to avoid any off-flavors associated with alginate.

Unilever NV

Technical Solution: Unilever has pioneered the use of sodium alginate in low-fat food developments through its advanced emulsion technology. The company has developed a method to create stable oil-in-water emulsions using sodium alginate as an emulsifier and stabilizer. This technique allows for the reduction of fat content in products such as mayonnaise and salad dressings by up to 70% while maintaining a creamy texture and mouthfeel[2]. Unilever's approach involves carefully controlling the ionic environment and pH of the food system to optimize the performance of sodium alginate. Additionally, they have combined sodium alginate with other natural ingredients to create synergistic effects, enhancing both texture and flavor in low-fat formulations[4].

Strengths: Strong expertise in emulsion technology, ability to achieve significant fat reduction while maintaining product quality, and a diverse product portfolio for application. Weaknesses: Potential limitations in high-temperature applications and the need for precise control of formulation parameters.

Core Innovations in Sodium Alginate-Based Fat Replacers

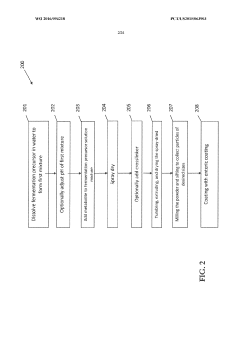

Enteric-coated functional food ingredients and methods for making the enteric-coated functional food ingredients

PatentWO2016094218A1

Innovation

- Enteric-coated compositions that encapsulate metabolites, such as SCFAs, in a polysaccharide matrix with an enteric coating that minimally dissolves in the stomach and primarily releases in the large intestine, ensuring targeted delivery and absorption.

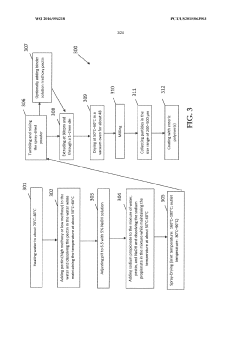

Palatable elemental medical food

PatentInactiveEP0994657B1

Innovation

- The development of an improved elemental formula using a lipid component blend of medium chain triglycerides, fractionated coconut oil, soy oil, high oleic safflower oil, and esterified glycerols, combined with L-asparagine and L-glutamine instead of L-aspartic acid and L-glutamic acid, to enhance organoleptic properties, reduce osmolarity, and increase Caloric density.

Regulatory Framework for Food Additives

The regulatory framework for food additives plays a crucial role in ensuring the safety and efficacy of sodium alginate in low-fat food developments. In the United States, the Food and Drug Administration (FDA) oversees the regulation of food additives, including sodium alginate, under the Federal Food, Drug, and Cosmetic Act (FD&C Act).

Sodium alginate is classified as a Generally Recognized as Safe (GRAS) substance by the FDA, which means it is considered safe for use in food products when used in accordance with good manufacturing practices. The FDA has established specific guidelines for the use of sodium alginate in various food applications, including low-fat products.

In the European Union, the European Food Safety Authority (EFSA) is responsible for evaluating the safety of food additives. Sodium alginate is approved for use in food products under the E-number E401. The EFSA has conducted thorough safety assessments and established acceptable daily intake (ADI) levels for sodium alginate.

The Codex Alimentarius Commission, a joint initiative of the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of sodium alginate in various food categories, including low-fat products.

Regulatory bodies require manufacturers to adhere to specific labeling requirements when using sodium alginate in food products. In most jurisdictions, sodium alginate must be declared in the ingredient list on food labels. Additionally, some countries may require specific function declarations or E-number listings.

It is important to note that regulatory requirements for food additives can vary between countries and regions. Manufacturers developing low-fat food products using sodium alginate must ensure compliance with local regulations in their target markets. This may involve conducting additional safety studies or submitting dossiers for regulatory approval in certain jurisdictions.

As the food industry continues to innovate and develop new low-fat products, regulatory frameworks may evolve to address emerging concerns or new scientific evidence. Manufacturers and researchers working with sodium alginate should stay informed about any changes in regulatory requirements and guidelines to ensure ongoing compliance and product safety.

Sodium alginate is classified as a Generally Recognized as Safe (GRAS) substance by the FDA, which means it is considered safe for use in food products when used in accordance with good manufacturing practices. The FDA has established specific guidelines for the use of sodium alginate in various food applications, including low-fat products.

In the European Union, the European Food Safety Authority (EFSA) is responsible for evaluating the safety of food additives. Sodium alginate is approved for use in food products under the E-number E401. The EFSA has conducted thorough safety assessments and established acceptable daily intake (ADI) levels for sodium alginate.

The Codex Alimentarius Commission, a joint initiative of the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference. The Codex General Standard for Food Additives (GSFA) includes provisions for the use of sodium alginate in various food categories, including low-fat products.

Regulatory bodies require manufacturers to adhere to specific labeling requirements when using sodium alginate in food products. In most jurisdictions, sodium alginate must be declared in the ingredient list on food labels. Additionally, some countries may require specific function declarations or E-number listings.

It is important to note that regulatory requirements for food additives can vary between countries and regions. Manufacturers developing low-fat food products using sodium alginate must ensure compliance with local regulations in their target markets. This may involve conducting additional safety studies or submitting dossiers for regulatory approval in certain jurisdictions.

As the food industry continues to innovate and develop new low-fat products, regulatory frameworks may evolve to address emerging concerns or new scientific evidence. Manufacturers and researchers working with sodium alginate should stay informed about any changes in regulatory requirements and guidelines to ensure ongoing compliance and product safety.

Sensory Evaluation of Sodium Alginate-Enhanced Low-Fat Foods

Sensory evaluation plays a crucial role in assessing the acceptability and quality of sodium alginate-enhanced low-fat foods. This evaluation process involves systematic analysis of the organoleptic properties of these products, including appearance, texture, flavor, and overall palatability.

The use of sodium alginate in low-fat food formulations has shown promising results in improving sensory attributes. In dairy products, such as low-fat yogurts and cheeses, sodium alginate helps maintain a creamy texture and mouthfeel, closely mimicking the sensory experience of full-fat counterparts. Studies have demonstrated that consumers often rate sodium alginate-enhanced low-fat yogurts similarly to their full-fat versions in terms of texture and overall liking.

In meat products, sodium alginate has been successfully employed to improve the juiciness and tenderness of low-fat formulations. Sensory panels have reported that sodium alginate-enhanced low-fat sausages and patties exhibit improved texture profiles, with reduced hardness and increased juiciness compared to traditional low-fat alternatives. These improvements in texture attributes contribute significantly to consumer acceptance of these products.

Bakery applications have also benefited from sodium alginate incorporation. Low-fat cakes and muffins formulated with sodium alginate have shown enhanced volume, softness, and moisture retention. Sensory evaluations indicate that these products maintain a desirable mouthfeel and texture, addressing common issues associated with fat reduction in baked goods.

However, it is important to note that the sensory impact of sodium alginate can vary depending on the food matrix and the level of incorporation. Optimal concentrations must be determined for each specific application to achieve the desired sensory improvements without introducing off-flavors or undesirable textural changes.

Trained sensory panels and consumer testing are essential in evaluating the effectiveness of sodium alginate in low-fat food developments. These assessments typically involve comparative analysis with full-fat controls and other low-fat alternatives. Descriptive sensory analysis techniques are often employed to quantify specific attributes and identify any potential sensory defects introduced by sodium alginate addition.

Consumer acceptance studies have shown that sodium alginate-enhanced low-fat foods generally receive positive responses, with many products achieving parity with full-fat versions in overall liking scores. This suggests that sodium alginate can be an effective tool in developing low-fat alternatives that meet consumer expectations for taste and texture.

In conclusion, sensory evaluation of sodium alginate-enhanced low-fat foods demonstrates the potential of this ingredient to address many of the sensory challenges associated with fat reduction. By improving texture, mouthfeel, and overall palatability, sodium alginate contributes to the development of low-fat products that can satisfy consumer demands for healthier options without compromising on sensory quality.

The use of sodium alginate in low-fat food formulations has shown promising results in improving sensory attributes. In dairy products, such as low-fat yogurts and cheeses, sodium alginate helps maintain a creamy texture and mouthfeel, closely mimicking the sensory experience of full-fat counterparts. Studies have demonstrated that consumers often rate sodium alginate-enhanced low-fat yogurts similarly to their full-fat versions in terms of texture and overall liking.

In meat products, sodium alginate has been successfully employed to improve the juiciness and tenderness of low-fat formulations. Sensory panels have reported that sodium alginate-enhanced low-fat sausages and patties exhibit improved texture profiles, with reduced hardness and increased juiciness compared to traditional low-fat alternatives. These improvements in texture attributes contribute significantly to consumer acceptance of these products.

Bakery applications have also benefited from sodium alginate incorporation. Low-fat cakes and muffins formulated with sodium alginate have shown enhanced volume, softness, and moisture retention. Sensory evaluations indicate that these products maintain a desirable mouthfeel and texture, addressing common issues associated with fat reduction in baked goods.

However, it is important to note that the sensory impact of sodium alginate can vary depending on the food matrix and the level of incorporation. Optimal concentrations must be determined for each specific application to achieve the desired sensory improvements without introducing off-flavors or undesirable textural changes.

Trained sensory panels and consumer testing are essential in evaluating the effectiveness of sodium alginate in low-fat food developments. These assessments typically involve comparative analysis with full-fat controls and other low-fat alternatives. Descriptive sensory analysis techniques are often employed to quantify specific attributes and identify any potential sensory defects introduced by sodium alginate addition.

Consumer acceptance studies have shown that sodium alginate-enhanced low-fat foods generally receive positive responses, with many products achieving parity with full-fat versions in overall liking scores. This suggests that sodium alginate can be an effective tool in developing low-fat alternatives that meet consumer expectations for taste and texture.

In conclusion, sensory evaluation of sodium alginate-enhanced low-fat foods demonstrates the potential of this ingredient to address many of the sensory challenges associated with fat reduction. By improving texture, mouthfeel, and overall palatability, sodium alginate contributes to the development of low-fat products that can satisfy consumer demands for healthier options without compromising on sensory quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!